Immobilization of Horseradish Peroxidase on Modified Electrospun

Nanofibrous Membrane for 2,4-Dichlorophenol Removal

Ning Wei

1,2

, Ran Xu

1,2*

and Rongzhi Tang

1,2

1

State Key Laboratory of Pollution Control and Resources Reuse, College of Environmental Science and Engineering,

Tongji University, Shanghai 200092, PR China

2

Shanghai Institute of Pollution Control and Ecological Security, Shanghai200092, P.R. China

Keywords: 2,4-Dichlorophenol, Horseradish Peroxidase Immobilization, Electrospinning, Nanofibrous Membrane,

Water Treatment

Abstract: In this study, a facile and simple method was used to modify the hydrophobic PAN/PVdF membranes into

hydrophilic ones. Results showed that the PAN/PVdF membranes have been modified successfully and the

water contact angle changed from 87.135° to 0°. Horseradish peroxidase (HRP) was immobilized onto the

modified PAN/PVdF membranes through covalent binding and the maximum enzyme loading was

approximately 440 mg/g under optimal conditions (after 8 h at pH 8.0 and 25

o

C). The effects of pH and

temperature on the relative activity of free and immobilized HRP were studied. Under the optimum

conditions of pH and temperature, immobilized HRP was greatly improved in operational and storage

stability. 2,4-DCP removal experiments showed that the immobilized HRP and free HRP had a similar

removal efficiency (87% and 93%, respectively). However, the immobilized HRP had an excellent

reusability. HRP-PAN/PVdF could still remove 47.6% of 2,4-DCP after 7 repeated runs, which could

overcome the inherent drawbacks of free enzymes-hard separation and non-reusability.

1 INTRODUCTION

Phenols, especially chlorinated ones, are considered

as persistent organic pollutants among different

kinds of pollutants in aquatic ecosystems mainly due

to their harmful effects on organisms even at very

low concentrations (Antizar-Ladislao and Galil,

2004) (Khenifi et al., 2009). Chlorophenols are one

of the most important industrial materials and widely

used in the production of insecticides, herbicides,

wood treatment agents and flame retardants (Zhang

et al., 2004). A typical example is 2,4-

dichlorophenol (2,4-DCP), which is regarded as a

priority pollutant by European Union (No, 2001) and

United States Environmental Protection Agency

(Keith and Telliard, 1979). It is mainly used in the

applications of higher chlorophenols manufacturing

and other productions of Cl-based herbicides

(Ormad et al., 2001). People who drink water

containing 2,4-DCP for long time might suffer from

headache, hyperpyrexia, sicchasia, anepithymia, and

even death. The fate and transport of 2,4-DCP in

aqueous media are rather complicated mainly due to

its high solubility and low air-water partition

coefficients (Khenifi et al., 2009). Biochemical

technology, mainly including activated sludge

process, biomembrane process and biological

fluidized bed process, is the most widely used

method for the treatment of organiccontaminations

in water. However, some disadvantages which

cannot be overcame still exist in the methods above.

For example, production of huge amount of sludge,

poor ability to resist impact load and high cost

greatly limits the application of activated sludge

technology. In addition, secondary pollution and

operation difficulties may also be the restrictions on

the methods above. However, enzyme immobilized

on nanofibrous membranes, which may overcome

those shortcomings to a certain extent, was

considered to be a great candidate for the removal of

chlorophenols due to their excellent properties of

large surface area, easy separation and reutilization

as well as high removal efficiency towards organic

pollutants. In our previous studies, we have found

that the removal of the organic pollutants by

immobilized enzyme on nanofibrous membranes

was mainly attributed to two aspects: the adsorption

of the membranes and the biodegradation by the

Wei, N., Xu, R. and Tang, R.

Immobilization of Horseradish Peroxidase on Modified Electrospun Nanofibrous Membrane for 2,4-Dichlorophenol Removal.

DOI: 10.5220/0008188902830292

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 283-292

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

283

enzyme (Xu et al., 2015c). Meanwhile, the organic

pollutants could be removed from water in a short

time. For example, horseradish peroxidase (HRP)

immobilized on chitosan/poly (vinyl alcohol)-

nanocrystalline cellulose nanofibrous membrane

could remove 98.34% 3,3’,5,5’-tetrabromobisphenol

in 2 h (Xu et al., 2015b). In another case, 24% of

diclofenac was absorbed by the electrospun carriers

while the total removal efficiency is 100% after 6 h

(Xu et al., 2015c). Bio-enzymes are considered to be

great candidates for pollutants removal due to their

high specificity, high efficiency and eco-

friendliness, in which HRP is a typical

representative. It is characterized by its tolerance to

pH, temperature and other outside interferences and

is adopted as the experimental enzyme (Nicell et al.,

1993).

Polyacrylonitrile (PAN) (Qin et al., 2007;Liu et

al., 2014;Selloum et al., 2014;Pan et al., 2015)

and polyvinylidene fluoride (PVdF) (Kim et al.,

2004) (Gao et al., 2006)are two commonly used

polymers to prepare electrospun nanofibers. Studies

(Yin et al., 1998) (Yang and Liu, 2003) found that a

suitable incorporation of PVdF will increase the

toughness of the PAN nanofiber, thus increasing the

applicability of the nanofibrous membranes for

future application. However, the PAN/PVdF

membrane is not easy to absorb aquatic pollutants

for its hydrophobicity.

In this study, we aimed to use a simple method to

modify the commonly used PAN/PVdF membrane

in order to change its property from hydrophobicity

to hydrophilicity and apply it as a carrier for HRP to

remove 2,4-DCP in water with operational and

storage stability. The immobilized HRP was used for

the treatment of 2,4-DCP in water. The research had

important scientific and practical significance for the

application of enzyme catalytic technology in

environmental engineering.

2 MATERIALS AND METHODS

2.1 Materials

Polyacrylonitrile (PAN, Mw=150,000), N,N-

dimethylformamide (DMF), Coomassie brilliant

blue (G250), citrate phosphate buffer solution

(CPBS), 2,2’-azinobis-(3-ethylbenzthizaoline-6-

sulphonate) (ABTS), 1,1’-carbonyldiimidazole

(CDI), were obtained from Sigma-Aldrich.

