The Effects of DTBP on the Pollutant of Diesel Engine

R N Li

*

, H Ding and Z Wang

School of Automotive and Traffic Engineer, Jiangsu University, Zhenjiang, 212013,

China

Corresponding author e-mail: R N Li, liruina0706@126.com

Abstract. Methanol and biodiesel, which are two of the oxygenated alternative fuels of

diesel, have the potential to reduce diesel engine emission. However, if methanol is blended

into biodiesel with a large proportion, the cetane number of the blend will be decreased a lot.

A cetane number improver - Di-Tert-Butyl Peroxide (DTBP) with the mass proportion of

0.25%, 0.50%, 0.75% was added into methanol/biodiesel blend with 15% methanol (BM15).

The engine bench test of the blend was finished in a 186FA type single-cylinder diesel engine

without any change, to investigate the effect of DTBP on the engine pollutant. It is revealed

that at the rated mode, DTBP can effective reduce NOx, CO and HC emissions, however the

exhaust smoke is increased a little.

1. Introduction

Energy shortage and environmental pollution are important issues facing the world, and even worse

in China. In 2016, China’s oil dependency on international oil market has already broken through

58%. It is estimated that this number will be near to 69% by the year 2020. More than a half of total

amount of fossil oil has been consumed by engines in China.

Methanol and biodiesel, both oxygenated fuels, are two of the promising alternative fuels. As an

alcohol fuel, potential resources of methanol are huge in China. Methanol is mainly produced from

coal, especially by the low-grade high-sulfur coal and recycling coke oven gas. China is abundant in

coal resources, but relatively less in fossil oil. Coal to methanol, which is with simple production

process and low cost, is a mature technology in chemical industry of China. Wang et al [1] studied

the reliability of diesel engine fueled with B5 biodiesel for 1000h, the result shows that B5 biodiesel

can be used in diesel engine, and the engine performance changes little. Özener’s [2] study also

shows that biodiesel could be used in diesel engine without any modification, and emission pollutant

can be reduced. As a kind of clean green energy, biodiesel has been got widespread attention and

become an important alternative fuel of diesel [3-5].

However, the cetane number of methanol is 5. When methanol is blended with a large proportion,

the cetane number of the blend will be decreased rapidly. The cetane number improvers can shorten

the ignition delay period and accelerate the combustion speed of the engine. 2,4-Di-tert-butylphenol

(DTBP) is a kind of cetane number improver which is most commonly used organic peroxide.

Liang etc.[6] added DTBP to diesel and studied the emissions of diesel engine. The study shows that

the diesel engine has the best comprehensive emission data when the mixed volume fraction of

DTBP to diesel is 0.3%.

308

Li, R., Ding, H. and Wang, Z.

The Effects of DTBP on the Pollutant of Diesel Engine.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 308-312

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

In this paper, DTBP was chosen to added into methanol/biodiesel blend, and the physical and

chemical properties of the blend were tested. A bench test was carried out on a direct injection diesel

engine and the pollutant of diesel engine were analyzed.

2. Material and methods

2.1. Fuel preparation

Referring to the existing research and through the test for methanol blending ratio, in this study, the

blending ration of methanol is 15%, and it is named as BM15. According to the researches [7, 8],

DTBP(C

8

H1

8

O

2

) can increase the cetane number of diesel fuel 6.5-8 by adding 1% (wt). In the test,

DTBP is added into BM15 with the ratio of 0.25%, 0.50% and 0.75%, named as BM15+DTBP0.25,

BM15+DTBP0.50 and BM15+DTBP0.75. The cetane number and LHV (lower heat value) of the

blends are calculated according to Kay’s mixing role. And the main properties of the fuels are listed

in table 1.

Table 1. Physical-chemical properties of the fuels.

