Isolation and Characterization of Chitosan from Coconut Crab Skin

Origin of Halmahera Island with Ftir

Zulkifli Zam Zam, Sudir Umar, Tamrin Robo, Fadlan Muin

Faculty of Teacher Training and Education, Khairun University

Jln. Bandara Babullah, Akhedua, North Ternate, Ternate

Keywords: Coconut crabs, Isolation, Characterization, Chitosan, FTIR

Abstract: This study aims to determine the isolation and characterization of chitosan from the skin of coconut crabs.

Isolation of chitosan from coconut crabs was carried out through four stages, namely deproteination (4%

NaOH, 80

o

C), demineralization (HCl 1.25 N, 70

o

C), depigmentation (4% NaOCl, 75

o

C), deasitilation (50%

NaOH, 80

o

C). The degree of deasitilation of chitosan from walnut crabs is 82.52%. Chitosan FTIR

spectrum analysis results of several main examples of wave numbers 3371.57 cm

-1

which show symmetrical

stretching vibrations due to overlapping OH and amines (NH), stretching vibrations of 1597.06 cm

-1

caused

by propagation of C=O and stretch vibrations 1651.07 cm

-1

which shows secondary amide. Characterization

of FTIR spectroscopy which showed the extraction of coconut crabs was chitosan.

1 INTRODUCTION

Halmahera Island has abundant natural resources in

the fisheries sector, one of which is coconut crabs.

The results of observations conducted in the markets

showed that the sale of coconut crabs carried out

was limited to the sale of the meat while the shell

crabs shell was discarded and left alone until it roted

without any utilization. If left unchecked it will

cause environmental pollution and damage to

environmental aesthetics. Crustacea (coconut crab)

skin waste consists of three main components,

namely protein (25% - 44%), calcium carbonate

(45% -50%), and chitin (15% 20%) (Fohcher et al,

1992). The chitin content in shrimp skin waste is

around 20-50% dry weight. Chitin polymers are

composed of monomers; 2-acetamide-2-deoxy-D-

Glucose (N-acetyl glucosamine) (Horton et al,

2002). The bond between chitin monomers is the

glycoside bond in the β- (1-4) position. The structure

of chitin molecules is a long straight chain. Chitin is

the largest natural polymer in the world after

cellulose (Yanming et al, 2001).

