Model to Implement Theory of Constraint in Sea Transportation

System

Mulyono

1

, Dian Prama Irfani

1

1

Universitas Pertamina, Indonesia

Keywords: Sea transportation system, Analytical Hierarchy Process

Abstract: Given the important role of sea transport costs, many researchers have made several efforts to increase the

productivity of sea transportation system. Nevertheless, litreature review suggests that many optimization

efforts that have been carried out so far are still limited to the local aspect of the system. This study aims to

develop and implement a method to identify and manage constraints of the sea transportation system to help

decision makers in increasing global productivity of such system. This study uses a combination of case

study and computer based simulation methods. Case study is carried out on a sea transportation system in a

company that engaged in the field of oil and gas. The developed constraint identification method can be

applied to the case company, so that it is known that the main constraint of the sea transportation cost in the

case company is the jetty capacity. This research contributes to stakeholders in the field of transportation

systems to identify system’s components that hamper global system performance. This research can be

expanded by replicating the proposed method to the context of other sea transportation systems to test the

generalizability of the proposed method.

1 INTRODUCTION

Since the impact of sea transportation costs on

macro and microeconomic growth is huge (Limao

and Venables, 2000), some researchers are interested

in finding new ways to increase the productivity and

efficiency of the sea transportation systems.

However, even though there have been many

researches conducted to improve the efficiency of

the sea transportation system, most of the existing

researches are still done partially. When conducted

partially, optimization activities of the components

of the marine transportation system tend to result in

local optimum solutions. For example, an

optimization aimed at increasing the speed and

carrying capacity of a ship is largely based on the

assumption that the speed and capacity of the

transport in the future can be utilized to its

maximum capacity. Fast ships with large capacity

will indeed have higher transport productivity

compared with slower ships with smaller capacity.

Nevertheless, in practice the speed and capacity of

the ship's transport may not be able to be utilized to

its maximum point given that in the real system

there are several limitations such as port drafts,

crowded shipment lines and so forth, which inhibit

ships from being able to sail at maximum speed and

loaded in accordance with its transport capacity. The

existences of several factors in the system that limit

the utilization level ultimately contribute to limiting

transport productivity and efficiency. In this case,

number of studies aimed at optimizing sea

transportation costs by reviewing ships,

management, and infrastructure as a holistic system

is still limited.

In addition to the scope of optimization, several

studies that have been carried out mostly focus on

the short-term time horizon. If the focus of the

improvement is only on the short term horizon, the

resulting solution can be not optimal for the parties

concerned with the system. When the capacity of a

system component which is seen as a given factor

has been utilized to the maximum point, efforts to

increase efficiency can no longer be done.

In terms of the dimensions, most of the efforts to

improve system efficiency that has been carried out

have not aligned the strategic, tactical, and

operational dimensions as an integrated performance

measure. In this case, improvement that is only

conducted at operational level does not necessarily

produce the best solution for the system.

In order to be effective, efforts to improve

system efficiency need to be conducted by

considering all the factors that make up the marine

Mulyono, . and Irfani, D.

Model to Implement Theory of Constraint in Sea Transportation System.

DOI: 10.5220/0008373700430049

In Proceedings of the 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2018), pages 43-49

ISBN: 978-989-758-455-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

43

transportation system as a whole, long-term

oriented, and aligned from the operational to the

strategic levels. Improvement activities must focus

on the factors that become the main constraints of

the system.

One concept that can be implemented is to use a

system thinking approach. In this case, Theory of

Constraint (TOC) is a methodology used to

implement systems thinking concepts. TOC is one of

the multi facet methodologies developed to help

organizations analyze problems and develop

solutions to solve problems (Mabin and Balderstone,

2000). TOC is based on the principle that the

performance of a system is limited by a constraint.

Improving the performance of the system’s

constraints will have a direct impact on the

performance holistically. Based on this principle,

efforts to improve performance are focused on

identifying and managing the constraints of the

system.

