Decoloration of Rhodamine B Aqueous Solution by Ultrasound

Assisted Pulse Discharge

Yu Fang

*

, Daiki Hariu, Takuya Yamamoto and Sergey Komarov

Graduate School of Environmental Studies, Tohoku University, 6-6-02 Aza Aoba, Aramaki, Aoba-ku Sendai, Japan

Keywords: Rhodamine B, decoloration, pulse discharge, cavitation, energy efficiency.

Abstract: Research on the decoloration of refractory dye, Rhodamine B (RhB) by ultrasound assisted pulse discharge

process has been carried out. The effects of ultrasound on the pulse discharge type, decoloration rate and

energy efficiency of pulse discharge were investigated in various electrical conductivity of the solution. The

proposed technique extends the treatable range of solution electric conductivity and shows a significant

improvement on RhB decoloration, and the energy efficiency of pulse discharge was promoted. In addition,

the RhB decoloration in the presence of H

2

O

2

was studied. Results show that RhB decoloration has been

inhibited by additive H

2

O

2

.

1 INTRODUCTION

Wastewater from textile, food, leather,

pharmaceutical, and paper industries are one of the

major water pollutant sources. Finding efficient

methods to disposal those colored wastewaters has

become an important issue for environmental

protection as well as those industries (Lee et al.,

2013). Rhodamine B (RhB) is a highly water soluble

refractory organic compound, which is a widely used

xanthene dye for industry purposes. It is harmful to

animals and human beings, which would cause

irritation to eyes, skin and respiratory tract.

(Merouani et al., 2010). Conventional methods to

remove RhB and similar refractory dye pollutant are

absorptions on activated carbon, reverse osmosis or

coagulation by chemical agents. However, those

non-destructive methods can hardly eliminate the

threat of RhB to environment (Behnajady et al.,

2008).

In recent years, advanced oxidation processes

(AOPs) have been widely investigated as a promising

method for organic pollutant removal(Siddique et al.,

2014, Liang et al., 2007). Pulse discharge, one of

major AOPs, shows great potential in pollutant

removal, especially the refractory organic

compounds pollutant (Van de Moortel et al., 2017).

By inducing high energy into reaction zone in a short

time, generation of radicals (·OH, O·, and HO

2

·),

shock waves, UV irradiation and direct pyrolysis of

pollutant could be achieved. Degradation efficiency

of RhB by ·OH radical attack has been proved in

pulse discharge process(Sugiarto et al., 2003).

However, conventional pulse discharge in liquid

requires much higher input voltage than that in air. In

addition, liquid discharge is also very sensitive to the

environment. High solution conductivity leads to

discharge type change from spark type to streamer

type, which shows undesirable decoloration

efficiency on RhB (Nakagawa et al., 2003).

Ultrasound has also been investigated as an AOP

for wastewater treatment. Ultrasound irradiation

induces generation of numerous cavitation bubbles in

which it is transmitted. After the nucleation and

compression-refractions cycles, those microbubbles

collapse when they reach a critical size(Fang et al.,

2018a). High temperature (6000K) and pressure

(1000atm) of bubble collapse in the small volume

induces the generation of radicals. Moreover, the

diameter of cavitation bubbles usually lies in the

range of tens of microns. Recent research shows that

micrometer scale bubbles in water can help generate

spark type discharge with a lower input voltage

(Bruggeman and Leys, 2009, Medodovic and Locke,

2009). Therefore, it is a promising approach to utilize

cavitation bubbles to obtain desirable spark

discharge, consequently, higher pollutant removal

efficiency.

In this research, a new technique which combines

pulse discharge and ultrasound is proposed to

enhance the decoloration of RhB. This research

306

Fang, Y., Hariu, D., Yamamoto, T. and Komarov, S.

Decoloration of Rhodamine B Aqueous Solution by Ultrasound Assisted Pulse Discharge.

