Fabrication of CuO Nanoflakes at Gas-liquid Interface Via Chemical

Bath Deposition with High Photocatalytic Activity

Xi Lin and Fengqiang Sun

*

School of Chemistry and Environment, South China Normal University, Guangzhou 510006, PR China

Keywords: CuO, gas-liquid interface, chemical bath deposition, photocatalytic activity

Abstract: Fabricating materials at gas-liquid interface is a kind of novel method and has aroused a great attention.

Herein, we introduce a new chemical bath deposition method to fabricate CuO nanoflakes directly at the

gas-liquid interface of a solution of CuSO

4

and NH

3

·H

2

O. The structure and morphology are characterized by

X-ray diffraction and scanning electron microscopy. The as-prepared CuO nanoflakes exhibited excellent

visible light photocatalytic activity in degradation of RhB in the presence of a little amount of H

2

O

2

under

tungsten halogen lamp. The method is easily-manipulated, low-cost, environment friendly and promising for

the fabrication of micro/nano-structured semiconductor functional materials including the photocatalyst.

1 INTRODUCTION

Copper oxide (CuO) is a typical p-type

semiconductor with narrow band gap, excellent

optical and electronic properties, mechanical stability

and has been widely applied in fields of

photocatalysis (Du et al., 2019), gas sensors (Hou et

al., 2018), supercapacitors (Dong et al., 2016) and so

on. Hydrothermal method (Andana et al., 2017),

thermal oxidation of metallic Cu (Zhang et al., 2016)

were used to fabricate CuO, but both of them were

consist of high cost, complicated manipulations.

Therefore, exploring a facile method to fabricate CuO

was essential.

Surface science has played an important role in

chemical research (Borders et al., 2018). Fabrication

of materials at gas-liquid interface is an important

branch, which has aroused a great attention because

of its novelty (Hsieh et al., 2016). Generally,

photochemical method (Hoshyarmanesh et al., 2016),

self-assembly method (Long et al., 2017) were used

to fabricate materials on gas-liquid interface.

Compared with above methods, chemical bath

deposition (CBD) can fabricate materials with high

performance because of its homogeneity,

controllability and high production (Yang et al.,

2016). However, as far as we know, fabricating

materials at gas-liquid interface via CBD has not

been reported yet.

In this work, we develop a new chemical bath

deposition method to fabricate CuO nanoflakes

directly at the gas-liquid interface of a solution of

CuSO

4

and NH

3

·H

2

O. The as-prepared CuO

nanoflakes exhibited excellent visible light

photocatalytic activity in degradation of RhB. The

method is easily-manipulated, low-cost,

environmental friendly.

2 EXPERIMENT SECTION

2.1 Materials

CuSO

4

.

5H

2

O (AR, 99%), hydrogen peroxide (AR)

and RhB (AR) were purchased from DaMao

Chemical Reagent Factory (Tianjin, China).

Ammonia (AR) was purchased from Guangzhou

Chemical Reagent Factory (Guangzhou, China).

2.2 Preparation of CuO Nanoflakes

The CuO nanoflakes were prepared by CBD method.

A typical procedure is described as following: Firstly,

2.5 g of CuSO

4

.

5H

2

O was dissolved in 200 mL of

distilled water in a beaker. Secondly, 8 mL of 25%

ammonia solution was gradually dropped into the

mixed solution by a pipette and a piece of filter paper

was put at the bottom of the beaker. The mixed

solution was heated at 90 ℃ in a water bath. CuO

208

Lin, X. and Sun, F.

Fabrication of CuO Nanoflakes at Gas-liquid Interface Via Chemical Bath Deposition with High Photocatalytic Activity.

DOI: 10.5220/0008187702080211

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 208-211

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

nanoflakes could form at the gas-liquid interface after

1 hour. The product was picked up by a glass sheet

and washed by distilled water, following by drying at

60 ℃ for 12 hours. The dried product was finally

ground into powder before storage.

2.3 Materials Characterization

The morphologies of CuO nanoflakes were

investigated via scanning electron microscopy (SEM,

Carl Zeiss Gemini 500), The chemical composition

was characterized via X-ray powder diffraction

(XRD, BRUKER D8 ADVANCE D/max2200, with

Cu-Kα radiation) in which the diffraction peaks and

the indices of crystallographic plane were

characterized by MDI Jade 6.5. The UV–Vis diffuse

reflectance spectra (DRS) of all samples were

measured with Shimadzu UV-2700

spectrophotometer.