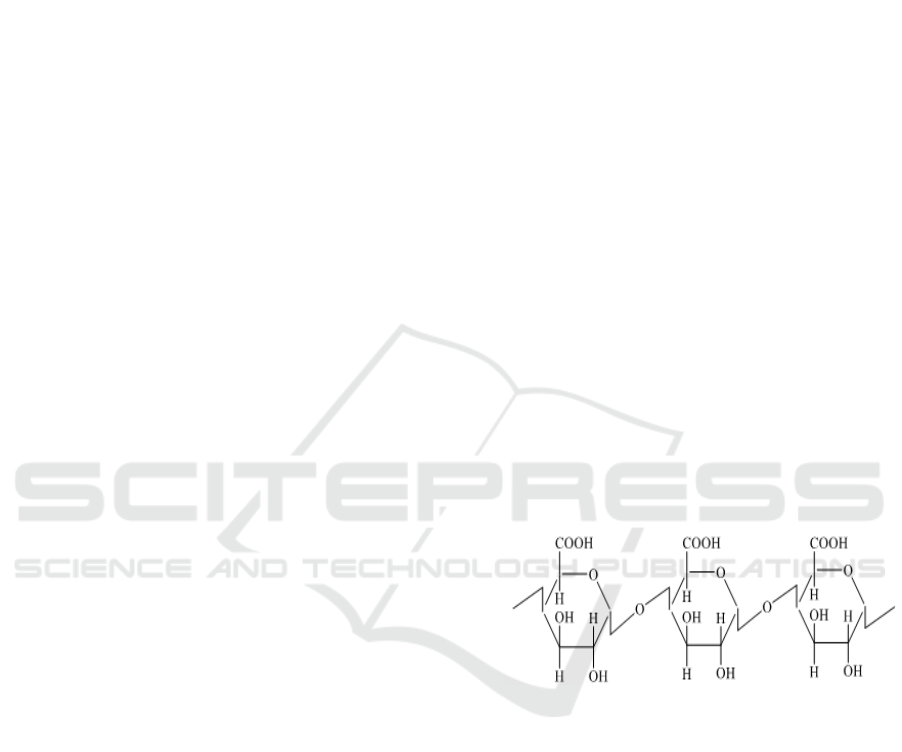

Chitosan [poly-2-amino-2-deoxy-β- (1-4) D-

glucopiranose)] is a poly-aminosaccharide

compound synthesized by partially removing 2-

acetyl groups from chitin [poly (2 acetamido-2-

deoxy-β-(1-4)-Dglukopiranosa)], linear biopolymers

with 2000-5000 monomer units, bound together by

β- (1-4) glycosidic bonds. Chitosan (C

6

H

11

NO

4

)n is

a yellowish white amorphous solid, polyelectrolyte

(Chen et all, 2007). Generally soluble in organic

acids, the pH is around 4–6.5, insoluble at lower or

higher pH. Solubility is influenced by molecular

weight and degree of deacetylation (Mima et al.,

1983).

Figure 1: Molecular Structure of Chitosan.

Things related to the environment are by

utilizing coconut crabs that form chitin and then

transformed into chitosan which can be applied in

various fields (Hargono et al., 2008). Since chitosan

has high economic value, it is very important to

conduct research to process skin into chitosan.

2 MATERIALS AND METHOD

2.1 Material

The materials used are coconut crab skin, acetic acid

(CH

3

COOH), hydrochloric acid (HCl), sodium

298

Zam, Z., Umar, S., Robo, T. and Muin, F.

Isolation and Characterization of Chitosan from Coconut Crab Skin Origin of Halmahera Island with Ftir.

DOI: 10.5220/0008901202980302

In Proceedings of the 1st International Conference on Teaching and Learning (ICTL 2018), pages 298-302

ISBN: 978-989-758-439-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

hydroxide (NaOH), technical sodium hypochlorite

(NaOCl), filter paper and aquades.

2.2 Tools

Petri dishes, pH meters, analytics, a set of reflux

tools, glass plates, magnetic stirrers, shakers, ovens,

mes machines, magnetic support devices, shakers,

ovens, mes machines, supporting tools in the form of

glassware, plastic and FTIR.

2.3 Experimental

2.3.1 Stages of Sample Preparation

Wash the skin of the coconut crabs with running

water to remove the impurities that are attached,

then dry them in an oven at 80˚C for 24 hours. After

that the dried coconut crab skin is mashed to 100

mesh, then processed to get chitosan.

2.3.2 Deproteination

Add 4% NaOH with a ratio of 1: 6 (b/v) to the skin

of finely ground coconut crabs, then heated at 80˚C

for 30 minutes. Then cool the resulting solution and

filter it so that it gets a solid, after that the solid is

dried at 80˚C for 24 hours (Roberts, 1992).

2.3.3 Demineralization

Mixing coconut crabs skin with HCl 1.25 N with a

ratio of 1:20 (b/v), then heated at a temperature of 70

˚C for 1 hour. The solution formed is then filtered so

that it gets solids. The solid is washed with water to

neutral pH, then dried at 80˚C for 24 hours. The

product produced is chitin

2.3.4 Depigmentation

Depigmentation stages using 4% NaClO to remove

impurities that may have been produced in the

previous process

2.3.5 Deacetylation of Chitin to Chitosan

Mix chitin powder with 50% NaOH solution with a

ratio of 1:10 (w / v) then heat it for 6 hours at a

temperature of 80˚C. Washing solids obtained with

distilled water to neutral pH after drying with an

oven at 80˚C for 24 hours. The product formed from

this process is chitosan. The chitosan obtained was

then analyzed by FTIR to determine the Degree of

Deacetylation (DD). Deacetylation degree

calculations using equations:

3 RESULTS AND DISCUSSION

3.1 Isolation of Chitosan Coconut Crabs

Coconut crabs skin is washed first to remove the dirt

that sticks. After washing, the coconut crabs skin is

dried in the sun to remove the water content. Then

the coconut crabs skin is mashed with a blender

(powder), aiming to simplify the deproteination,

demineralization, depigmentation and deaetylation

treatment processes.

