Evaluation Susceptibility of Equipment against Voltage Sags:

Lamp, Contactor and Variable Speed Drive

Surya Hardi

1

, R. Harahap

1

, S. Achmad

1

and Rohana

2

1

Department of Electrical Engineering, Universitas Sumatera Utara, Medan, Indonesia

2

Department of Eletrical Engineering,University of Muhammadyah Sumatera Utara, Medan, Indonesia

Keywords: Equipment testing, voltage sags, susceptibility standard curve.

Abstract: Information about susceptibility of equipment against voltage sags is important in order to avoid system

production drop out. Recently many electrical equipment are develop by using electronic components for

energy saving. The electronic components have been recognizing as susceptible against voltage sags. This

paper presents test results of susceptible equipments to voltage sags which are fluorescent and mercury

vapor lamps, contactors and variable speed drives. A Schaffner Proffline 2100 electromagnetic

compatibility (EMC) has been used to create voltage sag characteristics. Magnitude and duration are

considered as main characteristics for testing. Point on wave of sag initiation was considered for testing

contactor only. Therefore VSDs are three phase, they were test againt voltage sag types I, II and III. The test

results were evaluated by comparing with sensitivty of standard curve availablesuch as ITIC, SEMI F47 and

immunity curves recommended by IEEE P1668

TM

2014.

1 INTRODUCTION

Voltage sags are one of power quality problems,

which are interesting in power system. They can

cause a serious effect on the equipment performance

degradation. When the equipment is supplied by

voltage sags may result in disruption, malfunction,

tripping undesired and even damage. Finally,

apparent economic losses can occurred on

consumers. Susceptibility of equipment is depending

on voltage sag qualities and equipment types.

Magnitude and duration of voltage sags are main

characteristics and other characteristics are

symmetrical and unsymmetrical of voltage sags,

phase shift angle, point on wave (POW) of sag

initiation, etc. Voltage sags are resultedfrom short

circuit faults in power system and others are large

motor starting and transformer energizing.

There are some ways to asses susceptibility of

equipment against voltage variation among others is

mentioned power acceptability curve designed by

CBEMA viz. computer business equipment

manufacturers association in (Heydt et al. 2001). But

available specifically for voltage sags is

Semiconductor equipment and material institute

(SEMI-F47).Last is standard curve

recommendedby(IEEE P1668

TM

, 2014). The

standards are a method to evaluate ride through of

equipment to voltage sags, whichdistinguishfor one

phase load and three-phase load. Availability

susceptibility curve of equipment individually

become crucial. Because from the curve can be

known ride through of equipment when voltage sag

occurs whether the equipment in operation and

malfunction/trip region. These information can be

get from manufacturer, but it is infrequently or by

other way via laboratory testing. This paper is to

evaluate testing results of equipment sample such as

lamps, contactors and variable speed drives (VSDs).

Those equipment are legitimated as susceptible

against voltage sags. Results obtained were

constructed in a susceptibility curve and then

compared with susceptibility standard curve.

2 STANDARD CURVES RELATED

TO EQUIPMENT

SUSCEPTIBILITY

The CBEMA is earlier standard is named power

acceptability curve was introduced in 1980. The

curve is has become standard guidance within

Hardi, S., Harahap, R., Achmad, S. and Rohana, .

Evaluation Susceptibility of Equipment against Voltage Sags: Lamp, Contactor and Variable Speed Drive.

DOI: 10.5220/0008886800730078

In Proceedings of the 7th International Conference on Multidisciplinary Research (ICMR 2018) - , pages 73-78

