Service Life Design for Infrastructure under Indonesian

Environmental Exposure

Mochamad Hilmy

1

, Herry Prabowo

1

1

Laboratory for Construction, Innovative Structures, and Building Physics,

Department of Architecture, Politeknik Negeri Pontianak, Jl. Ahmad Yani, Pontianak 78124, Indonesia

Keywords: Service Life Design, Infrastructure, Indonesian Tropical Climate, Concrete Durability, Chloride Ingress

Abstract: Reinforced concrete material is the most common material used in construction. This is due to its high

durability which makes concrete classified as one of the world building materials having the longest service

life. On the other hand, many research studies claimed that the application of concrete also has many durability

problems. This is even worse for extreme environments such as sea due to its high chloride ion concentration.

Environmental parameters such as temperature, humidity, and carbon dioxide concentration also have direct

effects on the deterioration of concrete structures. Nowadays, the Indonesian Government builds much

infrastructure which uses reinforced concrete as its main construction material. Concrete is chosen since its

constituents are abundant in Indonesia. Deterioration mechanisms of concrete structures can be divided into

the mechanism of concrete material deterioration and the mechanism of reinforcing bar corrosion. The

corrosion of reinforcing bar is the most dangerous mechanism and the most difficult one to control. Chloride

ions commonly coming from seawater become the main factor resulting in severe corrosion. This paper was

aimed to give suggestions for several durability-related parameters such as cement type, water-cement ratio,

concrete cover, etc. under Indonesian tropical climate.

1 INTRODUCTION

Indonesia, the world’s largest archipelagic state, has

a gigantic maritime domain of about six million

square kilometers. It consists of more than 17,000

islands with five largest islands being Sumatera, Java,

Kalimantan, Sulawesi, and Papua. Being located in

proximity to the equator line, Indonesia is influenced

mainly by the tropical rainforest climate. This climate

is typically denoted by its high temperature, heavy

rainfall, and high humidity. Its temperature is quite

stable over the year, ranging between 23 °C to 28 °C

spread from coastal plains to higher mountainous

areas. It shows only a small fluctuation from season

to season. Indonesia only has two main seasons,

namely wet or rainy season and dry season. Most

areas have their rainy season from September until

March, which reaches its peak in January and

February. Lowland areas have rainfall ranging

between 1800 to 3200 mm per year. These values

increase with the elevation of the area up to an

average of 6000 mm in some mountainous regions. In

a dry season, the rainfall decreases to 1800 mm

annually. This dry season occurs from April to

August with its driest peak occurring in July. The

relative humidity varies between 70% and 90% (Logt,

2016).

Nowadays, the Indonesian Government has more

focus on infrastructure development. It is achieved by

improving ports and maximizing inter-island

connectivity, and, in the end, it is hoped that

Indonesia becomes a “Global Maritime Axis”. The

priority of this infrastructure development plan is in

the infrastructure of the maritime sector. It is

considered to be a project of nationally strategic

importance given that Indonesia is the largest

archipelago in the world (Carruthers, 2016).

There are many seaports having been built

recently. Concrete is chosen to be their main

construction material since its constituents are

abundant in Indonesia. It is no wonder that reinforced

concrete becomes very popular. Its high durability

capacity makes concrete classified as one of the world

building materials having the longest service life. On

the other hand, many research studies claimed that the

application of concrete also has many durability

problems. This is even worse for extreme

environments such as sea due to its high chloride ion

Hilmy, M. and Prabowo, H.

Service Life Design for Infrastructure under Indonesian Environmental Exposure.

DOI: 10.5220/0008904000002481

In Proceedings of the Built Environment, Science and Technology International Conference (BEST ICON 2018), pages 133-138

ISBN: 978-989-758-414-5

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

133

concentration. Environmental parameters such as

temperature, humidity, and carbon dioxide

concentration also have direct effects on the

deterioration of concrete structures. Deterioration

mechanisms of concrete structures can be divided into

the mechanism of concrete material deterioration and

the mechanism of reinforcing bar corrosion. The

corrosion of reinforcing bar is the most dangerous

mechanism and the most difficult one to control.