2.4 Measurement of Photocatalytic

Activity

Firstly, 0.025 g of as-prepared CuO nanoflakes

catalyst was added in 100 mL of RhB aqueous

solution in a beaker and the solution was ultrasonic

treated until the catalyst was dispersed and 4 mL of 3%

H

2

O

2

was added. The mixture was sequentially

stirred for 30 minutes in dark in order to achieve

absorption equilibrium. Secondly, two 150 W

commercial tungsten halogen lamps with 420 nm

cut-off filter were employed as visible light source

and a condenser pipe was immersed into the solution

to keep the photocatalytic reactions occur at room

temperature. Thirdly, 5 mL of mixed solution was

taken out every 20 minutes from beaker and

centrifuged at a speed of 4000 r/min for 2 minutes to

remove any solids after the photocatalytic reaction

started. The absorbance of the clarified liquid was

measured by UV–Vis spectrophotometer (SP-752,

Shanghai Spectrum, China) at a wavelength of 553

nm, which is consistent with the maximum

absorption wavelength of RhB. The

photodegradation rate η (%) was calculated by the

following formula:

η= C

t

/ C

0

× 100%

where η is the photodegradation rate (%), C

0

is

concentration of RhB after the absorption, and C

t

is

concentration of RhB at time t during photocatalytic

reaction.

3 RESULTS AND DISCUSSION

3.1 Composition and Morphology

Characteristic

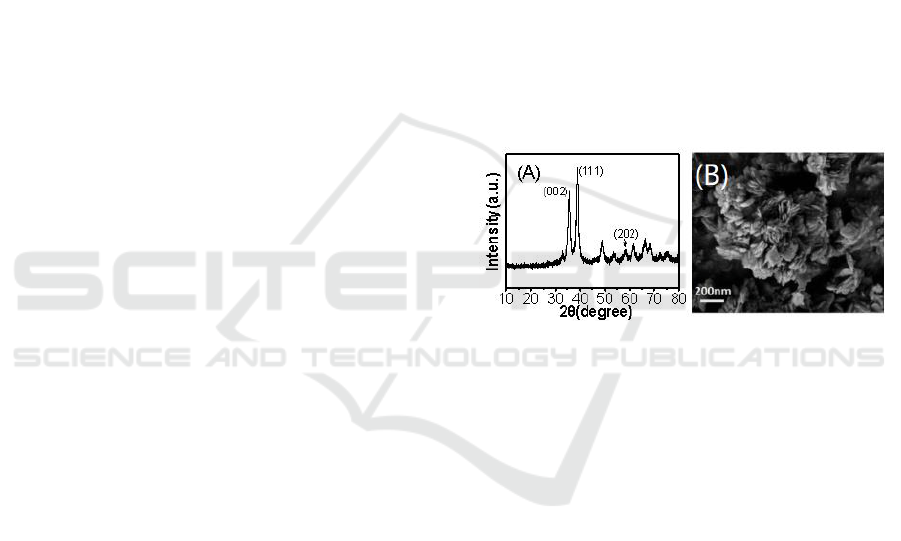

Figure 1A shows the XRD pattern of CuO formed at

the gas-liquid interface. Diffraction peaks at 35.5

o

,

38.7

o

and 2θ=58.0

o

correspond to the (002), (111) and

(202) planes of tenorite CuO (JCPDS card No.

48-1548) (Ahmadi and Siadati, 2018). The high

intensity of the peaks reveals that the CuO has high

crystallinity. No other diffraction peaks were

observed in the XRD pattern, meaning that the

as-fabricated sample had high purity. Figure 1B

shows the morphology of the as-fabricated CuO

nanoflakes. It could be clearly observed that the

sample was composed of uniform and rhombus

nanoflakes, which was corresponding to its tenorite

crystal system mentioned above and their average

thickness was 20 nm.

Figure 1: XRD spectrum (A) and SEM image (B) of CuO

nanoflakes.

3.2 Growth Mechanism

Briefly, when ammonia was added into the CuSO

4

solution, it could combine Cu

2+

ions by coordination

action to gradually produce [Cu(NH

3

)

4

]

2+

ions (Eq. 1).