ISBN: 978-989-758-437-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

73

industry to asses susceptability of automatic data

processing to voltage change in short duration

(Heydt et al. 2001). But it has been applied in many

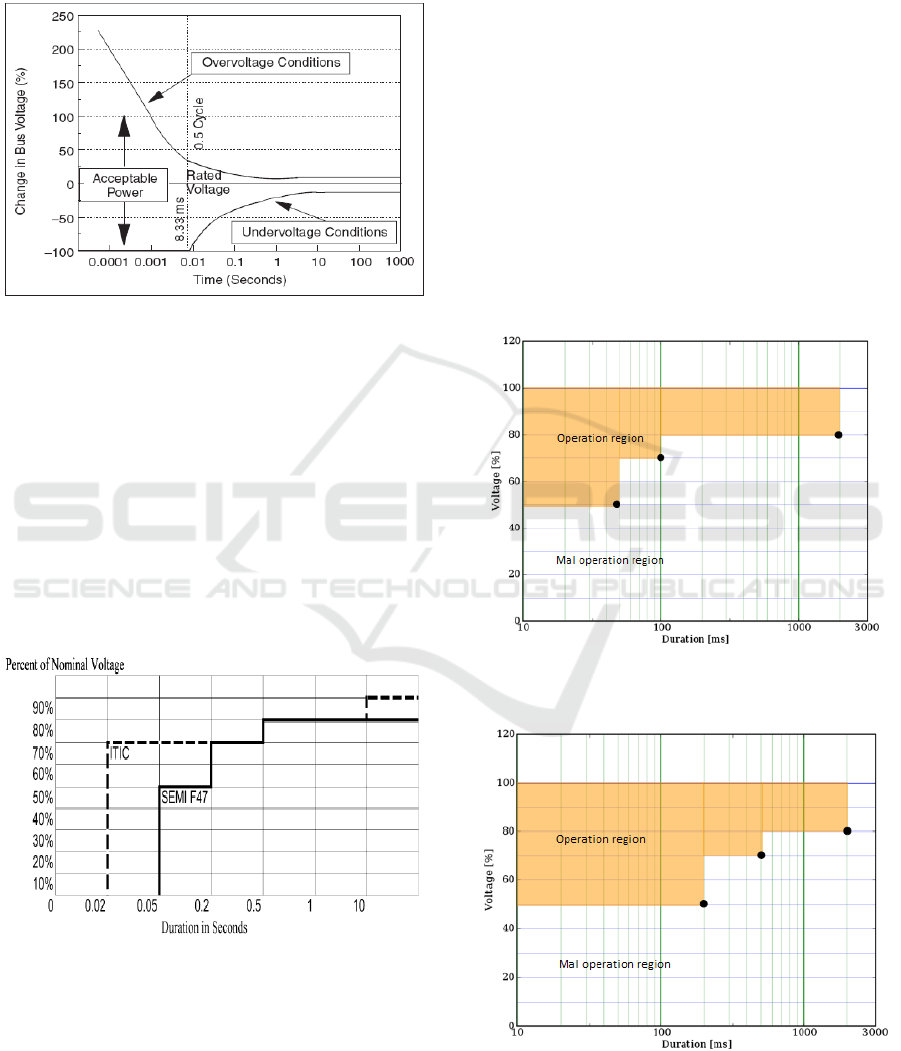

equipment. The curve is dispalyed in Figure 1.

Figure 1:ITIC curve.

This curve explains equipment susceptibility

against voltage variation significantly is influenced

by sag magnitude and duration.

In 1996, CBEMA curve was redesigned and was

called (ITIC), information technology industry

council curve is documented in (IEEE Std. 1346,

1998). This curve is almost similar with old

CBEMA and the different is more piecewise so that

easy to digitize. SEMI F47 is the first time

recommends susceptibility curve specific to voltage

sag (SEMI F47). ITIC and SEMIF47curves are

plotted simultaneously such as in Figure 2.

Figure 2: SEMI F47 and ITIC curves.

It can be seen that the duration of dip is less than

0.2 seconds, the SEMI curve is under ITIC curve

and it is stricter than ITIC. Several equipments pass

the ITIC requirement but not pass for the SEMI F47

requirement curve border.

From Figure2, it can be seen that ITIC has four

knee points which are (75%; 20 ms), (75%; 50ms)

and (80%;50ms), (80%, 100ms) and whereas SEMI

F47 has five knee points which are (50%;50ms),

(50%; 200ms) and (75%;200ms), (75%; 200ms),

(75%; 500ms). Those curves can be used for three

phase and single phase equipment without

distinguish. Generic shape of SEMI F47 has been

applied by some researchers to asses susceptibility

of adjustable speed drive among of found in (Hardi

Surya et al. 2013 and

DjokicS. Z et al. 2005).

IEEE P1668

TM

2014 recommended immunity

test for three phase equipment categorized as type I,

type II and type III. These categorizes base on

amount of phase voltage dropping. Susceptibility

curves are shown in Figure 3 and Figure 4. Those

can be seen that the curves are more simple

compared with earlier curve because they have three

knee points respectively.