Parameters DTBP BM15 BM15+DTBP0.25 BM15+DTBP0.50 BM15+DTBP0.75

Cetane numbe

r

- 43.25 44.38-44.75 46.00-44.75 47.63-44.75

Oxygen content (wt

%)

21.92 16.87 16.88 16.89 16.90

LHV (MJ·k

g

-1

) 32.67 34.74 34.74 34.73 34.73

Density (g·cm

-3

at

20°C)

0.80 0.86 0.86 0.86 0.86

Kinetic viscosity

(m

m

2

·s

-1

at 40°C)

3.32 3.22 3.22 3.22 3.22

2.2. Test apparatus and method

The engine bench test was carried out on 186FA diesel engine. The 186FA is a four strokes, air

cooled, direct injection, single-cylinder diesel engine, and the engine specifications are listed in table

2. The engine was operated at 3000 r/min with 10%, 25%, 50%, 75% and 100% load particularly.

The injection timing and fuel injection quantity of the engine were unchanged. During the

experiment, the pollutant concentration were recorded.

A type FGA4100 exhaust gas analyzer of was utilized to measure NOx, CO and THC

concentration online. The precision of exhaust gas analyzer for NOx, CO, and THC concentrations

was <4%, <5%, and <4%, respectively. The exhaust smoke was detected by a FBY-201 bosch smoke

meter.

Table 2. Engine specifications of 186FA.

Type

Direct-injected, 4 stokes,

ai

r

-cooled, natural aspiration

Number of cylinders 1

Cylinder bore(mm)×stroke(mm) 86×72

Displacement(L) 0.418

Compression ratio 19

Rated power(kW) / speed(r/min) 5.9/3000

Nozzle number × orifice diameter(mm) 5×0.20

Injection advanced angle (°CA BTDC) 12

Combustion chambe

r

ω type

The Effects of DTBP on the Pollutant of Diesel Engine

309

3. Results and discussion

3.1. NOx concentration

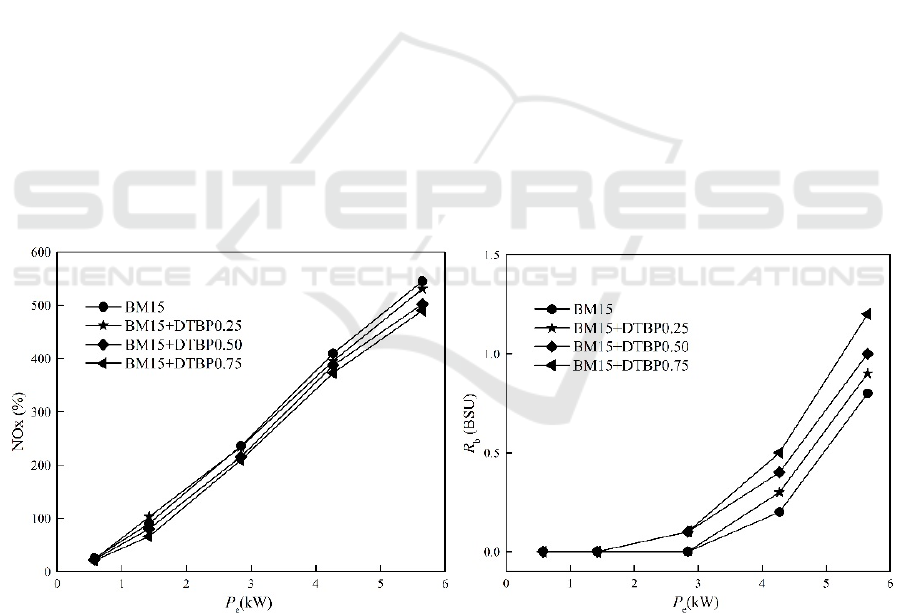

Figure 1 presents the NOx concentration of the diesel engine fueled with the fuels at 3000 r/min.

