Analysis of Mechanical Properties of Cement Concrete Mixed with

Waste Asphalt Mixture Powder

Desheng Jia

1

, Weiwei Han

1

and Na Li

1

1Xi'an Highway Research Institute, Xi'an, Shanxi, China

Keywords: Waste asphalt mixture powder cement concrete mechanical properties.

Abstract: In order to solve the problem of reutilization of waste asphalt mixture, at the same time, in order to improve

the mechanical properties of cement concrete, such as flexural tensile strength and so on, In this paper,

based on the test of waste asphalt mixture powder obtained by special crushing and screening equipment, it

replaces the quality of part of sand in cement concrete, and analyzes the influence of waste asphalt mixture

powder on the mechanical properties of cement concrete. Through tests, it has been shown that the flexural

tensile strength of cement concrete after replacing the 15% sand content in cement concrete with waste

asphalt mixture powder is significantly improved, and the elastic modulus is decreased.

1 INTRODUCTION

With the gradual extension of the time of the

road input and operation in China, the asphalt

pavement of the early construction has entered the

maintenance period, and the reutilization of the

waste asphalt pavement material has been paid much

attention. With the continuous popularization and

application of cement concrete pavement, the quality

requirements of the surface concrete material in the

opposite layer are increasing. It is required that the

surface concrete material should have higher

flexural strength and lower elastic modulus. So as to

avoid the occurrence of cracks in the early stage of

pavement construction, improve the performance of

cement concrete and prolong the service life of

pavement. This article starts with these two common

topics, blending waste asphalt mixture powder into

cement concrete, and analyzing the effect of waste

powder on the mechanical properties of cement

concrete.

2 PRODUCT FEATURES OF

WASTE ASPHALT MIXTURE

POWDER

The waste asphalt mixture used in this experiment is

used as the waste asphalt pavement milling material,

and the waste asphalt mixture with grain size below

2.36mm is obtained by the self-made crushing and

screening equipment.

2.1 Test of Waste Material Extraction

and Three Major Index Tests

The test adopts the centrifugal asphalt mixture fast

extraction instrument and takes the dry sample

1500g. According to the requirements of the test,

three parallel tests are carried out, the average value

is taken, finally obtains the asphalt content in the

waste asphalt mixture powder to be 9.5%.

In order to characterize the properties of the

waste material powder, the three indexes for

recovering the asphalt were tested after the

extraction test. The results are shown in Table 1.

Table 1 Extraction and recovery of asphalt properties.

inde

x

25℃penetrati

on (0.1mm)

15℃ductility

(cm)

softening point(ring

and ball method)(℃)

Valu

e

28.6 1.2 56.2

2.2 Screening Test of Waste Asphalt

Mixture Powder

In order to analyze the performance of waste

material and determine its gradation, sieving test

was carried out. Prior to each screening test, a small

amount of lumps in the waste material powder were

crushed, and then a certain amount of waste material

powder was taken and fully stirred and then

sampled, two parallel tests were performed each

time and a dry screening method was used. The test

results are shown in Table 2.

Table 2 Results of screening test for waste material

powder.

Screen size

(mm)

2.36 1.18 0.6 0.3 0.15

0.07

5

Percentage

passing

(%)

100 99.0 87.7 76.0 46.7 26.7

3 ANALYSIS OF MECHANICAL

PERFORMANCE OF CEMENT

CONCRETE MIXED WITH

WASTE POWDER

In this paper, the effect of waste material powder on

the flexural tensile strength and elastic modulus of

cement concrete is mainly analyzed. At the same

time, the change of concrete compressive strength is

analyzed, and the best dosage of the best waste

material is summed up. The test program is based on

the use of waste material powder instead of sand

0%, 10%, 15%, 20%, 25% five different mixing

ratio of the mechanical properties of the test.

3.1 Flexural Tensile Strength

The flexural tensile strength of cement concrete for

road pavement is the main strength index, and the

compressive strength is used as a reference strength

index. So when evaluating the performance of road

cement concrete, we should first analyze whether its

flexural strength meets the requirements. Through

indoor standard test, the flexural tensile strength of

concrete is shown in Table 3.