Polyvinylidene fluoride (PVdF) was purchased from

Arkema, China. Sodium hydroxide (NaOH), horse

radish peroxidase (HRP, RZ~3), tetrahydrofuran

(THF) were obtained from Sinopharm Chemical

Reagent Co. Ltd, China. Deionized water was used

in all experiments. All chemicals used were of

analytical grade.

2.2 Preparation of PAN/PVdF

Nanofibrous Membranes by

Electrospinning

PAN ( 8 g ) was dissolved in DMF( 92 g ) and

stirred for 8 h at 60

o

C, meanwhile PVdF( 5 g ) was

dissolved in DMF( 50 g ) and stirred for 5 h at 60

o

C. Then, 1.5 g of 10 % PVdF was added into 4.5 g

of 8 % PAN solution and stirred for 2 h at 60

o

C to

obtain the spinning solution, and the mixture

solution was poured into a 10 mL plastic injector

with a stainless steel spinneret of 1.2 mm inner

diameter after the air bubbles were completely

removed. The electrospinning conditions were

controlled as follows: a high voltage of 16 kV, a

flow rate of 1.5 mL/h, a tip-to-target distance of 18

cm and a relative humidity of 45 ± 5%. Finally, the

PAN/PVdF nanofibrous membranes were collected

for 4 h on a rotating cylinder wrapped with

aluminum foiland then dried in a vacuum drying

oven for 12 h to get a non-woven format. The

membranes were water insoluble.

2.3 Measurement and Characterization

Scanning electron microscopy (SEM) was used to

observe the morphology of the nanofibers on a field

emission XL-30 SEM system at 20 kV. Fourier

transform infrared-attenuated total reflectance

(FTIR-ATR) spectroscopy equipped with a

germanium crystal was used to assay the functional

groups of the original and modified nanofibers. The

immobilization efficiency and residual activity of

free and immobilized HRP were measured by

Shimadzu UV-1700 spectrophotometer.

2.4 Immobilization of HRP on the

PAN/PVdF Nanofibrous

Membranes

10 mg PAN/PVdF nanofibrous membrane was

immersed into the mixture solution of 10 mL 0.8 M

NaOH and 2 mL ethanol for 2 h to convert part of

the cyano groups into carboxylate. Then take out the

membrane and wash it with anhydrous THF to

remove any residue water. The reaction of carboxyl

groups with CDI was controlled under non-aqueous

conditions. CDI was dissolved in anhydrous THF at

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

284

a concentration of 0.3 M. The reaction lasted for 12

h at 25

o

C. Afterwards, the activated nanofibers were

washed 3 times with THF to remove excess CDI and

by-products, when THF vanished under natural

drying, the membranes were stored before use.

The activated membranes were immersed into an

HRP solution at a concentration of 1 mg/mL (pH 6.0

CPBS) at 25

o

C for 12 h. The effects of time (2, 4, 6,

7, 8,10,12 h) and pH (3,4,5,6,7,8,9) on HRP

immobilization were analyzed. After enzyme

immobilization, the membranes were removed from

the enzyme solution and rinsed with CPBS until no

HRP was detected in the washings, then the

membranes immobilized with HRP were stored at 4

o

C to protect the immobilized HRP from losing

activity for later use.

2.5 Assays of Immobilization Efficiency

and Activity of Free and

Immobilized HRP

The immobilization efficiency of HRP was

calculated by subtracting the loading of HRP

remained in the supernatants and washing buffer

from the total HRP initially added into the solution.

The loading of HRP (mg) and immobilization

efficiency (mg/g) were estimated at 595 nm by a

UV-1700 spectrophotometer from Shimadzu.

Determination of HRP activity was calculated

spectrophotometrically by monitoring the

absorbance change of ABTS at 420 nm on a UV-

1700 spectrophotometer (Shimadzu) (Xu et al.,

2015c). The formula for calculating the HRP activity

is as follows:

U=

∆A×V×10

ε×M×L×t

(1)

Where ΔA is the change in absorbance before and

after the reaction; V is the volume (L) of the liquid

added to the cuvette; M is the mass of the added

HRP (mg); L is the cuvette path (cm); t is Reaction

time (min).

In the immobilization experiment of HRP, the

concept of relative enzyme activity is often used. In

the horizontal gradient experiment, the enzyme

activity under the optimal conditions was taken as

100%, and the enzyme activities of other horizontal

gradients were relative to the activity of 100%

enzyme.

2.6 Stabilities of Free and Immobilized

HRP

Free HRP (1mg/mL) and a certain amount of

immobilized HRP were stored in CPBS at 4

o

C. The

effects of temperature on the activity of free and

immobilized HRP were examined by evaluating the

enzyme activity at pH 4.0 from temperature 20 to 50

o

C. The effects of pH on the activity of free and

immobilized HRP were obtained by evaluating the

enzyme activity at 25

o

C from pH 3.0 to 9.0.

The reusability of immobilized HRP was

determined as follows: the immobilized HRP was

used 10 times within a day at the optimum

conditions.

The storage stability of immobilized HRP was

determined as follows: After each reaction, the

immobilized HRP was washed with CPBS (pH 4.0)

to remove any residual substrate. The storage

stabilities of free and immobilized HRP were

obtained by calculating the residual activity of the

enzyme every 3 days at 4

o

C within 30 days.

2.7 Removal of 2,4-DCP by Free and

Immobilized HRP

Fifty mL of 20 mg /L 2,4-DCP in PBS was used as

substrate, 5 mg of free or immobilized HRP and 0.8

mmol/L H

2

O

2

were used for the removal of 2,4-

DCP. After 3 h, the upper solution was filtered

through syringe filters (membrane of nylon) with the

size of 0.45 μm and the residue concentration of the

2,4-DCP was measured using UV-1700 based on the

standard methods for the assay of phenols.

The effect of pH on the removal of 2,4-DCP was

investigated at 25

o

C, pH 3-8. The effect of initial

H

2

O

2

on the 2,4-DCP removal was carried out with

the concentration range of 0.2 mM to 1.2 mM. A

PAN/PVdF membrane modified by NaOH was used

as a pure carrier to study the adsorption capacity of

the membrane.