Figure 3:Susceptibility standard curve for voltage sagtype

I and type II.

Figure 4:Susceptibility standard curve for voltage sags

type III.

ICMR 2018 - International Conference on Multidisciplinary Research

74

3 FACILITY AND EQUIPMENT

TESTED

3.1 Facility

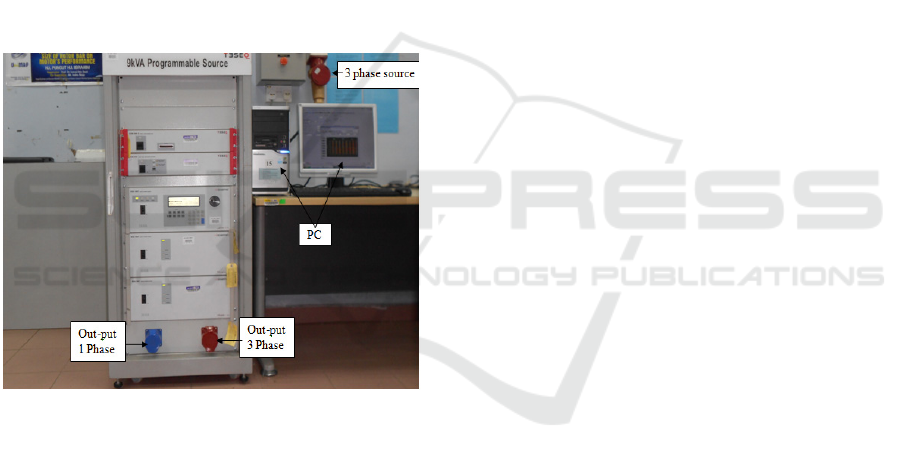

Schaffner Proffline 2100 electromagnetic

compatibility (EMC) is equipment capable for

generating the waveform required. It has 3x3kVA

power rating atvoltage magnitude in ranges 0-

300Vrms/phase. The equipment can produce kind

of power quality problems and one of them is as

voltage sag generator (VSG). Voltage sag

chracteristic is set via personal computer (PC).

There are two types out put available of the

equipment i.e. single phase and three phase. Photo of

the equipment tester is shown in Figure 5. This

equipment available at laboratory in Universiti

Malaysia Perlis (UniMAP) and has been used for

testing of equipmentsusceptibility.

Figure 5: Photograph of Schaffner 2100 EMC.

3.2 Equipment Tested

There are three sensitive equipment tested against

voltage sag i.e. lamps, contactors and VSDs.

3.2.1 Lamps

In general the lamps can be extinguished when

supplied with voltage sag, except incandescent lamp.

Both types of lamps such as fluorescent (FCL) lamp

with electronic ballast and mercury vapor lamp

many are widely used people with efficiency reason.

Electronic ballast uses a switch-mode power

supply to modify the input fundamental frequency

voltage to a much higher frequency voltage typically

in the range of 25 to 40 kHz.

The mercury vapor lamp (MVL) is a high

intensity discharge lamp. It uses an arc through

mercury vaporization in a high pressure tube to

generate greatly light bright which is obtained

straight from it is own arc. The lamps need high

voltage at first start. They also are developed from

electronic components therefore susceptible against

voltage sags.

3.2.2 Contactors

AC contactor is an electromagnetic device that acts

when the electromagnetic coil is connected to a

voltage source. Current will flow through the coil

induces a magnetic field consequnce spring attract

for closingits contacts. Magnetic force produced is

influenced by the voltage magnitude. When the

supply voltage is decreased or interrupted, the

springposition is back to initial position so the

contact keeps in open position. Contactors take large

current starting instants to close it contact is

compared with small current in operation condition.

Contactors are recognized also as susceptible

against voltage sags. Motor get energy supply form

utility via contactor. When contactor is subjected

voltage sags, it may trip so that connection between

motor and contactor disconnected.

3.2.3 Variable Speed Drives

Variable speed drives (VSDs) is many found

industrial sectors for controlling speed of an electric

motor. Rotational speed variation of the motor is not

expected, particularly in industry process. Because

can cause damage in end product. VSD is fabricated

from electronic components consequently it is

susceptible toward voltage sag (Petronijevic et al.

