A Soft-sencor and Parameter Optimization for Predicting Inulinase

Concentration at Recombinant Pichia Pastoris Fermentation Process

Qingqiang Guo

1

, Yingjia Zhang

1

, Yuxi Deng

1

and Xiuhong Wang

2*

1

School of Control science and engineering, Shandong University, Jinan 250061, China

2

Department of Electronic, Shandong College of Electronic Technology, Jinan 250061, China

Keywords: inulinase concentration, support vector machine, leave one out algorithm, particle swarm optimization

Abstract: Based on the least square support vector machine regression, a model is established to predict the inulinase

concentration during Pichia pastoris fermentation process, which is more suitable for the situation in which

there are more types but less numbers of input variables. To realize parameter optimization, leave one out

algorithm and particle swarm optimization algorithm are combined to recognize the model. Leave one out

algorithm is used as the target function to minimize the error of cross validation, and particle swarm

optimization algorithm is used to search the best parameters. The experimental results show that the

proposed model has better prediction accuracy than the soft-sensor based on standard support vector

machine. In addition, the proposed parameter optimization method can improve the prediction accuracy

significantly.

1 INTRODUCTION

Fructooligosaccharides has been widely used in

dietary supplements because it has many advantages,

such as indigestibility, caries resistance, improving

lipid metabolism and so on. One of the important

way to producing fructooligosaccharides is

hydrolysising inulin with endoinulinase that

obtained by Pichia pastoris (Zhang et al., 2004).

Pichia pastoris fermentation process involves many

important biochemical variables, which include

yeast concentration, methanol concentration and

inulinase activity concentration. According to many

type of input variables and little amount of samples,

it is difficult to set up the model of fermentation

process. The inulinase concentration still relies on

the offline analysis of enzyme activities, which not

only consumes lots of manpower and resources, but

also affects the implementation of real-time control

strategy and improvement of fermentation

technique.

Soft sensing is one of the effective ways to solve

the above measurement problem. Soft-sensor based

on Support Vector Machine (SVM) is more suitable

for the situation in which there are more types but

less numbers of input variables (Bogaerts and

Wouwer, 2003), since it uses a particular method to

compress process data information and extract the

feature of data to establish the relationship between

the dominant and auxiliary variables (Cortes and

Vapnik, 1995). Suykens proposed Least Squares

Support Vector Machines (LS-SVM), which not

only reduces the computational complexity, but also

accelerates the speed (Suykens and Vandewalle,

1999).

To optimize the kernel parameters setting for

SVM, Grid Search (GS) is done by minimizing some

estimates of the generalization error of SVM

(Chapelle et al., 2002). Huang presented a Genetic

Algorithm (GA) approach for feature selection and

parameters optimization (Huang and Wang, 2006).

Lin used Particle Swarm Optimization algorithm

(PSO) for parameter determination and feature

selection (Lin et al., 2008). Xi used Leave One Out

(LOO) method to cross validate the feature selection

result (Xi et al., 2016). While these methods deal

with offline data get good result, the balance

between speed and accuracy should be considered

when they are used in real-time control.

According to the character of our problem, a LS-

SVM based soft-sensor established to estimate and

predict inulinase concentration in the Pichia pastoris

fermentation process, which was difficult to be

measured online. Considering LS-SVM parameters

have important influence on the properties of the

14

Guo, Q., Zhang, Y., Deng, Y. and Wang, X.

A Soft-sencor and Parameter Optimization for Predicting Inulinase Concentration at Recombinant Pichia Pastoris Fermentation Process.

DOI: 10.5220/0008184700140018

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 14-18

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

soft-sensor, this paper present a LOO-PSO method

to realize parameter optimization.

2 EXPERIMENTAL MATERIALS

AND METHODS

2.1 Strains and Plasmids

In this experiment, inulin INU2 gene was cloned

from Aspergillus oryzae, which was constructed on

plasmids pPIC9K. The recombinant plasmid was

linearized to Pichia pastoris GS115, and the

expression of Inulinase INU2 was induced by

methanol. It is from China's general microbiological

preservation management center, pPIC9K vector and

GS115 pichia pastoris are all from national key

laboratory of microbiology technology.