The removal of 2,4-DCP by HRP-PAN/PVdF

includes two aspects: adsorption of the membrane

and biodegradation of HRP immobilized on

PAN/PVdF. The biotransformation by the

immobilized HRP was calculated by the following

Eq. (2):

C

b

= C

r

-C

a

(2)

C

r

, C

a

, and C

b

are the concentrations of the 2,4-

DCP removed, absorbed, and biotransformed by

HRP-PAN/PVdF NFM, respectively.

Immobilization of Horseradish Peroxidase on Modified Electrospun Nanofibrous Membrane for 2,4-Dichlorophenol Removal

285

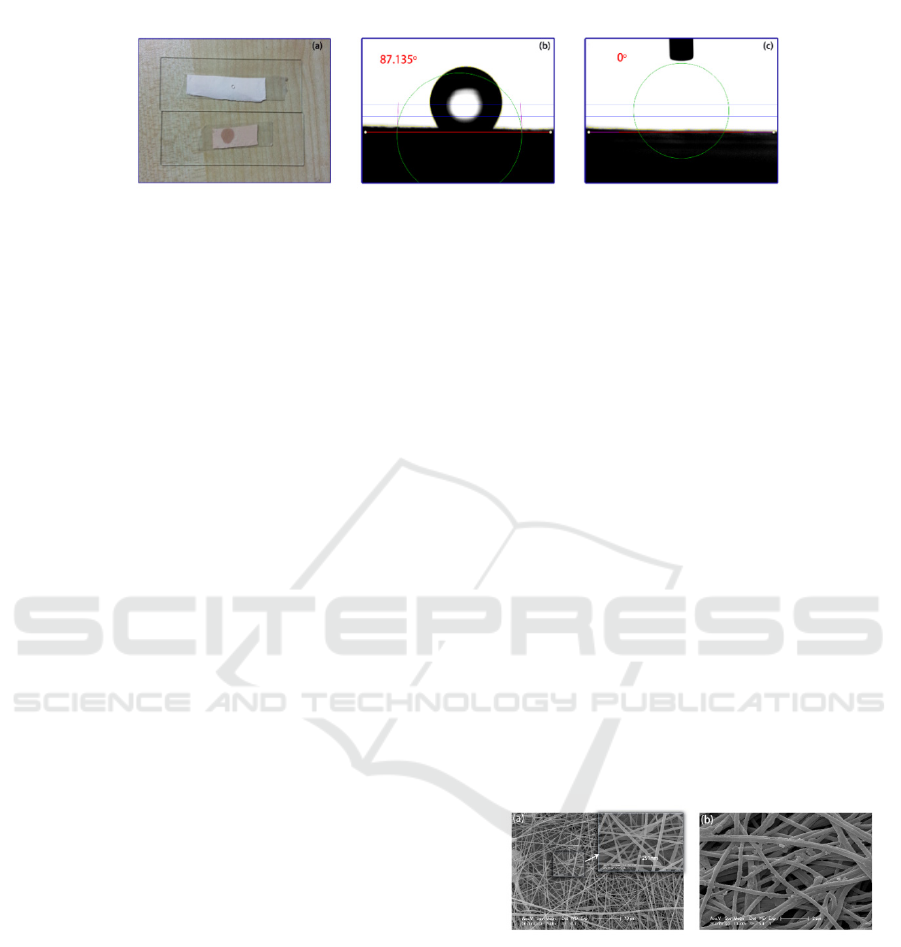

Figure 1: Water contact performances (a) comparison of PAN/PVdF membrane before and after treatment (b) water contact

angle of PAN/PVdF membrane (c) water contact angle of PAN/PVdF membrane after treatment.

2.8 Data Analysis

Non-linear regression analysis using first-order

model, Eq. (3)-(5) (Xu et al., 2015c), was used to

estimate the first order rates (k), the time required to

obtain 50% of substrate degradation/adsorption

(t1/2), and the 2,4-DCP removal efficiency after

(REt).

C

t

= C

0

exp(-kt)

(3)

C

0

and C

t

are the substrate concentrations at the

beginning of the run and at the time (t), and k is the

first-order rates (k), and the time required to obtain

50% of the substrate degradation/adsorption (t

1/2

),

and the 2,4-DCP removal efficiency after t (RE

t

).

t

1/2

= ln2/k

(4)

RE

t

=(C

0

-C

t

)/C

0

×100

(5)

3 RESULTS AND DISCUSSION

3.1 Characterization of the

Electrospun PAN/PVdF

Nanofibrous Membranes

The hydrophobicity of the pristine PAN/PVdF

membrane was a great limitation to its application.

Therefore, the PAN/PVdF membranes were treated

with 10 wt% NaOH and a certain amount of ethanol

beforehand to improve its hydrophilic performance.

Figure 1(a) shows the different water contact

performances of pristine PAN/PVdF and PAN/PVdF

membrane after treated with NaOH. It can be seen

that the color of the nanofiber membrane changes

from white to reddish brown after modification with

an aqueous solution of sodium hydroxide and

ethanol. It was found the water contact angle of

PAN/PVdF membrane was 87.135

o

(see Figure 1b),

while that of the membrane after NaOH treatment

was 0

o

(see Figure 1c). The smaller the water contact

angle, the greater the hydrophilicity. It means the

membrane surface had been changed from

hydrophobic to totally hydrophilic after NaOH

treatment. This change could be attributed to the

existence of carboxyl groups derived from cyano

groups.

The membranes were activated under non-

aqueous condition by CDI to form N-acylimidazoles

of high reactivity, followed by enzyme

immobilization through conjugation with amino

groups of HRP.