Chloride ions commonly coming from seawater

become the main factor resulting in severe corrosion.

2 LITERATURE REVIEW

Seawater is one of the external sources of chloride

ions which are corrosive to concrete reinforcing steel

other than internal sources coming from concrete

mixtures (Nguyen, et al., 2016). Corrosion due to

chloride ions is one of the main basis of deterioration

of reinforced concrete structures in chloride-exposed

environments. This results in reduced service and

security structures while increasing repair and

maintenance costs (Bastidas-Arteaga & Schoefs,

2015).

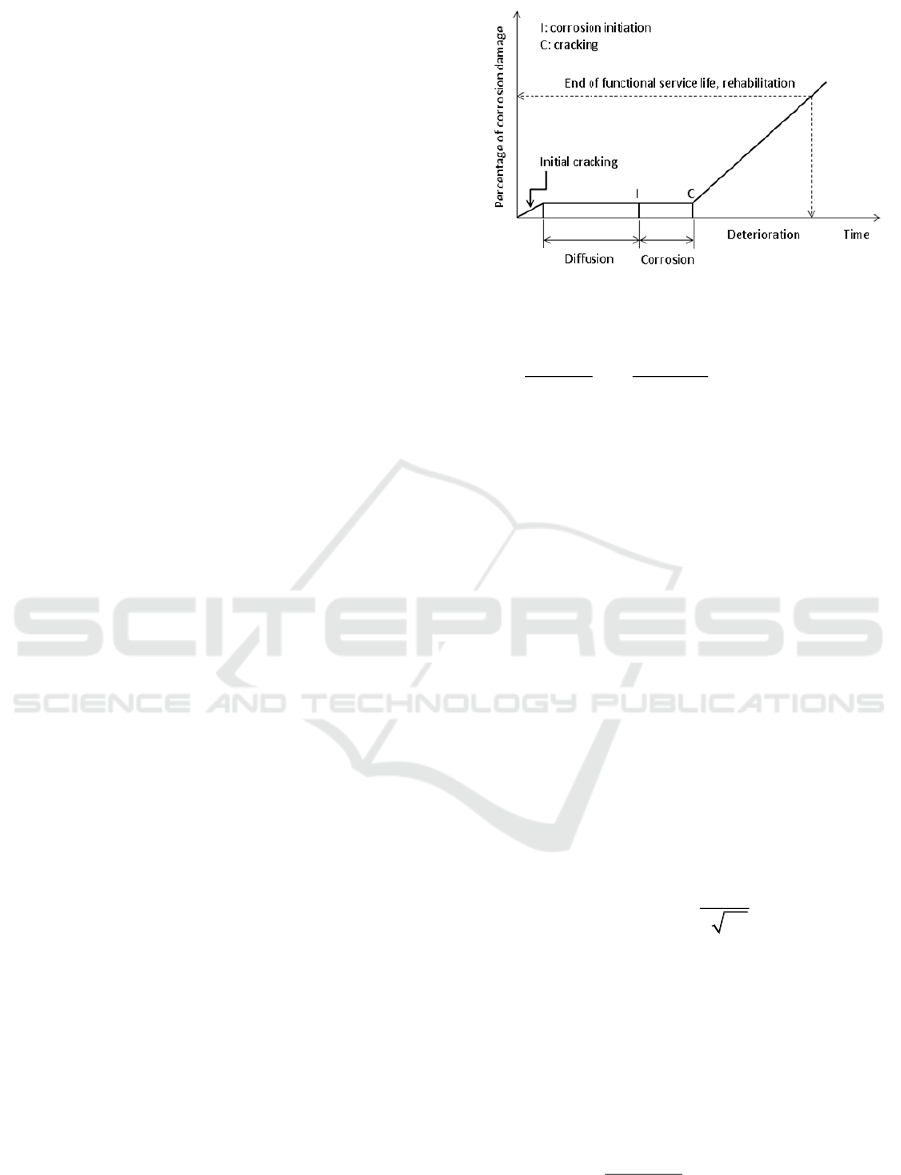

Tutti’s model (Figure 1) is widely accepted as a

conceptual model in the modelling of structural

deterioration. The model clearly shows the time of

corrosion initiation to the time of corrosion

propagation. In the initiation phase, chloride ions

diffuse from concrete to reinforcing steel. When this

phase ends, the initial corrosion of steel

reinforcement begins when the chloride ion

concentration reaches the threshold value. The

propagation phase is defined as the time when the

corrosion begins to the critical point of the loss of the

function of the reinforcing steel. In this case, the

service life of the structure is the sum of the initiation

phase and the propagation phase (Wu, et al., 2015).