During the subsequent CBD process, the ions would

gradually transformed into CuO (Eqs. 2-4). The

gas-liquid interface acts as a special nucleation site

which induces the formation of CuO nanoflakes by a

self-assembling process (Terasako et al., 2015).

H2CuO2)OH(Cu

H2)OH(CuOH2Cu

NH4Cu])NH(Cu[

OH4])NH(Cu[OHNH4Cu

2

22

2

3

22

43

2

2

4323

2

3.3 Photocatalytic Activity

To analyze the photocatalytic activity of CuO

nanoflakes (CuO flake), the degradation reactions of

RhB after the addition of CuO nanoflakes

commercial CuO powder (C-CuO), P25 with H

2

O

2

(1)

(3)

(4)

(2)

Fabrication of CuO Nanoflakes at Gas-liquid Interface Via Chemical Bath Deposition with High Photocatalytic Activity

209

and

pure

H

2

O

2

without catalyst were observed and the

degradation rate of RhB were calculated and

compared. Before the reaction, the catalysts were

added into RhB aqueous solution and the solution

was ultrasonic treated until the catalyst was well

dispersed. The mixture was then kept in dark for 30

minutes to build an absorption−desorption

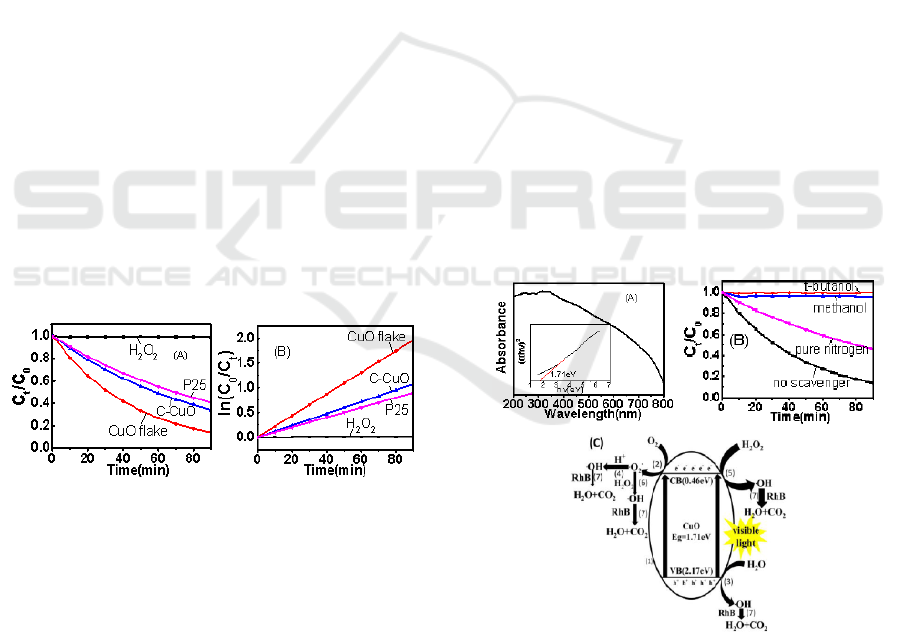

equilibrium. The result indicated that the sample

nearly had no discernible adsorption for the RhB

aqueous solution. The results of degradation rate of

RhB in 90 minutes were shown in Figure 2A. The

RhB aqueous solution with CuO flake catalyst and

3%H

2

O

2

added had obtained excellent

photodegradation rate and the corresponding value

could reach 85.9%, while the solutions with C-CuO

and P25 had degradation rate of 65.9% and 59.3%,

respectively. Furthermore, concentration of RhB

aqueous solution was almost constant when pure

H

2

O

2

was added, which reveals that pure H

2

O

2

had

poor activity. The curve of apparent reaction rate

(ARR) constant of CuO nanoflakes, C-CuO, P25 with

H

2

O

2

and

pure

H

2

O

2

added in RhB aqueous solution

and the corresponding ARR constant were calculated

and poltted in Figure 2B. It could be obviously

observed that the curve of ARR constant followed the

pseudo-first-order kinetics. The corresponding

equation was suggested as followings: ln(C

0

/C

t

) = kt

(Sudrajat et al., 2018), where k represents the

apparent reaction rate (ARR) constant. The

corresponding ARR constant of catalyst was 0.0218

min

-1

for CuO nanoflakes, 0.0119min

-1

for C-CuO,

0.0100min

-1

for P25, and 0.0001min

-1

for pure

H

2

O

2.

