Study of Kaliandra Tree as Source of Primary Energy

Surya Tarmizi Kasim

1

, Riki Ananda

1

and Fahmi

2

1

Department of Electrical Engineering, Faculty of Engineering, University Sumatera Utara, Medan,Indonesia

2

Centre of Excellence Sustainable Energy and Biomaterials, University Sumatera Utara,Medan,Indonesia

Keywords: Renewable energy, kaliandratree, electrification, wood pellet.

Abstract. Fulfilling the need for energy is still heavily dependent on fossil fuels. Meanwhile, our fossil energy

reserves are declining. On the other hand, Indonesia's electrification ratio is still at 80.4%. The lowest

electrification ratio is in East Nusa Tenggara (54.77%) and Papua (36.41%). Low electrification ratios

mostly occur in remote areas as well as small islands. Inadequate infrastructure and also the high cost of

building transmission lines to remote areas as well as small islands are the main obstacles. One of the efforts

made to overcome the electricity crisis is to utilize Renewable energy resources (Renewable energy

resources). This study discusses the study of the utilization of Kaliandra wood pellets as fuel for the power

plant. Research methodology is done by analyzing the results of lab tests conducted at PT. Sucofindo to

Kaliandra Pellet samples. The research was conducted by calculating Low Heat Value of Kaliandra pellets.

The results shows that 1 kg of Kaliandra pellet produces 5,477 kWh with the price of Rp. 744, 24 / kWhso it

is possible to be used as fuel for the steam power plant for small scale.

1 INTRODUCTION

Today electrical energy has become a primary need

for modern society. The need for electrical energy is

increasing along with the progress of science,

technology, and civilization of a nation. This

increasing power demand must be offset by the

construction of new plants. Most of the fuel for our

plants is fossil fuels such as fuel oil, coal, and gas.

Fossil fuels are non-renewable fuels. In contrast to

the growing need for electrical energy, the energy

reserves of fossil fuels are even less and will soon

run out.

Indonesia is still heavily dependent on fossil

fuels. Meanwhile, our fossil energy reserves are

declining. On the other hand, Indonesia's

electrification ratio is still at 80.4% (PLN, 2014).

The lowest electrification ratio was in East Nusa

Tenggara (54.77%) and Papua (36.41%).

Low electrification ratios mostly occur in remote

areas as well as small islands. Inadequate and costly

infrastructure to build transmission lines to remote

areas, as well as small islands, is a major obstacle.

To increase the electrification ratio in remote

areasand islands is the development of new plants.

The construction of power plants in small areas is

done in small capacity according to need. In

addition, efforts should also be made of the fuel that

is easily available in the area for the sustainability of

electricity generation.

One of the efforts made to overcome the

electricity crisis is to utilize Renewable energy

resources (Renewable energy resources). In

Indonesia, there are a lot of energy resources that

can be utilized. One of them is biomass. One

alternative fuel for power plants in remote and

remote islands is from Kaliandra trees.

1.1 Biomass

Biomass is an organic material produced through

photosynthetic processes, both in the form of

products and waste. Examples of biomass include

plants, trees, grasses, yams, agricultural wastes,

forest waste, feces and livestock manure. Besides

being used for the primary purpose of fiber,

foodstuff, animal feed, vegetable oil, building

materials and so on. Biomass is also used as a source

of energy (fuel).

Biomass energy sources have several advantages

such as a renewable energy source that can provide a

sustainable source of energy. In Indonesia, biomass

is a very important natural resource with a variety of

primary products as fiber, wood, oil, foodstuffs, and

26

Kasim, S., Ananda, R. and Fahmi, .

Study of Kaliandra Tree as Source of Primary Energy.

DOI: 10.5220/0008881800260030

In Proceedings of the 7th International Conference on Multidisciplinary Research (ICMR 2018) - , pages 26-30

ISBN: 978-989-758-437-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

others that are used to meet domestic needs also

exported and become the backbone of the country's

foreign exchange.

The Government encourages the Development of

Biomass and Biogas PLT through Minister of

Energy and Mineral Resources Regulation No. 27 of

2014 on the Purchase of Electricity from Biomass

Power Plant and Biogas Power Plant by PLN.

