Performance and Improvement Measures of Concrete with Internal

Addition of Water-based Organic Silicon

Kaili Yang

1,2

, Zhihong Fan

1,2

, Zhijie Zhang

3

, Wenjie Cen

1,2

, Mingfeng Zhong

3

and Chao Luo

1,2

1

.CCCC Fourth Harbor Engineering Institute Co.Ltd ,Guangzhou 510230 , China

2.

Key Laboratory of Harbor and Marine Structure Durability Technology, Ministry of Communications, PRC, Guangzhou 5

10230, China

3.

College of Materials Science and Engineering, South China University of Technology,Guangzhou 510230 , China

Keywords: Water-based organic silicon, modified meta kaolin, water absorption, compressive strength, chloride

diffusion coefficient.

Abstract: In this paper, the change laws of compressive strength, water absorption and chloride diffusion coefficient

of concrete mixed with different dosages of water-based organic silicon was studied. Meanwhile, the

influence of modified meta kaolin on concrete mixed with water-based organic silicon was studied. The

results show that the water-based organic silicon can significantly reduce water absorption of concrete,

nevertheless, it will reduce the compressive strength of concrete. The higher the dosage, the greater decrease

in strength. The mixing of meta kaolin can effectively improve the mechanical properties of the concrete

mixed with water-based organic silicon and its waterproof performance and chloride resistance.

1 INTRODUCTION

Concrete durability has become a hot spot in the

field of international concrete research, especially

the concrete structure in the marine environment and

chemical corrosion environment. It is noteworthy

that, in the pass century, a large number of

constructions had collapsed or demolished because

of poor durability performance[1-4]. Undesirable

ions penetrate into the concrete structure with water,

causing physically and chemically damage of it. In

order to improve the durability of the concrete

structure and ensure the structure meets the design

life requirements, when adopting the corrosion-

resistant high-performance concrete, the necessary

additional anti-corrosion technology measures

should also be taken in view of the corrosive

environment characteristics of different structure.

For the additional anti-corrosion technology, pieces

of research have been carried out in these years. At

present, it mainly includes two kinds of technical

method: external coating and internal addition.

External coating materials are easily affected by the

surface layer concrete properties and the anti-aging

properties of the materials. Once the surface

concrete occurs cracking, abrasion, or the anti-

corrosion materials are aging because exposed to the

outdoor environment for a long time, the protective

effect will be greatly reduced [5]. By mixing anti-

corrosion material in fresh concrete to produce

concrete with integral waterproof properties, the

above drawbacks of traditional surface anti-

corrosion materials can be effectively improved.

However, mixing the anti-corrosion materials by

internal addition generally has the problem of

reducing the compressive strength of the

concrete[6,7].

Metakaolin sakind of mineral admixture with

superpozzolanactivity, when modified by acid,the

thermal and mechanical activation, Activities of

SiO2and Al2O3 will be stimulated and give full play

to itspozzolanic effect and filling effect, and also

significantly improve strength and resistance

permeability of concrete[8-11]. In order to reduce

the side effect to the strength of concrete and greatly

improve the resistance permeability of concrete,

based on the study of the influence of the water-

based organic silicon on concrete, the modified

metakaolin and water-based organic silicon will be

mixed to explore the influence of the modified

metakaolin on water-based organic silicon concrete.

2RAW MATERIALS AND TEST

METHODS

2.1 Cement

The cement uses Yuexiu PII 42.5R portl and cement.

The main chemical composition of cement is shown

in Table 2.1, and the physical properties are shown

in Table 2.2.

Table2.1:Cement Chemical Composition(%).

composition SiO

2

Al

2

O

3

CaO SO

3

MgO Fe

2

O

3

LOI

cement 19.76 4.52 62.42 4.26 1.13 4.42 3.49

Table 2.2 :Cement Physical Properties.

