Reversible Thermochromic and Phase Change Composites Based on

Dicarboxylic Acid

Lu Wang

1,2

, Xiuwen Wu

1*

, Huanhuan Wang

1,2

, Bingxu Hou

1,3

, Can Cai

1,2

and Jinlin Zhang

1

1

School of Science, China University of Geosciences, Beijing 100083, PR China

2

School of Energy Resources, China University of Geosciences, Beijing 100083, PR China

3

School of Earth Sciences and Resources, China University of Geosciences, Beijing 100083, PR China

Keywords: Thermochromism, Phase change materials, Visualising phase change phenomena, Ultraviolet absorption

Abstract: Reversible thermochromic and phase change dual functional composites were synthesized with crystal violet

lactone as the leuco dye, the mixture of stearic acid and decanoic acid as the developer and phase change

materials, and cetyl alcohol as the solvent by a process of grinding, mixing, stirring and heating. The samples

have a well reversible thermochromic and phase change properties. The enthalpies reached up to about 200

J/g. The phase change temperatures and color change temperatures are about 40°C – 50°C. The absolute

differences between the phase change temperatures and color change temperatures of the optimum samples

were ≤1.92°C, meaning that to visualise phase change phenomena with a colour indicator is feasible. The

samples also exhibited an excellent ultraviolet absorption property, meaning they could be used in ultraviolet

protection aspect besides using as the phase change materials and colour indicators.

1 INTRODUCTION

Recently, reversible thermochromic and phase

change dual functional composites have been

reported by some authors (Li et al., 2018). On the one

hand, due to the significant changes in their

absorption and fluorescent properties in response to

external stimulation, giving them numerous potential

applications such as thermal indicators, optical

storage devices and other luminescent switches

(Seyfouri and Buddhi, 2017; Kumar et al., 2017; Jin

et al., 2017; Carmona et al., 2010; Berdahl et al.,

2008; Raditoiu et al., 2016; Oswald et al., 2014; Jeong

et al., 2018; Oh et al., 2016; Ma et al., 2001; Ma et al.,

2002; Mapazi et al., 2017; Liu et al., 2017; PospíŠil

and Nešpurek, 2000; Malherbe et al., 2010; Wu et al.,

2014; Shobo and Mawire, 2017; Yu et al., 2017). On

the other hand, phase change materials based on the

heat absorption or release exhibited some outstanding

advantages in some areas, for example, solar heat

storage or industrial waste heat recovery (Zalba et al.,

2003; Sharma and Buddhi, 2005; Amin et al., 2016).

Most good results about phase change materials,

focused on building energy efficiency, solar heating

systems, air-conditioning systems, photovoltaic

systems, temperature adaptable greenhouse, thermo-

regulating fibers, smart textile materials, and so on,

have been reported (Sharma et al., 2009; Sharma et

al., 2014; Sarı, 2005; Kant et al., 2016; Sarı et al.,

2015; Sarı et al., 2004; Costa et al., 2009; Gandolfo

et al., 2003; Kim et al., 2017; Hasl and Jiricek, 2014;

Dimaano et al., 2002). There are many studies on

phase change materials or thermochromic materials,

but the materials having the reversible

thermochromic and phase change properties at the

same time have been less studied (Li et al., 2018; Wu

et al., 2014). The phase change materials in Li et al.

(Li et al., 2018) or Wu et al. (Wu et al., 2014) studies,

were single fatty alcohol, which led to definitive and

nonadjustable phase change temperatures, and this

would narrow their application. The phase change

temperatures could be adjusted by binary fatty acid in

some ratio (Sarı, 2006; Keleş et al., 2005; Wang and

Meng, 2010; Ding et al., 2017). The focus in this

study is to prepare reversible thermochromic and

phase change materials with adjustable phase change

temperatures by binary fatty acid, and to visualise

phase change phenomena with a colour indicator. The

samples were prepared by using crystal violet lactone

(CVL) as a leuco dye, the mixture of stearic acid (SA)

and decanoic acid (DA) as the developer, and cetyl

alcohol (CA) as the solvent. The similar study has not

been reported till now. The as-sythesized samples

Wang, L., Wu, X., Wang, H., Hou, B., Cai, C. and Zhang, J.

Reversible Thermochromic and Phase Change Composites Based on Dicarboxylic Acid.

DOI: 10.5220/0008186501150122

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 115-122

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

115

could be applied inenergy storage, colour indicators,

memory materials, and so on.

2 EXPERIMENTAL SECTION

2.1 Materials

SA with a mass fraction purity of 98.0% and CA with

a mass fraction purity of 98.0% were supplied by

Xilong Chemical Co.Ltd (China). DA with a mass

fraction purity of 98.5% was supplied by Sinopharm

Chemical Reagent Co., Ltd (China) and CVL with a

mass fraction purity of 95.0% was supplied by Tokyo

Chemical Industry Co. Ltd (China). All the reagents

were used without further purification as received.