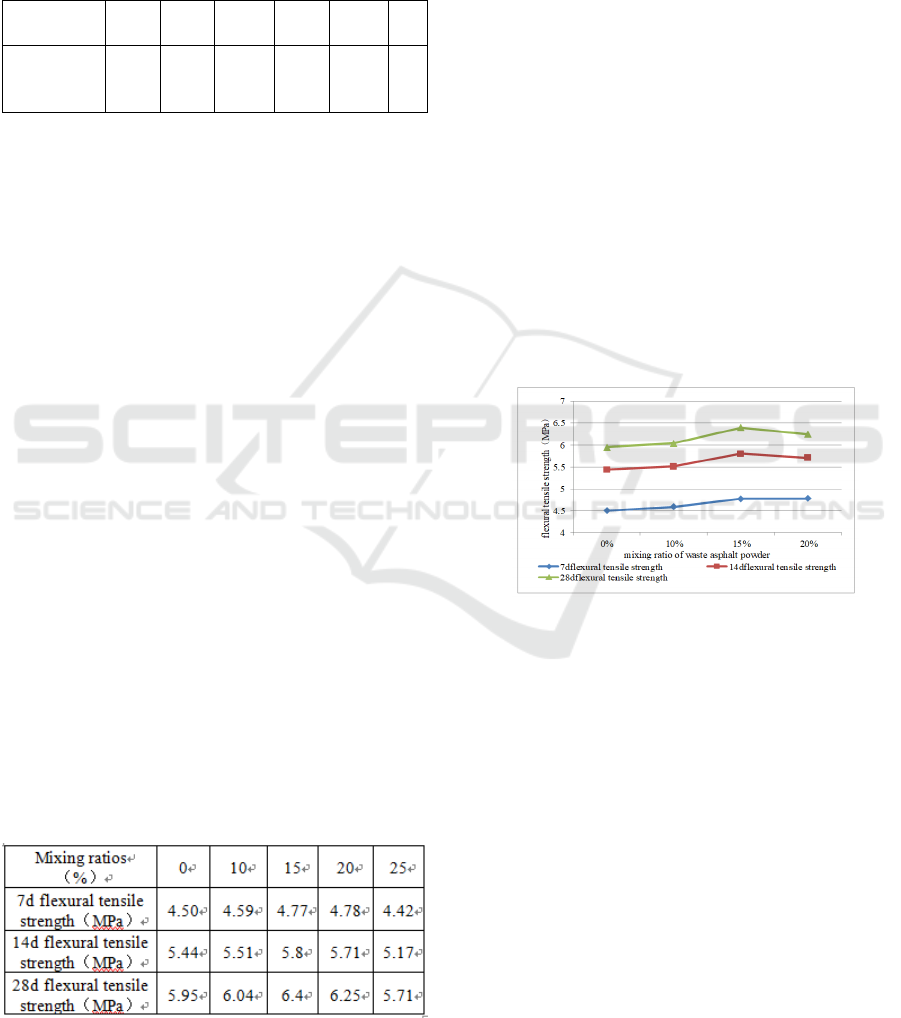

Table 3 The flexural tensile strength of concrete with

different mixing ratios and ages.

From Table 3 and Figure 1, we can see:

(1)When the mixing ratio is less than 20%,

the flexural tensile strength of cement concrete

mixed with waste material is improved, and when

the proportion of mixing is 25%, the flexural tensile

strength of the concrete is reduced to a certain

extent.

(2)When the curing period was 7 days, the

concrete flexural strengths of 10%, 15%, and 20%

were higher by 2.0%, 6.0%, and 6.2%, respectively,

than those of the concrete without blended waste

powder.

( 3 ) With a curing period of 14 days, the

concrete flexural strengths of 10%, 15%, and 20%,

respectively, increased by 1.3%, 6.6%, and 5.0%,

respectively, compared with the concrete without

undoped waste powder.

(4)When the curing age is 28 days, when the

proportion of waste powder mixed is 15%, the

concrete tensile flexural strength increases by 7.6%;

the blending ratio is 20%, and the concrete flexural

strength increases by 5.0%. Therefore, the integrated

early concrete flexural tensile strength and 28-day

standard strength, the best mixing ratio of waste

powder is 15%.

Figure 1 The flexural tensile strength of concrete with

different mixing ratios and ages.