Specificsurf

ace area(

m

2

/kg)

Standard

consistency

water demand P

(%)

Setting time(min

)

Flexural

strength(MPa)

Compressive

strength(MPa)

360 25.5

Initial

time

Final

time

3d 28d 3d 28d

121 197 6.82 8.86 32.43 52.09

2.2 Aggregate

Granite gravel (5~20mm) produced by Zhuhai

Jianbang Stone Field, apparent density is 2.70 g/cm

3, close bulk density is 1.63 g/cm 3, needle content

is 2.3%,crush value is 3.0%; fine aggregate with

Guangdong Xijiang sand, apparent density is

2.64g/cm 3, fineness modulus is 2.7, mud content is

0.4%, mud mass content is 0.2%.

2.3 Water-based Organic Silicon

The alkyl siloxane water-based organic silicon with

a long-chain molecular structure was used, and the

active ingredient was 40%.

The metakaolin made by calcining kaolin from

Guangdong Maoming was used. The main chemical

composition and specific surface area of metakaolin

are shown in Table 2.3. The metakaolin becomes

modified metakaolin when activated by acid,

thermal and mechanical activation methods.

2.4 Modified Metakaolin

Table 2.3:Metakaolin chemical composition (%) and specific surface area(m

2

/kg).

SiO

2

Al

2

O

3

CaO SO

3

MgO Fe

2

O

3

LOI Specific surface

metakaolin 53.00 42.67 0.04 0.14 0.08 0.73 1.35 15238

2.5 Concrete Mix Proportion

The mix proportion of the concrete specimens is

shown in Table 2.4. The 2%, 4% and 6% dosage of

water-based organic silicon was used to instead of

the total amount of cementitious materials, and the

same amount of mixing water was replaced at the

same time. Modified metakaolin replaces the total

amount of cementitious material with a 6% doping

amount.

Table 2.4: Mix proportion(kg/m

3

).

Mumber Cement

Modifiemeta

kaolin

Water

Water-

based

organic

silicon

Sand Gravel Superplasticizer

OPC 420 — 147 — 771.6 1065.6 2.58

SL2 420 — 142 8.4 771.6 1065.6 2.70

SL4 420 — 136.9 16.8 771.6 1065.6 2.66

SL6 420 — 121.8 25.2 771.6 1065.6 2.67

MK 394.8 25.2 147 — 771.6 1065.6 2.98

MKSL2 394.8 25.2 142 8.4 771.6 1065.6 3.07

2.6 Test Methods

2.6.1 Water Absorption Test

The water absorption test was conducted according

to the method in “Mortar, Concrete Waterproof

Agent”(JC474-2008).

2.6.2 Compressive Strength Test

According to the method in “Standard Test Method

for Mechanical Performance of Ordinary

Concrete”(GB/T50081-2002), the compressive

strengths on 3d, 7d and 28d ages of the concrete

were measured.

2.6.3 Rapid Chloride Migration Factor

Test(RCM Method)

Referring to “Standard Test Method for Long-

term Properties and Durability of Normal

Concrete”(GB/T50082-2009) to test the chloride

diffusion coefficient of concrete on 28d.