2010). It can trip if is supplied by certain low

voltage level in fixed sag duration. Specs ofthe

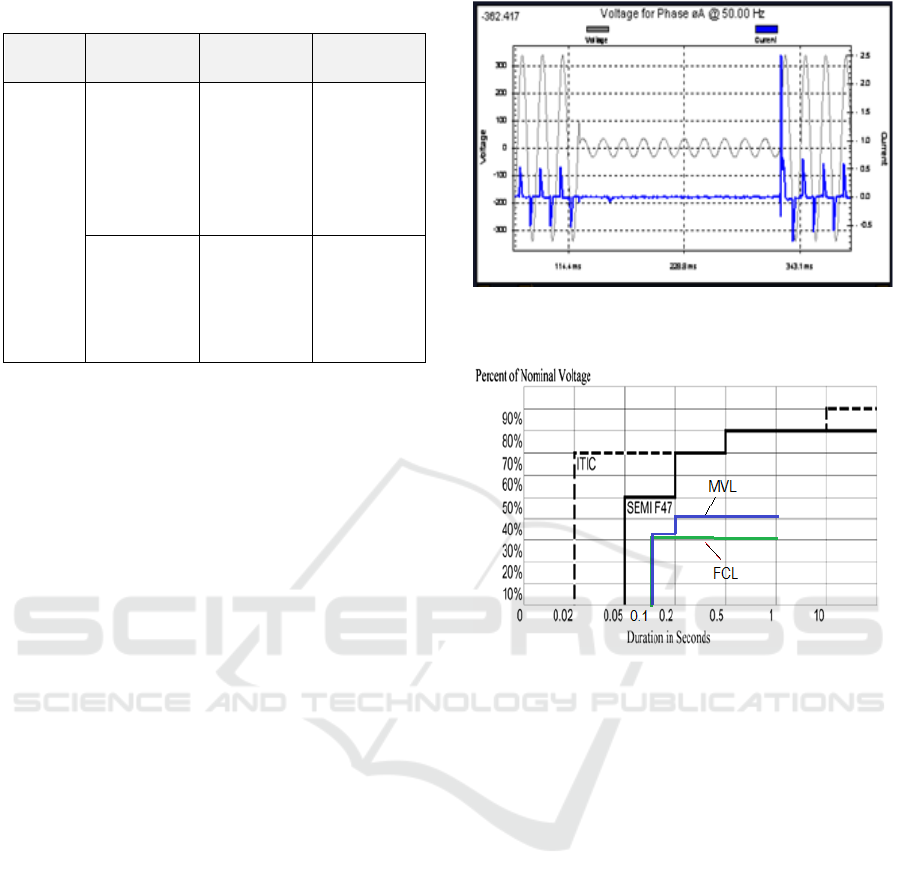

equipment tested are summarized as in Table 1.

Evaluation Susceptibility of Equipment against Voltage Sags: Lamp, Contactor and Variable Speed Drive

75

Table 1:Specs of the equipment tested.

Type Lamp Contactor VSD

Rated

FCL with

Ballast

electronic

240V AC,

36W

C(1)

240V, 20A

VSD (1)

3 phase,

0.5 HP,

380-450V,

400Hz.

Mercury

vapor lamp

240V AC

250W

C(2)

240V, 20A

VSD (2)

3 phase

1.5kW,

380- 450 V,

500Hz

3.2.4 Testing Procedure

The equipment was connected to VSG for genera-

ting voltage sags. Out-put voltage of VSG was set

from 90% up down 0% of nominal voltage with step

2.5%. Sag duration of 10ms was progressively

increased until the equipment trip/switch off. If the

equipment is not trip, proceeds for another voltage

sag level, record the equipment trip or not. The

lamps take into account sag magnitude and duration

only, because POW is not influenced on the Lamp.

But the POWof sag initiation was considered in

contactor testing. Because the VDF is three phase, it

was tested for voltage sags types I, II and III such as

recommended.

4 RESULT AND DISCUSSION

Magnitude and duration of voltage sags are main

characteristics used for testing of three types of

equipment namely; lamps, contactors and variable

speed drives.

4.1 Lamp Testing

Two types of lamps were used for testing viz.

Fluorescent lamp (FCL) and Mercury vapor

lamp(MVL).Waveform example of voltage supplied

and current drawn by FCL lamp is shown in Figure

6. This Figure shows the lamp was supplied by

voltage sag of 20% and 200ms in duration which it

in tripping condition. It can be seen during sag, the

current is zero and while end of the voltage sag, the

current extremely increased.