DOI: 10.5220/0008189303060310

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 306-310

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

focuses on the assistance of cavitation bubbles on

pulse discharge in liquid. To achieve this goal, test on

effects of ultrasound on discharge type was

performed firstly, and then RhB decoloration

experiments were carried out by ultrasound, pulse

discharge and ultrasound assisted pulse discharge

respectively. In addition, the effects of irradiative

H

2

O

2

solution were also investigated.

2 EXPERIMENTAL SETUP AND

METHODOLOGY

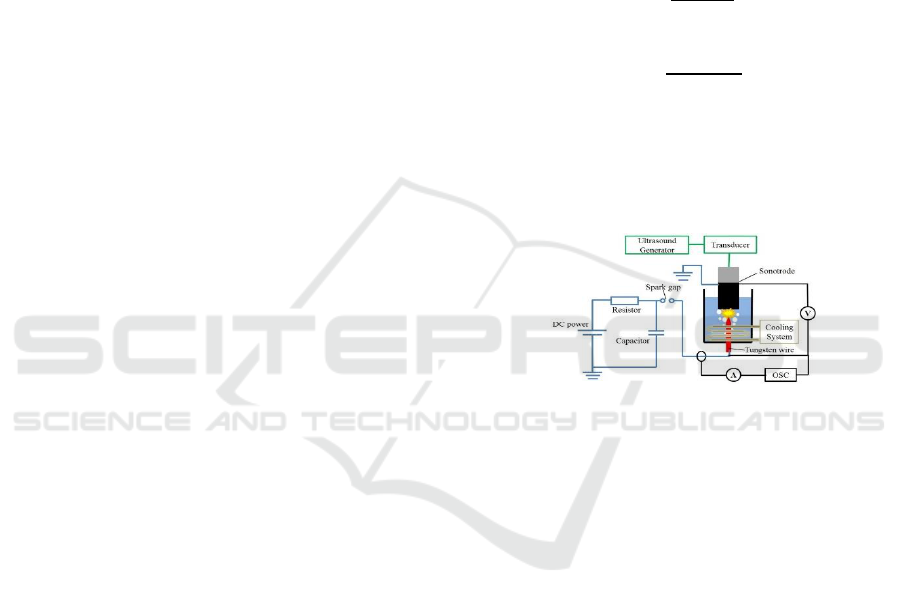

The experimental setup, as shown in Figure 1,

consists of an ultrasound generation system, main

reactor, pulse generation circuit, an electrical

analytical system and cooling device. An ultrasound

generator (TELSONIC, Switzerland) with adjustable

vibration amplitude was applied to irradiate

ultrasound waves at a frequency of 20 kHz into a

water bath through a sonotrode connected with a

piezoceramic transducer. The peak-to-peak

amplitude of the sonotrode tip was ranged from 40 to

75 m (p-p). Notice that the threshold vibration

amplitude exceeding which causes developed

cavitation in water is 4~5 m (p-p)(Komarov et al.,

2013). The reactor comprises of a cylindrical

sonotrode (Diam. 48 mm), a needle shape high

voltage electrode made of tungsten wire (Diam. 1

mm), and a cylindrical vessel (Diam. 140 mm, height

190 mm) made of acrylic resin. The sonotrode is

composed of two cylindrical parts, one is made of

ceramic to prevent the ultrasound generator from

high voltage damage, and the other one is made of

titanium serving as the sonotrode tip and grounded

electrode. Dimensions of both parts were adjusted to

resonance conditions. The distance between

electrodes is an important parameter influencing the

pulse discharge efficiency. In this research, the

distance was set to 4 mm according to preliminary

experiments in optimizing the performance of spark

type discharge unit.

Pulse generation circuit is showed by the blue line.

A DC power supply (0~+40 kV) was used to charge a

capacitor (1000 pF), and then it was discharged into

the reactor through a spark gap discharge unit.

Voltage and current signals between the electrode

during the plasma discharge were collected by an

oscilloscope through a 1000:1 reduction ratio high

voltage probe (PINTEC, China) and a coil current

probe (IWATSU, Japan) respectively. A

water-cooling coil was submerged in the reactor to

maintain the water temperature at a level of 202

o

C.