Figure 1 presents the effect of DTBP on NOx concentration. As can be seen, with the increase of

DTBP amount, the NOx concentration of the engine is reduced. When the engine is working at

3000r/min and Pe=0.57kW, and the addition of DTBP is 0.25%, 0.50% and 0.75% in BM15, the

volume concentration of NOx in exhaust gas is reduced by 2.59%, 7.58% and 10.2% compared with

that of BM15. This is because DTBP reduces the ignition delay period. Less mixture in the premixed

duration and the maximum pressure and temperature in the cylinder are reduced, resulting in the

reduction of NOx.

3.2. Smoke

Figure 2 is the smoke of the engine at 3000 r/min. It can be seen that with the increasing amount of

DTBP, the smoke of the engine is increased. When the engine is working at 3000r/min and

Pe=0.57kW, and the addition of DTBP is 0.25%, 0.50% and 0.75% in BM15, the exhaust smoke is

increased by 12.5%, 25% and 50% respectively compared with that of BM15. Study [9] has shown

that, OH has 3 times stronger ability than O to oxidize C2H2, and 20 times stronger than H. As C2H2

is the precursor of aromatic hydrocarbon, the oxidation reaction brakes the formation of aromatic

hydrocarbon, then reduces the amount of soot generated. In addition, OH also has strong oxidation of

the generated soot. All of the analysis above demonstrates that methanol has significant effect on the

inhibition of soot formation. When DTBP is added into BM15, the ignition delay period shortens.

Less mixture is in the premixed combustion period and more mixture is in the diffusion period,

making a little increase of soot.

Figure 1. NOx concentration. Figure 2. smoke number.

3.3. CO concentration

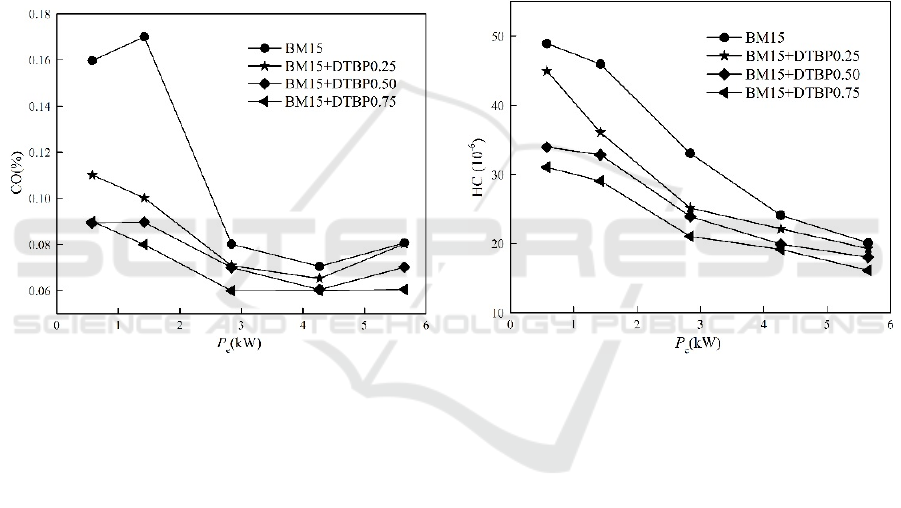

CO is an intermediate product of the fuel combustion and an product of incomplete combustion.

Figure 3 illustrates with the increasing amount of DTBP, the CO concentration is decreased

gradually. When the engine is working at 3000r/min and Pe=0.57kW, and the addition of DTBP is

0.25%, 0.50% and 0.75% in BM15, the volume concentration of CO in the exhaust is 0, 12.5%, and

25% lower than that of BM15. DTBP improves the ignitability of the blend and shortens the ignition

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

310

delay period. The low temperature and lean zone of the fuel spray is narrowed, accelerating the

combustion of CO. With the increase of engine load, the CO concentration is reduced first and then

increased a little at high load. When the engine fueled with BM15 at 25% load, the CO concentration

is increased a little compared with at 10% load.