3. RESULTS AND DISCUSSION

3.1 Compressive Strength

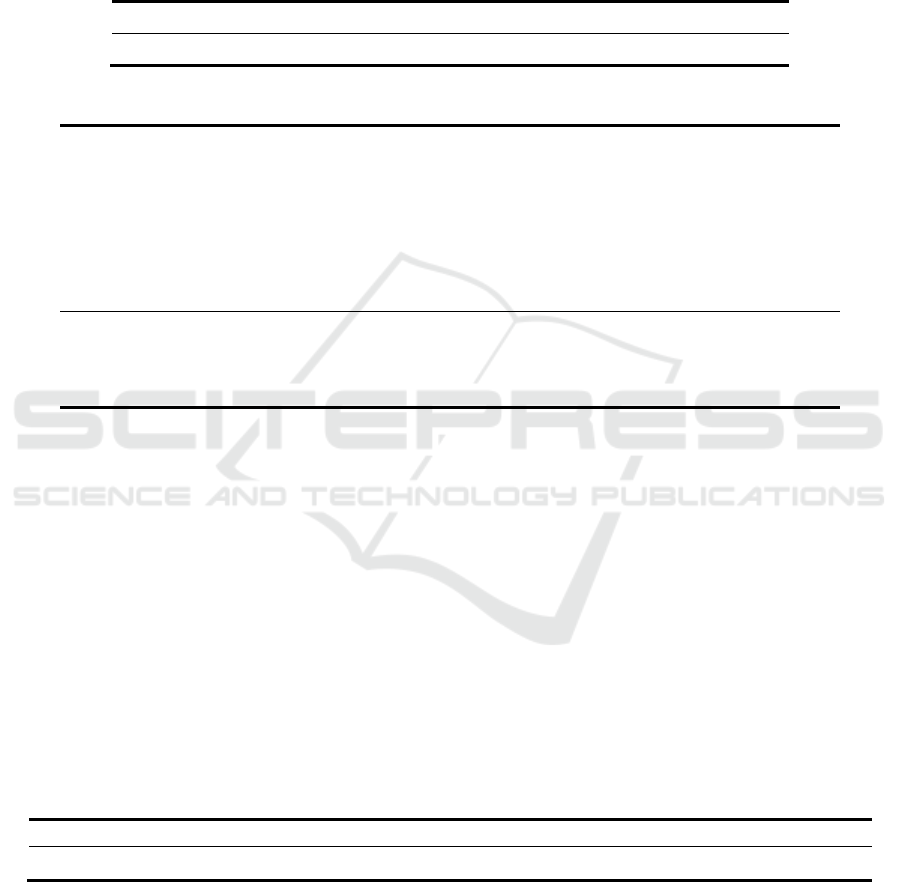

Figure 1 shows the effect of different dosage water-

based organic silicon on concrete for 3d, 7d and 28d.

It can be seen from the figure that the compressive

Fig 1: Effect of water-based organic silicon on

compressive strength of concrete.

strength of concrete at the three ages are reduced

because of add with water-based organic silicon, the

greater the dosage is, the more the compressive

strength decreases. Compared with the OPC which

without water-based organic silicon, the

compressive strength of SL2, SL4 and SL6 on 28d

were reduced by 2.9%, 8.1% and 12.5% respectively.

When the Water-based organic silicon mixed in

concrete, it will adsorb on the surface of the cement

particles. The greater the content of the water-based

organic silicon, the greater the surface area of the

adsorbed cement particles, the smaller effective

contact area between the cement particles and water,

the slower hydration rate and lower hydration degree

of the concrete, and finally lead to a lower

compressive strength of concrete.

0123456

40

45

50

55

60

65

Compressive strength (MPa)

Waterproof admixture (%)