Service life of structures means that the structure

will fulfil the performance requirements under

defined repair and maintenance within a specified

time period (Verma, et al., 2014). The estimation of

service life of reinforced concrete structures in the

marine environment is usually done by using a simple

basic model of chloride diffusion. This model is

popularly known as Fick’s second law of diffusion. It

is stated as follows.

Figure 1: Reinforced concrete structure deterioration

Process due to corrosion.

( ) ( )

2

2

,,C x t C x t

D

t

x

=

(1)

3 METHODS

An estimation of the service life of reinforced

concrete structures exposed to chloride ions is carried

out by means of chloride diffusion models. There are

three models used here namely empirical diffusion

model, long-term chloride concentration model, and

modified diffusion model.

3.1 Empirical Chloride Diffusion Model

This empirical chloride diffusion model is derived

from Fick’s second law of diffusion. The chloride

profile in concrete is obtained by assuming that the

governing transport mechanism is one-dimensional

diffusion. The mathematical solution of this problem,

equation (1), yields equation (2) as follows:

,

1

2

x t s

x

C C erf

Dt

=−

, (2)

where C

x,t

is the concentration of chloride at depth x

within time t, C

s

is the concentration of chloride at the

concrete surface, x is the depth from surface, t is time,

and D is the coefficient of apparent chloride diffusion.

Simplifying using parabolic function, equation (2)

reads as equation (3) (Khan, et al., 2017).

( )

2

,

0.5

1

23

x t s

x

CC

Dt

=−

. (3)