3.4. HC concentration

HC is mainly produced by the mixture in the poor-oil area around the fuel spray, generated by the

incomplete combustion. As methanol has a low boiling point and high heat of vaporization, methanol

is easy to evaporate from the fuel droplet, and the evaporated methanol forms a low temperature,

lacking of oil area in the mixture [10, 11]. It is hard to combust completely for mixtures in such area,

and thus more HC can be formed. Figure 4 shows the HC concentration of the diesel engine. When

DTBP is added to BM15, the HC concentration of the engine is reduced. When the engine is working

at 3000r/min and Pe=0.57kW, and the addition of DTBP is 0.25%, 0.50% and 0.75% in BM15, the

volume concentration of HC in the exhaust is 5.0%,10.0%,20.0% lower than that of BM15.

Figure 3. CO concentration. Figure 4. HC concentration.

4. Conclusions

The cetane number improver (DTBP) was chosen to added into methanol/biodiesel blend, and the

physical and chemical properties of the blend were tested. The 186FA diesel engine bench test is

conducted at rated rotation to analyze the pollutant of the diesel engine using diesel, biodiesel and

methanol/biodiesel with or without DTBP. The results can be summarized as following:

(1) With the increase of DTBP amount, the NOx concentration of diesel engine is reduced, but soot is

increased a little.

(2) With the increasing amount of DTBP, the CO concentration is decreased gradually, and the HC

concentration of the engine is also reduced.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China under

Grant (No. 51776089), and the Project supported by the sixteenth undergraduate research project of

Jiangsu University(Y16A112).

References

[1] Wang Z, Xu G J, Huang H L, Wang L, Zha H and Ma J R 2009 Reliability test of diesel engine

fueled with biodiesel (Transactions of the CSAE, vol 25) p 169-172

The Effects of DTBP on the Pollutant of Diesel Engine

311

[2] Özener L O, Yüksek, Ergenç A T and Özkan M 2014 Effects of soybean biodiesel on a DI diesel

engine performance, emission and combustion characteristics (Fuel, vol 115) p 875-883

[3] Wang X, GeY S, Yu L X and Feng X Y 2013 Comparison of combustion characteristics and

brake thermal efficiency of a heavy-duty diesel engine fueled with diesel and biodiesel at high

altitude (Fuel vol 107) p 852-858

[4] Lapuerta O A M and Rodríguez-Fernández J 2008 Effect of biodiesel fuels on diesel engine

emissions, (Fuel vol 34), p 198-223

[5] Li R N, Wang Z, Li M D, Xu G J, Mao G P and Wang X Z 2012 Study on effect of peroxide

properties of biodiesel and emission (ACTA ARMAMENTARI II, vol 33) p 1545-1548

[6] Liang C, Ji C W and Dai X X 2009 Experimental study on the effect of DTBP on combustion

and emission of diesel engine (Vehicle Engine, vol 4) p 83-87

[7] Lü X C, Zhang W G, Yang J G and Huang Z 2005 Effect of Cetane Number Improver on Heat

Release Rate and Emissions of High Speed Diesel Engine Fueled with Ethanol Diesel Blend

Fuel (Journal of Combustion Science and Technology, vol 11) p 56-61

[8] Wang Z, Qu L, Li M D and Chen L 2012 Effect of DTBP on biodiesel combustion and emission

characteristics of engine fuelled with bio-diesel (Transactions of the Chinese Society of

Agricultural Engineering, vol 28) p 60-66

[9] Schmidt K and Gerpen J V 1996 The Effect of Biodiesel Fuel Composition on Diesel

Combustion and Emissions (SA E paper)

[10] Zhang J Q, Lu H B, Wang X B and Jiang D M 2004 Combustion and Emission Characteristics

of a DI Diesel Engine Fueled by Diesel Methanol Blends (Journal of Combustion Science and

Technology, vol 10) p 171-175

[11] Cheung C S, Zhua L and Huang Z 2009 Regulated and unregulated emissions from a diesel

engine fueled with biodiesel and biodiesel blended with methanol (Atmospheric Environment,

vol 43) p 4865-4872

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

312