Adsorption of Cd (II) from Aqueous Solutions by a Hydroxyapatite-

Biochar Composite

Xiaowen Fu

1

, Lei Ji

1

, Qiang Zhang

1*

, Tianyuan Li

1

, Liwen Zheng

1

, Jianing Wang

1

and Shuhai Guo

1,2

1

Ecology Institute, Qilu University of Technology (Shandong Academy of Sciences), East Jingshi Road, Jinan, China

2

Institute of Applied Ecology, Chinese Academy of Sciences, Wenhua Road, Shenyang, China

Keywords: Biochar, Hydroxyaptite, Adsorption, Cadmium

Abstract: Based on the rice husk biochar(BC), a creative hydroxyapatite(HA)-biochar composite (HAC) was

fabricated in this study. SEM coupled with EDS, BET and XRD were employed to analyze the surface

features and pore structures of BC, BC+HA (the mixture of BC and HA) and HAC. The effects of solution

initial pH and the contact time between sorbents and Cd were also investigated. The results revealed that, on

the surface of HAC, HA was well loaded. Though initial pH and contact time would significantly influence

the adsorbing effects of Cd by all three sorbents, HAC showed a high efficient and capacity to adsorb Cd (II)

in the aqueous solutions than simple biochar, and a low cost than adding nano-HA.

1 INTRODUCTION

Heavy metals are known as one type of the most

severe contaminants in the environment because of

their toxicity and threaten to the ecological system

and human beings (Ahmad et al., 2014). Among

numbers of heavy metals, Cadmium(Cd) receives

the most concern because of its toxic, solubility,

mobility and biological accumulation (Wang et al.,

2015). The farmland and surrounding water bodies

are vulnerable to threaten from Cd contamination,

which is enhanced by industrial sludge, wastewater

irrigation, atmospheric pollutant settlement, and

utilization of organic fertilizer and pesticides (Lin et

al., 2015). Numerious former researches have

reproted several methods to solve heavy metal

contaminations from aqueous solutions, including

ion exchange, sedimentaiton, adsorption, biological

treatment, and electrokinetic remediation (Maatar

and Boufi, 2015). Among these methods, adsorption

has received more and more attentions due to their

advantages in treating heavy metals in the

enviroment, such as high efficiency, low cost, easy

to use, selectivity and so on (Tapaswi et al., 2014).

Biochar, as a form of biomass-derived black

carbon, is a type of adsorbent with high surface area

and good cation exchange property. It is generally

pyrolyzed under anaerobic condition by raw

materials of waste biomass, including agriculture

and forest by-products (Xinde et al., 2009). The

heavy metal adsorption mechanism of biochar

includes surface adsorption, metal exchange with

cations, electrostatic interactions and so on (Lu et al.,

2012). However, the utilization of biochar is limited

to its relatively low heavy metal adsorption capacity.

Therefore, researchers have developed many

modification mathods for biochar, espetially surface

modifications by combining nanoparticles to prepare

biochar-based nanocompsites (Ying et al., 2013).

After modifications, biochar’s removal ability of

heavy metals will be remarkably improved (Zhang

and Gao, 2013).

Hydroxyapatite (HA), naturaly found in bones

and teeth of annimals, has been confirmed to have

high adsorption capacity of divalent metal ions due

to the existence of immobilizing metallic cations of

P-OH groups and Ca on its surface (Saoiabi et al.,

2016). However, nano-HA has the defect of tending

to aggregate in clumps and encapsulated in aqueous

solutions, which will enfluence its surface character

and metal removal ability. Wang et al. reported that

with a macroporous adsorbent as the carrier, the

above disadvantages would be avoided (Wang et al.,

2018). Biochar-based adsorbent composited with

HA is produced to achieve desirable adsorption

properties.

In this work, a rice-husk based hydroxyapatite-

biochar composite (HAC) was fabricated to produce

Fu, X., Ji, L., Zhang, Q., Li, T., Zheng, L., Wang, J. and Guo, S.

Adsorption of Cd (II) from Aqueous Solutions by a Hydroxyapatite-Biochar Composite.