2.2 Offline Measurement of Inulinase

Concentration

In this paper, the concentration of inulinase in

reaction solution was measured by Bradford method.

The linear fitting results of OD595 absorbance and

protein concentration were obtained from protein

standard solution:

2

0.0012 0.076

0.9982

yx

r

(1)

Here,

y

represents light absorption value of

protein standard liquid OD595,

x

represents protein

concentration,

2

r

represents goodness of fitting.

3 LS-SVM BASED SOFT-SENSOR

3.1 The Establishment of LS-SVM

Based Soft-sensor

LS-SVM regression soft-sensor is data-driven, the

number and quality of training samples will

significantly affect the model's estimation ability and

generalization ability. Online measurement variables

include fermentation time (h), dissolved oxygen

concentration (%), inlet flow rate (L/h), stirring

speed (r/min), pH, temperature (℃), methanol flow

speed ratio (L/h), ammonia flow speed ratio (L/h)

and the product of reaction liquid (L), off-line

measuring variables include methanol concentration

(g/L), pichia concentration (g/L) and inulin enzyme

concentration (g/L). After principal component

analysis, the contribution rate of each principal

component can be obtained, as shown in Figure 1.

When the number of principal elements is 4,

Cumulative Percent Variance (CPV) is more than

90%, so the input principal elements of soft

measurement model are finally determined to be 4.

Figure 1: Score of principal components.

In LS-SVM regression estimation, optimization

problem can be expressed as equation (2) :

22

1

1

min ( , ) || ||

22

. . ( ) , 1,2 ...,

,

l

i

i

T

i i i

c

J

st y b i l

w ξ w

wx

(2)

In this formula,

1

l

w

is the weight vector of

the feature space,

1

l

ξ

is the relaxation vector, c

is the penalty coefficient, and b is the bias constant.

On the basis of formula (2), the Lagrange

function is constructed, as shown in formula (3).

22

1

1

1

min ( , ) || ||

22

( ( ) )

. . ( ) , 1,2 ...,

,

l

i

i

l

T

i i i i

i

T

i i i

c

L

by

s t y b i l

w ξ w

wx

wx

(3)

In this formula,

i

is the Lagrange multiplier.

Under the optimal conditions, the saddle point of

the Lagrange function satisfies the partial derivative

of the parameter

w

,

b

,

i

,

*

i

is equal to zero, as is

shown in formula (4).

*

0, 0, 0, 0

ii

L L L L

b

w

(4)

Further formula (5) can be obtained from

formula (4).

*

1

*

1

**

( ) ( )

( ) 0

0

0

l

i i i

i

l

ii

i

ii

ii

c

c

wx

1,2,...,il

.

(5)

Expected value

A Soft-sencor and Parameter Optimization for Predicting Inulinase Concentration at Recombinant Pichia Pastoris Fermentation Process

15

On the basis of the Mercer condition, the kernel

function is shown in formula (6).

( , ) ( ) ( ) 1,2,...

T

ii

K i lx x x x

(6)

1 1 1

11

1

0

0

1

1 ( , ) ( , )

1

1 ( , ) ( , )

1 1

l

ll

l l l

b

KK

y

c

y

KK

c

x x x x

x x x x

(7)

According to the definition of formula (5) (6)

and kernel function, the optimization problem can be

expressed as formula (7).

The sum can be obtained by solving the above

linear equations. The final decision function of LS-

SVM is shown in formula (8).

1

( ) ( , )

l

j i j i

i

f K b

x x x

(8)

It can also be expressed as formula (9) :

2

2

1

|| ||

( ) exp( )

2

l

ij

ji

i

fb

xx

x

(9)

In this formula,

represents the width of the

kernel function.