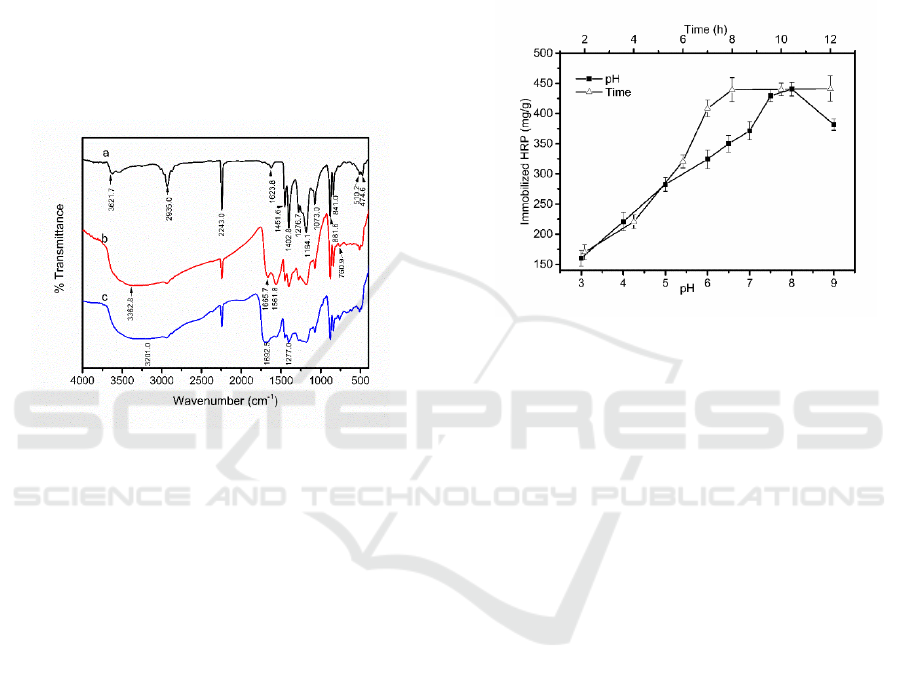

Figure 2 shows the SEM photographs of the

nanofibrous membranes before and after HRP

immobilization. The nanofibers’ surface was smooth

and their average diameter ranged from 200 to 300

nm. The HRP immobilized on the membranes made

the surface of the fiber coarser than those without

HRP. Several big beads appeared in the image may

be some fragments of the fiber or salt crystals.

Figure 2: SEM images of the nanofibrous membrane (a)

before and (b) after immobilization.

FTIR was used to characterize the PAN/PVdF

nanofibrous membrane (NFM), NFM after NaOH

treatment, and NFM immobilized with HRP. Figure

3a shows peaks at 1402.8, 1276.7 and 474.6 cm

-1

,

which are corresponding to CF

2

bending, CF

2

stretching and CF

2

wagging, respectively. Compared

Figure 3b with Figure 3a, new peaks at 1561.8 cm

-1

and 1665.7 cm

-1

indicate the existence of carboxylic

and formamide groups. The appearance of these

hydrophilic groups can also support the change of

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

286

membrane surface from hydrophobic to totally

hydrophilic after NaOH treatment. which depicted in

Figure 1. It can be seen that Figure 3c has a strong

adsorption band at 1692.5 cm

-1

, representing the

stretching vibration of C=O. Meanwhile, a peak at

1277.0 cm

-1

appeared which could be due to the

combination of C-N stretching vibration and N-H

bending vibration. In addition, the peak at 3201.0

cm

-1

indicates the stretching vibration of N-H. These

new peaks are produced during the immobilization

of HRP on the surface of the fiber membrane. As a

result, it can be confirmed that HRP molecules has

been successfully immobilized on PAN/PVdF NFMs

through chemical bonding.

Figure 3: FTIR graphs of (a) pristine PAN/PVdF

membrane (b) membrane after NaOH treatment (c)

membrane immobilized with enzyme.

3.2 Effects of pH and Time on HRP

Immobilization

Figure 4 shows the effects of time and pH on the

immobilization efficiency of HRP. Both pH and

time have significant influences on the

immobilization. It can be seen from Figure 4 that

extreme pH conditions greatly restricted the

immobilization efficiency. This is not only because

extreme pH condition will destroy the structure of

the enzyme, but more importantly because the mode

of interaction between the enzyme and the carrier

(eg, the orientation of the enzyme) depends on the

ionic strength and pH (Xu et al., 2016). The

optimum pH for HRP immobilization was between

7.5 and 8.0. It was in accordance with the results in

our previous study (Xu et al., 2015a). The

immobilization efficiency improved with the

increase of time until it levelled off after 8 h. It

might be resulted from the saturation of immobilized

HRP owing to steric constraints because the enzyme

occupies a certain volume of space (Cristóvão et al.,

2011). The maximum HRP loading was 440.2 mg/g

after 8 h at pH 8.0 and 25

o

C. This immobilization

efficiency was relatively higher than that reported

before (Takahashi et al., 2001) (Lai and Lin, 2005)

(Xu et al., 2013). The high HRP loading may be

attributed to the high specific surface area of the

PAN/PVdF membrane and the suitable

immobilization method which may retain high

residue activity of HRP.

Figure 4: Effect of pH (12 h at 25 oC with pH

3,4,5,6,7,8,9) and time (2, 4, 6, 7, 8,10,12 h at 25 oC with

pH 6.0 CPBS) on the HRP immobilization efficiency.