The concept of managing the performance in the

TOC is in line with the challenges faced by decision

makers in the context of the marine transportation

system. Firstly, efforts to improve the performance

of TOC-based systems involve analysing overall

system. The constraint identification activity which

is one of the stages in the TOC involves efforts to

identify the profile and relationship of each system

component and its effect on the performance of the

overall system. Secondly, the constraint handling

framework in the TOC provides guidelines for

formulating optimal solutions for the short and long

term. Thirdly, TOC can be used to formulate and

bridge strategic solutions with operational solutions.

TOC provides a stage that is focused on formulating

performance measures at the strategic, tactical and

operational dimensions.

Although has been widely implemented in the

manufacturing sector, currently TOC is not that

popular in the field of sea transportation services. In

this case, TOC implementation in sea transportation

service is still very limited. The concept of

constraint identification and constraint management

is still vague. Litreature suggests that there is no

operational guide on how to implement TOC

concept in the field of sea transportation context.

Based on the aforementioned, this paper aims to

develop a new method for implementing TOC

concept in the context of the marine transportation

system. The focus on research in this case is to:

1. Develop a new framework to

operationalize the concepts and philosophy of the

TOC in the context of the marine transportation

system.

2. Develop a model of marine transportation

system as a series of holistic systems.

3. Implement the developed framework into

the case company to identify constraints in the

marine transportation system.

2 LITREATURE REVIEW

Previously, Devanney et al. (1975) developed a

computer-based model to determine the efficiency

and inefficiency of several shipping activity

scenarios. They assumed that port time for all

shipping activities was the same. The assumption in

this case limits the benefits and usefulness of the

model developed (Lane, 1987). Meanwhile, Lane et

al. (1987) conducted a study by developing a

heuristic optimization model to schedule container

ships on the north Atlantic route. The purpose of

scheduling and using models is to optimize transport

productivity which translates to increasing

profitability and decreasing transit times.

Similarly, Perakis et al. (1991) developed a

linear programming model to minimize operating

costs from liner liners. Operational costs included

are fuel costs, daily running costs, port charges, and

canal fees. In a more detail, Laderman (1966)

developed an optimization model aimed at

minimizing the number of vessels needed to meet

transportation demand. Rao and Zionts (1968)

developed a linear model for assigning ships to

certain trips to minimize operational costs by adding

one variable to find out whether additional

chartering activities are needed or not.

Based on the litreature review that has been

carried out before, previous studies generally have

the following limitations:

1. Performed on processes or components of

the marine transportation system partially, so that

the resulting solution is local optimum.

2. Focused on the short term based on the

assumption that transportation demand and

operational or infrastructure conditions are fixed

over time. Although the efforts that have been made

can have a positive influence on the optimization of

operational costs in the short term, for the long term

the impact of the implementation of these models is

still a question mark, especially if transportation

demand and operational conditions change.

3. The performance targets of optimization

activities tend to focus on operational aspects, so

that the alignment with the achievement of strategic

performance criteria is not known with certainty

When compared with previous studies, this

research has several differences. This research

integrates components of a sea transportation system

holistically, which in this case includes

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

44

transportation equipment, management systems, and

infrastructure. In addition, this study also focused on

short and long term time horizons. Furthermore, this

study includes operational and strategic layers

performance measures. The output of the research is

focused on producing effective and efficient global

solutions. Position of this research can be seen in

Table 1.

Table 1: Position of This Study Relative to Previous

Researches.

Item

Covered

Research

[3] [5] [6] [7] [8] [9] Propos

ed

Resear

ch

Vessel √ √ √ √ √ √

Manage

ment

system

√

Infrastru

cture

√ √

Sort term

oriented

solution

√ √ √ √ √ √ √

Long

term

oriented

solution

√

Operatio

nal

performa

nce

√ √ √ √ √ √ √

Global

performa

nce

√

Efficienc

y focus

√ √ √ √ √ √ √

Effectivi

ty focus

√

3 METHODOLOGY

TOC provides five focusing steps to guide

practitioners in improving system’s performance.

