Analysis Characteristics of Silicon Aluminum Material based on

Fracture Period in Torque Test

Junaidi

1

, Soni Hestukoro

1

, Fadly Ahmad Kurniawan

2

, Ahmad Bakhori

3

and Edi Sarman Hasibuan

4

1

Department of Mechanical Engineering, Universitas Harapan Medan

2

Department of Mechanical Engineering, Politeknik Negeri Medan.

3

Department of Manufacture Engineering, Universitas Islam Sumatera Utara.

4

Department of Manufacture Engineering, Universitas Amir Hamzah Medan.

edisarmanhsb@yahoo.com

Keywords: Characteristics, Aluminum Silicon, Torque, Fracture Period.

Abstract: Aluminumcasting results are still manythat suffered damage.Some of the causes are the lack ofpermeability

andprint strength. This researchwasexpected to be able to know the capability ofcastingproductto

impactload from varioustemperature which wasmeasuredand expected toincreaseproductivity of

castingsresult.This researchwas expected to knowthe ability of castingproductstothetorque load of

variousforces thatweremeasured and expected to increase the productivityofthe castings. This research used

variation of permeability value by testing 3 materialstested with the same length and diameter. This study

was conducted by observing theeffect ofcorner and force of torque on the breaking strength performed by

torque testing with the firsttestofthe forceof 4.6 ton with the angle 2

0

with the fracture period at 70

0

with the

corner 0ton, test the two force of 4.6 ton with corner 2

0

with fracture at 0 ton with corner 70

0

, third test of

force 3 ton with corner 2

0

with fracture period at 76 ton with corner 0

0

.

1 INTRODUCTION

One of the composite-based materials is Al-SiC

(Aluminum Silicon Carbide) because this material

has a hard and light properties. Aluminum (Al) is as

the matrix (main material) and SiC as its amplifier.

Aluminum has advantages that have a lightweight,

corrosion resistance and composite brakes are not

having the sale value of the material is not

economical antitheft. Metal Aluminum, when

viewed from mechanical properties, such as

hardness value (hardness), is very low. Therefore,

Aluminum metal as a material has many

weaknesses, especially mechanical strength,

stiffness and coefficient of expansion. The

advantages of Aluminum metal include light weight,

corrosion resistant and easily formed (Zhongliang

Shi et al. 2001). One way to increase the metal

hardness is to strengthen the metal in a way coupled

with hard materials, such as ceramic materials. The

most commonly used and hardest ceramic type is the

SiC

This research performs characteristic of making

Al-SiC by stir casting method, with modification of

reinforcing fraction. Variations of addition

strengthening parameters are 5, 10 and 15% SiC.

The subjects covered include chemical composition

with various material composition, tensile and

impact test. The expected output from this research

is the result of tensile strength and impact price. The

use of brake blocks for railway canvas in Indonesia

commonly used is made from cast iron, where this

material has been started since the last decade. Brake

block material using cast iron weighs 11 kg, making

it difficult to install or installation cost is large

enough. One of the efforts that has been taken is to

combine the two constituent materials, namely

matrix and amplifier called composite.

Composite materials include: resin, fiber and

filler. The types of materials for railway brake

blocks are gray cast iron and Al-SiC. The composite

is a blend of selected ingredients based on the

combination of physical properties of each

constituent material to produce new and unique

materials. Various kinds of amplifiers eg SiC and

Al2O3. Based on the matrix material used, the

composite can be classified into 3 groups, namely:

metal matrix composite (MMC) as matrix, polymer

52

Junaidi, ., Hestukoro, S., Ahmad Kurniawan, F., Bakhori, A. and Sarman Hasibuan, E.

Analysis Characteristics of Silicon Aluminum Material based on Fracture Period in Torque Test.

DOI: 10.5220/0008882300520056

In Proceedings of the 7th International Conference on Multidisciplinary Research (ICMR 2018) - , pages 52-56

ISBN: 978-989-758-437-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

matrix composite (PMC) polymer as matrix, and

ceramic matrix composite (Ceramic Matrix

Compositor/ CMC) ceramics as matrix. While based

on the type of reinforcement, the composite material

can be explained as follows: particulate composite,

amplifier in the form of particles, fiber composite,

fiber-strengthening and structural composite,

composite materials.