3.2 Deproteination

The deproteination process aims to break the bonds

between protein and chitin by adding NaOH. The

skin of a 50 gram coconut crabs is dissolved with

500 ml of 4% NaOH then heated at 80

o

C for 2 hours

while continuing to stir. After being heated the

solution is cooled for 30 minutes then filtered with a

filter while washing with distilled water until the pH

is neutral. Then the coconut crabs skin was dried in

the oven for 24 hours and weighed. Deproteinization

of coconut crabs skin was 31.86 grams so that the

protein content contained in shrimp skin ranged

from 36.28%. In this process, NaOH functions to

break the intermolecular bond between chitin and

protein, then the protein will bind to Na

+

proteinat

which dissolves in water.

3.3 Demineralization

Demineralization to remove inorganic salts or

minerals contained in the skin of coconut crabs. The

main minerals contained in the skin of coconut crabs

are CaCO

3

and Ca

3

(PO

4

)

2

. Marganov, 2003,

minerals contained in the skin and shells of

crustaceans (shrimp, crabs, etc.) are more easily

separated than proteins because they are only

physically bound. The mineral separation process is

indicated by the formation of CO

2

gas in the form of

air bubbles when the HCl solution is added in the

sample, so that the addition of HCl into the sample

is done in stages so that the sample does not

overflow (Hendry, 2008). Reactions that occur:

Isolation and Characterization of Chitosan from Coconut Crab Skin Origin of Halmahera Island with Ftir

299

3.4 Depigmentation

Depigmentation stages using sodium hipolorit

(NaClO) to remove impurities that may be present in

the previous process, and produce a yield of 91.04%.

The product of this stage is called chitin and a

further process is needed to obtain chitosan which is

deacetylation.

3.5 Deacetylation

Deacetylation is the process of removing acetyl

groups (-COCH

3

) from chitin using an alkaline

solution to change to an amine group (-NH

2

) (Sirait,

2002). Chitin has a long crystalline structure with

strong hydrogen bonds between nitrogen atoms and

carboxylic groups in adjacent chains (Muzzarelli,

1986). Termination of the bond between the acetyl

group and the nitrogen group so that it turns into an

amine group (-NH

2

) needs to use NaOH with a

concentration of 50% at 80

o

C for 4 hours. The use of

alkali solutions with high concentrations and high

temperatures during the deacetylation process can

affect the degree of deacetylation produced (Kim et

al., 2004).

Depigmentation stages using sodium

hypochlorite (NaClO) to remove impurities that may

be present in the previous process, and produce a

yield of 91.04%. The product of this stage is called

chitin and a further process is needed to obtain

chitosan which is deacetylation.