The TOC implementation stages in the five focusing

steps are as follows:

1. Identify constraints

2. Exploitation constraints

3. Management of system flow that passes

through constraints

4. Increased constraint capacity

5. After the constraint is eliminated, return to

step 1.

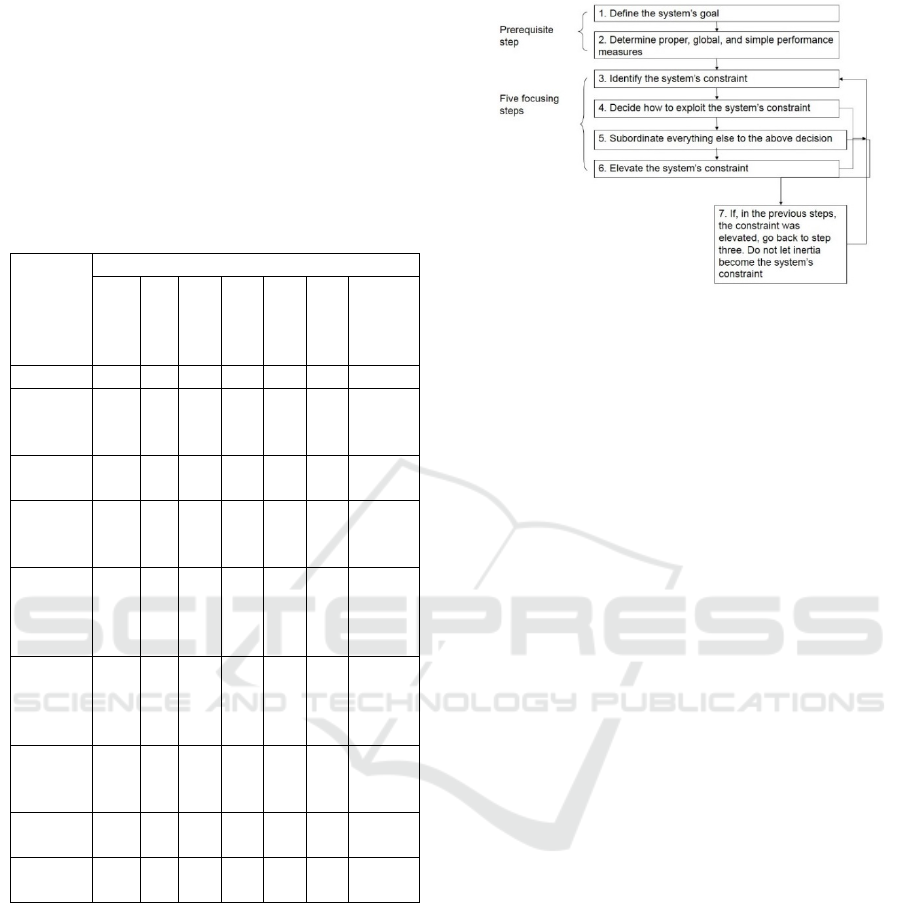

Figure 1: The Process of Ongoing Improvement (Goldratt,

1986)

The five focusing steps then evolved into the

Process of Ongoing Improvement (POOGI). POOGI

is basically the five focusing steps that are added

with two pre-requisite steps, namely defining system

goals and determining performance measures. In

general, the steps contained in POOGI can be seen

in Figure 1.

The explanation of each step contained in

POOGI is as follows:

1. Step 1: Define the system's goal

Defining the purpose of the system depends on

the purpose of the system. Goldratt (1986) explained

that the purpose of the system must represent why a

system exists.

2. Step 2: Determine global performance

measures

Goldratt (1986) explain that global performance

measures serve to translate the goals of the system

into measurable units.

3. Step 3: Identify the Constraint

Constraint identification activity means

identifying elements or factors that limit system

performance improvement related to the

achievement of system objectives.