2 RESEARCH METHODS

This research was conducted in February 2017 at the

Basic Physics Laboratory, Laboratory Faculty of

Engineering Mechanical, Engineering Study

Program, University of Harapan Medan, as for the

procedural Implementation of research as below:

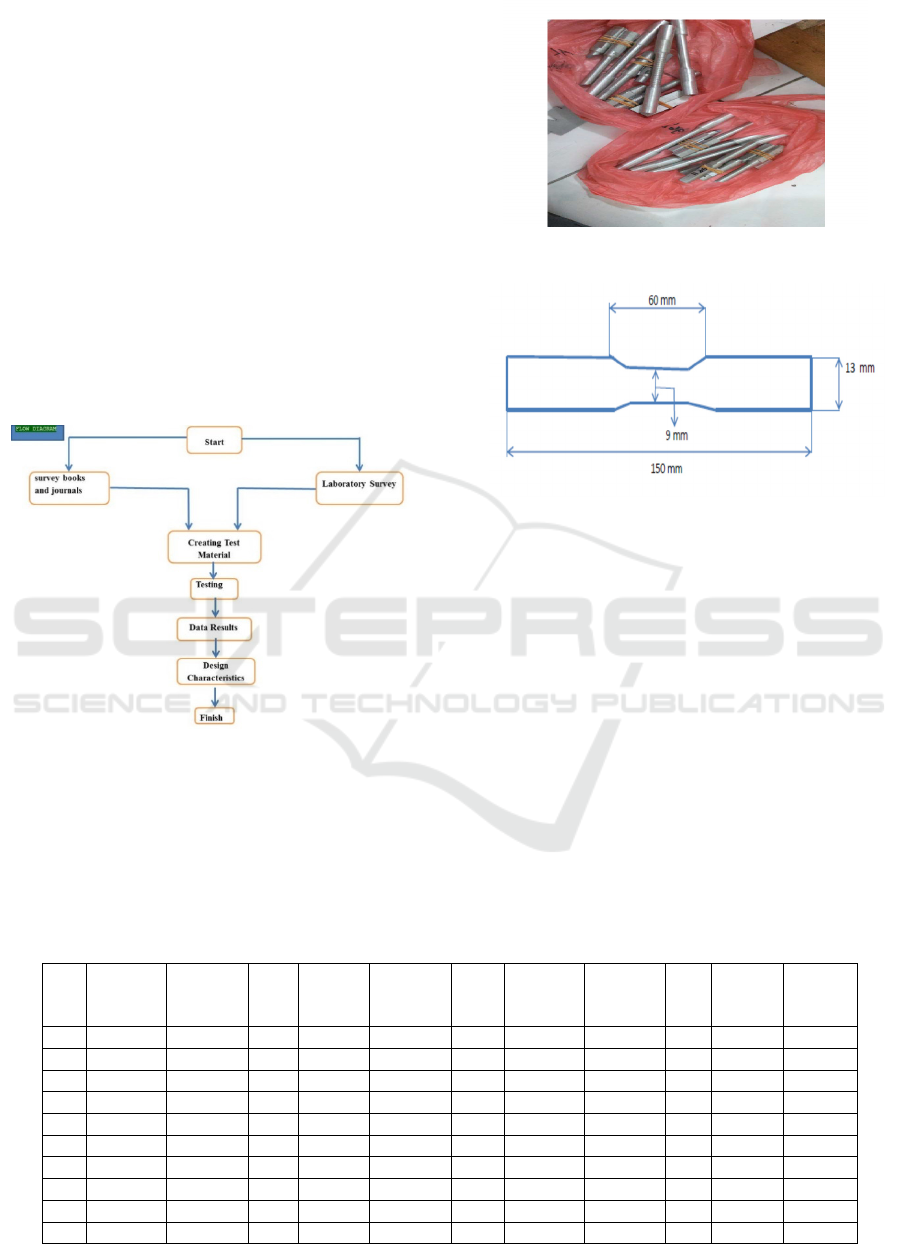

Figure 1: Procedure Implementation of Research.

Figure 2: Profile Materials.

Figure 3: Size of Test Object.

3 RESULTS AND DISCUSSION

The research conducted using torque testing. Testing

torsionused Torsion Machine torque test equipment.

The Aluminum Silicon Carbide specimen, the

maximum force applied to the torque testing

apparatus was 4.6 N while the 5%, 10% and 15%

Al-SiC specimens and Al-SiC composites with the

maximum force of 76 N. The result of the torque test

was the amount of broken force that could be seen in

the tool with a percentage scale of the maximum

force applied to the specimen. Torque testing by

measuring the angle of the material was against the

shock load, using the Charp method.