1.2 Biomass as a Source of Energy

Biomass as a Renewable Energy Source that can

always be replanted and harvested in ways that

humans use it as fuel from time immemorial.

Activity utilizing biomass as energy fuel is often

also referred to as "green farming" activity without

the need for capital / cost which is too high but able

to involve labor so-called "pro job action."

Biomass utilization has the following effects

(Kong, 2010):

1. The air around the biomass burning process is

cleaner than the air quality near the burning

process of fossil fuel.

2. For managers of biomass-fueled power plants,

this can put pressure on investment costs an

unnecessary overhaul unit of emissions as well

as daily operational costs. The more complex the

operation, the greater the electrical energy

required because each pollution prevention unit

also needs electrical energy.

3. CO2 of biomass burning is categorized as

"carbon neutral" because it is reabsorbed by

plants to sustain its growth.

4. Planting energy plants in marginal lands in

addition to boosting local people's income can

also prevent soil erosion and thus reduce the

potential for landslides.

5. When the "sleeping" areas are used for crops,

then the rainwater absorbing function is

reactivated as a means of preventing flooding.

The potential of biomass in Indonesia that can

be used as an energy source is very abundant. Waste

derived from animals and plants are all potential to

be developed. Food crops and plantations produce

considerable waste, which can be used for other

purposes such as biofuels.

Utilization of waste as a biofuel provides three

immediate benefits. First, the improvement of

energy efficiency as a whole because the energy

content contained in the waste is large and will be

wasted if not used. Second, cost savings, as often

waste disposal can be more expensive than using it.

Third, reducing the need for landfill sites due to the

provision of landfills will become more difficult and

expensive, especially in urban areas.

1.3 PLTU Fueled from Wood Pellet Red

Kaliandra

PLTU is a plant that uses steam as the prime mover.

To produce steam, there must be a combustion

process to heat the water. PLTU is a power plant

system that converts chemical energy into electrical

energy by using water vapor as its working fluid,

with turbine blades moving the turbine shaft, for the

next turbine shaft to move the generator which is

then generated into electrical energy.

Steam Turbine is one of the basic components in

a steam power plant. Where the main components of

the system are: kettle, condenser, boiler water pump,

and turbine itself. Steam that serves as a working

fluid is produced by a boiler, a device that serves to

convert water into vapor.

Energy Conversion Process at PLTU has three

stages, namely (Suyitno, 2011):

1. Chemical energy in the fuel is converted

into heat energy in the form of high-

pressure steam and high temperature.

2. Heat energy (steam) is converted into

mechanical energy in the form of rotation.

3. Mechanical energy converted into electrical

energy.

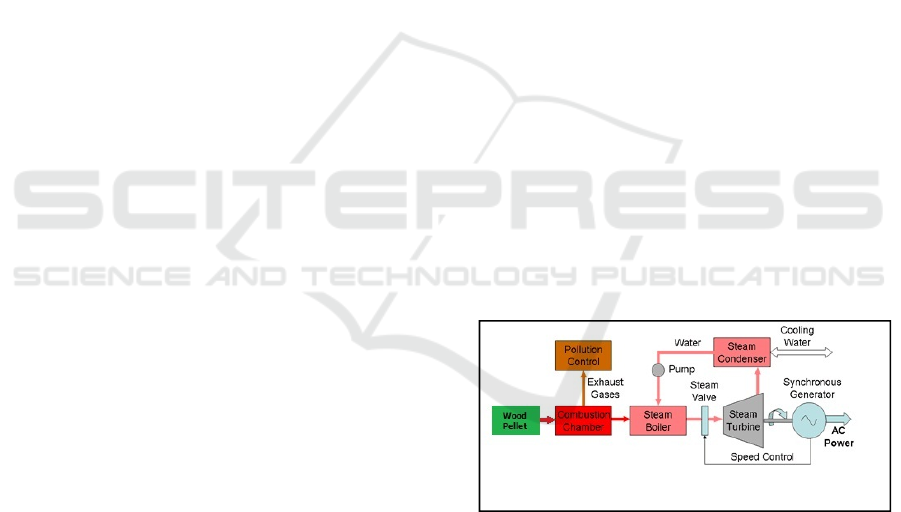

The process of converting chemical energy into

electrical energy can be seen in Figure 1:

Figure 1: Wood Pellet Power Plant diagram block.