2.2 Sample Preparation

Mixtures of CVL, stearic acid, decanoic acid and

cetyl alcohol in the mass ratio area 1: (5 – 8): (2 – 5):

(10 – 50) (Table 1) were firstly ground in a mortar for

15 min, and then transferred into a beaker. The solid

mixtures were heated to become the transparent

solutions, and then cooled automatically in the air to

form the solid samples. All the experiments were

repeated at least three times, and the experimental

data were given in average.

2.3 Characterization

Thermochromic properties tests were done as

follows. The samples were heated and cooled in air

between 20°C and 70°C to check the colour change

and the respective temperatures during the sample

melting and solidifying. The sample colour was

recorded by a digital photo. The colour change

temperatures were detected by an electronic

thermometer. To further test the thermochromic

properties of the samples, absorption bands were

analyzed by a UV-VIS-NIR Spectrometer

(UV3600PLUS, Japan) in the wave length area 200

nm – 850 nm. The scanning rate was medium, and

scanning step was 1 nm.

The sample thermal stability was determined

using a thermal gravimetric analyzer (American STA

Q5000 IR, TGA) at a scan rate of 10°C/min from

25°C to 500°C under a nitrogen atmosphere. A

typical mass of the samples used in the TGA analysis

was 2.5 mg – 4.2 mg.

The enthalpies, phase change temperatures and

thermal cycle stability of the samples were measured

using differential scanning calorimetry (American

Q2000, DSC). All experiments were carried out in

heating and cooling rates of 5°C/min in the

temperature area of −20°C – 80°C under a constant

flow of dry nitrogen (100 ml/min). DSC calibration

was done with certified Indium standard reference

material. The phase change temperatures were taken

at the intersection of an extrapolated base line and

tangent to the heat flow curve drawn at the inflection

point of the appropriate side of the peak. Enthalpies

of the samples were obtained by a numerical

integration of the area between the heat flow curve

and the extrapolated base line. The reproducibility

error of the calorimeter was within ±1%, and the

temperature ±0.01°C.