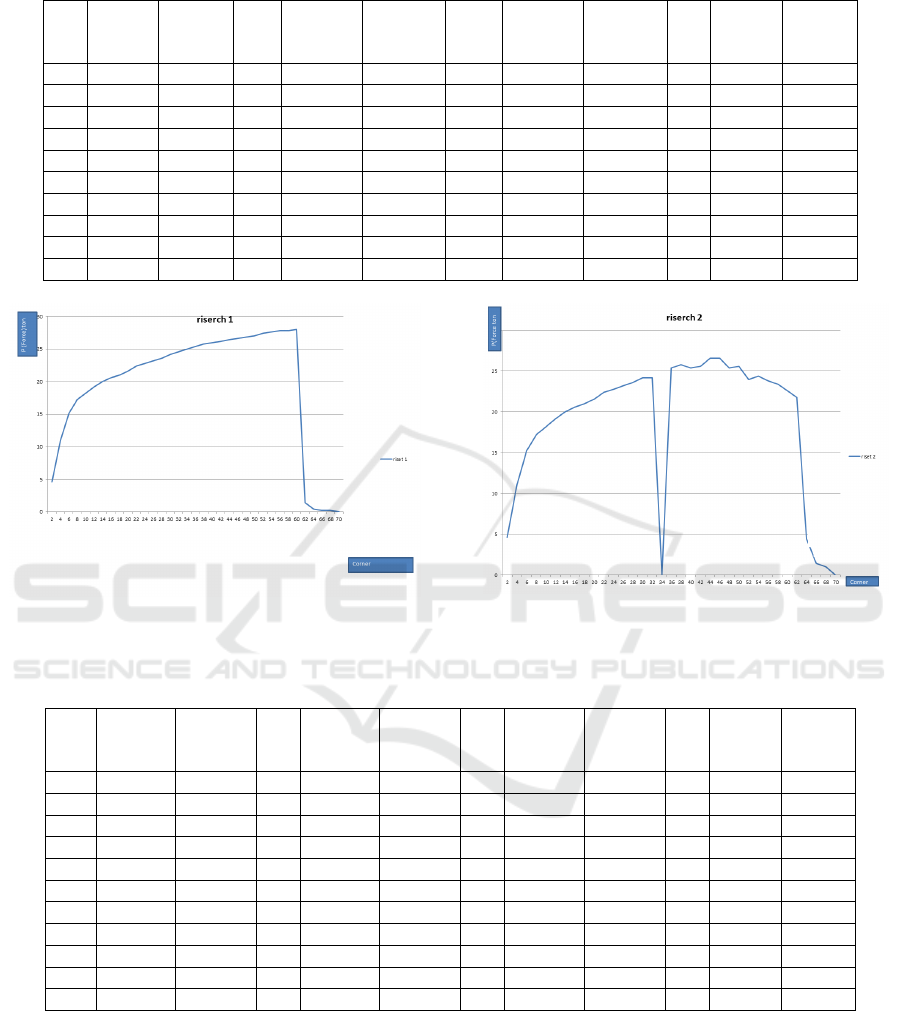

Table1: Research Results on Materials 1.

No Ɵ

Corner

P

(Force)

ton

No Ɵ

Corner

P

(Force)

ton

No Ɵ

Corner

P

(Force)

ton

No Ɵ

Corner

P

(Force)

ton

1 2 4,6 11 22 22,4 21 42 26,2 31 62 1,4

2 4 11 12 24 22,8 22 44 26,4 32 64 0,4

3 6 15,2 13 26 23,2 23 46 26,6 33 66 0,2

4 8 17,2 14 28 23,6 24 48 26,8 34 68 0,2

5 10 18,2 15 30 24,2 25 50 27 35 70 0

6 12 19,2 16 32 24,6 26 52 27,4

7 14 20 17 34 25 27 54 27,6

8 16 20,6 18 36 25,4 28 56 27,8

9 18 21 19 38 25,8 29 58 27,8

10 20 21,6 20 40 26 30 60 28

Analysis Characteristics of Silicon Aluminum Material based on Fracture Period in Torque Test

53

Table 2: Research Results on Materials 2.