High purity RhB was purchased, and 5 mg/L RhB

concentrations solutions were prepared using

distilled water. H

2

O

2

solution (500ml) with 30%

concentration was purchased from Wako, Japan.

Each experiment of RhB degradation lasted for 12

minutes, and solution samples were taken each 3

minutes. RhB concentration was determined from the

absorbance measured by a spectrophotometer

(AS-ONE ASV11D, Japan) at 554 nm wavelength.

After the treatment, the decoloration rate ξ and

energy efficiency η was calculated as follows:

ξ =

Δ

[

𝑅ℎ𝐵

]

[

𝑅ℎ𝐵

]

0

η =

VΔ

[

𝑅ℎ𝐵

]

𝐸𝑓𝑇

where

[

𝑅ℎ𝐵

]

0

is the initial RhB concentration, V

is the solution volume, Δ

[

𝑅ℎ𝐵

]

is the concentration

change of RhB, E is the energy of fully a charged

capacitor, 𝑓 is the pulse discharge frequency, T is

the treatment time.

Figure 1: Sketch of the experimental setup.

In this research, the output voltage was 25 kV, pH

was about 5 (RhB aqueous solution without any acid

or alkaline addition). The solution conductivity was

adjusted using a NaCl solution.

3 RESULTS AND DISCUSSION

3.1 Effects of Ultrasound on Pulse

Discharge Type

Pulse discharge type plays a vital role in liquid

discharge technique for pollutant removal, especially

for refractory organic pollutants (Sugiarto and Sato,

2001). In the proposed process, the electrodes,

which comprises a tungsten wire and sonotrode, can

be regarded an as a needle-plate electrode

arrangement. Moreover, in a needle-plate pulse

liquid discharge system, discharge type can be

varied into spark discharge, streamer discharge and

mixing discharge (spark and streamer discharge

type). These discharge types mainly concerned with

Decoloration of Rhodamine B Aqueous Solution by Ultrasound Assisted Pulse Discharge

307

the output voltage of the power supply, distance

between electrodes, electric conductivity of solution

and the pressure. In this research, the output voltage,

electrode distance, and pressure were fixed. Thus,

electric conductivity was considered as the only

factor to discharge type changes.

Spark discharge usually appears as a single

plasma channel between electrodes with high energy

density. The formation of this plasma channel

induces strong electron clusters, UV irradiation, and

shock waves into liquid around the channel, which

remarkably promotes exciting ionizing water

molecular. Consequently, the generation of radicals

is improved.

In the case of streamer discharge, it has many

intense but weak channels growing from one

electrode (usually from a needle electrode in

needle-plate system). Streamer discharge generates

higher pulse current and stronger UV light than

spark discharge. However, the low energy density of

streamer discharge induced limit ionization and

excitation gives low radicals yield(Medodovic and

Locke, 2009).

Mixing discharge type in this research means a

combination discharge type (spark discharge and

streamer discharge), that long plasma channel

between electrodes and short, intense channels exist

at the same time. These channels are more stretched

than in the other cases. This discharge type gives the

best degradation efficiency on phenol than spark and

streamer type, presented by Sugiarto (Sugiarto and

Sato, 2001).

In this research, Table 1 shows the discharge type

changes of pulse discharge and ultrasound assisted

pulse discharge in various electric conductivity. This

test was carried out with an electric conductivity

range of 5~1000 μS/cm. Different discharge types

can be identified with digital data from oscilloscope

and observation. For solely pulse discharge, spark

and mixing discharge, which is believed to be

effective in pollutant removal, was limited in 5~70

μS/cm, while for ultrasound assisted pulse discharge

process, it was remarkably expanded to 1000 μS/cm,

almost increased by 13 times.

With the assistance of ultrasound, numerous

cavitation microbubbles were generated between

electrodes, which help decrease the breakdown

threshold and help plasma propagate through the gas

phase inside bubbles. Bubble surface takes an

important role in pulse discharge. When applying an

electric field on a liquid-gas phase, the charge will

accumulate on the surface of bubbles (Gershman et

al., 2007, Yamabe et al., 2005). Due to the huge

bubble surface of numerous cavitation bubbles, the

discharge will be generated through bubbles instead

of water medium, and a spark type discharge can be

achieved even in higher electrical conductivity

solution.