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

134

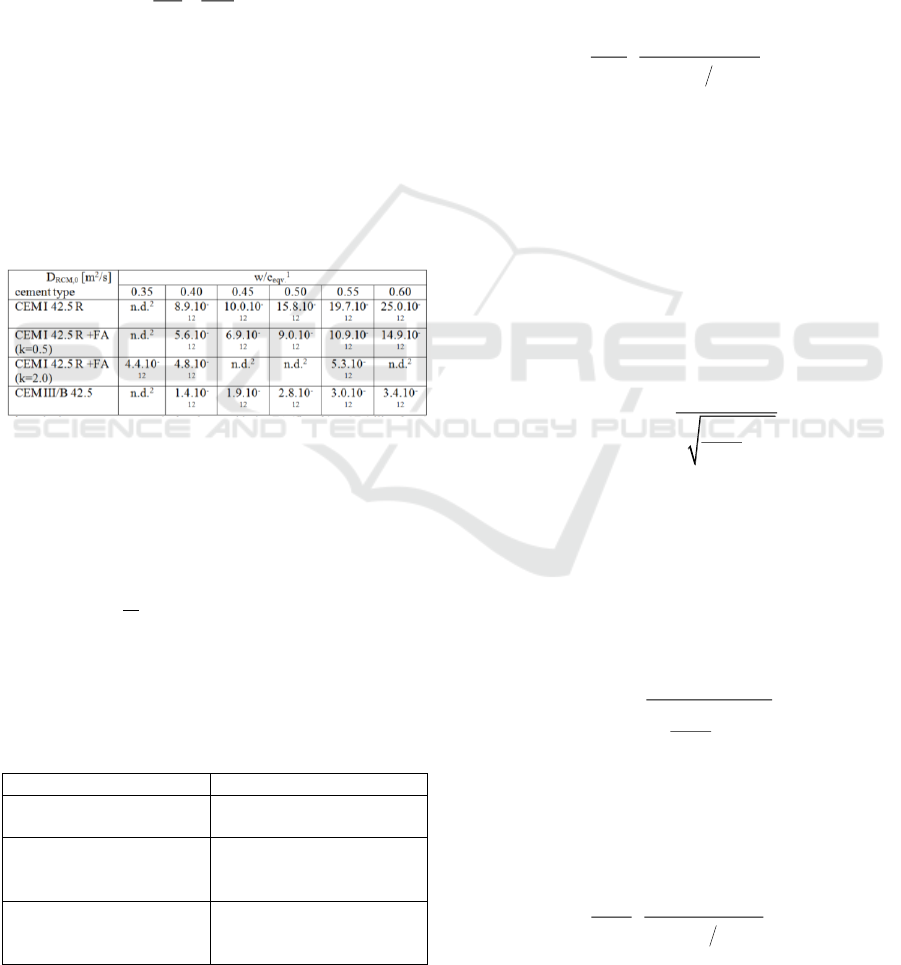

The coefficient of apparent chloride diffusion, D,

is defined by (Fib, 2006) as follows:

, ,0

()

app c e RCM t

D k D k A t=

,

(4)

where ke is the environmental transfer variable,

D

RCM,0

is the chloride migration coefficient (table 1),

kt is the transfer parameter (set to 1), and A(t) is the

sub-function considering the ageing.

11

exp

ee

ref real

kb

TT

=−

, (5)

where be is the regression variable, Tref is the

reference temperature (193 K = 20 °C), and Treal is

the temperature of the ambient air or structural

element.

Table 1: D

RCM,0

parameter quantification for different

concrete mixtures.

1

equivalent water-cement ratio, hereby considering FA (fly

ash) or SF (silica fume) with the respective k-value

(efficiency factor). The considered contents were as

follows: 22 wt.-%/cement; SF: 5 wt.-%/cement.

2

n.d.–chloride migration coefficient RACC,0-1 has not

been determined for these concrete mixes.

( )

0

a

t

At

t

=

, (6)

where t

0

is the reference point of time (chosen to be

0.0767 year = 28 day), and t is the time in year.

Table 2: Ageing exponent,a

e

, parameter quantification.

Concrete

Ageing exponent a

e

[-]

5

Portland cement concrete

CEM I; 0.40≤w/c≤0.60

Beta (m

1

= 0.30; s

2

= 0.12;

a

3

= 0.0; b

4

= 1.0)

Portland fly ash cement

concrete f≥0.20z; k=0.50;

0.40≤w/c

eqv

≤0.60

Beta (m

1

= 0.60; s

2

= 0.15;

a

3

= 0.0; b

4

= 1.0)

Blast furnace slag cement

concrete CEM III/B;

0.40≤w/c≤0.60

Beta (m

1

= 0.45; s

2

= 0.20;

a

3

= 0.0; b

4

= 1.0)

1

m = mean value,

2

s = standard deviation,

3

a = lower bound,

4

b = upper bound,

5

quantification can be applied for the

exposure classes: splash zone, tidal zone, and submerged

zone.

This chloride diffusion model can be utilized to

predict the chloride-induced corrosion initiation time.

It is assumed that C

x,t

is the critical chloride

concentration (C

crit

), t is the time of initiation, and x

is the concrete cover thickness (a). The equation (3)

now reads as follows.

( )

2

1

0.5

1

12

1

crit s

a

t

D

CC

=

−

(7)

In this research, the values of C

crit

and C

s

are taken

0.3 and 0.6, respectively.

3.2 Chloride Diffusion Model

Incorporating Time Effect

A model reported by (Lei, et al., 2018) incorporating

the effect of time in the chloride diffusion model is as

follows:

,

1

1

2

1

x t s

m

x

C C erf

D

t

m

−

=−

−

,

(8)

where m is a constant of time decay factor.

A constant of time decay factor, m, depends on

ratio of concrete mix and ambient surroundings. This

paper assumes that m equals to 0.69, which is taken

based on (Lei, et al., 2014).

2

,

0.5

1

1

3

2

1

x t s

m

x

CC

D

t

m

−

=−

−

.

(9)

Analogous to equation (7), equation (10) can be

derived in the same manner, which results in the

following equation:

( )

2

1

2

0.5

1

12

1

m

crit s

ma

t

D

CC

−

−

=

−

.