DOI: 10.5220/0008186601230126

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 123-126

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

123

a higher removing capcities of Cd(II) in aqueous

solutions. The physical-chemical characteristics of

HAC were analyzed and compared with these of

biochar pyrolized from rice husk (BC) and the

physical mixture of BC and hydroxyapatite

(BC+HA). The effects of solution initial pH and

contact time were also studied.

2 MATIERALS AND METHODS

All chemical reagents used were in analytical

reagent grade and all the aqueous solutions were pre

pared with deionised water (DW). The nano-particle

hydroxyapatite (HA) was purchased from the

Macklin Biochemical (Shanghai, China). The rice

husks were derived from farmlands of Ulanhot,

Inner Mongolia, China.

2.1 Sorbent Preparation

Rice husk was applied as the raw material of biochar

in this study. The biochar was prepared as the

progress below. Rice husk was pyrolyzed in a

programmable muffle furnace under an atmosphere

of nitrogen (100 cm

3

/min). The furnace was

programmed to heat to 500°C with a rate of

10 °C/min and keep for 3 hours. Biochar (BC) was

obtained after the pyrolyzed rice husk was cooled to

room temperature naturally.

After BC was prepared, the hydroxyapatite-

biochar (HAC) composite was fabricated with the

following process. The prepared BC (10.0 g) was

first added to a H

3

PO

4

(15 M) which was stirring

vigorous to form the suspension solution A. Then a

Ca(OH)

2

(0.001 M) solution was prepared as the

solution B. The pH levels of solutions A and B were

both adjusted to about 10.0 with HCl or NaOH

(0.1M). After that, solution A and B were mixed

gradually. In the next 24 hours, the mixed solution

was stirred occasionally and the pH of which was

determined. After 24 h, the pH would achieve a

constant. Then the solution was centrifuged to

isolate the precipitate, which was washed three times

with ethanol. Finally, the HAC composite was

obtained after drying at the room temperature. The

mixture of BC and hydroxyapatite (BC+HA) was

obtained by a physical mixture and grind of BC and

the nano-particle hydroxyapatite with a ratio of 2:1.

2.2 Sorbent Characterization

The sorbents of BC, BC+HA, and HAC were all

characterized to compare similarities and differences.

Field emission scanning electron microscope

(Hitachi, SU8010) was applied to perform SEM

patterns of sorbents. The surface elemental

composition analysis of the sorbents was conducted

by energy-dispersive spectroscopy (EDS). Via a

X'Pert PRO MPD X-ray diffractometer, the XRD

patterns of sorbents were obtained. IR spectra from

4000-400 cm

−1

were measured on a Nicolet Nexus

470 FT-IR spectrometer. The specific surface area

was measured by a BET analyzer of Micromeritics

TriStar II 3flex.

2.3 Adsorption Experiments

In each adsorption kinetic experiment, 0.5 g sorbents

were added to Cd (II) solutions (500 mL, 50 mg/L)

and then stirred at 1000 rpm. Samples (0.5 mL) were

collected at noted different adsorption time (from 10

to 1500 min), filtered through the filter of 0.45 μm,

and analyzed via Atomic Absorption Spetrophoto-

meter (AAS). The impact of initial pH on adsorption

efficiency was performed by varying the solution’s

initial pH between 2 and 7 using NaOH or HNO

3

.

All solutions in experiments were performed in

40 mL brown glass vials and shaken in a

thermostatic oscillator with a speed of 150 r/min.

Through calculating the difference Cd(II)

concentrations between before and after the

adsorption equilibrium, the adsorption capacities of

adsorbents were valued. There were three replicates

for all experiments in this study. Standard solutions

were determined with every ten samples. The

recovery percentages were 97.6-104.3%, and the

relative standard deviations were below 2.45%.

3 RESULTS AND DISCUSSION

3.1 Characterization of Sorbents

The elemental contents of BC, BC+HA and HAC

are shown in Table 1, indicating significant

differences between three materials. BC+HA and

HAC both showed significant decrease in surface

carbon content and increase in surface oxygen

content compared to BC. This result implied the

existence of larger amounts of oxygen-containing

functional groups and thus higher polarity in the

sorbents of HAC and BC+HA than BC. The results

of specific surface areas (S

BET

), and average pore

width of BC, BC+HA and HAC (Table 1) revealed

that all materials showed mesoporous structures. The

significant decrease of surface area of HAC

suggested the occupation of pores of BC by HA,

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

124

which could also explained by the increase of

average pore width.