4. Step 4: Exploit the Constraint

Constraint exploitation is an activity carried out

to optimize existing resources, so that the

performance of the constraint can be maximized.

5. Step 5: Subordinate Everything Else

Non-constraint resources must be managed so

that constraints can be utilized until the optimal

point at any time.

6. Step 6: Elevate the constraint

In (Groop, 2012), elevate the constraint means

increasing the capacity of the constraint in order to

increase the throughput of the overall system.

Model to Implement Theory of Constraint in Sea Transportation System

45

7. Step 7: If the constraint has been removed,

go back to step three

After the constraint is successfully removed, the

system must have another new constraint (Groop,

2012).

Because the method to implement TOC concepts

in the field of marine transportation system is

limited, this research aims to adapt, modify, and

propose new tools that can be used to translate the

general stages contained in the TOC into such

system. The methodology will be built through the

synthesis of some of the literatures. To find out the

applicability of the TOC, the proposed methods will

be applied to develop an improvement plan in one

company that provides sea transportation services.

4 THE PROPOSED

FRAMEWORK TO

IMPLEMENT TOC IN MARINE

TRANSPORTATION SYSTEM

The proposed framework to implement the TOC

concept in the context of the marine transportation

system is as follows:

1. Step 1: Define the system's goal

Interviews or focus group discussions to top

executives who represent the role of the system

owner are proposed to define the system’s goal.

Analytical Hierarchy Process (AHP) method is

proposed to be used to select the system’s goal.

2. Step 2: Determine global performance

measures

TOC has four operational indicators called

Throughput, Inventory, Operating Expense, and

Productivity. In this study, those indicators are

operationalized as follows:

a. Throughput is defined as the volume of

cargo that is successfully transported in one unit of

time or the amount of revenue generated from

shipment services.

b. Inventory can be defined as a cargo

loading space that is not or not yet utilized for a

period of time. From the aspect of port

infrastructure, inventory can be interpreted as

converted monetary value of the jetty resource,

loading and unloading device, and other equipment

that is not yet or not yet efficient.

c. Operating Expense is the total costs

incurred to change the ship's space and capacity of

the port infrastructure to provide transportation

services

d. Productivity in sea transport systems can

be interpreted as the ratio between the volumes of

cargo transported to the costs incurred to carry out

cargo.

To prevent system optimization that focuses on

the operational level, in this study global indicators

at the strategic level are also proposed. Several

indicators that can be used to measure strategic

indicators of the sea transportation system are Net

Profit, Net Present Value, and Return on Investment

(ROI).

Step 3: Identify the System's Constraint

The proposed methods to identify constraints

system are as follows:

1. Identify the main activities of the marine

transportation system

2. Arrange the main activities of the marine

transportation system into a series of transportation

processes

3. Identify the resources used for each

activity

4. Identify units or units of measures used by

each resource

5. Convert different units of measures into

one global unit of measures

6. Identify the maximum capacity of each

resource currently available

7. Identify currently utilized resource

capacity

8. Identify resources that causes bottlenecks

on marine transportation systems by comparing

utilization rates

Step 4 and 5: Exploit the System's Constraint

and Subordinate Everything Else

To exploit constraints and do subordinate

system's resources, the method that will be used in

this study is to modify the existing system,

especially in the scheduling pattern. Modification is

done through an iterative system simulation.

Step 6: Elevate System's Constraint

Constraint elevation activity is related with

investment activities. In this study, system's

constraint elevation is proposed by using a

simulation approach.

5 APPLICATION OF THE

PROPOSED FRAMEWORK

5.1 Description of Company A

The sea transportation system that is used as a case

is the transportation system in Company A, which is

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

46

a company engaged in the oil and gas business both

in the upstream and downstream sectors. Business in

the upstream sector is carried out in several regions

in Indonesia and abroad including activities in the

fields of exploration, production and transmission of

oil and gas. In the downstream sector, Company A’s

activities includes processing of crude oil, marketing

and trading of oil, gas and petrochemical products.