3.2 Elastic Modulus

Elastic modulus is one of the important mechanical

properties of concrete. It reflects the relationship

between concrete stress and its strain. It is one of the

parameters necessary to calculate the deformation of

concrete structure, crack cracking and temperature

stress. In this paper, the compressive elastic modulus

of cement concrete prism is analyzed, and the

mechanical properties of cement concrete mixed

with waste material powder are evaluated. The

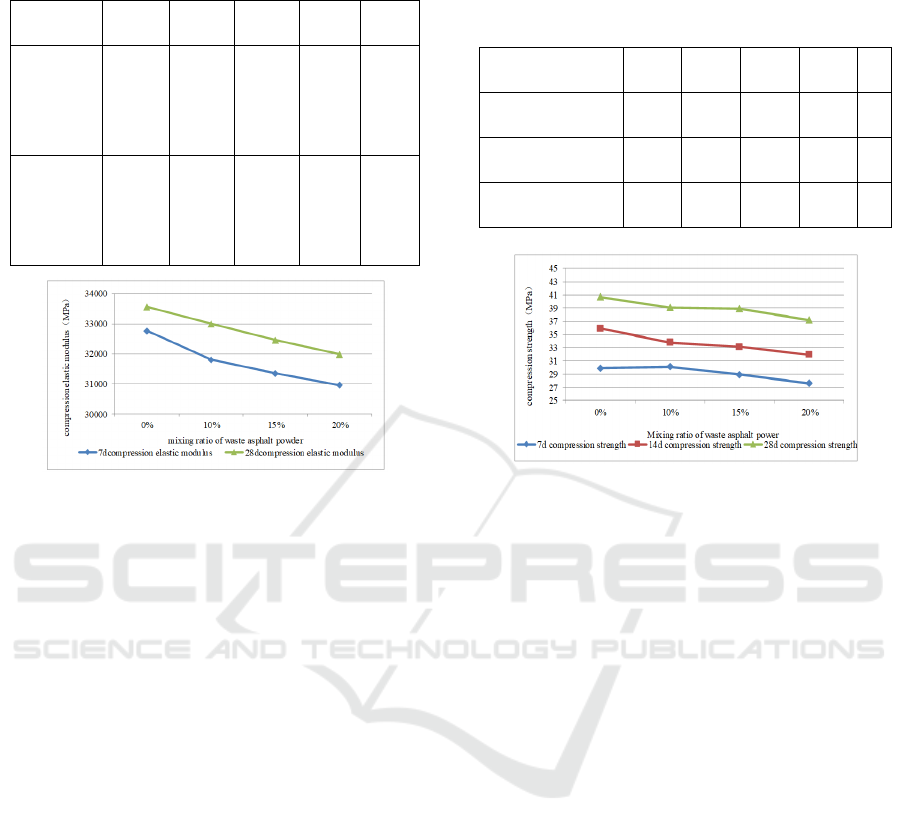

experimental results are shown in Table 4.

Table 4 Concrete compression elastic modulus with

different mixing ratios and ages.

mixing

ratios(%)

0 10 15 20 25

7d

compression

elastic

modulus(

MPa)

32760 31797 31348 30959 31774

28d

compression

elastic

modulus(

MPa)

33560 32996 32453 31983 32587

Figure 2 Concrete compression elastic modulus with

different mixing ratios and ages.

From Table 4 and Figure 2 we can see:

( 1 ) The compressive elastic modulus of

cement concrete mixed with waste material is lower

than that of the concrete without waste material,

However, as the curing age continues to increase,

the decrease in the elastic modulus at the later stage

of the concrete becomes smaller, that is, the decrease

in elastic modulus at the later stage is less obvious

than at the early stage.

( 2 ) When the proportion of waste powder

mixed is 20%, the compressive elastic modulus of

cement concrete decreases by a maximum of 4.7%

over 28 days.

Combine the change rule of the compressive

elastic modulus of the concrete of each age, and

determine the best proportion of the waste material

mixed is 20%.

3.3 Compressive Strength

According to the standard method, this test was

made of cubic compressive specimens of 150mm x

150mm x 150mm, which were cured under standard

curing conditions for 7d, 14d, and 28d. Their

ultimate compressive load was measured according

to the standard method. The test results are shown in

Table 5.

Table 5 Concrete compression strong with different

mixing ratios and ages.

mixing ratios(%

)

0 10 15 20 25

7d compression

strength(MPa)

29.9 30.1 28.9 27.6 25.3

14d compression

strength(MPa)

35.9 33.8 33.1 31.9 30.2

28d compression

strength(MPa)

40.7 39.1 38.9 37.2 36.1

Figure 3 Concrete compressive strength with different

mixing ratios and ages.

From Table 5 and Figure 3, it can be seen that

the compressive strength shows a different degree of

decline, and as the proportion of blending increases,

the decrease extent increases. At curing age of 28

days, the compressive strength of concrete with a

content of more than 20% decreased by

10%.Therefore, in order to ensure the compressive

strength requirements of road concrete, it is

recommended that the mixing ratio of waste material

should not exceed 20%.