3d

7d

28d

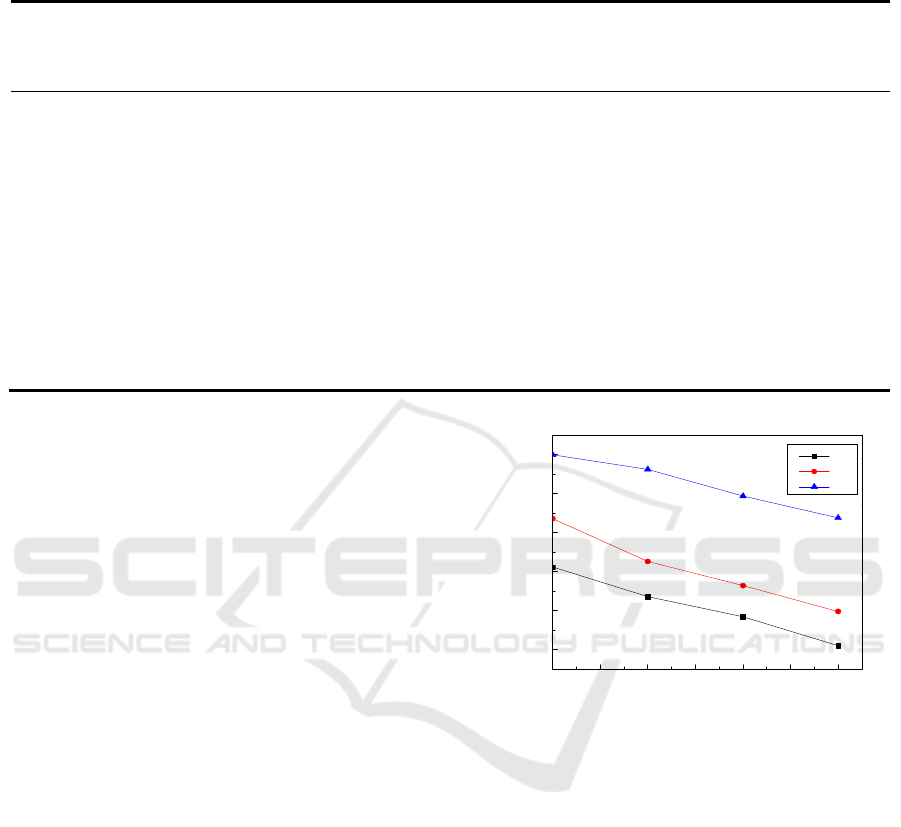

Fig2: Effect of modified metakaolin on compressive

strength of concrete with water-based organic silicon.

Figure 2 shows the effect of modified

metakaolinon compressive strength of concrete with

water-based organic silicon. The addition of

modified metakaolin can effectively improve the

compressive strength of concrete with water-based

organic silicon.

Comparing with the OPC, the compressive

strength of MK increased by 7.3%, 13.7% and

18.3% respectively on 3d, 7d and 28d. Compared

with the SL2, the compressive strength of MKSL

increased by 8.1%, 11.5% and 9% respectively on

3d, 7d and 28d, and 28d compressive strength

increased 5.9% compared to OPC. After the acid

treatment to metakaolin ,thermal and mechanical

activation can effectively stimulate the activity of

SiO2 、 Al2O3 and other active substances, and

significantly improve the strength of concrete[11].

When mixing the modified metakaolin with the

water-based organic silicon, the strength promotion

effect of modified metakaolin effectively

compensates for the side effect of reducing the

strength of the concrete with water-based organic

silicon.

3.2 Water Absorption

Figure 3 shows the effect of different dosage water-

based organic silicon on water absorption of

concrete and the water-based organic silicon can

significantly reduce the water absorption of

concrete. Compared with the OPC , the water

absorption of SL2, SL4 and SL6 on 28d were

decreased by 64.4%, 69.9% and 65.8% respectively.

With the increase of the amount of water-based

organic silicon, there is little difference in reducing

water absorption of concrete. When the content of

water-based organic silicon increase to 6%, the

water absorption of concrete will also increase,

meaning the decrease of the waterproof ability. This

is because the water-based organic silicon has a low

surface tension and the surface energy promote a

fine hydrophobic performance, which can react with

cement in concrete and forms the interwoven

hydrophobic layer, preventing water molecules from

penetrating into the concrete, as well as reducing the

water absorption of concrete [6]. However, as the

content of water-based organic silicon increases, the

more cement particles adsorbed by water-based

organic silicon, the greater the influence on the

hydration of cement in concrete, which will reduce

its waterproof ability to a certain extent.