3.2 Soft-sensor Parameter

Optimization

It can be seen from the expression of soft-sensor that

penalty coefficient c and width coefficient of kernel

function

2

are parameters that need to be

optimized. The penalty coefficient c reflects

punishment degree of the model to sample data

beyond the range of insensitive loss. The width

coefficient of kernel function

2

reflects the degree

of correlation between support vectors. When c is

too small or

2

is too large, the model is relatively

simple, but the model precision is insufficient, and

the training error is large. On the contrary, the value

of c is too large or

2

is too small, the model

precision is high, but the model structure is too

complex, and the generalization ability drops.

LOO is a concrete realization method of cross

validation thought, the number of subsets with

training was set equals the number of training

samples, where each instance with a sample test, all

the remaining samples as training set. LOO, based

on the generalization error estimation theorem, has

been proved in theory to be an unbiased estimate of

the true error rate.

The given training set

{( , ), 1,2,..., }

ii

y i lx

,

l

represents the number of training samples.

The error estimation of the generalization ability

of this regression problem by LOO can be expressed

as formula (10).

1

1

( , ( ))

l

li

ii

i

E L y f

l

x

(10)

In this formula,

()

li

i

f x

represents the decision

function obtained by training with the remaining

training set after removing the i training sample;

( , ( ))

li

ii

L y f x

is the loss function.

Specific parameter optimization procedures are

as follows:

1) Initialize population size N and selection

times E of particle swarm optimization algorithm.

For the LS-SVM parameter pair (

c

,

2

) to be

optimized, N particles are generated within its

constraint range and the position and velocity values

of each particles are initialized.

2) Randomly select one sample from the sample

training set

{( , ), 1,2,..., }

ii

y i lx

as the test set and

the rest as training set.

3) The LS-SVM regression soft-sensor of

particle and training set was selected to obtain the

prediction model of inulinase concentration

1,1

(x)f

(subscript represents particle label and test sample

label respectively). Use

1,1

(x)f

to forecast the

sample data and get the prediction error

1,1

E

.

4) Repeat steps 2 and 3 to get a total of l

prediction errors

1,

( 1,2,..., )

i

E i l

. Combined with

formula (10), one method of cross validation error of

particles can be obtained, as is shown in

formula(11).

1 1, 1,1

11

11

| ( )|

ll

i i i

ii

E E y - f

ll

x

(11)

In addition, the fitness function of the particle

1

A

is

11

()F A E

.

5) For other particles

( 2,3,... )

j

A j N

, repeat

steps 2 to 4 to get the corresponding fitness function

value

()

j

FA

.

6) Compare

()

i

FA

with the optimal fitness

function value of the particle itself

()

gbest

FA

, if

( ) ( )

ibest gbest

F A F A

, adjust

( ) ( )

gbest ibest

F A F A

, and

take the current position of the particle as optimal

position of the whole particle group.

7) Compare

()

ibest

FA

with the optimal fitness

function value of the entire particle population

()

gbest

FA

, if

( ) ( )

ibest gbest

F A F A

, adjust

( ) ( )

gbest ibest

F A F A

, and take the optimal position of

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

16

particle as the optimal position of the whole particle

group.

8) Adjust the velocity and position of the current

particle according to the velocity adjustment formula

(12) and the position adjustment formula (13).

11

22

( 1) ( ) ( )( ( ) ( ))

( )( ( ) ( ))

i V i ibest i

gbest i

V t w V t c rand t A t A t

c rand t A t A t

(12)

( 1) ( ) ( 1)

i i A i

A t A t w V t

(13)

When the optimal fitness function value of the

whole particle swarm exceed presetting range, or the

optimization algebra reaches predetermined value,

the parameter optimization process will stop, and

output the optimization results of the parameters.

That is the optimal position value of the whole

particle swarm. If not, return to step 2) and continue

the optimization process.