3 RESULTS AND DISCUSSION

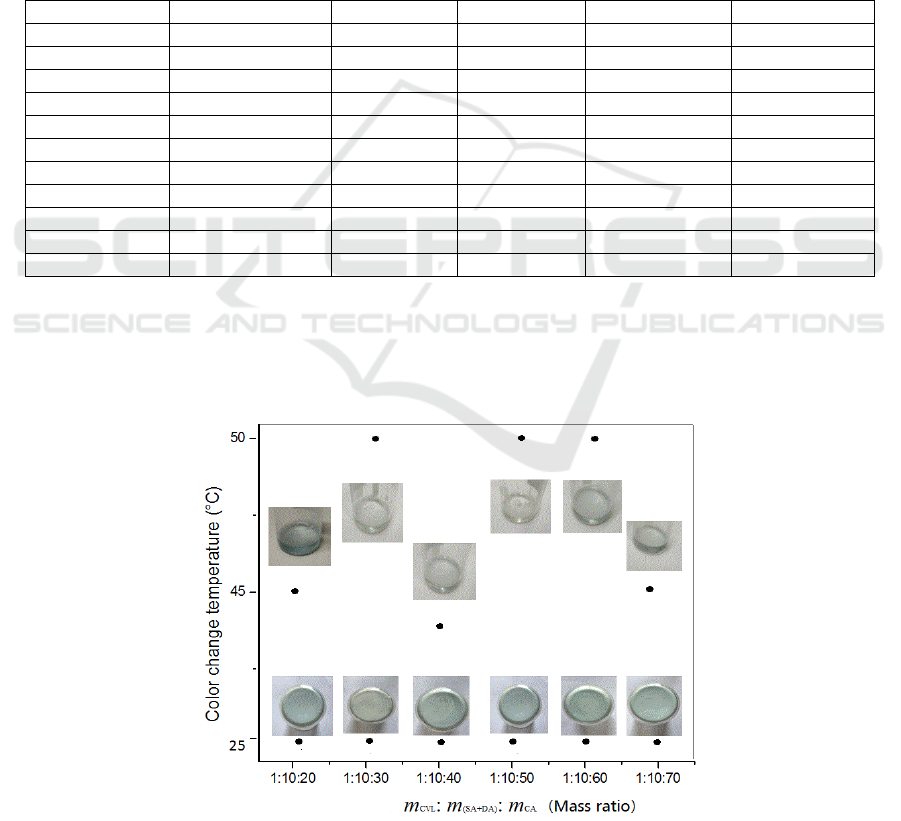

3.1 Thermochromic Properties

To synthesize the samples which have both high

latent heats in their phase change processes and

obvious color change phenomena, and the same

temperature area in their phase change processes and

thermochromic processes, a series of the raw material

ratios were used in preparing the samples. After some

preliminary experiments and found that the solvent

amount affects the sample color obviously. The

sample showed weak color and leaded to the

thermochromic phenomena were not easy to be

observed when the excessive solvent was used. But

the thermochromic phenomena did not occur when

the less solvent was used. The effect of the raw

material ratios to the thermochromic temperatures

was listed in Table 1, and the thermochromic

phenomena were recorded by the digital photos

(Figure 1). Thermochromic temperatures are usually

related with the melting or solidifying temperatures,

but they are not the same. The initial color change

temperatures in the melting processes and the

temperatures when the samples restored their initial

colors in the solidifying processes are in the

temperature areas of 40.90°C –48.90°C and 39.60°C–

46.00°C, and the melting and solidifying

temperatures are in the areas of 40.00°C–48.00°C and

34.20°C–39.60°C, respectively, when the raw

material (CVL, (SA+DA) and CA) mass ratio

changed from 1: (8+2): 10 to 1: (5+5): 50. No obvious

relationship was observed between the

thermochromic temperatures with the raw material

mass ratio. The samples SDC8210, SDC8220,

SDC6420 and SDC5520 could not restored their

initial colors in their solidifying processes when the

CA mass percentage ≤64.5%. The sample melting

and solidifying temperatures, normally related with

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

116

the phase change temperatures and they could be

tuned by changing the mass ratio of SA and DA which

were well studied in the previous study (Wu, 2016),

showed a decrease tendency with the SA and DA

mass ratio decreasing, this is in agreement with the

results reported before (Sarı, 2006; Keleş et al., 2005;

Wang and Meng, 2010; Ding et al., 2017), and

reasonable because DA melting temperature (31.5°C)