(10)

Service Life Design for Infrastructure under Indonesian Environmental Exposure

135

3.3 Chloride Diffusion Model

Incorporating Linear Stress

Distribution

This model of chloride diffusion is gained by

considering the linear stress distribution on a

sectional structure. It is considered that the cross-

sectional stress is under pure axial compressive load

(Lei, et al., 2018). The resulting formula can be seen

as follows:

( )

,

2

01

1

2

x t s

ss

x

C C erf

D A A t

=−

++

,

(11)

where A

0

and A

1

are the considered cross-sectional

areas, and σ

s

is the cross-sectional stress. In this

paper, A

0

= 0.56, A

1

= 0.38, and σ

s

= 0.32 MPa.

( )

( )

2

,

0.5

2

01

1

23

x t s

ss

x

CC

D A A t

=−

++

.

(12)

Equivalent to equation (7), equation (13) can be

derived in the same manner, which yields the

following equation:

( )

( )

2

3

0.5

2

01

1

12

1

ss

crit s

a

t

D A A

CC

=

++

−

.

(13)

Those three formulas of corrosion initiation time,

equations (3), (9), and (12), are then compared to each

other taking into account parameters such as cement

type, water-cement ratio, and concrete cover suitable

for Indonesian construction practices.

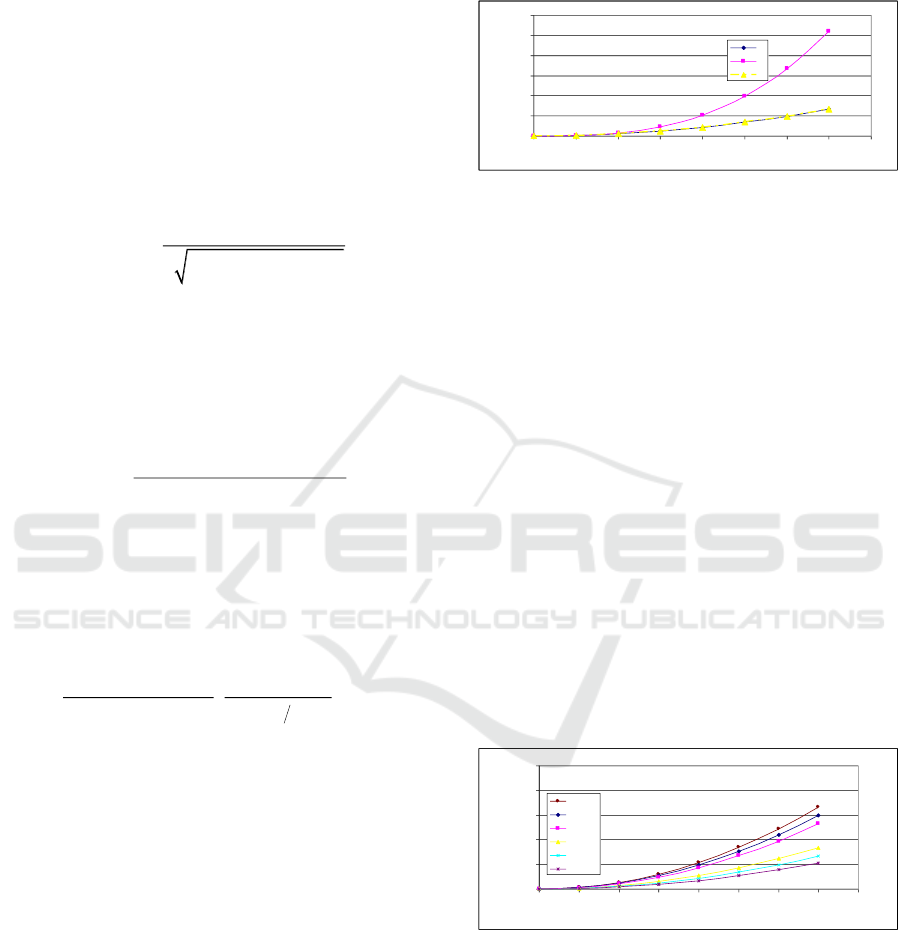

4 RESULTS AND DISCUSSION

The prediction of reinforced concrete structures’

service life is performed to study the effect of the use

of each diffusion model on how long the initiation

time will last. These simulations are carried out for

several parameters such as water-cement ratio,

cement type, and temperature. Every simulation uses

the three model of chloride diffusion, which are

equations (3), (9), and (12). The results of the

simulations are then plotted in “concrete cover” vs

“initiation time of corrosion” graphs (Figure 2 until

Figure 5).