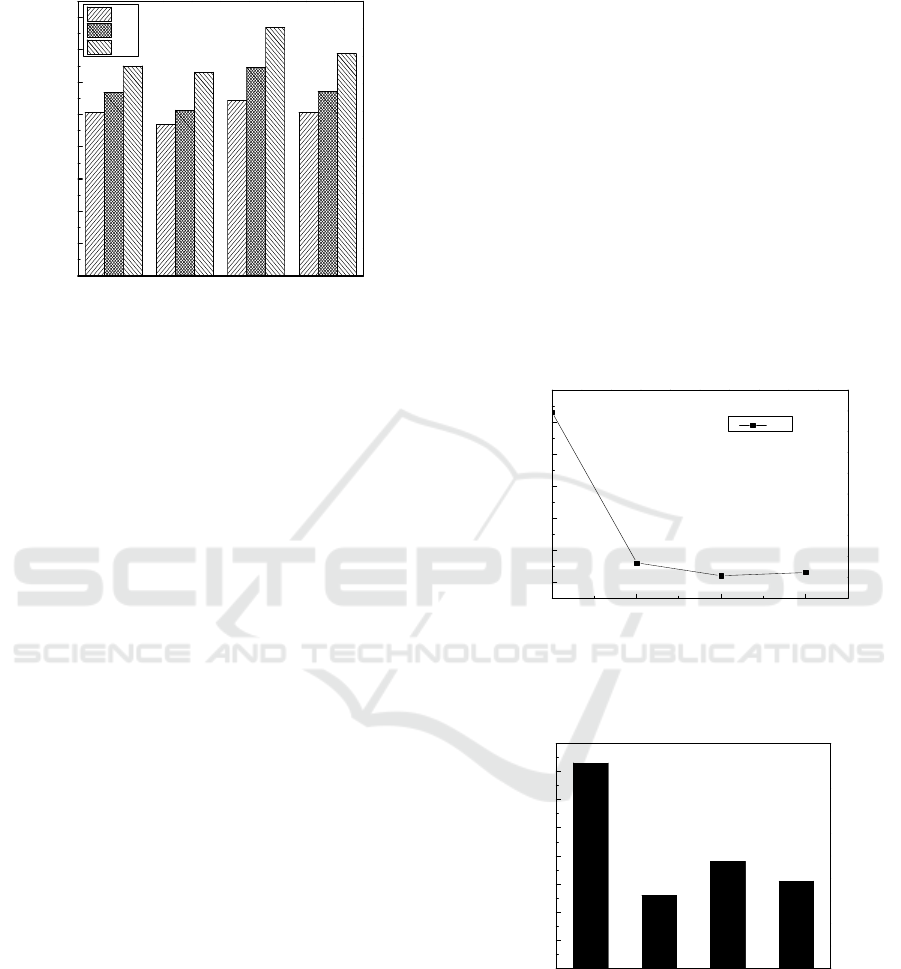

Fig 3:Effect of water-based organic silicon On water

absorption of concrete.

Fig4: Effect of modified metakaolin on water

absorption of concrete with water-based organic

silicon.

Figure 4 shows the effect of modified metakaolin

on water absorption of concrete with water-based

organic silicon ,the modified metakaolin and water-

OPC SL2 MK MKSL2

0

10

20

30

40

50

60

70

80

Compressive strength (M Pa)

3d

7d

28d

0246

2

3

4

5

6

7

8

Water absorption (%)

Waterproof admixture (%)

28d

OPC SL2 MK MKSL2

0

1

2

3

4

5

6

7

8

Water absorption(%)

based organic silicon both can significantly reduce

the water absorption of concrete. Compared with the

OPC , the water absorption of MK and MKSL were

decreased by 47.9% and 60.3% respectively.

However, when comparing with the SL2,the water

absorption of MK and MKSL was increased

by49.2% and 19.2%. With the increasing content of

SiO

2

and Al

2

O

3

modified within the metakaolin,

their secondary react with the cement hydration

product—Ca(OH)

2

will be generated and padding

the concrete pore, resulting in the increasing

compactness of the concrete structure and the

reducing of the water absorption performance of

concrete[12].

3.3 Resistance of Chloride Ion

Penetration

Corrosion of steel reinforcement in concrete is

considered to be one of the most significant reasons

for durability damage of marine concrete structures.

Cl- transmission from the concrete surface to the

internal surface of steel, when its accumulated to a

certain value of the concentration of the rebar

depassivation and rust occurs, the expansive

corrosion product make the concrete cover falls off,

and lead to the failure of the structure eventually.