Table 1: Discharge type changes of P (pulse discharge) and

UP (ultrasound assisted pulse discharge) in various ranges

of electric conductivity of solution (/μS·cm

-1

).

5~30

30~70

70~1000

P

Spark

Mixing

Streamer

UP

Spark

Spark

Mixing

3.2 Effects of Ultrasound Assistance on

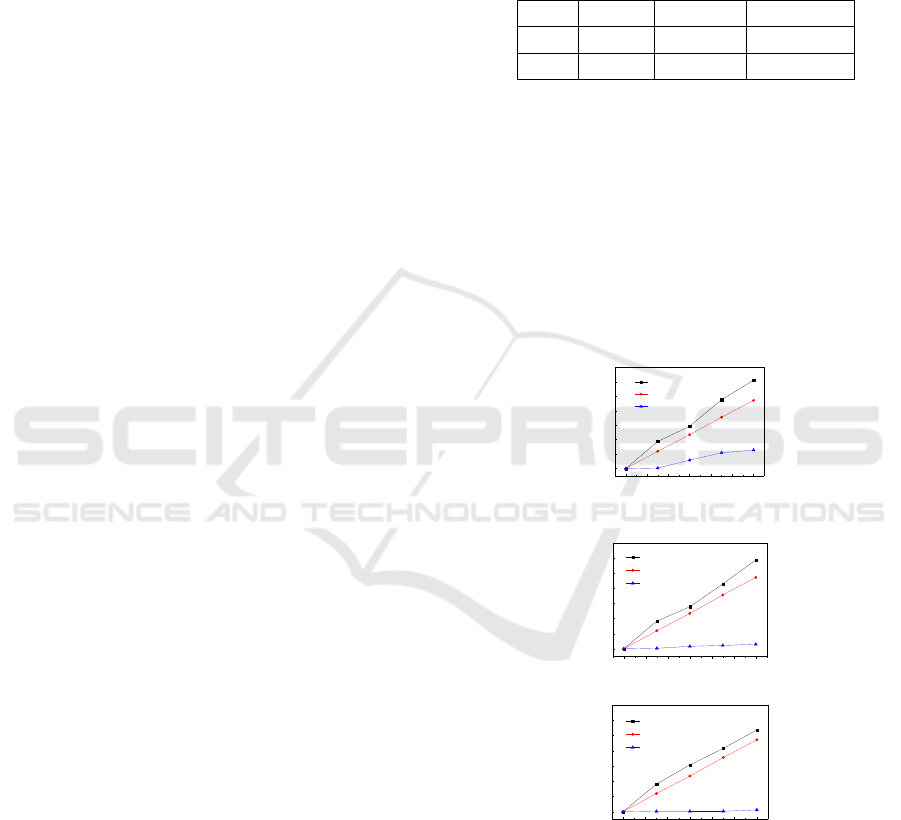

RhB Decoloration

Decoloration tests of RhB were carried out to

evaluate the performance of the proposed process.

Due to the decomposition of RhB molecular, the

electric conductivity of solution will continuously

increase. To avoid discharge type changing caused

by electric conductivity, the decoloration tests were

limited in 12 minutes, with an average of 10 μS/cm

growth in electric conductivity.

0 2 4 6 8 10 12

0

5

10

15

20

25

30

35

Decoloration rate

/ %

Time / minute

(a)

UP

U

P

0 2 4 6 8 10 12

0

5

10

15

20

25

30

35

Time / minute

(b)

Decoloration rate

/ %

UP

U

P

0 2 4 6 8 10 12

0

5

10

15

20

25

30

35

UP

U

P

Time / minute

(c)

Decoloration rate

/ %

Figure 2: RhB decoloration rate of various methods (UP:

ultrasound assisted pulse discharge. U: ultrasound singly.

P: pulse discharge singly) in (a) 20, (b) 60 and (c) 200

μS/cm solutions.