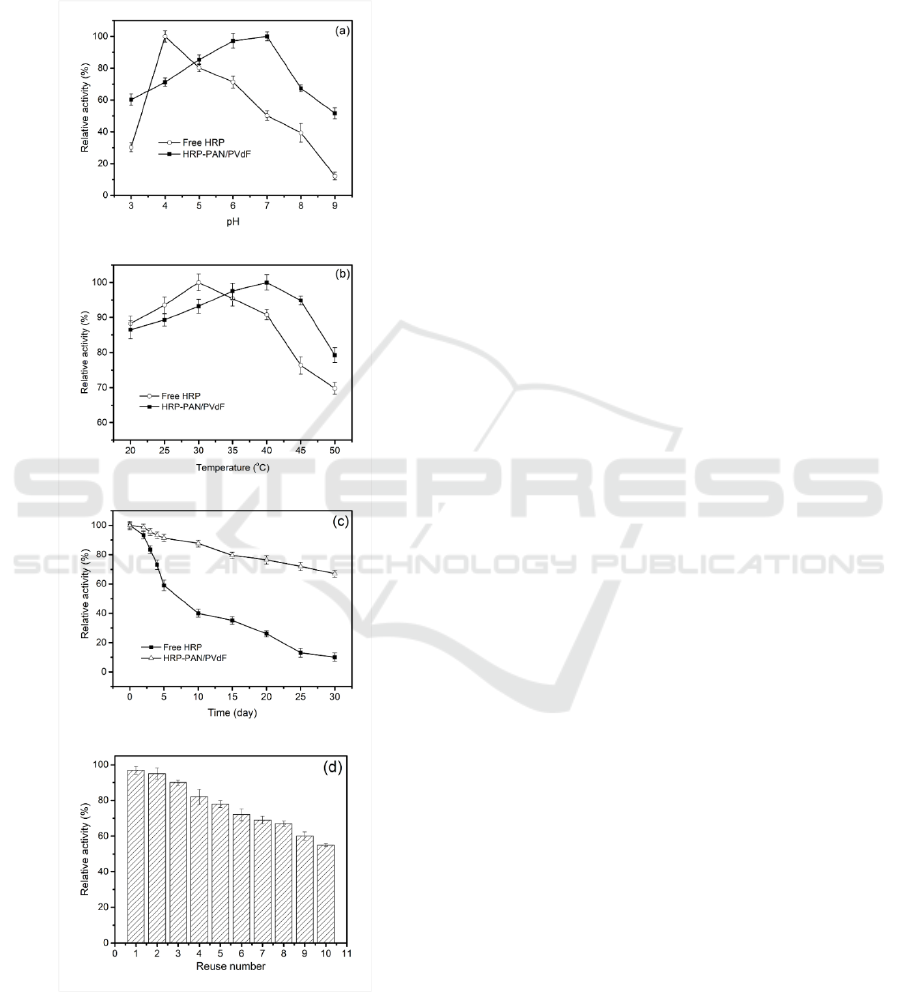

3.3 Characterization of Free and

Immobilized HRP

Stabilities are important indexes to measure the

properties of the immobilized enzymes for their

further industrial applications. Figure 5(a) and (b)

shows the effects of pH and temperature on the

relative activity of free and immobilized HRP. Free

HRP reached optimum activity at pH 4.0 and 30

o

C

while immobilized ones shifted to pH 7.0 and 40

o

C.

The enzyme activity of immobilized HRP was

higher than that of free ones in the pH range from

3.0 to 3.5 and5.0 to 9.0, demonstrating that the

immobilized HRP was less sensitive to the pH

conditions during the testing period. For example,

the relative activity of immobilized HRP at pH 9

was 50.2%, which was significantly higher than that

of free HRP (10.1%). It could be attributed to the

buffering effect provided by the support of

membrane (Liu et al., 2013). Additionally, the

immobilized HRP showed greater relative activity

than free HRP, especially at temperature higher than

40

o

C. As temperature increased, the relative activity

of immobilized HRP decreased significantly slower

than that of free HRP, indicating that the

immobilized HRP had a higher temperature stability.

It may be attributed to the protecting effect provided

Immobilization of Horseradish Peroxidase on Modified Electrospun Nanofibrous Membrane for 2,4-Dichlorophenol Removal

287

by the immobilization support at high temperatures

when enzyme deactivation occured (Osma et al.,

2010). The enzyme rigidity increased through the

immobilization process demonstrated by an

increased thermal stability against denaturation

(Abdel-Naby, 1993).

Figure 5: pH (a) (at 25

o

C with pH 3-9), temperature (b)

(at 20-50

o

C with pH 4), storage (c) (optimum conditions)

and operational stabilities (d) (optimum conditions) of free

HRP and HRP-PAN/PVdF.

Generally, enzymes are unstable in solution, and

their activities would decrease as storage period

increases. In contrast, immobilized enzyme can

overcome this disadvantage. Figure 5c shows the

activity of free HRP decreased significantly faster

than immobilized HRP (p<0.05). For example, after

30 days, the immobilized HRP still retained an

activity of 66.9%, while for free HRP, the relative

activity was only 10.0%. Therefore, immobilized

HRP was more stable than free HRP. It was

attributed to the limited conformational changes in

enzyme molecules in the matrix of fibrous

membrane (Xu et al., 2015b).

Immobilized enzyme can be more easily

separated from the reaction solution compared with

free enzyme, which would greatly decrease the cost

of enzyme for further application (Quintanilla-

Guerrero et al., 2008). It was found from Figure 5d

that HRP-PAN/PVdF retained 55% of its initial

activity after 10 cycles of reuse. The loss in enzyme

activity may be related to the inactivation of enzyme

caused by denaturation of the protein as well as the

breakage of the membrane (Huang et al., 2008).