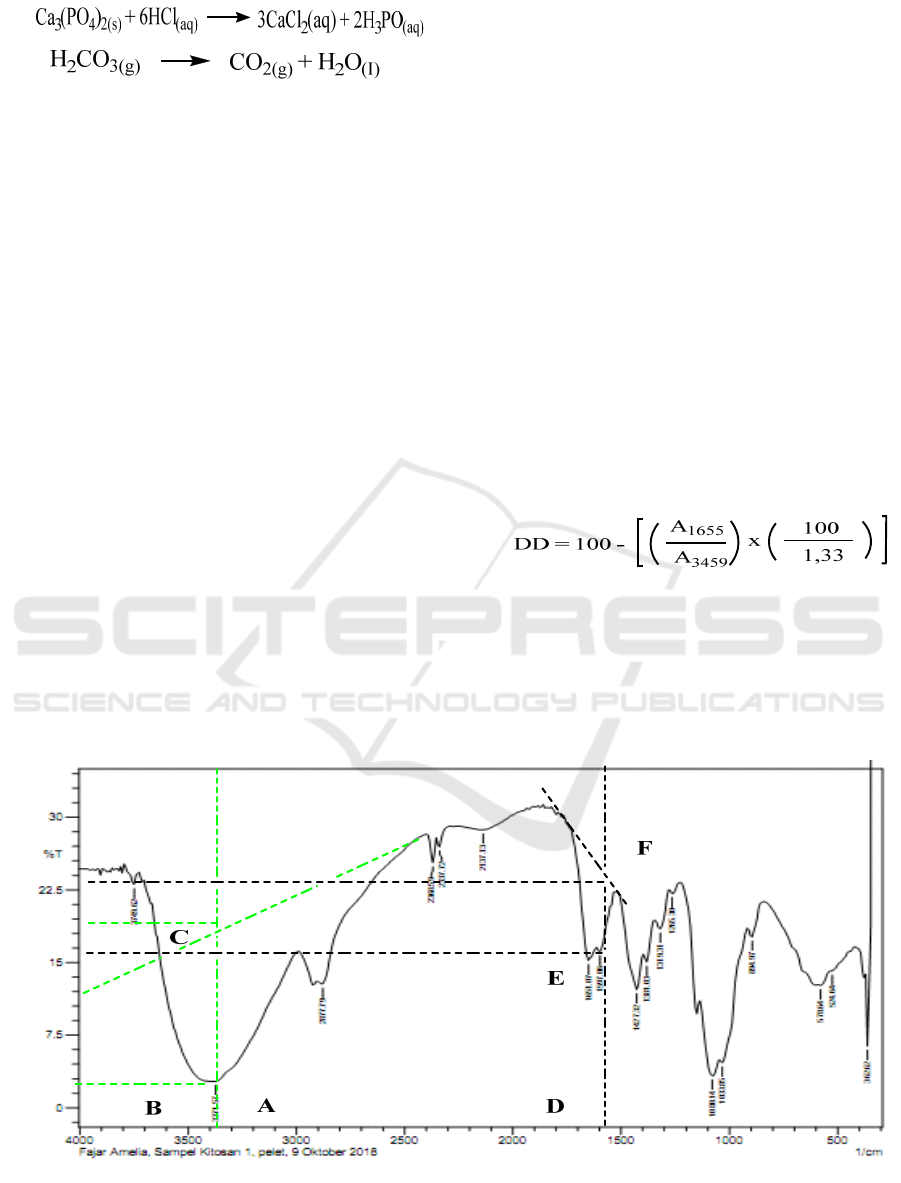

3.6 Degrees of Deacitilation and

Characterization of Chitosan with

FTIR

3.6.1 Degree of Deacitylation of Chitosan

The FTIR spectrum analysis of chitosan from the

skin of coconut crabs was carried out in the

functional group and fingerprint region with a

frequency of 4000 cm

-1

-400 cm

-1

. The degree of

deacetylation of chitosan is determined by the base

line method based on the FTIR spectrum, the

formula used:

Where, A

1655

shows absorption in the amide

band, A

3459

shows absorption in the hydroxyl band,

and factor 1.33 shows the value of the ratio

A

1655

/A

3459.

Figure 2: Calculation of the Degree of Deacetylation of Chitosan from the Skin of Coconut Crabs.

ICTL 2018 - The 1st International Conference on Teaching and Learning

300

Determination of the degree of deacetylation of

coconut crabs:

Where,

So that, the value of the degree of deacetylation

obtained:

DD = 100 - 17,48

DD = 82,52%

Degree of deasitilation of coconut crabs skin is

82.52%, indicating the provision of an amine

group (NH

2

) as an active group. The degree of

deacetylation is carried out to determine the

formation of chitosan from chitin. The degree of

deacetylation of chitosan in this study was 82.52%,

which was determined based on the FTIR

spectrophotometer method with the Base Line

method as proposed by Baxter et al (Khan et al.,

2002). The degree of deacetylation is still in

accordance with the value of deacetylation degree

according to Protan Laboratory which states that

the degree of deacetylation of chitin to chitosan

usually ranges from 70-100%.