Almost all electrical energy is generated by using

a synchronous generator. Therefore, synchronous

generator plays an important role in a power plant.

Synchronous generator (often called an alternator) is

a synchronous machine that functions to convert

mechanical energy in the form of rotation into

electrical energy back and forth (AC)

The working principle of a synchronous

generator is (Marsudi, 2005):

1. The field coil present in the rotor is connected to

a particular excitation source which will supply

Study of Kaliandra Tree as Source of Primary Energy

27

direct current to the field coil. Given the direct

current flowing through the field coil, it will

cause a flux whose magnitude over time is fixed.

2. Prime Mover which is already coupled with the

rotor is immediately operated so that the rotor

will rotate at its nominal speed. This corresponds

to Equation 1.

n

120

f

p

(1)

where:

n = Rotary speed of rotor (rpm)

p = Number of rotor poles

f = frequency (Hz)

3. The rotation of the rotor will simultaneously

rotate the magnetic field generated by the field

coil. The rotary field generated on the rotor will

be induced on the anchor coil so that on the

anchor coil located in the stator will be generated

magnetic flux which varies with time. Any

change in the magnetic flux surrounding a coil

will induce an induced emf at the ends of the

coil, according to Equation 2 (Zuhal, 1993):

∅

(2)

∅ sin

(3)

∅

(4)

where:

E = emf induction (Volt)

N = Number of turns

C = Constants

p = Number of poles

n = Rotation speed (rpm)

f = Frequency (Hz)

ϕ = Magnetic flux (weber)

For a three-phase sync generator, three anchor

spools are placed in the stator arranged in a

particular shape, so that an anchor coil arrangement

such as that will generate an induced voltage across

the three equal-but-different 120° phase of each

anchor coil. After that, the three anchor coil

terminals are ready to operate to generate electrical

energy.

2 MATERIAL AND METHOD

The steps in conducting an analysis of calculation

study of Kaliandra tree utilization as a primary

energy source are:

1. Calculating the availability of Kaliandra pellet

fuel per year.

2. Determining the hours of operation of the plant

used in a year.

3. Determining the low energy content of the fuel

and its equivalence with the energy generated per

hour

4. Determining the cost of red Kaliandra pellet fuel

per kWh

3 RESULTS AND DISCUSSION

After the measurement, it can be known that fuel

availability per year, fuel energy content of Low

Heating Value (LHV), hours of operation of the

plant in a year, the output power generated per hour,

and the price of fuel.

3.1 Wood Pellet Availability per Year

Wood fuel availability of Kaliandra wood pellets is

highly dependent on the area of land developed for

growing wood pellets. According to ICCTF

(Indonesian Climate Change Trust Fund), the wood

pellet that can be processed from 1 ha of crops in

one

year is 30 tons. So that in 200 ha of

Kaliandra plant obtained fuel of 600 tons.

3.2 Hours of Operation

Forced Outage Rated (FOR) is a rating that

describes the number of hours of interruption

(generator not in operation) by the number of hours

of operation with the added number of hours of

interference. FOR on hydropower ranges from

0.01.As for the PLTU is in the range 0.01 - 0.05.

The more reliable a generating unit, the smaller the

value of its FOR.

Length of time of year-long disruption according

to Equation 5 (Suyitno, 2011)

Hours of Operation = FOR x 8760

(5)

The value of FOR in this study is assumed to be

0.05. So the amount of disturbance obtained by

multiplying FOR by the number of hours in a year

ICMR 2018 - International Conference on Multidisciplinary Research

28

so that the hour of disturbance that occurs within a

year is 438 hours. By knowing the number of

disturbances in a year, it can be determined hours of

operation of the plant within a year. The hours of

operation of the plant are known by performing a

reduction operation against the number of hours in a

year subtracted by the amount of interference:

Hours of operation = 8760-438 = 8.322 hours

From the above calculation then we can get the

hours of operation of the plant in a year is equal to

8,322 hours. From these calculations, the fuel used

per hour in a year results from the amount of fuel

availability in a year is distributed by the

number of hours of operation of the plant

within a year. Thus, the fuel used in one

hour of operation is 720.98 kg / hour.