4 ANALYSIS OF

EXPERIMENTAL RESULTS

4.1 Comparison of Parameter

Optimization Results

For GS method is the most widely used method in

the field of SVM parameter optimization (Aazi et

al., 2016). This section mainly compare the GS

method, the PSO algorithm and the LOO-PSO

algorithm parameters optimization effect, to test the

validity of the proposed LOO-PSO algorithm in LS-

SVM regression soft-sensor optimization. According

to experience, the range of parameters to be

optimized is set:

0 10

(2 ,2 )c

,

2 0 10

(2 ,2 )

. In

addition to the above settings, the main parameter of

the GS method is the search step length, which is set

as 0.1 in this paper.

For the parameter optimization process of PSO

and LOO-PSO, it can be seen from the PSO

algorithm formula that the initial parameter value

and its meaning need to be set as shown in Table 1.

In this paper, the Relative Standard Deviation

(RSD) is used to represent the estimation and

prediction error of inulinase concentration, and the

calculation formula is shown in formula (14).

n

i

i

n

i

ii

P

n

PP

n

PRSD

11

2

1

)

ˆ

(

1

)(

(14)

In this formula,

i

P

represents the actual measured

value of inulinase concentration at time i

()gL

, and

ˆ

i

P

represents the predicted value of inulinase

concentration at time i

()gL

.

The optimization time and prediction error of

various algorithms are shown in Table 2. Among

them, the optimization time of PSO and LOO-PSO

algorithm is the time required for the target function

after iterate 300 generations.

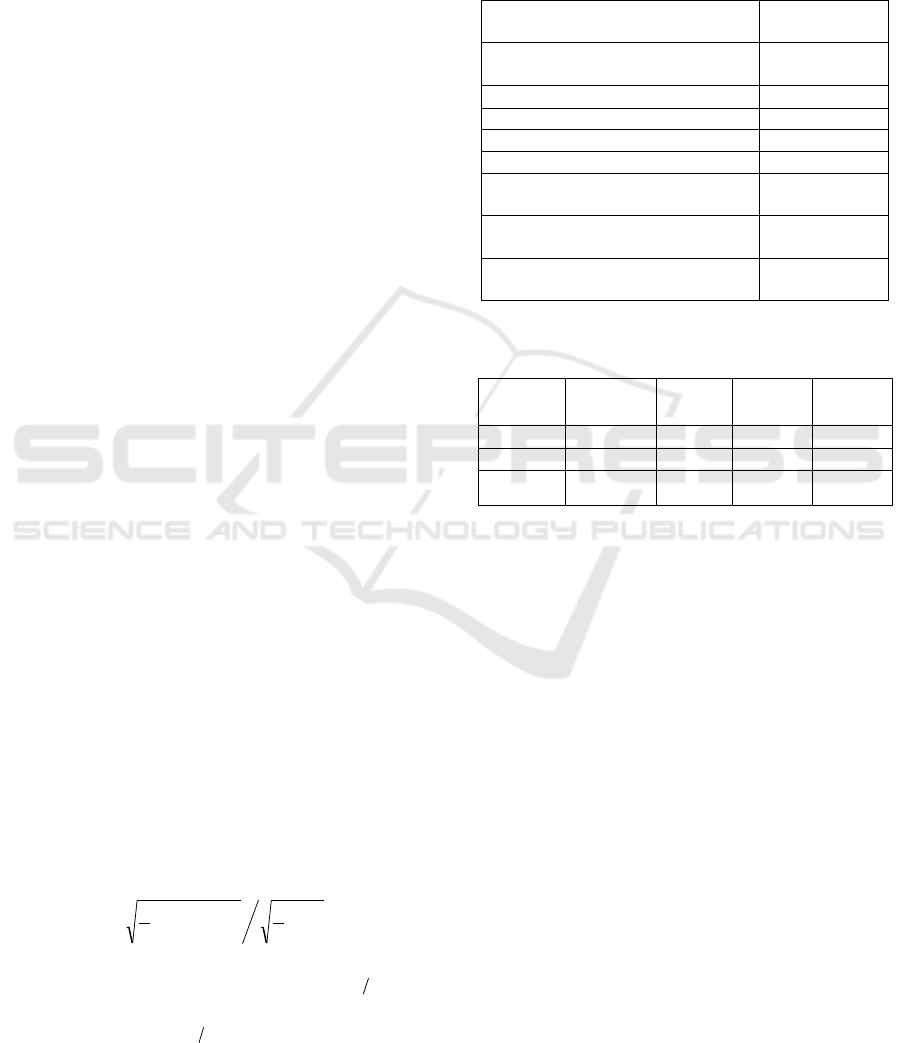

Table 1: Parameters of Particle Swarm Optimization.