Table 1: Selected physiochemical properties of BC,

BC+HA and HAC.

Sorbents

BC

BC+HA

HAC

Surface atomic composition (%)

C

66.8±1.08

18.1±0.44

16.1±0.61

O

29.1±1.39

38.9±0.67

37.9±0.77

P

-

11.6±0.18

3.79±0.15

Ca

-

22.5±0.29

16.0±0.29

S

BET

(m

2

/g)

204.8

193.7

68.64

Pore width

(nm)

4.34

14.36

12.41

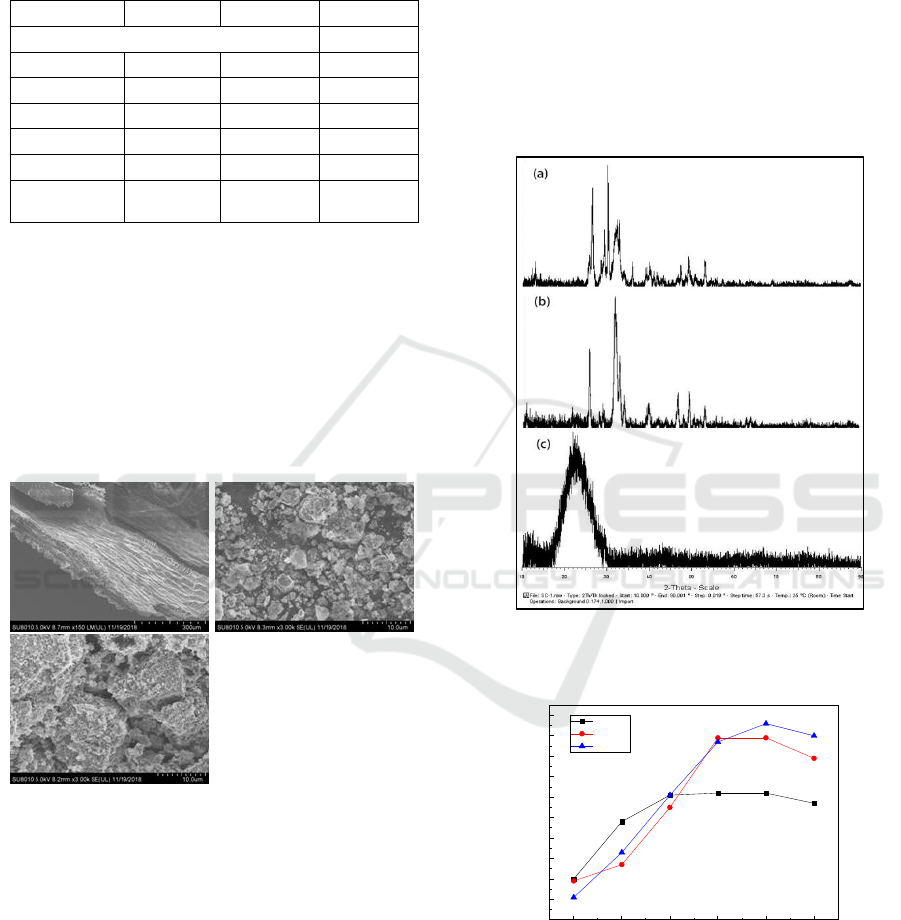

SEM images of BC, BC+HA and HAC showed

the clear differences among three sorbents. BC

showed a porous structure on its surface which

indicating adsorption sites (Figure 1a). The surface

of BC+HA and HAC both featured larger numbers

of particles (Figure 1b&c), which could be thought

as composing of hydroxyapatite deposited on the

surface of biochar. This conclusion was supported

by the fact of the increased percentages of Ca and P

on the surface of BC+HA and HAC (Table 1).

Figure 1: Electron microscopy of BC (a), BC+HA (b) and

HAC (c).

