Schiff-base Complexes Immobilized on the Fe

3

O

4

@SiO

2

for

Selective Oxidation of Benzyl Alcohol

F H Li

1

, S S Jia

1

, Y W Fang

1

and Y B Song

1, *

1

College of Science,Shantou University, Shantou, Guangdong, 515063, China

Corresponding author and e-mail: Y B Song, ybsong@stu.edu.cn

Abstract. Efficient and highly selective heterogeneous catalysts were prepared through

grafting the metal-salen on the modified magnetic nanoparticles. Fe

3

O

4

nanoparticles were

prepared was hydrothermal synthesis, after the Fe

3

O

4

@ SiO

2

was amino-functionalized using

3-aminopropyltriethoxysilane and then Fe

3

O

4

@ SiO

2

-NH

2

was obtained by the reaction.

Finally, Fe

3

O

4

@ SiO

2

[(EtO)

3

Si-L

2

]/Mn were successfully synthesized. These

surface-modified nanoparticles were using various characterize techniques such as XRD,

FT-IR and SEM. The heterogeneous catalyst showed high conversion and selectivity in the

reaction of oxidation of benzyl alcohol. Furthermore, the catalysts were easily separated by

the external magnetic field after the reaction, reused at least 8 consecutive cycles without

significant loss catalysis activity.

1. Introduction

Metal Schiff-base complexes have a wide range of applications in catalysis. Schiff-base complexes

coordinate with transition metal easily, and form steadily metal Schiff-base complexes with different

valence state. The metal Schiff-base complexes could catalysis a lot kinds of chemical reactions, and

prepare essential chemical intermediates, such as polymerization reaction [1], oxidation reaction

[2-3], epoxidation reaction [4], reduction reaction [5], Michael addition reaction [6], cyclopropane

reaction [7-8], ring opening reaction [9]. Homogeneous metal Schiff-base complexes have high

catalytic activity. However it is difficult to separate them from the products, they are not conducive to

reuse, which greatly limits the catalyst of reuse. In addition, in the process of the catalysis reaction,

polymerization phenomenon can also lead to deactivation of catalyst. So the heterogenization of the

homogeneous catalyst research increasingly draws people attention. Heterogenization not only can

keep the structure of the homogeneous catalyst and the excellent properties, but also can avoid the

disadvantage of recycling hard. At the same time, Heterogenization could show some synergistic

effect, which can improve the catalyst of performance.

At present, the supporting according to their material can be divided into inorganic supporting,

organic synthetic polymer supporting, natural high polymer supporting. Inorganic supports mainly

including carbon nanotubes, carbon nanofibers, SiO

2

particles, zeolites. These supports with high

specific surface area to disperse the metal Schiff-base complex greatly improve the catalytic

performance. Guangxing Li encapsulated Co(salen) in NaY type molecular sieve to catalyze the

oxidative carbonylation reaction of benzene ammonia under the condition of 170°C , and high

conversion and selectivity were obtained [10]. Priti Sharma grafted Mn Schiff-base complexes on the

modified SBA-15 to catalyze the oxidation of sulfide [11]. Organic synthetic polymer carrier contains

Li, F., Jia, S., Fang, Y. and Song, Y.

Schiff-Base Complexes Immobilized on the Fe3O4@SiO2 for Selective Oxidation of Benzyl Alcohol.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 409-415

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

409

polyacrylic acid polymer material, polypropylene, polyvinyl alcohol and polyethylene imine. Kim et

al. prepared heteropoly nuclear complexes by inserting the metal Schiff-base complexes into the

structure of the polymer to catalyze ring-opening reaction of epoxide. Alan J.McCue reported [12]

epoxidation reaction catalyzed by one kind of chiral metal Schiff- base immobilized onto PAMAM

polymer.

Ferroferric with the spinel structure oxide belongs to the cubic crystal system. It has good

magnetic properties that make it useful in the field of magnetic storage, microwave absorbing

materials, coatings with special function, drug targeting, magnetic multifunctional composite

materials, biological engineering [13]. The catalyst immobilized on the magnetic materials can be

recycled by the extra magnetic field, which can reduce the cost of reaction and avoid the organic

solvents pollution to the environment. Magnetic nanoparticles may be synthesized by several typical

methods, including coprecipitation [14], microemulsion synthesis [15], hydrothermal synthesis [16],

thermal decomposition [17], sol-gel [18], and others [19]. The morphology and properties of the

product vary from preparation process. People can select the suitable preparation methods to achieve

the desired goal according to the need.