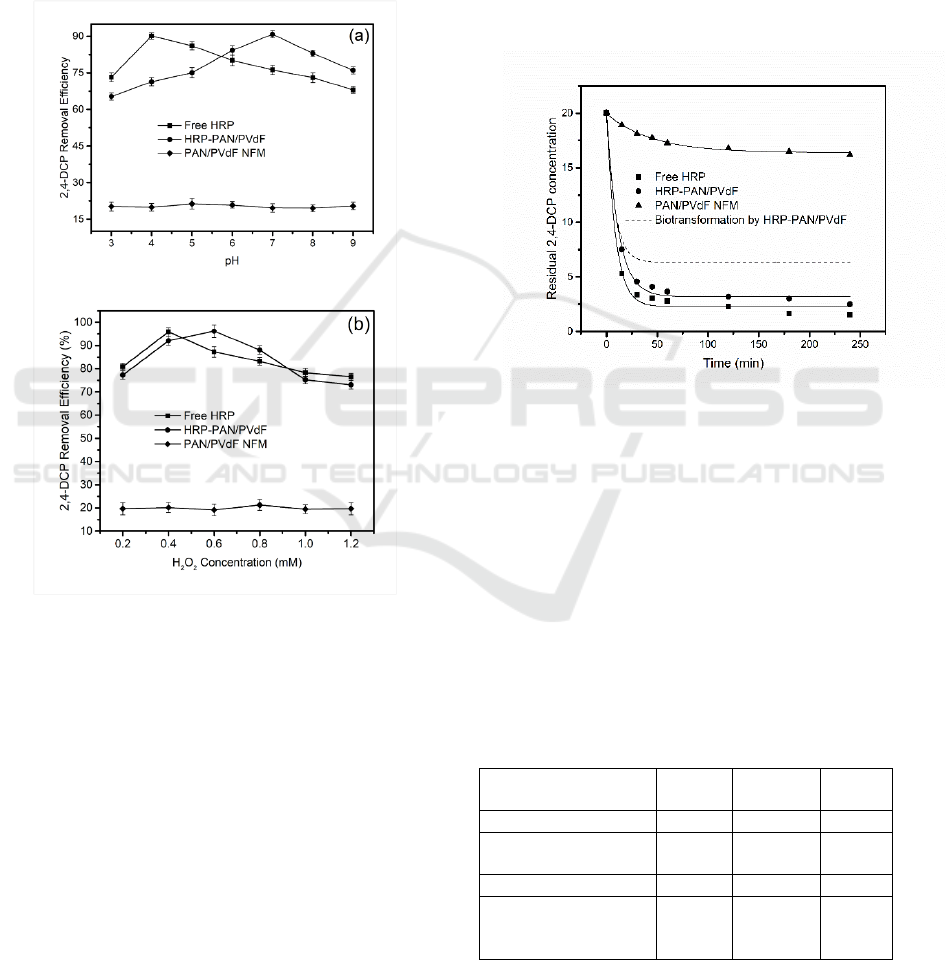

3.4 Removal of 2,4-DCP by Free and

Immobilized HRP

Figure 6 shows the effect of pH and H

2

O

2

initial

concentration on the removal efficiency of 2,4-DCP

by free HRP, PAN/PVdF NFM as well as HRP-

PAN/PVdF. As illustrated in Figure 6(a), the

adsorption of the PAN/PVdF membrane removed

approximately 20% of 2,4-DCP in the experiment

about the effect of pH, and no significant variation

(p>0.05) was observed as pH value changed, which

could due to the strong stability of the PAN/PVdF

membrane under different pH conditions. The

removal efficiency of 2,4-DCP reached a maximum

of 90% at pH 7.0 by immobilized HRP and 89.2%

by free HRP at pH 4.0. The difference in optimum

pH conditions for 2,4-DCP removal by free and

immobilized HRP was consistent with the pH

stability results. Furthermore, immobilized HRP

showed high removal efficiency towards 2,4-DCP

than free HRP, especially under alkaline conditions.

It may be explained by the protection of the carrier.

Figure 6(b) shows that the maximum 2,4-DCP

removal efficiency reached as high as 94.9% by free

HRP at an initial H

2

O

2

concentration of 0.4 mM and

94% by immobilized HRP at an initial H

2

O

2

concentration of 0.6 mM. As initial H

2

O

2

concentration changed, there was no significant

change (p>0.05)in adsorption rate of 2,4-DCP by

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

288

PAN/PVdF NFM. In addition, superabundant H

2

O

2

had adverse effect on the removal of 2,4-DCP. It

may be attributed to the following reasons: Firstly,

excess HRP may react with the intermediates and

result in a less active form of HRP during the

process of 2,4-DCP catalytic oxidation (Cai and

Tien, 1992). Secondly, an overdose of H

2

O

2

may

participate in irrelevant reactions (Maloney et al.,

1986).Therefore, a suitable amount of H

2

O

2

is a key

factor for 2,4-DCP removal in an reaction system.

Figure 6: Effect of pH (a) (4h with 20 mg/L 2,4-DCP, 5

mg of free or immobilized HRP and 0.8 mmol/L H2O2)

H2O2 initial concentration (b) on the removal efficiency

of 2,4-DCP by free HRP and HRP-PAN/PVdF. (4h with

20 mg/L 2,4-DCP, 5 mg of free or immobilized HRP and a

constant pH)

Figure 7 shows the removal efficiency of 2,4-

DCP in a 4 h batch experiment. The degradation

efficiency of 2,4-DCP by free HRP reached

approximately 83% in the first 30 min and 93% after

a 3 h treatment. By contrast, the removal efficiency

of 2,4-DCP by HRP-PAN/PVdF reached 77% in the

first 30 min and 87% after 3 h. According to the Eq.

(2), we could easily calculate that about 68% of 2,4-

DCP was biotransformed by HRP-PAN/PVdF.

Although the enzyme molecules immobilized on

PAN/PVdF NFM were relatively less than that of

free HRP, the removal efficiency towards 2,4-DCP

did not show significant difference. It was due to the

combined effects of biodegradation and adsorption

by HRP-PAN/PVdF NFM. The adsorption of 2,4-

DCP on the nanofiber membrane carrier was

concentrated in 1 hour after the start of the reaction,

and there was no significant increase after 1 hour.

This indicates that the adsorption of 2,4-DCP on the

carrier is in the initial stage of the reaction, after

which the adsorption-desorption equilibrium is

reached. Figure 7 also shows that the kinetics of 2,4-

DCP removal followed a first-order reaction.

Figure 7: Removal kinetics of 2,4-DCP by free HRP (4h

at 25

o

C with pH 4.0 and 0.4 mM H

2

O

2

initially) and HRP-

PAN/PVdF (4 h at 25

o

C with pH 6.0 and 0.6 mM H

2

O

2

initially).

Table 1 showed the biodegradation rate of HRP

immobilized on NFMs was slower than that of free

HRP. It may be explained by spatial limitations for

substrate diffusion and protein flexibility after

enzyme immobilization on the carrier (Bai et al.,

2006) (Sari et al., 2006), as well as the fact that the

immobilized HRP was partly inactivated during the

immobilization process.

Table 1: Value of k, t

1/2

, and RE

240

of free HRP, HRP-

PAN/PVdF NFM, and NFM towards 2,4-DCP.