The XRD results of BC, BC+HA and HAC were

shown in Figure 2. The pattern of BC shows a broad

hump peak at 23°, which indicates that the sample

was amorphous. The XRD patterns of BC+HA and

HAC were similar and significantly different from

that of BC, indicating that HAP was loaded on the

surface of the two biochars of BC+HA and HAC.

3.2 Effects of Initial pH

Figure 3 shows that initial pH is a very vital factor

that affected the adsorption rates and processes of

BC, BC+HA and HAC. The Cd (II) adsorption

capacity increased when the initial pH ranged from 2

to 6, due to the electrostatic interactions were

facilitated by affecting the electric charge density of

the surface, resulting the increase of adsorption rate

(Jefferson et al., 2015). However, when the initial

pH was higher than 7, the metal-deposition reactions

of Cd(II) led to the decrease of soprtion rates .

Figure 2: XRD patterns of BC (c), BC+HA (a) and HAC

(b).

2 3 4 5 6 7

0

10

20

30

40

50

60

70

80

90

100

uptake percentage (%)

pH

BC

BC+HA

HAC

Figure 3: Effects of initial pH on the adsorptions of Cd.

3.3 Sorption Kinetics

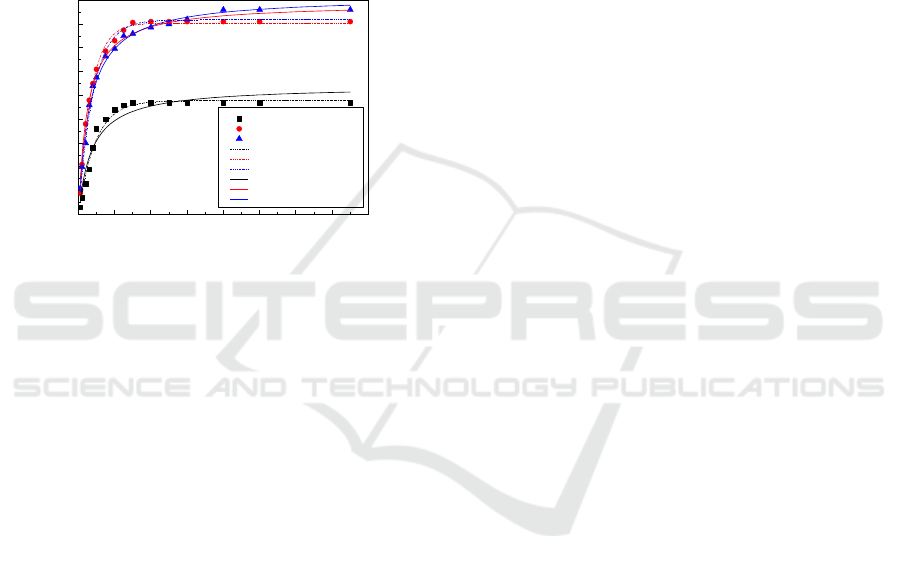

Figure 4 revealed the Cd(II) sorption kinetics of

three adsorbents in aqueous solutions. The

adsorption rates increased quickly during the first

(a)

(b)

(c)

Adsorption of Cd (II) from Aqueous Solutions by a Hydroxyapatite-Biochar Composite

125

200 mins. Almost 90% of the ultimate sorption

occurred in the first 300 mins for all three sorbents,

and follwed with a quick approach to the

equilibrium. The Cd (II) removal percentages by BC,

BC+HA and HAC at equilibrium were 41.1%,

80.5%, and 82.7%, respectively. To fit the

experimental data, equations of pseudo first order

and pseudo second order were both used. For HAC,

the R

2

value of pseudo-second-order model (0.992)

was relatively higher than that of pseudo-second-

order model (0.982), indicating the chemisorption

involved between Cd(II) and sorbents in the sorption

process.

0 200 400 600 800 1000 1200 1400 1600

0

5

10

15

20

25

30

35

40

45

BC

BC+HA

HAC

pseudo-1st-order of BC

pseudo-1st-order of BC+HA

pseudo-1st-order of HAC

pseudo-2nd-order of BC

pseudo-2nd-order of BC+HA

pseudo-2nd-order of HAC

sorption amount (mg/g)

time (min)

Figure 4: Cd(II) sorption kinetics of BC, BC+HA and

HAC.