Figure 2: The photocatalytic activities of CuO nanoflakes,

commercial CuO powder, P25 with H2O2 and pure H2O2

without catalyst (A) The degradation rates of RhB in 90

minutes; (B) The curve of apparent reaction rate (ARR)

constant of CuO nanoflakes, C-CuO, P25 with H2O2 and

pure H2O2 without catalyst.

3.4 Mechanism of Photocatalysis

The optical property of CuO nanoflakes was

measured by ultraviolet-visible (UV-Vis) diffuse

reflectance spectra (DRS) and the result was shown

in Figure 3A. It can be observed in Figure 3A that the

absorption edge of the pure CuO sample is at

wavelength of about 725 nm and the corresponding

energy band gap (Eg) is ∼1.71 eV. The DRS results

indicate that CuO nanoflakes possessed narrow band

gap, which lead to higher photocatalytic activity. In

order to determine the effect of hole (h

+

), hydroxyl

radical (·OH), superoxide radical (·O

2

-

), we

additionally drop methanol, which was used as h

+

scavenger and t-butanol, which was used as OH

scavenger into the RhB aqueous solution, also, pure

nitrogen, which was considered as ·O

2

-

removal agent

was bubbled through the RhB aqueous solution in the

control photocatalytic experiments. As shown in

Figure 3B, compare with the solution without any

scavenger, the addition of methanol or t-butanol had

almost completely prevented the degradation of RhB,

while pure nitrogen was bubbled through the solution,

the degradation rate of RhB was obviously decreased.

Therefore, as Figure 3C indicated, holes and

electrons were generated when the semiconductor

was irradiated by UV light or visible light, during the

reaction, the photo-generated electrons react with

dissolved oxygen

and thus lead to the generation of

superoxide radicals, the superoxide radicals further

react with photo-generated holes, H

+

,

to form

hydroxyl radicals. Furthermore, the hydroxyl radicals,

which are conducive to the degradation of RhB, are

generated by the reaction of H

2

O

2

and

photo-generated electrons or superoxide radicals

(Wang et al., 2016, Li et al., 2018) and the reaction of

photo-generated holes and H

2

O (Huang et al., 2015,

Ma et al., 2018, Zhang et al., 2012).

Figure 3: (A) UV–vis diffuse reflectance spectra (DRS) and

band gap energy(inset) of CuO nanoflakes; (B)

Photodegradation dynamics of the RhB aqueous solution in

the presence of CuO nanoflakes, H

2

O

2

and t-butanol, CuO

nanoflakes, H

2

O

2

and methanol, CuO nanoflakes, H

2

O

2

and

pure nitrogen, CuO nanoflakes and H

2

O

2

, respectively; (C)

Schematic of proposed mechanism of the RhB aqueous

solution degradation in the presence of CuO nanoflakes and

H

2

O

2

.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

210

4 CONCLUSIONS

In summary, CuO nanoflakes at gas-liquid interface

was fabricated by a facile CBD method. The product

was composed of uniform and rhombus nanoflakes

with high crystalline. The CuO nanoflakes exhibited

excellent photocatalytic activity with the addition of

H

2

O

2

and the corresponding photodegradation rate

was 85.9%. The results indicated that fabricating

materials on gas-liquid interface via chemical bath

deposition was a promising method.

ACKNOWLEDGEMENTS

This work was co-supported by the National Natural

Science Foundation of China (No. 21571068), the

Natural Science Foundation of Guangdong Province

(No. 2015A030313387) and the Science and

Technology Program of Guangzhou (No.

201607010301).

REFERENCES

Ahmadi, M., Siadati, M.H., 2018. Synthesis, mechanical

properties and wear behaviour of hybrid

Al/(TiO

2

+CuO) nanocomposites. Journal of Alloys and

Compounds. 769, 713-724.

Andana, T., Piumetti, M., Bensaid, S., Veyre, L. et al.,

2017. CuO nanoparticles supported by ceria for

NOx-assisted soot oxidation: insight into catalytic

activity and sintering. Applied Catalysis B:

Environmental. 216, 41-58.

Borders, T., Wang, L., Fushimi, R., Redekop, E. et al., 2018,

Pulse response analysis using the Y-produce: A data

science approach. Chemical Engineering Journal. 192,

46-60.