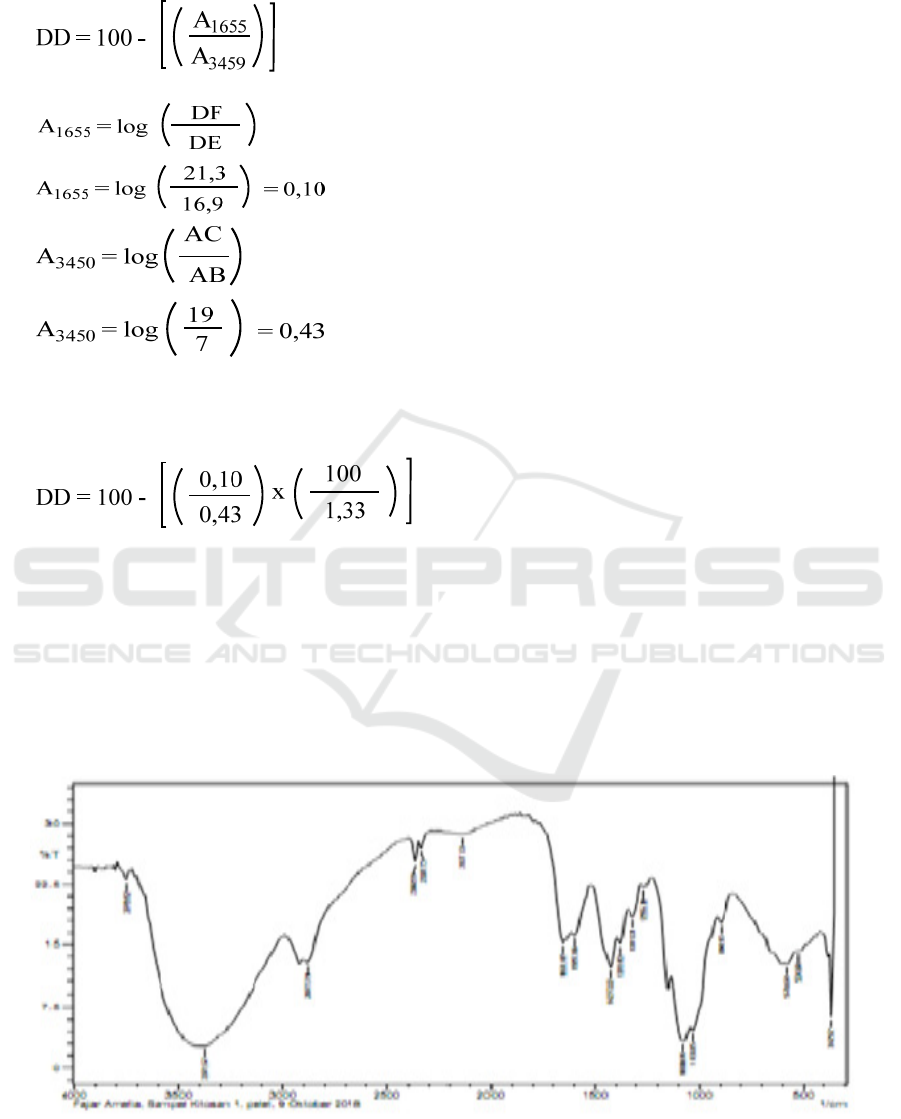

3.6.2 Characterization of Coconut Crabs

Skin with FTIR Spectrophotometer

In figure 3 shows the FTIR spectrum of the skin of

coconut crabs in the area 400 - 4000 cm

-1

. Chitosan

produced from coconut crabs was characterized by

FTIR spectroscopy. The chitosan IR spectrum is

presented in Figure 3, to identify the functional

groups. Characteristic absorption of chitosan is at

wave number 3371.57 cm

-1

which indicates the

presence of hydrogen bonds from the -OH group

which overlap with the -NH range (Guibal, 2004).

Uptake at 2877.79 cm

-1

indicates the existence of a

range of vibrations from the -CH, while the tensile

vibration -CH appears at a stirring number of

1381.03 cm

-1

. -NH gulp vibration appears at wave

number 1597.08 cm

-1

. C-O obstacle vibration is

one of the characteristic absorption of

polysaccharides. Appears at wave number 1080.14

cm

-1

. Based on the picture, it is also seen that the

absorption in the area of 1651.07 cm

-1

is getting

weaker and this indicates that diacetylation is

perfectly close (Marguerite, 2006).