was lower than SA (60°C). The thermochromic

phenomena could be observed in the raw material

(CVL, (SA+DA) and CA) mass ratio area 1: 10: 30 –

1: 10: 70, and the mass ratio corresponding to the

most obvious color change was 1:10:50. All the

thermochromic phenomena showed a good repeat

ability, suggesting that the samples, except those of

the CA mass percentage ≤64.5%, could be applied as

color indicators of phase change phenomena if the

thermochromic temperatures and phase change

temperatures were much the same by selecting the

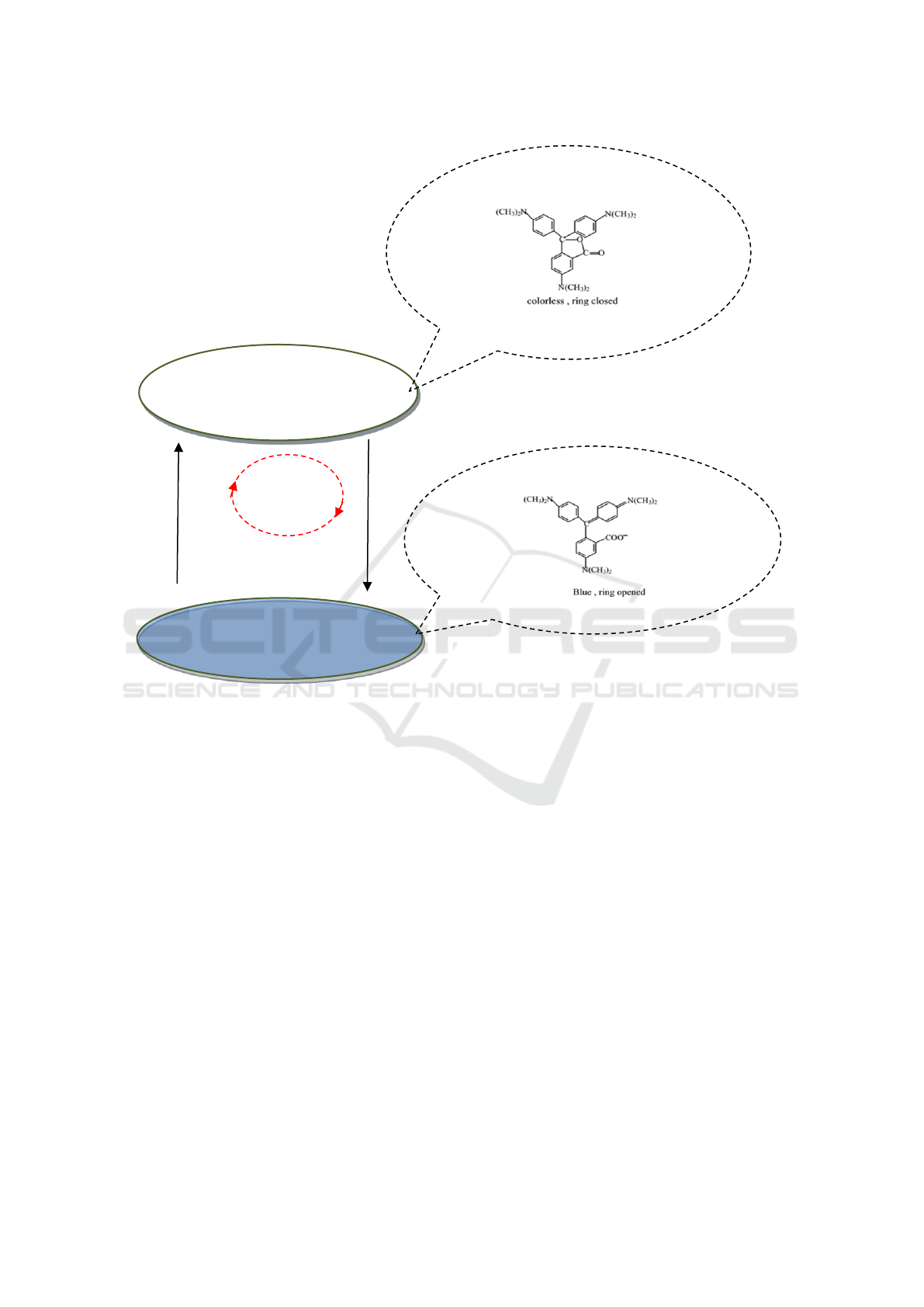

appropriate raw material ratios. For further explaining

the ideal thermochromic phenomena, a sketch about

sample color shown after many thermal cycles was

shown in Figure 2. When a sample is in a liquid state,

the CVL ring closes, and the sample is colorless.

When a sample is in a solid state, the CVL ring opens,

and the sample color is blue.

Table 1: Effect of raw material ratios to sample melting-solidifying temperatures and color change temperatures.

Sample

R

a

T

m

b

(°C)

T

s

b

(°C)

T

cm

c

(°C)

T

cs

c

(°C)

SDC8210

1: (8+2): 10

43.40

34.20

–

–

SDC8220

1: (8+2): 20

48.00

35.33

–

–

SDC8230

1: (8+2): 30

45.30

37.51

48.90

40.81

SDC8240

1: (8+2): 40

43.00

35.72

43.30

41.53

SDC8250

1: (8+2): 50

48.00

36.90

48.21

46.00

SDC6420

1: (6+4): 20

45.70

34.51

–

–

SDC5520

1: (5+5): 20

43.31

35.54

–

–

SDC8260

1: (8+2): 60

43.22

37.21

48.70

43.00

SDC8270

1: (8+2): 70

43.01

39.60

45.02

39.60

SDC6450

1: (6+4): 50

40.00

35.91

40.90

40.50

SDC5550

1: (5+5): 50

42.20

35.53

44.53

41.04

a

Mass ratio of CVL: (xSA+yDA): zCA.

b

Sample melting temperatures and solidifying temperatures.

c

Sample initial color change temperatures in melting processes and temperatures when samples restored their initial

colors in solidifying processes.

Figure 1: Digital photos of samples in heating and cooling processes.

Reversible Thermochromic and Phase Change Composites Based on Dicarboxylic Acid

117

Figure 2: Sketch of sample color shown after many thermal cycles.