2. Experiments

2.1. Materials and characterization

Ferric chloride (FeCl

3

·6H

2

O), 3-Aminopropyltriethoxysilane, tetraethyl orthosilicate (TEOS),

ethylene glycol,3,5-Dinitro-2-hydroxybenzaldehyde , metal acetate, ammonia (25 wt.%) were

purchased from commercial sources and used for the reaction without further purification. Thermo

scientific Nicolet Magna 750 Research FT-IR Spectrophotometer. X-Ray power diffraction (XRD)

pattern were carried out utilizing a Brucker D8 Advance diffractor meter equipped with Cu-Kα

radiation (λ=0.15418nm) at 40 kV and 40 mA. The diffraction data were revealed under 2θ between

10~70°. The surface morphology and microstructure of these samples was exhibited utilizing a

Scanning Electron Microscope (SEM).

2.1.1. Preparation of ligand and magnetic nanoparticles (Fe

3

O

4

). The ligand was prepared according

to the reported method [20-21]. The preparation of magnetic nanoparticles specific experimental

steps: 1.35 g of ferric chloride hexahydrate was dissolved in 60 ml of ethylene glycol with stirring to

form a clear solution. Then surface active agent and anhydrous sodium acetate (6.12 g) was added

under magnetic stirring to form a uniform system. Next transferred into a Teflon-lined stainless-steel

autoclave with a capacity of 100 ml, heated to 200 ºC for 10h. After cooling to room temperature the

resultant solid was filtered, and the black solid products were collected and washed with ethanol and

distilled water some times, respectively. Finally the products were dried in vacuum for 10 h at 60 ºC .

2.1.2. Preparation of magnetic Fe

3

O

4

@SiO

2

nanoparticles. Ferroferric oxide nanoparticles (1 g)

were distributed and ultrasonic in the mixture of ethanol 35 ml and deionized water 10 ml for 15 min.

TEOS 1.5 ml was added slowly to the dispersion and ultrasonic for another 10 min. Then aqueous

ammonia (10 %, 1.4 ml) was added slowly over 10 min under mechanical stirrer. The reaction

continued for 12 h at 40°C . After the reaction, the silica coated magnetic nanoparticles was separated

from the mixture using the extra magnetic field and washed several times with distilled water and

ethanol. The products were vacuum dried for 10 h at 60°C . At last obtained the silica coated

ferroferric oxide nanoparticles Fe

3

O

4

@SiO

2

.

2.1.3. Preparation of Fe

3

O

4

@ SiO

2

[(EtO)

3

Si-L

2

]/Mn. For the modification step: 2 g of Fe

3

O

4

@SiO

2

were dispersed in 100 ml of toluene. After 15 min ultrasonic processing 2 ml

3-Aminopropyltriethoxysilane were added into the suspension under nitrogen atmosphere. Then the

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

410

mixture was refluxed for 12 h. After the result solid cooled to room temperature, the products were

separated by the magnetic field, and washed with a certain volume of ethanol and deionized water

several times, respectively. Last the products were vacuum dried for 10 h at 100 ºC. For the grafting

step: The modified material was dispersed into 100 ml of acetonitrile ultrasonic for 10 min. Added

3.2 mmol 3,5-Dinitro-2-hydroxybenzaldehyde and 0.5 ml triethylamine into the suspension, then the

resulted mixture was refluxed for 12 h. When it cooed room temperature, the products were removed

by the extra magnetic field, washed with a certain volume of ethanol several times. The final

products dried vacuum 100 ºC for 10 h. The above products dispersed into the solution of 50 ml of

ethanol solution containing 1.5 mmol of metal acetate. After ultrasonic for 10 min, the resulted

mixture was refluxed for 10 h. While the reaction cooled room temperature, the final products were

removed by the extra magnetic field, and then washed with ethanol several times and vacuum dried

for 10 h at 100 ºC.

2.2. Test the catalytic performance

The oxidation reaction was carried out in a 50 ml round bottomed flask equipped with a condenser

and a stirrer. H

2

O

2

was used as oxidation. Benzyl alcohol 0.28 mmol and 30 ml toluene, catalyst 100

mg was added into the flask. The flask was immersed into an oil bath to keep the reaction

temperature at 60 °C . The reaction continued for 4 h. Then use the gen GC 800 to detect the reaction

conversion and selectivity.

3. Results and discussion

3.1. Preparation and characterization of the modified Fe

3

O

4

@ SiO

2

catalyst.