5.2 Framework Implementation

To choose the goal of the marine transportation

system in Company A, in this study interviews were

conducted with management team. The process of

determining the objectives of the system is carried

out using the Analytical Hierarchy Process (AHP)

method. After eigenvector-based normalization,

consistency index calculation, and consistency ratio

calculation, the final result of each goal shows that

the selected goal of the marine transportation system

in company A is to fulfil the shipment demand

efficiently.

Performance measures that will be used to

analyse the sea transportation system in Company A

is shown in Table 2.

Table 2. Performance Measurement in Company A

Layer

I

ndicato

r

Formula Measure

s

Operati

onal

T

hroughp

u

t

Volume of cargo

transported over a

period of time

Kilo

Litre

I

nventory Converted monetary

value of the ship

space and port

infrastructure that

are not or not yet

utilized for a period

of time

IDR

Operating

E

xpense

The total costs

incurred to change

the ship's loading

space and port

infrastructure

capacity for

transporting cargo

over a period of

time

IDR

P

roductiv

i

ty Ratio

Comparison

between volume of

cargo transported to

the costs to carry

out cargo

Ratio

Strategi

c

N

et Profit Throughput -

Operating Expense

IDR

N

PV Sum of some IDR

Layer

I

ndicato

r

Formula Measure

s

present values for

benefits obtained

over a period of

time

R

OI Net Profit /

Inventory

Ratio

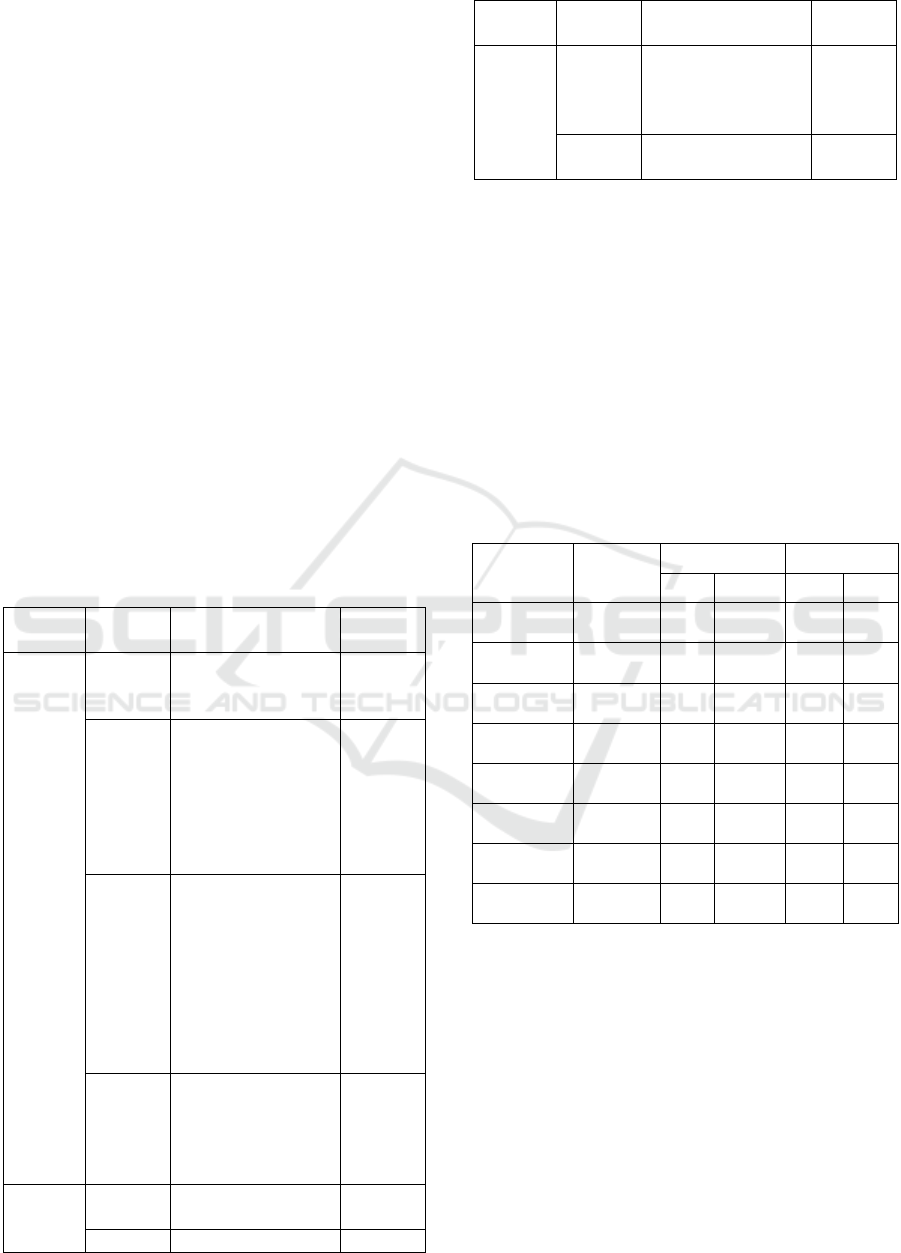

Sea transportation system consists of several

factors whose unit of measures are not standardized.

To identify system’s constraint, such measures need

to be firstly standardized into common unit. In this

research, the proposed unit for measuring capacity

and utilization of each resource in the marine

transportation system is the ratio between volumes

of cargo handled over a period of time. In this case,

Kilo Litre per day is suggested. Table 3 shows the

utilization of several marine transportation resources

in company A that is presented in the original and

standardized units.