3.4 Mechanism of Action Analysis

( 1 ) Influence of waste powder on flexural

tensile strength of cement concrete

From the observation of the truncation of the test

specimens of concrete flexural tensile strength test,

it can be seen that compared with the ordinary

concrete specimens, the cross section color is

relatively dark, the surface pores are relatively small,

and the sand on the surface is relatively less.

The following analysis of the mechanism of

action of waste powder in concrete from three

aspects:

①Filling mechanism. The strength of concrete

depends mainly on the strength of the cement slurry,

and the porosity is a decisive factor in the strength of

the cement slurry, so the porosity of the concrete

structure is an important factor affecting its strength.

The waste material used in this test is a kind of

powder like mineral powder on the particle size. It

effectively fills the void in cement concrete structure

in cement concrete structure, making the whole

structure of concrete more dense and improving the

flexural strength.

②Viscoelastic mechanism. The old asphalt in

the waste material has a certain bonding effect,

which forms a chain or reticular structure inside the

concrete structure under the effect of temperature.

On the one hand, this kind of bonding can reduce the

appearance of early micro cracks or prevent the

further expansion of the cracks. On the other hand,

the waste material powder, as an elastic medium,

exists in the concrete. The strain of the material is

buffered under the stress action, that is, a certain

buffer action is played when the micro cracks appear

under the action of load and temperature.

③Reaction mechanism. Along with the

hydration of cement, the bitumen and mineral

powder in the waste material will react with the

concrete and the aggregate minerals in a series of

physical and chemical reactions mainly by acid and

alkali neutralization reaction. It is mainly reflected

in the hydration and exothermic environment. The

acid aging asphalt in the waste material is reacted

with the cement to produce some kind of material.

At the same time, the mineral powder reacts with

some minerals of the aggregate in the concrete, and

the physical and chemical changes occur.

( 2 ) Influence of waste powder on elastic

modulus of cement concrete

The waste asphalt mixture powder that replaces

part of the sand in this test is a powdery substance

with a particle size of 2.36 mm or less and has

viscoelastic properties. After mixing with cement

paste in concrete, it is equivalent to increasing the

fluidity of the mixture and exerting its viscoelastic

characteristics, thus reducing the modulus of

elasticity of concrete.

4 CONCLUSIONS

Through the mechanical performance test and

analysis, we can get the following conclusions.

(1)The waste material which is replaced by

sand 15% can obviously improve the flexural

strength of cement concrete, and its modulus of

elasticity has a downward trend, and has little effect

on the decline of compressive strength.

(2)After processing the waste asphalt mixture

through the special crushing and screening

equipment, the waste material is obtained. Replacing

some of the sand in the cement concrete can

obviously improve the mechanical properties of the

concrete, such as the flexural tensile strength and so

on, thus reducing the production of pavement cracks

and prolonging the life life of the pavement.

REFERENCES

1. Huang, X.M. Zhao, Y.L., et al. Analysis of Asphalt

Pavement Recycling Test [J], Chinese Journal of

Geotechnical Engineering, 2001(04):468-471.

2. Wang, H.P. Research on crack resistance of cement-

stabilized macadam with mixed waste materials[D],

Chang’an University, 2011.

3. Liu, Z.H. Research on the Recovery Test and

Recycling Technology of Used Asphalt Pavement [D],

Chongqing traffic University, 2012.

4. Zhang, D.S. Wang, H.P., Research on Crack

Resistance of Cement Stabilized Crushed Stones

Mixed with Waste Old Asphalt Mixtures[J].China

Foreign Highway,2006(05):221-225.

5. Bi, H.J., Zhang, X.H., The recycling of used asphalt

mixture[J], Traffic World, 2006(01):70-73.

6. Ru. B., continued macro. Application of asphalt

milling material regeneration technology [J], Shanxi

Architecture: 2003(06):111-112.

7. Qu, Q.Y., Zhang, L.J., Fu, C.C., The performance of

self-compacting concrete mixed with used asphalt

mixture[J], Subgrade Engineering, 2017(02):118-121.

8. Shang, H.S., Zhao, Y.G., Research on the Test of

Waste Stabilized Bituminous Mixtures[J].Journal of

Gansu Sciences,2016(06):85-88.

9. Wang, H.P., Zhang, D.S., Lu, J.J., Impact of mixed

fine asphalt mixture on the compressive strength of

cement stabilized macadam [J], Highway,

2012(06):204-208.

10. JTG E30-2005. Test protocol for cement and cement

concrete in highway engineering [S], Beijing: China

Communications Press, 2005.