Sample k/(min) t

1/2

(min)

RE

240

(%)

Free HRP 0.122 5.68 92.35

HRP-PAN/PVdF

NFM

0.087 7.97 87.55

PAN/PVdF NFM 0.022 31.51 19.00

Biotransformation by

HRP-PAN/PVdF

NFM

0.112 6.19 68.55

Immobilization of Horseradish Peroxidase on Modified Electrospun Nanofibrous Membrane for 2,4-Dichlorophenol Removal

289

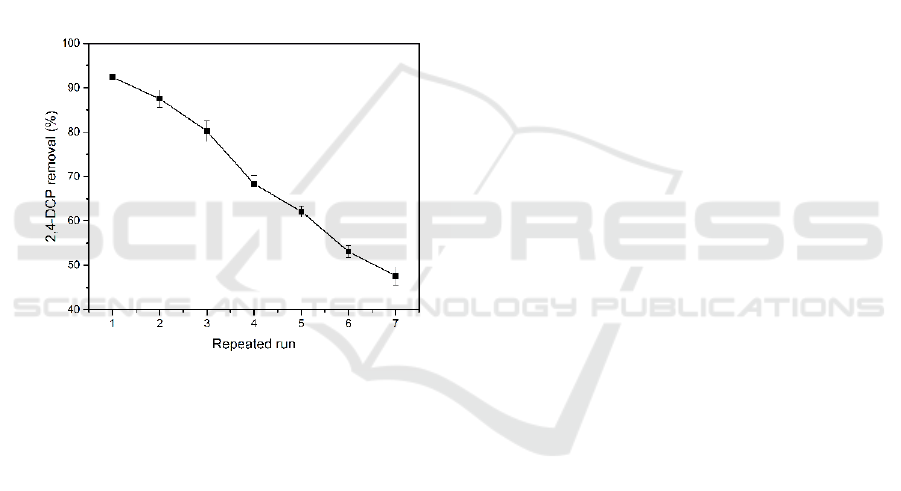

3.5 Reusability of HRP-PAN/PVdF

NFM

Immobilization of the enzyme can overcome the

inherent drawbacks of free enzymes-hard separation

and non-reusability. Figure 8 shows that HRP-

PAN/PVdF could still remove 47.6% of 2,4-DCP

after 7 repeated runs, which is much higher than

some other researches (Magri et al., 2007). The

decrease of the 2,4-DCP removal efficiency could be

explained by the adsorption of the reaction products

as well as the appearance of some undissolved

substances like the damaged components of the

PAN/PVdf membrane. The adsorption prevented the

contact between enzyme and substrate and the

undissolved substances slowed down the flow

velocity (Durán et al., 2002).

Figure 8: Variation of the 2,4-DCP removal rate by HRP-

PAN/PVdF. (at 25

o

C with pH 6.0 and 0.6 mM H

2

O

2

initially)

4 CONCLUSIONS

One novel method for horseradish peroxidase

immobilization was developed in this study. The

PAN/PVdF membranes fabricated by

electrospinning were converted from hydrophobic

into hydrophilic ones and were successfully applied

for HRP immobilization to retain high activity.

Under the optimum immobilization conditions, the

maximum enzyme loading of PAN/PVdF

nanofibrous membranes were 440 mg/g. Meanwhile,

the enzyme could retain high relativity after

immobilization. Compared with free HRP, the

immobilized HRP has better pH, thermal, storage

and operational stability. The work range of pH and

temperature was extended as well. Free HRP and the

immobilized HRP were applied in the removal of

2,4-DCP. Results showed that the removal

efficiency of the immobilized HRP for 2,4-DCP was

87%, while that of free HRP was 93%. The removal

efficiency of the immobilized enzyme as good as

free HRP. It could be concluded from the

experiments that the degradation of immobilized

HRP was first-order reaction and the removal of the

pollutants could be attributed to the adsorption of

nanofibrous membrane and the biodegradation of

HRP. HRP immobolized on PAN/PVdF membranes

also had better reusability. Therefore, HRP

immobilized on modified PAN/PVdF membrane

could be deemed as a promising material for future

applications in aquatic organic pollutants removal.

ACKNOWLEDGEMENTS

This work was funded by the National Natural

Science Foundation of China (21777119) and

Sichuan Science and Technology Program

(2018TJPT0017).

REFERENCES

Abdel-Naby, M. A., 1993. Immobilization ofAspergillus

niger NRC 107 xylanase and β-xylosidase, and

properties of the immobilized enzymes. Applied

biochemistry and biotechnology, 38, 69-81.

Antizar-Ladislao, B. & Galil, N. I., 2004. Biosorption of

phenol and chlorophenols by acclimated residential

biomass under bioremediation conditions in a sandy

aquifer. Water Research, 38, 267-276.

Bai, Y.-X., Li, Y.-F. & Wang, M.-T., 2006. Study on

synthesis of a hydrophilic bead carrier containing

epoxy groups and its properties for glucoamylase

immobilization. Enzyme and microbial technology, 39,

540-547.

Cai, D. & Tien, M., 1992. Kinetic studies on the formation

and decomposition of compounds II and III. Reactions

of lignin peroxidase with H2O2. Journal of Biological

Chemistry, 267, 11149-11155.

Crist V O, R. O., Tavares, A. P., BR Gida, A. I., Loureiro,

J. M., Boaventura, R. A., Macedo, E. A. & Coelho, M.

A. Z., 2011. Immobilization of commercial laccase

onto green coconut fiber by adsorption and its

application for reactive textile dyes degradation.

Journal of Molecular Catalysis B: Enzymatic, 72, 6-

12.

Dur N, N., Rosa, M. A., D’Annibale, A. & Gianfreda, L.,

2002. Applications of laccases and tyrosinases

(phenoloxidases) immobilized on different supports: a

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

290

review. Enzyme and Microbial Technology, 31, 907-

931.

Gao, K., Hu, X., Dai, C. & Yi, T., 2006. Crystal structures

of electrospun PVDF membranes and its separator

application for rechargeable lithium metal cells.

Materials Science and Engineering: B, 131, 100-105.

Huang, X.-J., Yu, A.-G. & Xu, Z.-K., 2008. Covalent

immobilization of lipase from Candida rugosa onto

poly(acrylonitrile-co-2-hydroxyethyl methacrylate)

electrospun fibrous membranes for potential bioreactor

application. Bioresource Technology, 99, 5459-5465.

Keith, L. & Telliard, W., 1979., ES&T special report:

priority pollutants: Ia perspective view. Environmental

Science & Technology, 13, 416-423.

Khenifi, A., Zohra, B., Kahina, B., Houari, H. & Zoubir,

D., 2009. Removal of 2, 4-DCP from wastewater by

CTAB/bentonite using one-step and two-step methods:

a comparative study. Chemical engineering journal,

146, 345-354.

Kim, J. R., Choi, S. W., Jo, S. M., Lee, W. S. & Kim, B.