Figure 6: Voltage and current waveform for sag of 20%

and 200ms in duration.

Figure 7:Susceptibility curves for MVL and FCL lamps.

Susceptibilties of the lamps is shown in Figure 7.

MVL lamp is more sensitive than FCL lamp and it

trips is starting at voltage level 40% whereas FCL

sensitive voltage level at 30%. Even so the lamps

meet standard required because they curve lines are

far below standard curves.

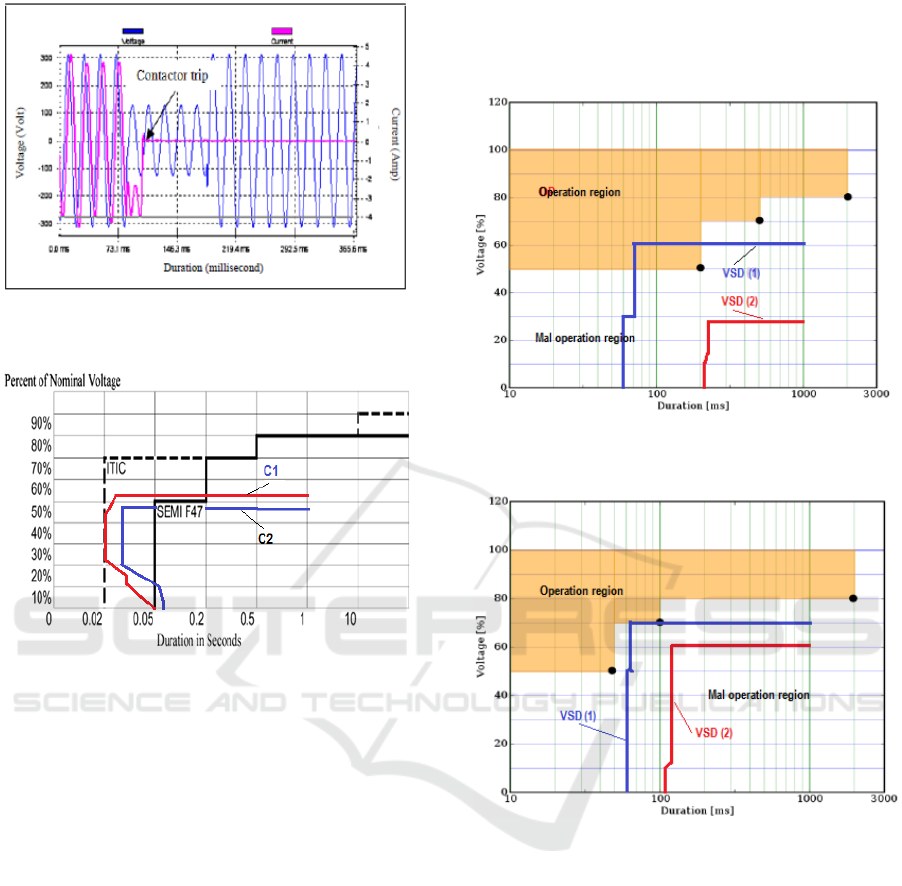

4.2 Contactors Testing

Two contactors from distinct manufacturer, which

have same rated, were used in the testing. The

voltage and current waveform when the contactor

C1 subjected to voltage sag of 40% in 100ms

duration. Figure 8 shows the contactor is tripping

condition. Earlier study considered other

characteristics of voltage sag such as POW of sag

initiation was studied by (Jeong et al.2007) in

simulation model and(S. Hardi and I. Daut, 2010) in

experimental test. In this paper the POW considered

from 0

o

until 90

o

in step 15

o

. The most sensitive test

results only are displayed in this paper which the

contactors was supplied by voltage sags with 60

o

POW. The curves resulted such as in Figure 9.

ICMR 2018 - International Conference on Multidisciplinary Research

76

Figure 8: Voltage sag of 40% and current waveform

throughcontactorC1.

Figure 9: Susceptibility curve for contactor C1 and C2.

From Figure 9, it can be seen that there are some

testing points from 20ms to 50ms are above curve

line of SEMI F47. It means the contactors are not

meeting the standard curve but pass for ITIC

standard. For other POWs, the contactors are

satisfying curve standards. The result is not

prensented in this paper. Contactor C1 begins to trip

at voltage level 52.5% and below for duration

around 30ms. Contactor C2 less sensitive compared

with contactor C1. It starts to trip at voltage level

47.5% and duration of 30ms above.