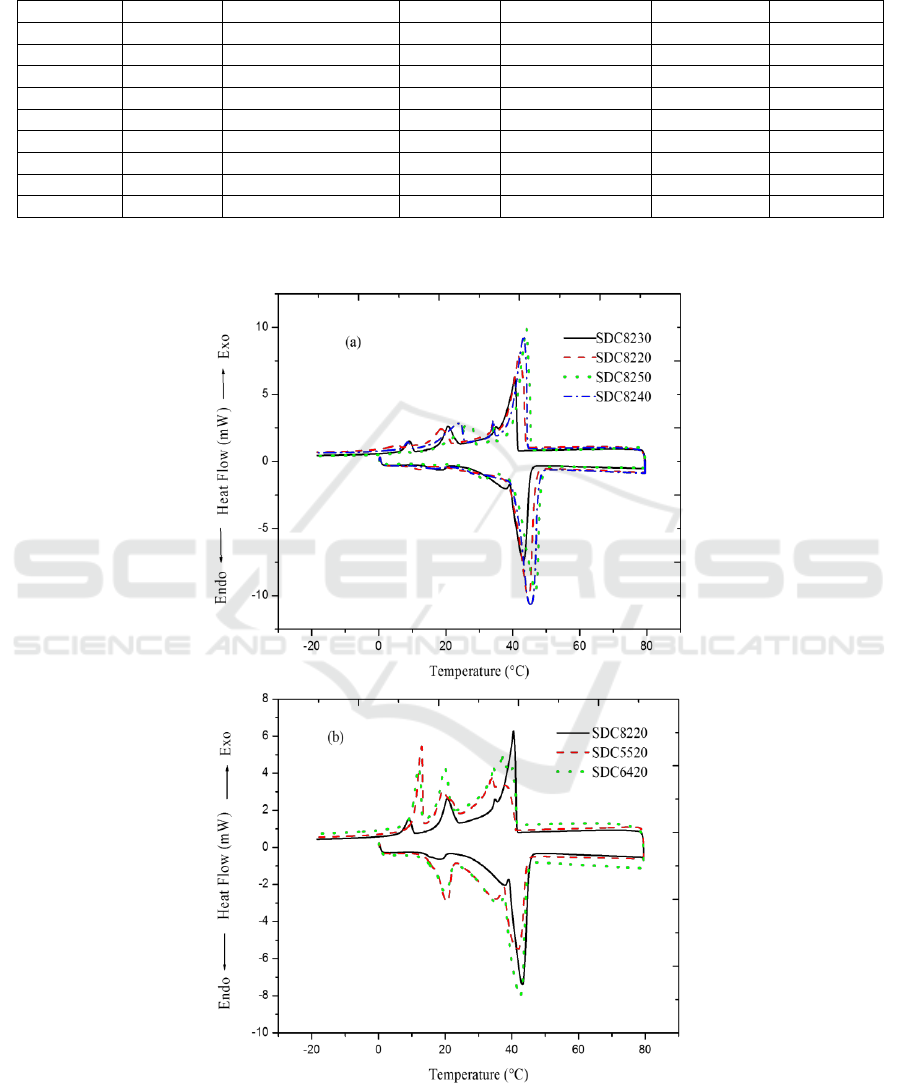

3.2 Phase Change Properties

The phase change parameters of all the samples,

except SDC8210, SDC8220, SDC6420 and

SDC5520 for the undetected thermochromic

phenomena or bad thermochromic repeatability, were

listed in Table 2, and the DSC curves were shown in

Figure 3. The melting and solidifying enthalpies are

in the areas of 190.3 J/g – 208.6 J/g, and 184.4 J/g –

214.2 J/g, respectively. The enthalpies increased and

then showed a decrease tendency when the mass

percentage of CA increased from 73.17% to 86.42%,

with a turn point at 81.97%. The phase change

temperatures are in the areas of 40.25°C – 47.96°C

and 41.67°C – 44.31°C, respectively, in the melting

and solidifying processes, and showed an increase

tendency in the melting process with the CA mass

percentage increasing from 73.17% to 86.42% when

the mass ratio of SA and DA was 8: 2. The reason

about the increase tendency is that the CA as both of

an solvent and phase change material has a relatively

higher phase change temperature (49.6°C) compared

with that of the mixture of SA and DA. When the

mass ratio of SA and DA decreased from 8: 2 to 5: 5,

the phase change temperatures are in the areas of

40.25 °C – 47.75 °C, and 42.33 °C – 44.08 °C,

respectively, in the melting and solidifying processes.

But no obvious changing tendency in the phase

change temperatures was found related with the mass

ratio of SA and DA. The optimum mass ratio of CVL,

DA, SA and CA, evaluated by the enthalpies, the

phase change temperatures and the thermochromic

temperatures, are 1: 6: 4: 50 and 1: 8: 2: 50,

corresponding to the samples SDC6450 and

SDC8250. The phase change parameters of these two

samples are as follows.

Thermal

cycles

Sample in liquid state

Sample in solid state

Melting

CVL

CVL

Solidify

ing

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

118

Table 2: Sample phase change properties.

Sample

T

pm

a

(°C)

ΔT

m

=T

cm

-T

pm

(°C)

T

ps

b

(°C)

ΔT

s

=T

cs

-T

ps

(°C)

△H

m

a

(J/g)

△H

s

b

(J/g)

SDC8230

44.63

+4.27

41.67

−0.87

191.7

184.4

SDC8240

45.17

−1.87

44.31

−2.81

203.7

194.3

SDC8250

47.75

+0.45

44.08

+1.92

207.7

214.2

SDC6420

42.38

+2.22

37.44

–

197.1

184.8

SDC5520

41.84

+2.66

37.86

–

196.4

185.4

SDC6450

40.25

+0.65

42.33

−1.83

208.6

202.1

SDC5550

41.09

+3.41

43.15

−2.15

205.2

196.8

SDC8260

46.87

+1.83

43.04

−0.04

190.3

194.1

SDC8270

47.96

−2.96

43.64

−4.04

198.6

193.6

a

Phase change temperature and enthalpy in melting process.

b

Phase change temperature and enthalpy in solidifying process.

Figure 3: DSC curves of samples.

Reversible Thermochromic and Phase Change Composites Based on Dicarboxylic Acid

119

The Phase change temperatures and latent heats in

melting and solidifying processes: 40.25°C and

42.33°C, 208.6 J/g and 202.1 J/g of SDC6450,

47.75°C and 44.08°C, 207.7 J/g and 214.2 J/g of

SDC8250. The absolute differences between the

phase change temperatures and color change

temperatures were ≤1.92°C, meaning that the original

experimental goal was achieved, and visualising

phase change phenomena with a colour indicator is

feasible. The extra relative weak peaks existing in

Figure 3 caused by the phase seperation, and this

could be weaken by prolonging the mixing time our

mixing method (Li et al., 2018; Wu, 2016).