Parameter names

Parameter

values

Input dimension of objective

function

2

Local search capability parameters

1.5

Global search capability parameters

1.7

Maximum evolutionary algebra

300

Population size

50

The elastic coefficient in the

velocity updating formula

1

The elasticity coefficient in the

population renewal formula

1

Maximum velocity variation of

particle velocity

0.1

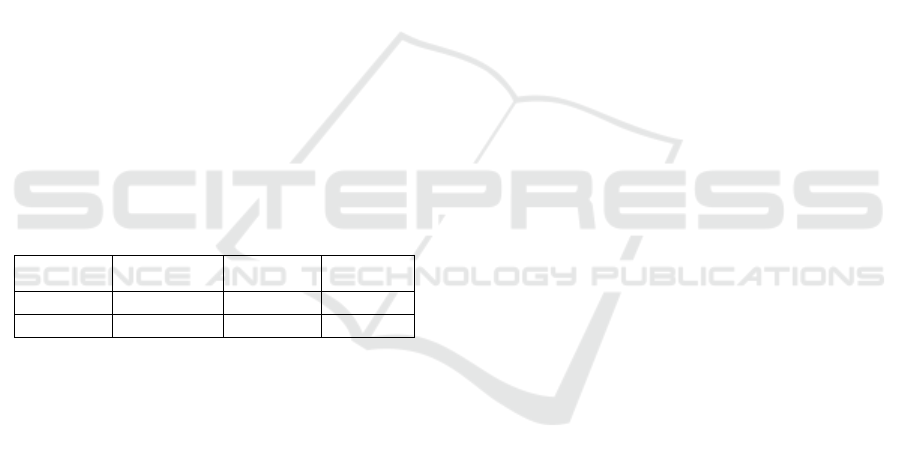

Table 2: Comparison of different parameters optimization

methods.

Algorithm

names

(

1c

,

2

)

Running

time(s)

Training

error (%)

Prediction

error (%)

GS

(1024, 1)

283

3.92

11.1

PSO

(1024, 1)

78

3.92

11.1

LOO-PSO

(876.3,

11.6)

84

5.55

5.79

After analysing Table 2, the following two

conclusions can be obtained:

1) The GS method takes a long time, and its

accuracy is limited by the search step length. In the

actual optimization process, it can be seen that if the

step length is too large, it can reduce the running

time of GS, but will reduce the accuracy of the

optimal parameters obtained. If the step size is too

small, the search time will be significantly increased

while the parameter precision is improved. By

contrast, the PSO algorithm is not much different

from the GS method in terms of prediction error, but

the time of parameter optimization is greatly shorter.

Therefore, the PSO method is superior to the

traditional GS method.

2) Comparing the optimization results of the

LOO-PSO method with the previous two methods,

the optimization time of the LOO-PSO method is

between the GS method and the PSO method.

Although the training error is increased, the

prediction ability for the unknown samples is greatly

improved. The above changes are mainly due to the

use of leave one method on the basis of PSO

optimization. In every iteration, l-1 samples are

A Soft-sencor and Parameter Optimization for Predicting Inulinase Concentration at Recombinant Pichia Pastoris Fermentation Process

17

selected from all training samples. The remaining 1

sample is tested, and the average error of the l

prediction is taken as the objective function of the

optimization, so that the model is added to the model

generalization ability. Therefore, the prediction

accuracy of inulinase concentration for unknown

samples can be significantly improved by the LOO-

PSO method, which is the reason why it takes longer

time to find the optimal results than PSO method.