Figure 2 shows the effects of ultrasound

assistance on RhB decoloration in various electric

conductivity solutions. Treatments by ultrasound and

pulse discharge singly were also investigated for

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

308

comparisons. Ultrasound assisted pulse discharge

gives the highest decoloration rate rather than

another two approaches, and the decoloration

slightly decreases in a higher electrical conductivity

solution. No significant effects of electrical

conductivity can be found on the decoloration by

ultrasound singly, while the decoloration rate almost

decreases to zero when conductivity above 60 μS/cm.

In 20 μS/cm solution, it will cost much energy to

breakdown water medium. When solution

conductivity increase, pulse discharge type usually

transfers from spark type to streamer type, which has

more intense plasma channels but low energy

density (Šunka, 2001). In this case, much energy

was consumed into current heat instead of RhB

decomposition. The sole ultrasound gives relatively

high decoloration rate even the amplitude was set at

40 m (p-p), the minimum of an ultrasound generator.

This is because even with the minimum amplitude of

sonotrode, a strong cavitation field could be

generated, and caused effective decomposition of

RhB molecular.

In addition, irradiation of ultrasound in liquid

will cause a macro steady flow due to the

soundwave attenuation in water medium, named

acoustic streaming, which helps improve the mass

transfer in reactor, consequently yield a better

decoloration rate (Fang et al., 2018b).

Table 2 shows the data of energy efficiency of

each approach.

p’

is the mean energy efficiency of

improved pulse discharge by ultrasound, which was

calculated as follows:

𝜂

𝑃

′

= 𝜂

𝑈𝑃

− 𝜂

𝑈

Where 𝜂

𝑈𝑃

is energy efficiency of ultrasound

assisted pulse discharge, 𝜂

𝑈

is the energy efficiency

of ultrasound. It can be found that in energy

efficiency of pulse discharge was significantly

improved by ultrasound, especially in higher

electrical conductivity solution.As di scussed in

previous part, the existence of cavitation bubbles

between electrodes help plasma to propagate in the

gas phase inside bubbles, thus more energy could be

used for RhB decoloration. Moreover, discharge

types in 60 and 200 μS/cm solution were changed by

cavitation bubbles to spark discharge and mixing

discharge respectively. Spark discharge and mixing

discharge give a much higher radical yield, and

induce extreme physical conditions (strong shock

wave and 3000~5000K high temprature), which

improve the decoloration of RhB. While for streamer

discharge, much energy was consumed into current

heat, consequently decreased energy efficiency.

Compare with other liquid discharge process for dye

decoloration (Malik, 2010), especially for those RhB

decoloration researches, ultrasound assisted pulse

discharge shows a promising energy efficiency, such

as Anto presented 0.081 g/kWh for spark discharge

and 0.025 g/kWh for streamer discharge (Sugiarto et

al., 2003).

Table 2: Energy efficiency (g/kWh) in P (solely pulse

discharge) and P

’

(improved pulse discharge) with different

solution electrical conductivities.

20 μS/cm

60 μS/cm

200 μS/cm

P

0.191

0.048

0.013

P

’

0.267

0.257

0.107

3.3 Effects of Additive H

2

O

2

Solution

H

2

O

2

is a commonly used method to combine with

AOP process to help generate radicals to decompose

pollutants (Mehrdad and Hashemzadeh, 2010,

Mehrdad et al., 2011). In this part, effects of

different concentrations of H

2

O

2

were investigated

with ultrasound assisted pulse discharge method.