Figure 2: Concrete cover vs. initiation time of corrosion—

three models.

Figure 2 depicts the relation between concrete

cover and the initiation time of corrosion

incorporating three models of chloride diffusion. The

models are empirical diffusion model, long-term

chloride concentration model, and modified diffusion

model, which are indicated as t1, t2, and t3,

respectively. As can be observed, the initiation time

of corrosion is longer for thicker concrete cover.

For common interior structural elements, the

concrete cover is usually 40 mm thick. This value

corresponds to initiation time of corrosion in around

20 year for models t1 and t3 and 50 years for model

t2. In general, chloride diffusion models t1 and t3

coincide with each other, while model t2 tends to

deviate from the other models. For concrete cover

ranging from 0 mm to 25 mm, all three models result

in almost similar initiation time. When concrete cover

reaches 30 mm, model t2 yields initiation time values

which are higher than those of the two other models.

Overall, model t2 predicts higher values of initiation

time.

Figure 3: Concrete cover vs. initiation time of corrosion—

w/c ratio.

It is obtained that t2 deviates a lot from other two

models and yields illogical values of initiation time of

corrosion for higher concrete cover. It is, thus,

reasonable to choose t1 and t3 for the rest of the

simulations. Having known that the results from t1

and t2 are coinciding, it is easier to use t1 model as

the governing model. The relation between concrete

cover and initiation time of corrosion which

0

50

100

150

200

250

300

0 10 20 30 40 50 60 70 80

Concrete Cover (mm)

Initiation Time of Corrosion

(year)

t1

t2

t3

0

50

100

150

200

250

0 10 20 30 40 50 60 70 80

Concrete Cover (mm)

Initiation Time of Corrosion

(year)

wc 0.35

wc 0.40

wc 0.45

wc 0.50

wc 0.55

wc 0.60

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

136

incorporates various water-cement ratio parameters

can be seen in Figure 3. In general, all plotted graphs

are giving the same curve trends. The simulations

take five water-cement ratios (w/c): 0.40; 0.45; 0.50;

0.55; and 0.60. There are two groups of water-cement

ratios that are close to each other. These two groups

are w/c ratios from 0.40 to 0.45 and w/c ratios from

0.50 to 0.60. Taken as a whole, the w/c ratio 0.40

predicts the highest time of initiation, while the w/c

ratio 0.60 yields the lowest initiation time of

corrosion.

Figure 4: Concrete cover vs. initiation time of corrosion—

cement type.

Figure 4 simulates the relation between concrete

cover and initiation time of corrosion taking into

account different cement types. These cement types

include CEM I, CEM I + FA, CEM I + SF, and CEM

III/B. From the simulations, it can be noted that the

highest prediction values of corrosion initiation time

are given by CEM III/B. On the other hand, CEM I

gives the lowest values.

Figure 5: Concrete cover vs. initiation time of corrosion—

temperature

In order to give insight into Indonesian tropical

climate’s parameter, figure 5 illustrates the relation

between concrete cover and initiation time of

corrosion taking into consideration temperature

effect. The temperatures are simulated from 23 °C to

28 °C. For concrete cover ranging from 0 to 25 mm,

all six graphs give almost similar initiation time.

When concrete cover reaches 30 mm, each model

gives values of initiation time which are slightly

different.

5 CONCLUSIONS

A service life estimation of reinforced concrete

structures exposed to chloride-induced corrosion has

been performed using three models of chloride

diffusion. These models are empirical diffusion

model, long-term chloride concentration model, and

modified diffusion model. Several relevant

parameters are included in the service life simulations

in order to predict deterioration behavior under

Indonesian climate. Some important parameters in

reviewing initiation time of corrosion such as

concrete cover, water-cement ratio, and cement type

are calculated. Based on the results, the following

conclusions are achieved:

1. Empirical diffusion model and modified diffusion

model simulate similar trends and values in

predicting initiation time of corrosion.