C., 2004. Electrospun PVdF-based fibrous polymer

electrolytes for lithium ion polymer batteries.

Electrochimica Acta, 50, 69-75.

Lai, Y.-C. & Lin, S.-C., 2005. Application of immobilized

horseradish peroxidase for the removal of p-

chlorophenol from aqueous solution. Process

Biochemistry, 40, 1167-1174.

Liu, Q., Kong, X., Zhang, C., Chen, Y. & Hua, Y., 2013.

Immobilisation of a hydroperoxide lyase and

comparative enzymological studies of the immobilised

enzyme with membrane‐bound enzyme. Journal of

the Science of Food and Agriculture, 93, 1953-1959.

Liu, S., Fu, J., Ge, M., Tan, L. & Du, W., 2014.

Electrospinning of polyacrylonitrile nanofibers using

strain-hardening spinning solutions. Fibers and

Polymers, 15, 2441-2445.

Magri, M. L., De Las Nieves Loustau, M., Victoria

Miranda, M. & Cascone, O., 2007. Immobilisation of

soybean seed coat peroxidase on its natural support for

phenol removal from wastewater. Biocatalysis and

Biotransformation, 25, 98-102.

Maloney, S. W., Manem, J., Mallevialle, J. & Fiessinge, F.

1986. Transformation of trace organic compounds in

drinking water by enzymic oxidative coupling.

Environmental science & technology, 20, 249-253.

Nicell, J., Bewtra, J., Biswas, N., St. Pierre, C. & Taylor,

K., 1993. Enzyme catalyzed polymerization and

precipitation of aromatic compounds from aqueous

solution. Canadian Journal of Civil Engineering, 20,

725-735.

No, D., 2001. 2455/2001/EC of the European Parliament

and of the Council of 20 November 2001 establishing

the list of priority substances in the field of water

policy and amending Directive 2000/60/EC. Official

Journal of the European Communities, 15, 1-5.

Ormad, M., Ovelleiro, J. & Kiwi, J., 2001. Photocatalytic

degradation of concentrated solutions of 2, 4-

dichlorophenol using low energy light: identification

of intermediates. Applied Catalysis B: Environmental,

32, 157-166.

Osma, J. F., Toca-Herrera, J. L. & Rodr Guez-Couto, S.,

2010. Biodegradation of a simulated textile effluent by

immobilised-coated laccase in laboratory-scale

reactors. Applied Catalysis A: General,

373, 147-153.

Pan, H., Yang, J., Wang, S., Xiong, Z., Cai, W. & Liu, J.,

2015. Facile fabrication of porous carbon nanofibers

by electrospun PAN/dimethyl sulfone for capacitive

deionization. Journal of Materials Chemistry A, 3,

13827-13834.

Qin, X. H., Yang, E. L., Li, N. & Wang, S. Y., 2007.

Effect of different salts on electrospinning of

polyacrylonitrile (PAN) polymer solution. Journal of

applied polymer science, 103, 3865-3870.

Quintanilla-Guerrero, F., Duarte-V Zquez, M., GARC A-

ALMENDAREZ, B., TINOCO, R., VAZQUEZ-

DUHALT, R. & REGALADO, C., 2008. Polyethylene

glycol improves phenol removal by immobilized

turnip peroxidase. Bioresource technology, 99, 8605-

8611.

Sari, M., Akg L, S., Karatas, M. & Denizli, A., 2006.

Reversible immobilization of catalase by metal chelate

affinity interaction on magnetic beads. Industrial &

engineering chemistry research, 45, 3036-3043.

Selloum, D., Chaaya, A. A., Bechelany, M., Rouessac, V.,

Miele, P. & Tingry, S., 2014. A highly efficient

gold/electrospun PAN fiber material for improved

laccase biocathodes for biofuel cell applications.

Journal of Materials Chemistry A, 2, 2794-2800.

Takahashi, H., Li, B., Sasaki, T., Miyazaki, C., Kajino, T.

& Inagaki, S., 2001. Immobilized enzymes in ordered

mesoporous silica materials and improvement of their

stability and catalytic activity in an organic solvent.

Microporous and Mesoporous Materials, 44, 755-762.

Yin, X., Cheng, H., Wang, X., and Yao, Y., 1998.

Morphology and properties of hollow-fiber membrane

made by PAN mixing with small amount of PVDF.

Journal of membrane science, 146, 179-184.

Xu, R., Chi, C., Li, F. & Zhang, B., 2013. Immobilization

of horseradish peroxidase on electrospun microfibrous

membranes for biodegradation and adsorption of

bisphenol A. Bioresource technology, 149, 111-116.

Xu, R., Si, Y., Li, F. & Zhang, B., 2015a. Enzymatic

removal of paracetamol from aqueous phase:

horseradish peroxidase immobilized on nanofibrous

membranes. Environmental Science and Pollution

Research, 22, 3838-3846.

Xu, R., Tang, R., Liu, S., Li, F. & Zhang, B., 2015b. An

environmentally-friendly enzyme-based nanofibrous

membrane for 3, 3 ′ , 5, 5 ′ -tetrabromobisphenol

removal. RSC Advances, 5, 64091-64097.

Xu, R., Tang, R., Zhou, Q., Li, F. & Zhang, B., 2015c.

Enhancement of catalytic activity of immobilized

laccase for diclofenac biodegradation by carbon

nanotubes. Chemical Engineering Journal, 262, 88-95.

Xu, R., Yuan, J., Si, Y., Li, F., & Zhang, B., 2016. Estrone

removal by horseradish peroxidase immobilized on a

nanofibrous support with Fe 3 O 4 nanoparticles.

Yang, M.-C. & Liu, T.-Y., 2003. The permeation

performance of polyacrylonitrile/polyvinylidine

Immobilization of Horseradish Peroxidase on Modified Electrospun Nanofibrous Membrane for 2,4-Dichlorophenol Removal

291

fluoride blend membranes. Journal of membrane

Science, 226, 119-130.

Zhang, J., Shen, H., Wang, X., Wu, J. & Xue, Y., 2004.

Effects of chronic exposure of 2, 4-dichlorophenol on

the antioxidant system in liver of freshwater fish

Carassius auratus. Chemosphere, 55, 167-174.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

292