Therefore, it is an important means to evaluate the

durability of concrete to test the Cl- permeability of

concrete. In addition, the transmission performance

of concrete reflected by the resistance to chloride

permeability of concrete is a fundamental problem

directly influencing the durability of concrete.

Figure 5 shows the chloride diffusion coefficient

of concrete with different dosage water-based

organic silicon by RCM method and the chloride

diffusion coefficient observably reduced with the

water-based organic silicon. Compared with the

OPC , the chloride diffusion coefficient of SL2, SL4

and SL6 on 28d were decreased by 23.6%, 30.6%

and 32.3% respectively. The effect of water-based

organic silicon on the diffusion coefficient of

chloride ions in concrete is similar to that of water

absorption, meaning that with the increase of water-

based organic silicon, the diffusion coefficient of

chloride ion is slightly changed. Water-based

organic silicon hydrophobicity changed the surface

tension of concrete and its internal pore, resulting in

a hydrophobic surface and scatter within the

concrete to block the connectivity of capillary pore

at the same time, which can effectively reduce the

chloride ion diffusion coefficient of concrete.

Fig 5:Effect of water-based organic silicon on chloride

diffusion coefficient of concrete.

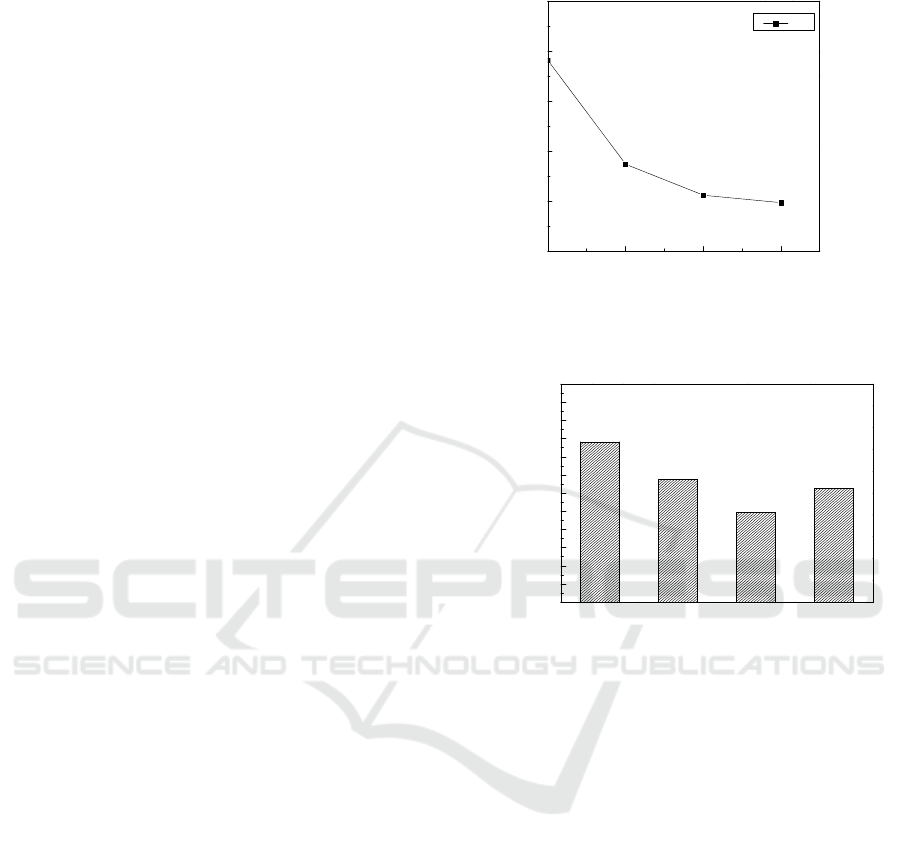

Fig6: Effect of modified metakaolin on chloride

diffusion coefficient of concrete with water-based

organic silicon.