2. Concrete cover parameter should be chosen

carefully so that it is not too thick (considering the

influence of the weight and performance of the

structure and the economical aspects of the

construction) or even too thin that it will

accelerate corrosion. The ideal concrete cover for

the Indonesian marine environment based on the

simulations is 70 mm. Figure 5 shows that all of

the values of initiation time of corrosion are over

60 years. They are higher than the design service

life of Indonesian common buildings, which is

only 50 years.

3. It is important to regulate and keep the water-

cement ratio parameter low in order to hamper the

speed of the migration process of chloride ions.

This not only helps postpone the corrosion

process but also affects the control of volumetric

deformation of concrete material, for example, the

phenomenon of creep and shrinkage. The ideal

value for water-cement ratio is 0.35. Figure 3

shows that the w/c ratio of 0.35 in conjunction

with 70-cm cover is enough to give the concrete

structures life of more than 150 years.

4. It is also important to observe the predefined

values in the formulation, especially its

compatibility aspects with Indonesian

construction practices and the Indonesian climate

condition in most cases.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the financial

support from the Indonesian Ministry of Research,

Technology, and Higher Education

0

100

200

300

400

500

0 10 20 30 40 50 60 70 80

Concrete Cover (mm)

Initiation Time of Corrosion

(year)

CEM I

CEM I + FA

CEM I + SF

CEM III

0

20

40

60

80

100

120

0 10 20 30 40 50 60 70 80

Concrete Cover (mm)

Initiation Time of Corrosion (year)

TC 23 C

TC 24 C

TC 25 C

TC 26 C

TC 27 C

TC 28 C

Service Life Design for Infrastructure under Indonesian Environmental Exposure

137

(KEMENRISTEKDIKTI) of fiscal year 2018. The

assistance or encouragements from colleagues and

extraordinary works by technical staffs are also

gratefully acknowledged.

REFERENCES

Bastidas-Arteaga, E. & Schoefs, F., 2015. Sustainable

maintenance and repair of RC coastal structures.

s.l., s.n.

Carruthers, A. M., 2016. Developing Indonesia’s Maritime

Infrastructure: The View from Makassar.

Perspective.

Fib, 2006. Fib Bulletin 34 - Model Code For Service Life

Design Of Concrete Structures. s.l.:Fib.

Khan, M., Ahmad, S. & Al-Gahtani, H., 2017. Chloride-

induced Corrosion of Steel in Concrete: An

Overview on Chloride Diffusion and Prediction of

Corrosion Initiation Time. International journal of

corrosion.

Lei, M. et al., 2018. Modified chloride diffusion model for

concrete under the coupling effect of mechanical

load and chloride salt environment. AIP Advances,

Volume 8.

Lei, M., Peng, L. & Shi, C., 2014. An experimental study

on durability of shield segments under load and

chloride environment. Tunnelling and

Underground Space Technology, Volume 42, pp.

15-24.

Logt, P. v. d., 2016. Climate Change Profile: Indonesia,

s.l.: Netherlands Commission for Environmental

Assessment.

Nguyen, P., Bastidas-Arteaga, E. & El Soueidy, C., 2016.

An efficient chloride ingress model for long-term

lifetime assessment of reinforced concrete

structures under realistic climate and exposure

conditions. International Journal of Concrete

Structures and Materials, 11(2), pp. 199-213.

Verma, S., Bhadauria, S. & Akhtar, S., 2014. Probabilistic

Evaluation of Service Life for Reinforced Concrete

Structures. Chinese Journal of Engineering.

Wu, L., Zhou, Y., Kou, X. & Jiang, M., 2015. Reliability-

based service life prediction of existing concrete

structures under marine environment. Journal of

Central South University, Volume 22, p.

3608−3614.

BEST ICON 2018 - Built Environment, Science and Technology International Conference 2018

138