Figure 3\: Chitosan FTIR Spectrum from Coconut Crabs Skin.

Isolation and Characterization of Chitosan from Coconut Crab Skin Origin of Halmahera Island with Ftir

301

4 CONCLUSION

This study has succeeded in isolating chitosan

compounds from the skin of coconut crabs through

the process of deproteinization reaction with

NaOH, demineralization with HCl, depigmentation

with NaOCl and deacetylation with NaOH. The

degree of deacetylation from the isolation of

chitosan from coconut crabs skin was 82.52%. The

results of infrared spectroscopy characterization

showed that the extracted compound was chitosan.

ACKNOWLEDGEMENTS

The authors acknowledge the research grant

provided by the Khairun University under the

Short Term Grant Scheme.

REFERENCES

Chen, C. H., Wang, F. Y., Mao, C. F., Yang, C. H. 2007.

Studies of chitosan. preparation and characterization

of chitosan/poly (vinyl alcohol) blend films. Journal

of Applied Polymer Science, 105, 1086–1092.

Gao, Y. M, Oshima, S. Motomizu, 2000. Adsorption

Behaiver Of Metal Ions on Cross-Linked Chitosan

and Determination of Oxoabions after Pretreatment

with a Chitosan Column. Analytical Science, Vol. 16.

Guibal, Eric 2004. Interactions of metal ions with

chitosan-based sorbents: a review. Separation and

Purification Technology 38 (2004) 43–74.

Fohcher, B., Naggi, A., Tarri, G., Cosami, A.,

Terbojevich, M. 1992. Structural differences

between chitin polymorhs and their precipitates from

solution evidences from CP-MAS 13 C-NMR, FTIR

and FTRaman Spectroscopy. Carbohydrate Polymer

17 (2) : 97-102.

Hendry, J. 2008, Enzymatic Deproteination Technique

(Portonus pelagious) by Using Pseudomonas

aeruginosa Bacteria for Making Chitin Polymers and

Deacetylation, Accessed 10 November 2014 at

http://www.fmipa. unila.ac.id / proceedings 2008.

Horton, R.H., Moran, L.A., Ochs, R.S., Rawn. J.D. dan

Scrimgeour, K.G. 2002. Principles of biochemistry

(Third Edition). New York: Prentice-Hall,Inc.

Khan, T.A, Peh, K.K, and Chang, H.S. 2002. Reporting

Degree of Deacetylation Values of Chitosan: The

Influences of Analytical Methods. J.Pharm.Sci. 5

(3), 205-212.

Kim, Eun-young, et al. 2005. Leaching Behavior of

Nickel from Waste Multi-layer Ceramic Capacitors

Marganov. 2003. Potential of Shrimp Waste as

Absorbent of Heavy Metals (Lead, Cadmium, and

Copper) in Waters. Dissertation, IPB, Bogor.

Marguerite, Rinaudo. 2006. Chitin and Chitosan:

Properties and applications. Prog Polym. Sci. (31):

603-632.

Mima, S., Miya, M., Iwamoto, R. and Yoshikawa, S.

1983. J Appl Polym Sci. 28 (6): 1909-1917

Roberts GAF. Structure of chitin and chitosan. In:

Roberts GAF, editor. Chitin chemistry. Houndmills

Macmillan; 1992. p. 1–53.

Sirait, R. I. 2002. Utilization of chitosan from the skin of

shrimps and bark shells to reduce the levels of Ni

and Cr wastes of metal coating industries. USU S-2

Thesis.

Yanming, D., Congyi, X.U., Jianwei, W., Mian,W.,

Yusong, W.U., Yonghong, R. 2001. Determination

of degree of substitution for N-acylated chitosan

using IR spectra. Science in China 44 (2) : 216224.

ICTL 2018 - The 1st International Conference on Teaching and Learning

302