No Ɵ

Corner

P

(Force)

ton

No Ɵ

Corner

P

(Force)

ton

No Ɵ

Corner

P

(Force)

ton

No Ɵ

Corner

P

(Force)

ton

1 2 4,6 11 22 22,4 21 42 25,6 31 62 21,8

2 4 11 12 24 22,8 22 44 26,6 32 64 4,4

3 6 15,2 13 26 23,2 23 46 26,6 33 66 1,4

4 8 17,2 14 28 23,6 24 48 25,4 34 68 1

5 10 18,2 15 30 24,2 25 50 25,6 35 70 0

6 12 19,2 16 32 24,6 26 52 24

7 14 20 17 34 25 27 54 24,4

8 16 20,6 18 36 25,4 28 56 23,8

9 18 21 19 38 25,8 29 58 23,4

10 20 21,6 20 40 25,4 30 60 22,6

Figure 4: Material Characteristics in Experiment 1.

Figure 5: Material Characteristics in Experiment 2.

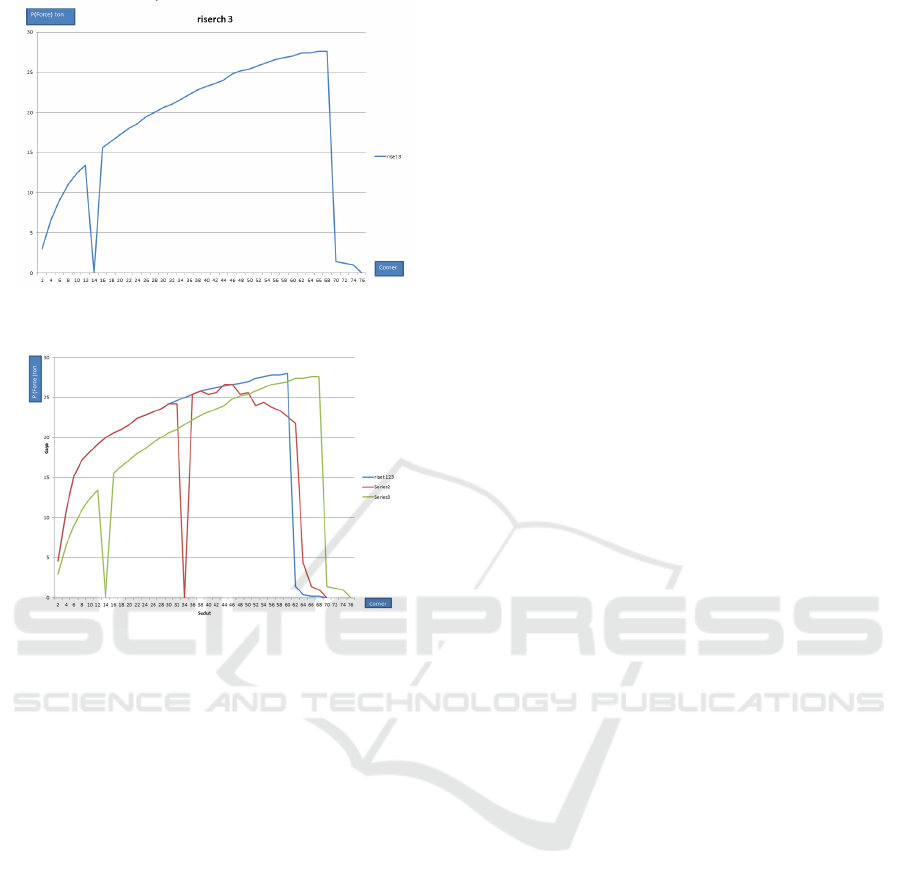

Table 3: Research Results on Materials 3.

No Ɵ

Corner

P

(Force)

ton

No Ɵ

Corner

P

(Force)

ton

No Ɵ

Corner

P

(Force)

ton

No Ɵ

Corner

P

(Force)

ton

1 2 3 12 24 18,6 23 46 24,8 34 68 27,8

2 4 6,6 13 26 19,4 24 48 25,2 35 70 1,4

3 6 9 14 28 20 25 50 25,4 36 72 1,2

4 8 11 15 30 20,6 26 52 25,8 37 74 1

5 10 12,4 16 32 21 27 54 26,2 38 76 0

6 12 13,4 17 34 21,6 28 56 26,6

7 14 14,4 18 36 22,2 29 58 26,8

8 16 15,6 19 38 22,8 30 60 27

9 18 16,4 20 40 23,2 31 62 27,4

10 20 17,2 21 42 23,6 32 64 27,4

11 22 18 22 44 24 33 66 27,6

ICMR 2018 - International Conference on Multidisciplinary Research

54

Figure 6: Material Characteristics in Experiment 3.