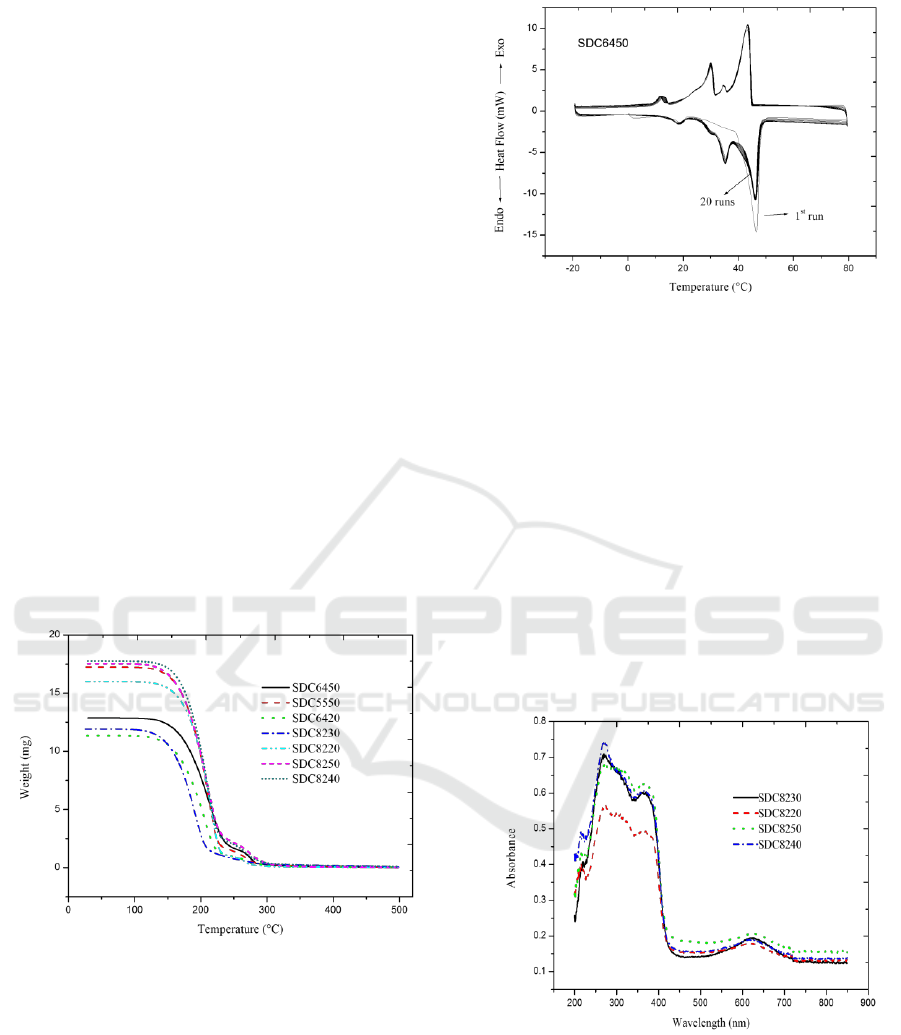

3.3 Thermal Stability

The thermal stability of the samples were evaluated

by the thermogravimetric analysis and the parameters

of the sample thermochromism and phase change

processes after some thermal runs. The

thermogravimetric curves of the samples were

presented in Figure 4. The curves of the samples were

horizontal when the temperatures were ≤130°C and

≥280°C, with a sharp weight loss in the temperature

area of 130°C – 225°C, indicating that the samples are

thermal stable at ≤130°C, or in their phase change

processes.

Figure 4: TGA curves of samples.

To evaluate the sample thermal durability,

SDC6450 was chosen as a representative. The DSC

curves of SDC6450 from the 1st to 20th runs were

presented in Figure 5. No obvious changes in the

enthalpies and the phase change temperatures were

detected from the 1st to 20th runs.

3.4 UV-VIS-NIR Spectrometer

Analysis

Figure 6 showed the absorption spectra of the

samples at 25°C. In the visible region, an steamed

bun peak at 550 nm – 650 nm could be seen,

corresponding to yellow and orange light regions.

This was consistent with the sample color (light blue)

appeared in the thermochromic experiments. In the

ultraviolet region, there was a wide and strong

absorption peak in the area 230 nm – 380 nm,

indicating other potential application related with this

property, such as ultraviolet protection equipment.

Figure 6: UV-VIS-NIR spectral curves of samples.