4.3 Variable Speed Drives Testing

Three phase VSDs of distinct rated power and

distinct brand were used for testing against voltage

sag types I, II and III. Difference these types are

based on number of phases dropping and phase

angle shift. Voltage sag type I, only single phase the

voltage drops and voltage sag type II, two phases

voltage drop and phase shift occured. Voltage sag

type III, third phase voltage drop and there is no

phase shift. Test results of VSD subjected to voltage

sags are shown in Figure 10 and Figure 11. Voltage

sag type I did not cause VSD trip hence

susceptibility curve is not presented.

Figure 10:Susceptibility curve of VSDs caused by voltage

sag type II.

Figure 11. Susceptibility curve of VSDs caused by voltage

sag type III.

Figures 10 and 11 show susceptibilities of

VSD(1) are higher than VSD(2). This is because

distinct in VSD capacitance design as energy saving

and setting over current or under voltage protection

of the ASD (Stockman, 2003 and Pedra et

al.2005).VSD(2) is not passing for voltage sag type

II, because some of the curve lines are in operation

region. But it satify standard curve for testing type

III.

5 CONCLUSIONS

Difference fabrication of equipment gives

susceptibility different results. In general

Evaluation Susceptibility of Equipment against Voltage Sags: Lamp, Contactor and Variable Speed Drive

77

susceptibility of the equipment is within tolerance

limit, except for contactors. This is because

susceptible contactors was presented has highest

susceptibility at 60

o

POW. But it passes for ITIC

standard curve. VSD (1) is more susceptible than

VSD (2). It is not get through when subjected to

voltage sags type II and trip at voltage level of 60%

below, 80ms in duration.

REFERENCES

Djokic S. Z., J. Desmet, G. Vanalme, J. V. Milanovic´,

and K. Stockman., 2005. Sensitivity of personal

computers to voltage sags and short

nterruptions,”IEEE Trans. Power Del., vol. 20, no. 1,

pp. 375–383.

Hardi Surya, Daut I., Nisja I. and Rohana. 2013. Effect of

Voltage Sag Types on AC Motor Drive: Test Result.

Journal of Environmental Research And Development

Vol. 7 No. 4A, April-June. Pages 1615-1621.

Heydt, G.T., Ayyar R and Thallam R. 2001. Power

Aceptabilty. IEEE Power Engineering Review,

September. Pages:12-15.

IEEE Std. 1346-1998. Recommended Practice for

Evaluating Electric Power System Compability with

electronics Process Equipment.

IEEE P1668™.2014. IEEE Trial-Use Recommended

Practice for Voltage Sag and Short Interruption Ride-

Through Testing for End-Use Electrical Equipment

Rated Less than 1000 V.

Jeong, S.W., Lee G.J. and Gim J.H. 2009. The Study on

the Characteristics of Operating Limits of AC

Contactor during Voltage Sag. Transmission &

Distribution Conference & Exposition: Asia and

Pacific, IEEE Conference Publications. Pages: 1 – 4.

Pedra, J., Corcoles F. and Suelves F.J., 2005. Effect

ofBalanced and Unbalanced Voltage Sags on VSI-FED

Adjustable Speed Drives. IEEE Trans. On Power

Delivery, Vol. 20. No. 1, January. Pages: 224 – 233

.

Petronijevic M., Veselic B., Mitrovic N., KosticV.,Jeftenic

B. 2010. Comparative study of unsymmetrical voltage

sag effects on adjustable speed induction motordrives.

IET Elect. Power Appl., Vol. 5. Issue 5, pages: 432-

442.

SEMI F47 available at: https:

//www.powerstandards.com/tutorials/what-is-semi-f47

Stockman, K. ,D’hulsterF., Verhaege, K. and Didden, M.,

2003.Ride through of Adjustable Speed Drives During

Voltage Dips. Electric Power system Research 66

Pages: 49-58.

Surya Hardi and I.Daut., 2010. Sensitivity of Low Voltage

Consumer to Voltage Sags. The 4International Power

Engineering and Optimization Conf. (PEOCO2010),

Shah Alam, Selangor, MALAYSIA: 23-24 June.

Pages:396-401.

ICMR 2018 - International Conference on Multidisciplinary Research

78