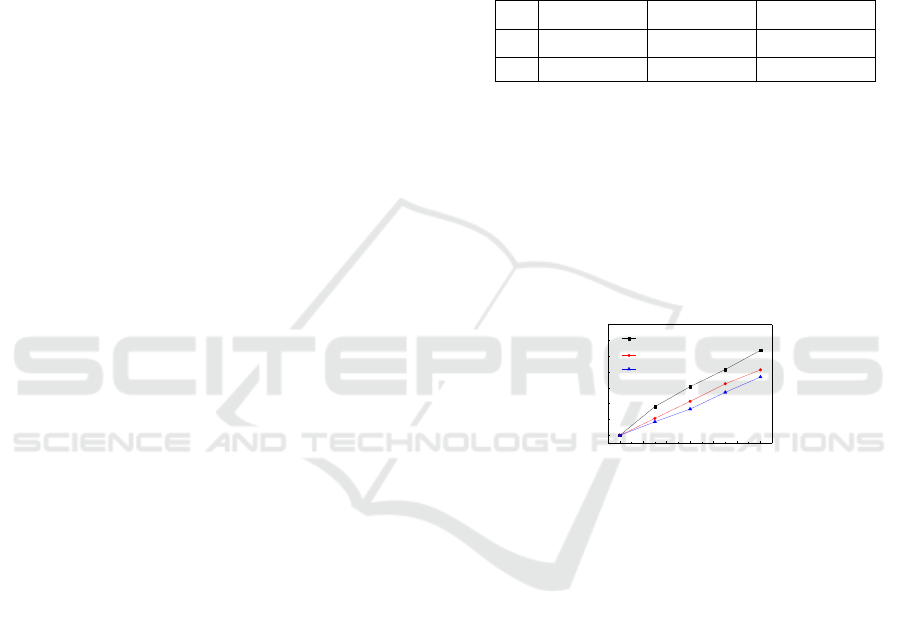

The result is shown in Figure 3.

0 2 4 6 8 10 12

0

5

10

15

20

25

30

35

No H

2

O

2

15 mg/L

45 mg/L

Time / minute

Decoloration rate

/ %

Figure 3: RhB decoloration rate as a function time of time

with various concentrations of H

2

O

2

.

It is clear that the decoloration rate decreases in

higher H

2

O

2

concentration. Similar results have been

reported in related researches (Behnajady et al.,

2008, Merouani et al., 2010). However, in these

researches decreasing trend of RhB decoloration

appears after a relatively large dosage of the additive

H

2

O

2

solution.

It is known that solely H

2

O

2

solution shows very

limit decoloration on RhB. OH radical is mainly

responsible for RhB decoloration of those AOPs

techniques. In this research, because of the short life

time and diffusion distance of OH radicals,

decoloration reaction is mainly conducted on the

interface between liquid phase and gas phase

(induced by cavitation and plasma evaporation).

However, H

2

O

2

would also take part of the interface,

after reaching a certain saturation limit, there would

be no enough interface area for the decoloration

reaction. The acoustic streaming will also improve

Decoloration of Rhodamine B Aqueous Solution by Ultrasound Assisted Pulse Discharge

309

H

2

O

2

diffusion to the interface. Consequently, the

decoloration rate was decreased. On the other hand,

due to a large amount of ·OH radical generated in

proposed process, more OH radicals were scavenged

by H

2

O

2

instead of attacking RhB molecular. The

inhibitory effect of H

2

O

2

could be explained as

follows:

H

2

O

2

+ ·OH → H

2

O + HOO·

In this case, the scavenging effect of H

2

O

2

shows

more influences rather than releasing ·OH radical.

Thus, the decoloration will decrease with the

increasing additive H

2

O

2

.

4 CONCLUSIONS

The present work has shown that RhB can be

effectively removed from aqueous solution by

proposed ultrasound assisted pulse discharge.

Solution electrical conductivity for desirable

discharge type is widely extended. Energy efficiency

of discharge is significantly improved by ultrasound,

especially in higher electrical conductivity of

solution. Additive H

2

O

2

solution shows an inhibitive

effect on RhB decoloration in proposed method.

Additive H

2

O

2

performs as a inhibitor in the

experiments.

ACKNOWLEDGMENTS

This work is supported by China Scholarship

Council.

REFERENCES

Behnajady, M., Modirshahla, N., Tabrizi, S. B. &

Molanee, S. 2008. Ultrasonic degradation of

Rhodamine B in aqueous solution: influence of

operational parameters. Journal of Hazardous

Materials, 152, 381-386.