Figure 7: Collect Characteristics of Materials in

Experiment 1, 2, 3.

4 CONCLUSIONS AND

SUGGESTIONS

4.1 Conclusion

1. For test experiment 1, it shows the beginning

oftorque at corner 20 with a force of 4.6 tons,

there is a fracture mass on. 700 angleswith

Force P = 0 ton.

2. For the experimental test, it shows the

beginning of torque at a corner of 20 with a

force of 4.6 tons, there is a fracture mass on.

700 corners with Force P = 0 ton, but at the

force of approximately 25 ton with corner

340.almosthappenedstress.

3. For the experimental test, it shows the

beginning of torque at corner 20 with a force of

3 tons, there is afracture mass on. corner 760

with Force P = 0 tons, but at a force of

approximately 170 N with an angle of 140is

almost stressful

4.2 Suggestion

1. For the execution of testing, it is required that

the torsion test equipment be calibrated so that

the tested results obtain valid data results.

2. The material of the test object shall be finished

and the surface for clamping the standard

forclamping, so as not to be detached from the

holder.

3. Characteristic planning tools should be valid in

data searched.

REFERENCES

A. Y. junaidi, dharmawati, “Analysis Cutting Tool High

Speed Steel ( HSS ) With Cast Iron Material From

Universal Lathe,” in IRSTC 2015 PROCEDING, 2015,

pp. 464–477.

Indra Roza Junaidi, weriono, “IrrigationWater Debit

Analysis that will be used on Micro Power Plant in

SEI . Rampah Sub-District of Serdang Bedagai

Regency,” Int. J. Innov. Sci. Res. Technol., vol. 3, no.

1, 2018.

Indra Roza Junaidi, weriono, “Process Analysis of High

Speed Steel Cutting Calculation (HSS) with S45 C

Material On Universal Machine Tool,” IJISRT

(International J. Innov. Sci. Res. Technol., vol. 3, no.

1, pp. 447–456, 2018.

Junaidi, “Analyze cutting tools (HSS) with cast iron

material on Universal Lathes,” in Makalah PEKAN

ILMIAH Periode XXII-TA.2014/2015 FAKULTAS

TEKNIK UISU, 2015, pp. 51–58.

Junaidi, “The Effect of Exposuretime on the Crack Length

of Austenite AISI 304,316 and 316L Stainless Steel

Material with Failure Stress Corrosion Cracking,” in

WAHANA INOVASI Jurnal Penelitian dan

Pengabdian, 2013, pp. 291–298.

Junaidi and Eddy, “Analysis of Cutting Carbide Tools

with S45C Material on Universal Lathes,” in Seminar

Nasional FT.UISU, 2017, pp. 116–123.

J. Budi Santri Kusuma, “Analysis of the effect of cooling

media and heating on hardness and microstructure in

the tempering process of SKD 11 tool steel.,”

PROSIDING Seminar Nasional Pembangunan

Berkelanjutan Bangsa Berbasis Iptek (PB3I-ITM).

BIRO PUBLIKASI DAN DOKUMENTASI -ITM

jLN.Gedung Arca No.52 Medan, MEDAN, pp. 63–67,

2014.

J. Junaidi, S. Hestukoro, A. Yanie, J. Jumadi, and E. Eddy,

“IMPLEMENTATION ANALYSIS of CUTTING

TOOL CARBIDE with CAST IRON MATERIAL

S45 C on UNIVERSAL LATHE,” in Journal of

Physics: Conference Series, 2017, vol. 930, no. 1.

J. Weriono, “Noise Analysis of Variations in Engine Turn

on 1300 CC Cars Due to Mechanical Vibration,” J.

Technol. Harapan, vol. 6, no. 1, pp. 7–10, 2017.

S. H. junaidi, weriono, indra roza, “Economic Planning

Analysis Characteristics of Silicon Aluminum Material based on Fracture Period in Torque Test

55

Analysis of MHP PLTMH Using Pico-hydro Turbine:

Hundreds of watts - 5 KW,” IJISRT (International J.

Innov. Sci. Res. Technol., vol. 3, no. 2, pp. 112–116,

2018.

T. Siagian, I. Siregar, and H. Lubis, “Characteristics of

St.37 Steel Materials with Temperature and Time on

Heat Treatment Test using Furnace,” 2018.

ICMR 2018 - International Conference on Multidisciplinary Research

56