3.3 Energy Content

Heating Value (HV) or Caloric Value is the calorific

value incurred by 1 kilogram of fuel. The

calorificvalue areof 2 kinds, namely Low Heating

Value (LHV) / Top Value and High Heating Value

(HHV) / Value down.

Fuel combustion at thermal power plants releases

exhaust gases at temperatures well above the water

dew point; the energy balance calculations are based

on lower calorific values because at the high exhaust

gas temperature the water

is in the vapor phase.

Calorific Value (LHV) also called Gross

Calorific Value.

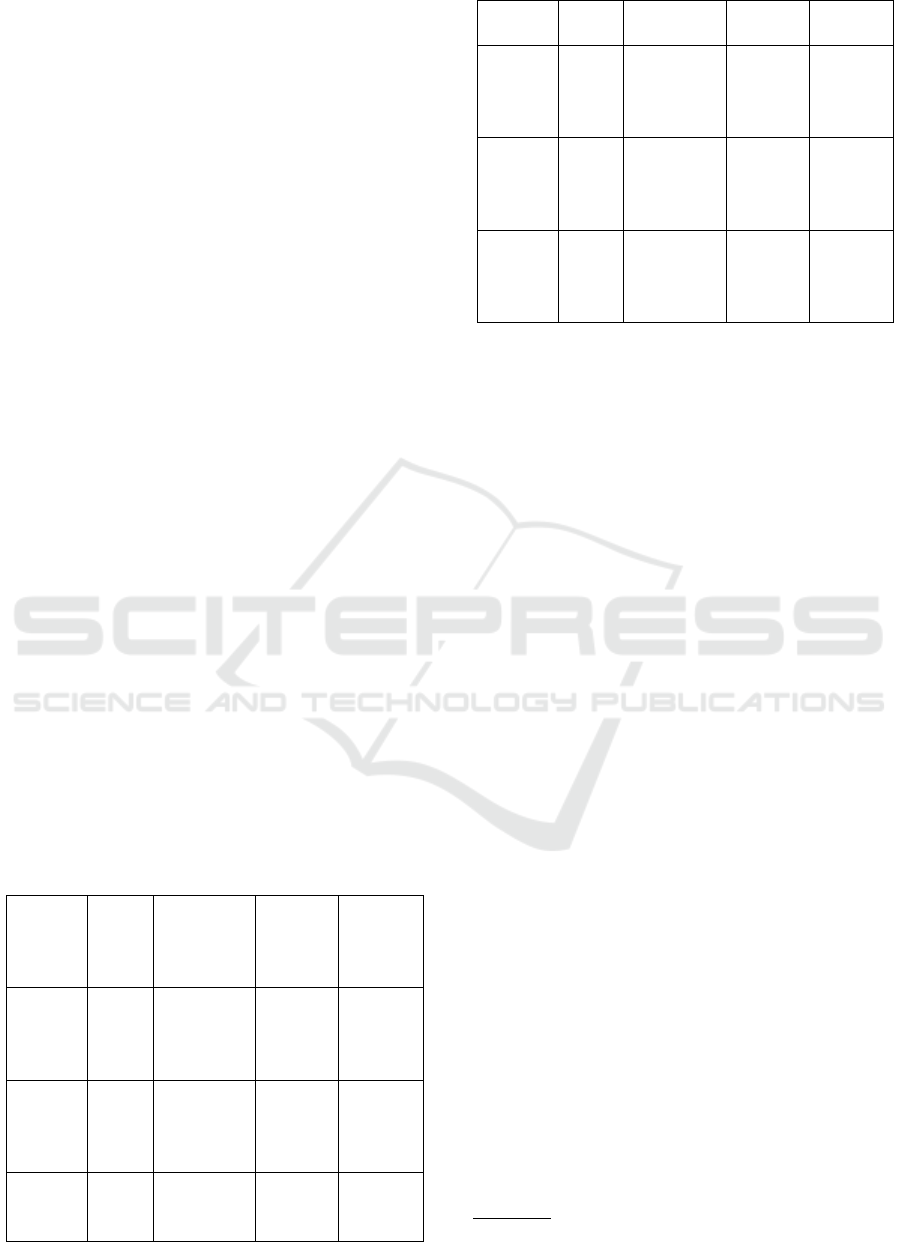

Table 1 shows the measurements of the Red

Kaliandra wood pellets.

Table 1: Measurement of Kaliandra Calorific Value.

Paramet

ers

Unit As

Received

DB

(Dried

Basis)

Test

Method

Total

moistur

e

% wt 5.8 --- ASTM

D 2961-

11

Ash

content

% wt 4.7 4.9 ASTM

D 3174-

11

Volatile

matter

% wt 73.5 78.1 ASTM

D 3175-

11

Fixed

Carbon

% wt 16.0 17.0 By

differen

ce

Total

Sulfur

% wt 0.16 0.18 ASTM

D 3177-

07

Gross

Calorifi

c Value

% wt 4436 4710 ASTM

D 5865-

11a

From Table 1 it can be seen that Kaliandra Gross

Caloric Value (LHV) is 4710 kcal / kg. As for 1 kcal

is equivalent to 1.163 wh, so 4710 kcal is equal to

5,477 wh.

3.4 Power Output

The generator output is obtained by performing

multiplication operations between Gross Caloric

Value (LHV) wood pellet fuel and generating

efficiency. So the energy produced is (Fransescato,

2008):

P = Low Heating Value x efficiency(η) (6)

= 5.477 x 0.27

= 1.478 watt hour

Thus, Power (P) obtained is 1,478 watts hour.

The power that can be generated for operations

for a year is the multiplication of the amount of fuel

available with the fuel power output per kilogram.