Table 3. Process Mapping and Unit of Measure

Conversion

Process

Resources

Original Unit Converted Unit

Value Unit Value Unit

Sailing at Sea Speed 11 Knots 18,400

KL/

Day

Steaming In Draft 4.5 Meter 10,700

KL/

Day

Berthing Jetty 2 Unit 2,000

KL/

Day

Clearance

Human

Resource

12

Ships/

Day

50,400

KL/

Day

Laboratory

Test

Human

Resource

12

Ships/

Day

50,400

KL/

Day

Discharging

Pump and

Pipe

400

CuM/

Hour

9,600

KL/

Day

Tank

Inspection

Human

Resource

8

Ships/

Day

33,600

KL/

Day

Document

Processing

Human

Resource

8

Ships/

Day

33,600

KL/

Day

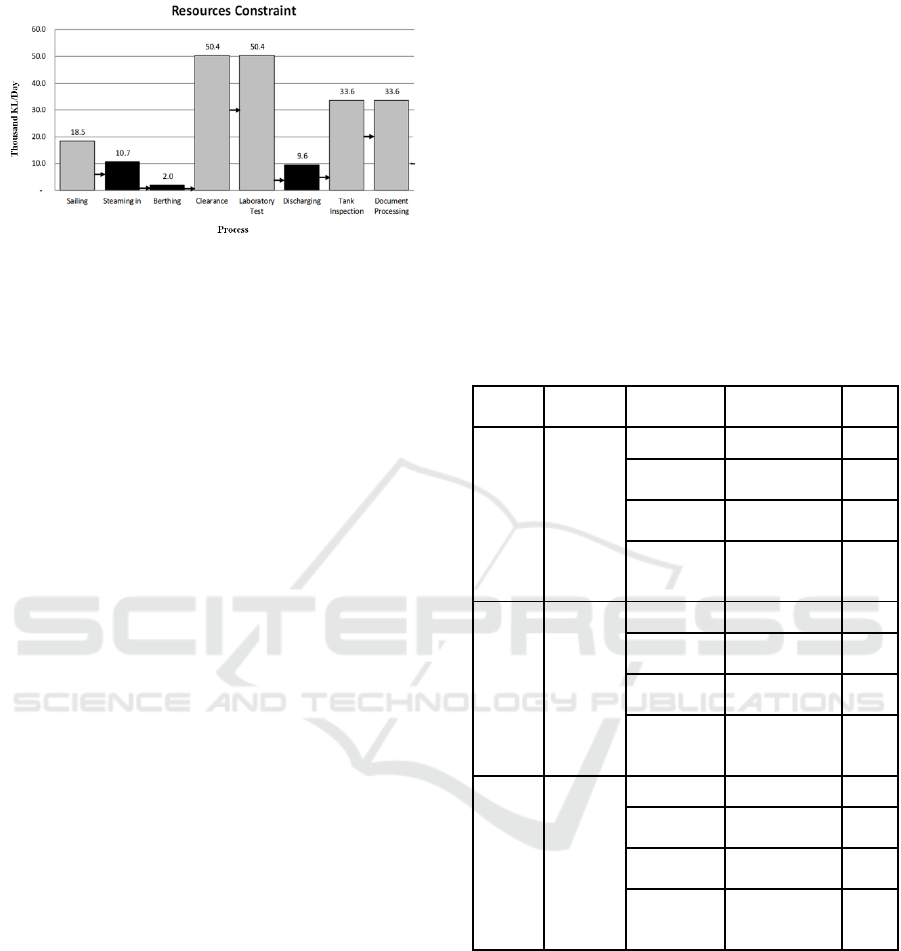

The process map of the sea transportation system

in Company A is shown in Figure 2.

Model to Implement Theory of Constraint in Sea Transportation System

47

Figure 2: Result of Process Map Analysis to the Sea

Transportation System in Company A

Based on the process map in Figure 2, it is

known that jetty capacity in Company A is only able

to handle 2,016 KL of cargo per day. Meanwhile,

the cargo pump at Company A can only handle

9,600 KL of cargo / day. With a 4.5-meter port draft,

the system at COMPANY A can only handle as

much as 10,739 KL / Day. Therefore, based on the

process map it can be seen that the main constraint

that limit the performance of the marine

transportation system at Company A is the jetty

capacity.

Company A currently have two berths with the

number of ship arrivals approximately 306 times in

one year. Thus, the jetty occupancy rate is 88%.

Based on the existing conditions, scheduling

optimization simulations are carried out by

rearranging ship arrivals with the objective function

to maximize jetty utilization and meet the

transportation demand at the port. Based on some

simulation results, the steps in the TOC framework