Figure 5: DSC curves of SDC6450 from 1st run to

20th run.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

120

4 CONCLUSIONS

Reversible thermochromic and phase change dual

functional materials were prepared with the raw

materials CVL, DA, SA and CA by mixing, heating

and cooling processes. The adequate mass ratio of

CVL, (SA+DA) and CA are in the area 1: 10: 30 – 1:

10: 70. The melting and solidifying enthalpies of the

samples reached up to 208.6 J/g and 202.1 J/g

corresponding to the mass ratio of CVL, (SA+DA)

and CA 1: (6+4): 50. The phase change temperatures

of the samples (40.25°C – 47.96°C) were well

matched with the thermochromic temperatures

(39.60°C – 48.90°C). The samples have good thermal

stability in their phase change processes. The absolute

differences between the phase change temperatures

and color change temperatures of the optimum

samples were ≤1.92°C. In addition, the samples also

exhibited an excellent ultraviolet absorption property,

meaning they could be used in ultraviolet protection

aspect.

ACKNOWLEDGEMENTS

This work was supported by Fundamental Research

Funds for the Central Universities of China (NO.

2652017157), and National Undergraduate

Innovation Project of China University of

Geosciences, Beijing (NO. 201711415091,

2018AB069).

REFERENCES

Amin, M., Putra, N., Kosasih, E.A., Prawiro, E., Luanto,

R.A., Mahlia, T.M.I., 2016. Thermal properties of

beeswax/graphene phase change material as energy

storage for building applications. Applied Thermal

Engineering 112 273.

Berdahl, P., Akbari, H., Levinson, R., William, A., 2008.

Weathering of roofing materials – An overview.

Construction & Building Materials 22 (4) 423.

Carmona, N., Bouzas, V., Jiménez, F., Plaza, M., Pérez, L.,

García, M.A., Villegas, M.A., Llopis, J., 2010. Cobalt

(II) environment characterization in sol–gel

thermochromic sensors. Sensors & Actuators B

Chemical 145 (1) 139.

Costa, M.C., Sardo, M., Rolemberg, M.P., Ribeiro-Claro, P.,

Meirelles, A.J., Coutinho, J.A., Krahenbuhl, M.A.,

2009. The solid-liquid phase diagrams of binary

mixtures of consecutive, even saturated fatty acids:

differing by four carbon atoms. Chemistry & Physics of

Lipids 160 (2) 85.

Dimaano, M.N.R., Watanabe, T., 2002. Performance

investigation of the capric and lauric acid mixture as

latent heat energy storage for a cooling system. Solar

Energy 72 (3) 205.

Ding, L., Wang, L., Georgios, K., Lü, Y., Zhou, W., 2017.

Thermal characterization of lauric acid and stearic acid

binary eutectic mixture in latent heat thermal storage

systems with tube and fins. Journal of Wuhan

University of Technology-Materials Science Edition 32

(4) 753.

Gandolfo, F.G., Bot, A., Flöter, E., 2003. Phase diagram of

mixtures of stearic acid and stearyl alcohol.

Thermochimica Acta 404 (1) 9.

Hasl, T., Jiricek, I., 2014. The prediction of heat storage

properties by the study of structural effect on organic

phase change materials. Energy Procedia 46 301.

Jeong, J., Kumar, R.S., Naveen, M., Son, Y.A., 2018.

Synthesis, thermochromic, solvatochromic and axial

ligation studies of Zn-porphyrin complex. Inorganica

Chimica Acta 469 453.

Jin, Y., Bai, Y., Zhu, Y., Li, X., Ge, M., 2017.

Thermosensitive luminous fiber based on reversible

thermochromic crystal violet lactone pigment. Dyes &

Pigments 146 567.

Kant, K., Shukla, A., Sharma, A., 2016. Performance

evaluation of fatty acids as phase change material for

thermal energy storage. Journal of Energy Storage 6 (C)

153.

Keleş, S., Kaygusuz, K., Sarı, A., 2005. Lauric and myristic

acids eutectic mixture as phase change material for

low‐ temperature heating applications. International

Journal of Energy Research 29 (9) 857.

Kim, D., Kim, J.H., Kwon, S.H., Lee, S.O., Seo, B., Lim,

C.S., 2017. The studies of physical properties of

dimeric fatty acid-modified thiodiphenyl epoxy resins.

Polymer Bulletin 74 (11) 4595.

Kumar, R.S., Jeong, J., Mergu, N., Oh, W., Son, Y.A., 2017.

Solvent effect on the thermochromism of new betaine

dyes. Dyes & Pigments 136 458.

Li, Z., Wu, X.-W., Wu, N., Fan, Y.-Y., Sun, X.-C., Song,

T.-T., Zhong, Q., 2018. Shape-stabilized

thermochromic phase-change materials. Journal of

Thermophysics and Heat Transfer 32(1) 269.

Liu, H., Yuan, L., Qi, H., Wang, S., Du, Y., 2017. In-situ

optical and structural insight of reversible

thermochromic materials of Sm

3

-xBi

x

Fe

5

O

12

(x= 0, 0.1,

0.3, 0.5). Dyes & Pigments 145 418.

Ma, Y., Zhang, X., Zhu, B., Zhu, B., Wu, K., 2002.