Figure 6 shows the chloride diffusion coefficient

of water-based organic silicon concrete with

modified metakaolin. Compared with the OPC , the

chloride diffusion coefficient of MK was decreased

by 43.8% and compared with the SL2, the chloride

diffusion coefficient of MK and MKSL were

decreased by 43.8% and 7%, the results show that

the effect modified metakaolin on the chloride

diffusion coefficient on concrete is much more

serious than that of water-based organic silicon. The

modified metakaolin can improve the compactness

of the pore structure, reducing the content of

capillary pore in concrete, improving the gel content,

and promoting the formation of F salt in the concrete

under the chloride environment. It can not only

reduce the transmission channel of Cl- in concrete

but also improve the curing capacity of Cl-.In this

way, the resistance of chloride permeation of

0246

5

6

7

8

9

10

Chloride ion diffusion coefficient(10

-12

m

2

/s)

Waterproof admixture(%)

28d

OPC SL2 MK MKSL2

0

1

2

3

4

5

6

7

8

9

10

11

12

Chloride ion diffusion coefficient(10

-12

mm

2

/s)

concrete with water-based silicone concrete is

improved[10].

4. CONCLUSIONS

1.Water absorption of concrete can be significantly

reduced by adding with water-based organic silicon

in concrete, when the dosage of water-based organic

silicon between 2%-6% , the water absorption of

concrete can be reduced by over 65%.

2.Adding water-based organic silicon in concrete

will reduce the compressive strength of concrete,

and it will be more distinct with the increase of the

concentration. Considering the water absorption and

compressive strength of concrete, the optimum

dosage of water-based organic silicon can be refined

as2%.

3.Mixing with modified metakaolin and water-

based organic silicon is able to improve the

compressive strength and waterproof ability at the

same time. Compared with OPC, the compressive

strength on 28d of MKSL was increased by 5.9%,

and the water absorption and the chloride diffusion

coefficient were decreased by 60.3% and

28.9%respectively.

ACKNOWLEDGEMENT

Thanks for support from Guangzhou science and

technology project-the key technology research and

industrialization of waterproofing strengthening

agent for concrete (201604016042)

REFERENCES

1. Zhan Hongyan, etc. The damage causes and repair

methods of coastal concrete buildings[J].Journal of

Qingdao university of technology, 2003, 24(1):88-91.

2. Feng Xiaoxin, etc. Cause analysis and prevention

countermeasures of damage of coastal highway and

bridge[J]. Highway, 2002(1):31-34.

3. Victor R, Baskir G, Camp J, et al. 2013 Report Card

for America's Infrastructure[J]. Reston Va American

Society of Civil Engineers, 2013.

4. Li Junyi.Theory of durable concrete work in Shanghai

in 100 of the basic technical conditions[J]. Port &

Waterway Engineering, 2002(5):4-7.

5. Jiang Zhengwu, etc. Silane impregnation concrete

waterproof technology[C]. China institute of

architecture waterproof engineering and materials

academic BBS, 2010:1-4.

6. Li Faping, ect. Study on the basic properties of

modified waterproof mortar with organic silicon in it

[J]. Waterproofing of Chinese buildings, 2017(8):5-8

7. Jin hao. Effect of internal - doped organo silicon

waterproofing agent on the properties of mortar[J].

Railway construction, 2016(1):89-91.

8. Siddique R, Klaus J. Influence of metakaolin on the

properties of mortar and concrete: A review[J].

Applied Clay Science, 2009, 43(3):392-400.

9. Wei Ying. Effects of mixing metakaolin and limestone

powder on concrete[J]. China concrete and cement,

2013(2):19-21.

10. Zeng Junjie, ect. Improvement Effect and Mechanism

of Metakaolin on Marine Concrete Chloride

Penetration Resistance [J]. Journal of Wuhanuniversity

of technology, 2015, 37(4):22-28.

11. Chen Yilan, ect. High performance concrete with

metakaolin mixed replacing of silica fume[J]. Journal

of the Chinese ceramic society, 2004, 32(4):524-529.

12. Cao Deguang, ect. Study on the alkali-gelation of

burnt clay [J]. China nonmetallic ore industry guide,

2000(2):21-22.