From the calculation it is obtained 1.124 Mwh for

200 ha of land.

3.5 Fuel Costs

Kaliandra tree that has been processed into wood

pellet fuel price ranges between Rp. 1,100 per kg

orRp. 1,100,000 per tonne (ICCTF, 2011). If the

wood pellet used is 720.98 kg / hour. Thus, the cost

of wood pellet fuel per hour is:

720,98 x Rp. 1.100=Rp. 792.000

The price per kwh is:

..

.,

= Rp. 572,87/ kwh

Study of Kaliandra Tree as Source of Primary Energy

29

4 CONCLUSION

From the studies that have been done, it some

conclusions can be taken:

1. Wood Pellet Fuel Kaliandra is one of the

alternative materials of PLTU in the future with

the decreasing of fossil fuel reserves.

2. Our dependence on fossil-fuel-based fuels should

be reduced by developing biomass-based

technologies (bioenergy).

3. The easy and cheap breeding and processing of

Kaliandra wood pellets will make it an

alternative fuel in the future that will be taken

into account.

4. Wood pellet processing technology and also the

efficiency of a generation still need to be

improved.

REFERENCES

Francescato, Valter. 2008. Wood Fuels Handbook,

Productions, Quality Requirements, Trading.

Agripolis: Italian Agriforestry Association.

Kong, GanThay. 2010.

PeranBiomassaBagiEnergiTerbarukan. Jakarta: PT.

Elex Media Komputindo.

Marsudi, Djiteng. 2005. PembangkitanEnergiListrik.

Jakarta: PenerbitErlangga.

PT. PLN (Persero).2014. Rencana Usaha

PenyediaanTenagaListrik (RUPTL) 2015-2024 PT.

PLN Persero. Jakarta: PT. PLN (Persero).

Suyitno, M. 2011. PembangkitEnergiListrik. Jakarta:

PenerbitRinekaIlmu.

Zuhal.1993.

DasarTeknikTenagaListrikdanElektronikaDaya.

Jakarta: GramediaPustakaUtama.

ICMR 2018 - International Conference on Multidisciplinary Research

30