Research on reversible effects and mechanism between

the energy-absorbing and energy-reflecting states of

chameleon-type building coatings. Solar Energy 72 (6)

511.

Ma, Y., Zhu, B., Wu, K., 2001. Preparation and solar

reflectance spectra of chameleon-type building

coatings. Solar Energy 70 (5) 417.

Malherbe, I., Sanderson, R.D., Smit, E., 2010. Reversibly

thermochromic micro-fibres by coaxial electrospinning.

Polymer 51 (22) 5037.

Mapazi, O., Matabola, P.K., Moutloali, R.M., Ngila, C.J.,

2017. A urea-modified polydiacetylene-based high

Reversible Thermochromic and Phase Change Composites Based on Dicarboxylic Acid

121

temperature reversible thermochromic sensor:

Characterisation and evaluation of properties as a

function of temperature. Sensors & Actuators B

Chemical 252 671.

Oh, W., Angupillai, S., Muthukumar, P., So, H.S., Son, Y.,

2016. Synthesis of novel tert-butyl substituted fluorans

and an investigation of their thermochromic behavior.

Dyes & Pigments 128 235.

Oswald, H., Lachmann, A., Roy, S., Chandratre, S., 2014.

Color changing cleansing composition. Clariant

Finance.

Pospı

́

Šil, J., Nešpurek, S., 2000. Photostabilization of

coatings. Mechanisms and performance Progress in

Polymer Science 25 (9) 1261.

Raditoiu, A., Raditoiu, V., Nicolae, C.A., Raduly, M.F.,

Amariutei, V., Wagner, L.E., 2016. Optical and

structural dynamical behavior of Crystal Violet Lactone

– Phenolphthalein binary thermochromic systems. Dyes

& Pigments 134 69.

Sarı, A., 2005. Eutectic mixtures of some fatty acids for low

temperature solar heating applications: Thermal

properties and thermal reliability. Applied Thermal

Engineering 25 (14) 2100.

Sarı, A., 2006. Eutectic mixtures of some fatty acids for

latent heat storage: Thermal properties and thermal

reliability with respect to thermal cycling. Energy

Conversion & Management 47 (9) 1207.

Sarı, A., Alkan, C., Özcan, A.N., 2015 Synthesis and

characterization of micro/nano capsules of

PMMA/capric–stearic acid eutectic mixture for low

temperature-thermal energy storage in buildings.

Energy & Buildings 90 (2) 106.

Sarı, A., Sarı, H., Önal, A., 2004. Thermal properties and

thermal reliability of eutectic mixtures of some fatty

acids as latent heat storage materials. Energy

Conversion & Management 45 (3) 365.

Seyfouri, M.M., Binions, R., 2017. Sol-gel approaches to

thermochromic vanadium dioxide coating for smart

glazing application. Solar Energy Materials & Solar

Cells 159 52.

Sharma, A., Buddhi, D., 2005. Effect of thermophysical

properties of the PCM and heat exchanger material on

the performance of a latent heat storage system.

International Journal of Sustainable Energy 24 (2) 99.

Sharma, A., Shukla, A., Chen, C.R., Wu, T.N., 2014.

Development of phase change materials (PCMs) for

low temperature energy storage applications.

Sustainable Energy Technologies & Assessments 7 17.

Sharma, A., Tyagi, V.V., Chen, C.R., Buddhi, D., 2009.

Review on thermal energy storage with phase change

materials and applications. Renewable & Sustainable

Energy Reviews 13 (2) 318.

Shobo, A.B., Mawire, A., 2017. Experimental comparison

of the dynamic operations of a sensible heat thermal

energy storage and a latent heat thermal energy storage

system. International Conference on Domestic Use of

Energy. IEEE 240.

Wang, L., Meng, D., 2010. Fatty acid eutectic/polymethyl

methacrylate composite as form-stable phase change

material for thermal energy storage. Applied Energy

87(8) 2660.

Wu, N., 2016. Preparation and properties of stearic acid

composite phase change materials [D]. Beijing: China

University of Geosciences 36.

Wu, Z., Ma, X., Zheng, X., Yang, W., Meng, Q., 2014.

Synthesis and characterization of thermochromic

energy-storage microcapsule and application to fabric.

Journal of the Textile Institute Proceedings &

Abstracts 105 (4) 398.

Yu, H., Wei, Z.H., Hao, Y.H., Liang, Z.W., Fu, Z.J., Cai,

H., 2017. Reversible solid-state thermochromism of a

2D organic–inorganic hybrid perovskite structure

based on iodoplumbate and 2-aminomethyl-pyridine.

New Journal of Chemistry 41 9586.

Zalba, B., José, M., Cabeza, L.F., Mehling, H., 2003.

Review on thermal energy storage with phase change:

materials, heat transfer analysis and applications.

Applied Thermal Engineering 23 (3) 251.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

122