Bruggeman, P. & Leys, C. 2009. Non-thermal plasmas in

and in contact with liquids. Journal of Physics D:

Applied Physics, 42, 053001.

Fang, Y., Shimizu, S., Yamamoto, T. & Komarov, S.

2018a. Generation of OH Radical by Ultrasonic

Irradiation in Batch and Circulatory Reactor. IOP

Conference Series: Earth and Environmental Science,

120, 012019.

Fang, Y., Yamamoto, T. & Komarov, S. 2018b. Cavitation

and acoustic streaming generated by different

sonotrode tips. Ultrasonics Sonochemistry, 48, 79-87.

Gershman, S., Mozgina, O., Belkind, A., Becker, K. &

Kunhardt, E. 2007. Pulsed electrical discharge in

bubbled water. Contributions to Plasma Physics, 47,

19-25.

Komarov, S., Oda, K., Ishiwata, Y. & Dezhkunov, N.

2013. Characterization of acoustic cavitation in water

and molten aluminum alloy. Ultrason Sonochem, 20,

754-61.

Lee, H., Park, S. H., Park, Y.-K., Kim, B. H., Kim, S.-J. &

Jung, S.-C. 2013. Rapid destruction of the rhodamine

B using TiO 2 photocatalyst in the liquid phase

plasma. Chemistry Central Journal, 7, 156.

Liang, J., Komarov, S., Hayashi, N. & Kasai, E. 2007.

Improvement in sonochemical degradation of

4-chlorophenol by combined use of Fenton-like

reagents. Ultrasonics Sonochemistry, 14, 201-207.

Malik, M. A. 2010. Water purification by plasmas: Which

reactors are most energy efficient? Plasma Chemistry

and Plasma Processing, 30, 21-31.

Medodovic, S. & Locke, B. 2009. Primary chemical

reactions in pulsed electrical discharge channels in

water. Journal of Physics D: Applied Physics, 42,

049801.

Mehrdad, A. & Hashemzadeh, R. 2010. Ultrasonic

degradation of Rhodamine B in the presence of

hydrogen peroxide and some metal oxide. Ultrasonics

sonochemistry, 17, 168-172.

Mehrdad, A., Massoumi, B. & Hashemzadeh, R. 2011.

Kinetic study of degradation of Rhodamine B in the

presence of hydrogen peroxide and some metal oxide.

Chemical engineering journal, 168, 1073-1078.

Merouani, S., Hamdaoui, O., Saoudi, F. & Chiha, M.

2010. Sonochemical degradation of Rhodamine B in

aqueous phase: effects of additives. Chemical

Engineering Journal, 158, 550-557.

Nakagawa, Y., Mitamura, S., Fujiwara, Y. & Nishitani, T.

2003. Decolorization of rhodamine B in water by

pulsed high-voltage gas discharge. Japanese journal of

applied physics, 42, 1422.

Siddique, M., Farooq, R. & Price, G. J. 2014. Synergistic

effects of combining ultrasound with the Fenton

process in the degradation of Reactive Blue 19.

Ultrasonics sonochemistry, 21, 1206-1212.

Sugiarto, A. T., Ito, S., Ohshima, T., Sato, M. & Skalny, J.

D. 2003. Oxidative decoloration of dyes by pulsed

discharge plasma in water. Journal of Electrostatics,

58, 135-145.

Sugiarto, A. T. & Sato, M. 2001. Pulsed plasma

processing of organic compounds in aqueous solution.

Thin solid films, 386, 295-299.

Šunka, P. 2001. Pulse electrical discharges in water and

their applications. Physics of plasmas, 8, 2587-2594.

Van De Moortel, N., Van Den Broeck, R., Degrève, J. &

Dewil, R. 2017. Comparing glow discharge plasma

and ultrasound treatment for improving aerobic

respiration of activated sludge. Water research, 122,

207-215.

Yamabe, C., Takeshita, F., Miichi, T., Hayashi, N. &

Ihara, S. 2005. Water treatment using discharge on the

surface of a bubble in water. Plasma Processes and

Polymers, 2, 246-251.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

310