to exploit the constraints and subordinate system

components to optimize jetty utilization produce a

final solution where the idle jetty frequency is 5

times. The solution can reduce idle jetty. However,

in terms of the congestion, the resulting solution is

no better than the current scenario. The simulation

results with the existing model show the frequency

of congestion 7 times, while the optimization results

actually produce 8 times the frequency of

congestion. Based on this, it can be seen that the

exploitation stage and subordinate system

components are not effective to improve the

system’s performance.

To overcome the constraint, one of the steps

proposed is to simulate the marginal return on

investment if constraint elevation is carried out

through investment activities. In this study, the

evaluation of investment activities was carried out

for two layers, namely the strategic layer and the

operational layer. At the strategic layer, an

evaluation of the jetty expansion simulation will be

measured by a Net Present Value indicator of

benefits obtained over a period of time. In this case,

an investment in the form of jetty constraint

expansion can be said to be feasible if the simulation

results show that the investment activities carried out

produce a positive Net Present Value.

Meanwhile, from the operational aspect, the

evaluation of investment returns will be carried out

by using the indicators of productivity of the sea

transportation system. An investment in the form of

jetty constraint expansion can be said to be feasible

from the operational aspect if the simulation results

show that the investment activities carried out have

an impact on increasing the productivity of the sea

transportation system. The simulation result of

constraint elevation is shown in Table 4.