4.2 Comparison of SVM Regression

Soft-sensor

This section mainly compares the prediction effect

of LS-SVM regression soft-sensor and standard

SVM regression soft-sensor.

The parameter optimization effect of LOO-PSO

algorithm has been proved before, so in order to

guarantee the rationality of the contrast, in this

section, the LOO-PSO parameter optimization

method is adopted for the two soft measurement

models. The PSO parameter setting is the same as

that of the 4.1 section. See Table 1 for details.

The predictive effect of inulinase concentration

in standard SVM and LS-SVM regression soft-

sensor is shown in Table 3.

Table 3: Comparison of different soft-sensors based on

support vector machines.

Model

names

Optimization

time

Estimation

error (%)

Prediction

error (%)

Standard SVM

92

5.34

7.02

LS-SVM

84

5.55

5.79

It can be seen from the previous table that there

are not significant difference between standard SVM

model and LS-SVM model for the inulinase

concentration estimation results at the same LOO-

PSO parameter condition. But the prediction effect

of the LS-SVM regression soft-sensor is better than

the standard SVM regression soft-sensor.

5 CONCLUSIONS

According to the type of input variables and the

amount of samples, a soft-sensor is established to

predict inulinase concentration during the Pichia

pastoris fermentation process based on LS-SVM

regression. The prediction effect of LS-SVM soft-

sensor is better than the standard SVM regression

soft-sensor for unknown inulinase concentration.

To find the best parameters of LS-SVM soft

measurement model, this paper proposed LOO-PSO

parameter optimization method combined with PSO

and LOO method. By comparing the experimental

results with the GS method and the PSO, it is found

that the proposed LOO-PSO parameter optimization

method has the advantages of fast convergence

speed and high prediction precision in predicting the

accuracy of inulinase concentration of unknown

samples.

The soft-sensor can provide references and

guidance for the implementation of real-time control

strategy and improvement of fermentation

technique. Since fermentation process has the

character of shift and variety with time, the soft-

sensor should consider adjusting online to fit new

condition in the future.

ACKNOWLEDGEMENTS

Financial support for this work was provided by the

Key Research and Development Program of

Shandong Provence (No.2016ZDJS02B02).

REFERENCES

Aazi, F. Z., Abdesselam, R., Achchab, B., Elouardighi, A.,

2016. Feature selection for multiclass support vector

machines [J]. AI Communications, 29(5): 583-593.

Bogaerts, P., Wouwer, A. V., 2003. Software sensors for

bioprocesses[J]. ISA transactions, 42(4): 547-558.

Chapelle, O., Vapnik, V., Bousquet, O. et al., 2002.

Choosing multiple parameters for support vector

machines[J]. Machine learning, 46(1-3): 131-159.

Cortes, C., Vapnik, V., 1995. Support-vector networks[J].

Machine learning, 20(3): 273-297.

Huang, C. L., Wang, C. J., 2006. A GA-based feature

selection and parameters optimization for support

vector machines[J]. Expert Systems with applications,

31(2): 231-240.

Lin, S. W., Ying, K. C., Chen, S. C. et al., 2008. Particle

swarm optimization for parameter determination and

feature selection of support vector machines[J]. Expert

systems with applications, 35(4): 1817-1824.

Suykens, J. a. K., Vandewalle, J., 1999. Least Squares

Support Vector Machine Classifiers[J]. Neural

Processing Letters, 9(3): 293-300.

Xi, M. L., Sun, J., Liu, L. et al., 2016. Cancer Feature

Selection and Classification Using a Binary Quantum-

Behaved Particle Swarm Optimization and Support

Vector Machine[J]. Computational and Mathematical

Methods in Medicine, 10(115):9.

Zhang, L., Zhao, C., Zhu, D. et al., 2004. Purification and

characterization of inulinase from Aspergillus niger

AF10 expressed in Pichia pastoris[J]. Protein

expression and purification, 35(2): 272-275.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

18