4 CONCLUSIONS

Based on the rice husk biochar and the

hydroxyapatite, a hydroxyapatite-biochar composite

was fabricated in this study. Through characteristics,

effect of initial pH and kinetic analysis, HAC

showed a better sorption performace than pure

biochar and a lower cost than physical mixture of

biochar and hydroxyapatite. The results revealed that

HAC exhibited a potential application as an

excellent sorbent for Cd (II) reduction from polluted

waters.

ACKNOWLEDGEMENTS

This research was supported by the following funds:

the National Science Foundation of China

(41807111), the Shandong Provincial Natural

Science Foundation, China (ZR2016YL002), and the

Research Project (Youth Fund) of Shandong

Academy of Sciences (2017QN007).

REFERENCES

Ahmad, M., A. U. Rajapaksha, J. E. Lim, Z. Ming, N.

Bolan, D. Mohan, M. Vithanage, S. L. Sang and S. O.

Yong, 2014. Biochar as a sorbent for contaminant

management in soil and water: A review.

Chemosphere 99(3): 19-33.

Jefferson, W. A., C. Hu, H. Liu and J. Qu, 2015. Reaction

of aqueous Cu–Citrate with MnO 2 birnessite:

Characterization of Mn dissolution, oxidation products

and surface interactions. Chemosphere 119: 1-7.

Lin, W., X. Cui, H. Cheng, C. Fei, J. Wang, X. Zhao, C.

Lin and P. Xiao, 2015. A review of soil cadmium

contamination in China including a health risk

assessment. Environmental Science & Pollution

Research 22(21): 16441-16452.

Lu, H., W. Zhang, Y. Yang, X. Huang, S. Wang and R.

Qiu, 2012. Relative distribution of Pb 2+ sorption

mechanisms by sludge-derived biochar. Water

Research 46(3): 854-862.

Maatar, W. and S. Boufi, 2015. Poly(methacylic acid-co-

maleic acid) grafted nanofibrillated cellulose as a

reusable novel heavy metal ions adsorbent.

Carbohydrate Polymers 126: 199-207.

Saoiabi, S., A. Gouza, H. Bouyarmane, A. Laghzizil and

A. Saoiabi, 2016. Organophosphonate-modified

hydroxyapatites for Zn(II) and Pb(II) adsorption in

relation of their structure and surface properties.

Journal of Environmental Chemical Engineering 4(1):

428-433.

Tapaswi, P. K., M. S. Moorthy, S. S. Park and C. S. Ha,

2014. Fast, selective adsorption of Cu 2+ from

aqueous mixed metal ions solution using 1,4,7-

triazacyclononane modified SBA-15 silica adsorbent

(SBA-TACN). Journal of Solid State Chemistry

211(5): 191-199.

Wang, H., B. Gao, S. Wang, J. Fang, Y. Xue and K. Yang,

2015. Removal of Pb(II), Cu(II), and Cd(II) from

aqueous solutions by biochar derived from KMnO 4

treated hickory wood. Bioresource Technology 197:

356-362.

Wang, Y. Y., Y. X. Liu, H. H. Lu, R. Q. Yang and S. M.

Yang, 2018. Competitive adsorption of Pb(II), Cu(II),

and Zn(II) ions onto hydroxyapatite-biochar

nanocomposite in aqueous solutions. Journal of Solid

State Chemistry 261: 53-61.

Xinde, C., M. Lena, G. Bin and H. Willie, 2009. Dairy-

manure derived biochar effectively sorbs lead and

atrazine. Environmental Science & Technology 43(9):

3285-3291.

Ying, Y., G. Bin, C. Jianjun and Y. Liuyan, 2013.

Engineered biochar reclaiming phosphate from

aqueous solutions: mechanisms and potential

application as a slow-release fertilizer. Environmental

Science & Technology 47(15): 8700-8708.

Zhang, M. and B. Gao, 2013. Removal of arsenic,

methylene blue, and phosphate by biochar/AlOOH

nanocomposite. Chemical Engineering Journal

226(24): 286-292.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

126