Table 4: Changes of Global Performance Measures after

Constraint Elevation

Scenario

Descripti

on

Performance

Measure

Value Unit

Scenario

1

Capacity

is

increased

by 50%

Throughput 1,026,602,448 Litre

Operating

Expense

64,378,970,945 IDR

Productivity

Ratio

0.0159

Litre/

IDR

Inventory 1,583,540

Kilo

Litre

Day

Scenario

2

Capacity

is

increased

by 100%

Throughput 1,026,602,448 Litre

Operating

Expense

65,273,219,692 IDR

Productivity

Ratio

0.0157

Litre/

IDR

Inventory 2,266,158

Kilo

Litre

Day

Scenario

3

Capacity

is

increased

by 150%

Throughput 1,026,602,448 Litre

Operating

Expense

66,873,219,692 IDR

Productivity

Ratio

0.0154

Litre/

IDR

Inventory 2,992,184

Kilo

Litre

Day

Based on Table 4, it can be seen that scenario

that provides the optimum return for Company A is

the scenario of adding 1 jetty.

6 CONCLUSION

Based on the series of processes that have been

carried out, several conclusions can be formulated as

follows:

1. This study has successfully developed

integrated framework to implement the concept of

ISOCEEN 2018 - 6th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

48

TOC. Several existing managerial methods and tools

like AHP, process map, and simulation tools have

been incorporated in the TOC-based framework. In

addition, this research has proposed a new method to

identify the constraint of the marine transportation

by converting unit of measures of each process in

the system into one standardized unit. Additionally,

performance indicators like throughput, operating

expense, productivity ratio, and inventory have also

been redefined and proposed to be used in the

context of marine transportation system.

2. TOC-based model can be applied in the

context of sea transportation systems, more

specifically to help formulate performance

measures, identify key constraints that limit the

performance of the marine transportation system,

and formulate strategic steps to improve the

performance of the marine transportation system.

3. The developed method can be applied in

the case company to formulate the objectives of the

sea transportation system, define performance

measures, identify constraints, and handle

constraints

This research can be further enhanced by

applying the developed methods on other

transportation systems. In addition, statistical tests to

determine the impact of formulated improvements

can also be done.

REFERENCES

Goldratt, Eliyahu M. (1986): The Goal: a process of

ongoing improvement, North River Press.

Groop, Johan (2012): Theory of Constraints in Field

Service: Factors Limiting Productivity in Home Care

Operations, Aalto University Publication Series,

Helsinki.

Laderman, J., et al. (1966): Vessel Allocation by Linear

Programming, Naval Research Quarterly, 12, 315 -

320.

Lane, D. E., et al. (1987): Planning and Scheduling for

Efficiency in Liner Shipping, Maritime Policy and

Management, 14, No. 2, 109 - 125.S. Boffey, J. Oper.,

1979. Res. Soc, 30, 413 – 425.

Limao, Nuno dan Venables, J. Anthony (2000):

Infrastructure, Geographical Disadvantage, and

Transport Costs, Washington.

Mabin, J. Victoria dan Balderstone, J. Steven (2000): The

World of the Theory of Constraints: a Review of the

International Literature, St. Lucie Press, pp 11 – 12J.

W. Devanney, J Trans, 1975. Econ. Policy, 9.

Perakis, A. N., and Jaramillo, D. L. (1991): Fleet

Deployment Optimization for Liner Shipping,

Maritime Policy & Management 18 (3), 183 – 200.

Rao, M. R., dan Zionts, S. (1968): Allocation of

Transportation Units to Alternative Trips – A Column

Generation Scheme with Out-of-Kilter Sub problems,

Operation Research 16, 52 – 63.Ellis and C. Steven,

2011. Flor Inter.

Ronen, B., dan Spector Y. (1992): Managing System

Constraints: A Cost/Utilization Approach,

International Journal of Production Research, Vol. 30,

No. 9, pp. 2045 - 2061.

Model to Implement Theory of Constraint in Sea Transportation System

49