Dong, C.J., Xing, X.X., Chen, N., Liu, X., Wang, Y.D.,

2016, Biomorphic synthesis of hollow CuO fibers for

low-ppm-level n-propanol detection via a facile

solution combustion method. Sensor. Actuat. B-Chem.

230, 1-8.

Du, X.D.,Zhang, Y.Q.,Si, F., Yao, C.H., Du, M.M. et al.,

2019, Persulfate non-radical activation by nano-CuO

for efficient removal of chlorinated organic

compounds: Reduced graphene oxide-assisted and

CuO (0 0 1) facet-dependent. Chemical Engineering

Journal.356, 178-189.

Hoshyarmanesh, H., Ghodsi, M., Park, H.H., 2016.

Electrical properties of UV-irradiated thick film

piezo-sensors on superalloy IN718 using

photochemical metal organic deposition. Thin Soild

Films. 616, 673-679.

Hou, L., Zhang, C.M., Li, L., Du, C., Li, X.K. et al., 2018.

CO gas sensors based on p-type CuO nanotubes and

CuO nanocubes: Morphology and surface structure

effects on the sensing performance. Talanta. 188,

41-49.

Hsieh, K., Wang, H. J., Locke, B.R., 2016. Analysis of a

gas-liquid film plasma reactor for organic compound

oxidation. Journal of Hazardous Materials.317,

188-197.

Huang, X.M., Ding, J., Zhong, Q., 2015. Catalytic

decomposition of H

2

O

2

over Fe-based catalysts for

simultaneous removal of NO

X

and SO

2.

Applied

Surface Science. 326, 66-72.

Li, D., Fang, M.J., Jiang, C.L. et al., 2018. Size-controlled

synthesis of hierarchical bismuth selenide nanoflowers

and their photocatalytic performance in the presence

of H

2

O

2

. Journal of nanoparticle research. 20.

Long, J., Yang, Z.H., Zeng, X., Huang, J.H., 2017.

Self-assembly of exfoliated layered double hydroxide

and graphene nanosheets for electrochemical energy

storage in zinc/nickel secondary batteries. Journal of

Powder Source.359, 111-118.

Ma, X.Y., Xiang, Q.J., Liao, Y.L., Wen, T.L., Zhang, H.W.,

2018. Visible-light-driven CdSe quantum

dots/graphene/TiO

2

nanosheets composite with

excellent photocatalytic activity for E. coli disinfection

and organic pollutant degradation. Applied Surface

Science. 457, 846-855.

Sudrajat, H., Hartuti, S., 2018. Structural properties and

catalytic activity of a novel ternary CuO/gC

3

N

4

/ Bi

2

O

3

photocatalyst. Journal of Colloid and Interface

Science. 524, 227-235.

Terasako, T., Murakami, T., Hyodou, A., Shirakata, S.,

2015. Structural and electrical properties of CuO films

and n-ZnO/p-CuO heterojunctions prepared by

chemical bath deposition based technique. Solar

Energy Materials and Solar Cells.132, 74-79.

Wang, Q.L., Li, H.Y., Yang, J. H., Sun, Q., Li, Q.Y., Yang,

J.J., 2016. Iron phthalocyanine-graphene

donor-acceptor hybrids for visible-light-assisted

degradation of phenol in the presence of H

2

O

2

. Applied

Catalysis B: Environmental. 192, 182-192.

Yang, J., Cho, M., Lee, Y.K., 2016. Synthesis of

hierarchical Ni(OH)

2

hollow nanorod via chemical bath

deposition and its glucose sensing performance.

Sensor. Actuat. B-Chem. 222, 674-681.

Zhang, G.Q., Li, Z., Wang, X., Zheng, H.Y., Hao, Z.Q.,

Wang, J.J., 2016. Influence of surface oxygenated

groups on the formation of active Cu species and the

catalytic activity of Cu/AC catalyst for the synthesis of

dimethyl carbonate. Applied Surface Science.390,

68-77.

Zhang, N., Zhang, Y.H., Xu, Y.J., 2012. Recent progress on

graphene-based photocatalysts: current status and

future perspectives. Nanoscale. 4, 5792-5813.

Fabrication of CuO Nanoflakes at Gas-liquid Interface Via Chemical Bath Deposition with High Photocatalytic Activity

211