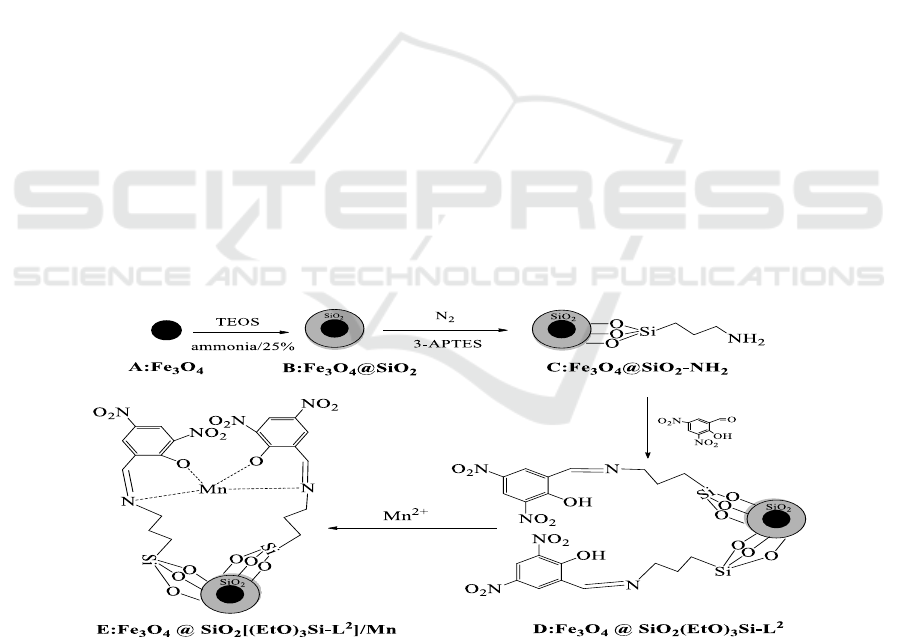

As illustrated in Figure 1 the overall procedure for the preparation of the catalyst contains three steps.

Firstly, Fe

3

O

4

nanoparticles were synthesized via a solvothermal method according to the previous

report [22-23].

Secondly, a thin silica layer was coated on the surface of the prepared Fe

3

O

4

nanoparticles to form Fe

3

O

4

@SiO

2

composites through adding TEOS and aqueous ammonia (10 %).

Thirdly, the Fe

3

O

4

@SiO

2

composites were modified with ammonia propyl triethoxy silane to

increase the functional group. The groups were used to grafting the metal Schiff-base complexes.

Figure 1. Catalyst preparation process: (A) Fe

3

O

4

(B)Fe

3

O

4

@ SiO

2

(C) Fe

3

O

4

@ SiO

2

-NH

2

(D)

Fe

3

O

4

@ SiO

2

(EtO)

3

Si-L

2

(E) Fe

3

O

4

@ SiO

2

[(EtO)

3

Si-L

2

]/Mn.

Schiff-Base Complexes Immobilized on the Fe3O4@SiO2 for Selective Oxidation of Benzyl Alcohol

411

3.2. Characterization of the catalyst

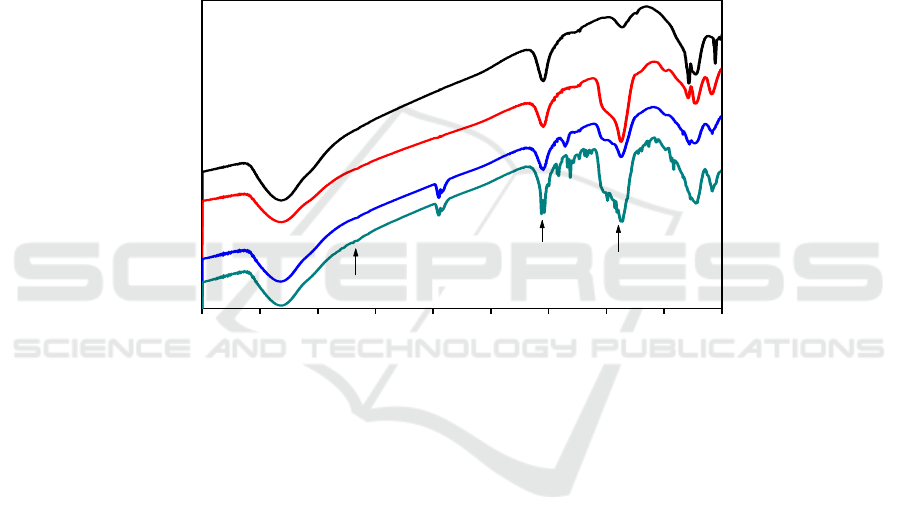

3.2.1. FT-IR. The strong absorb bands related to Si–O–Si stretching vibrations was observed in all

spectra at 1000-1100 cm

-1

shown in Figure 2. It is suggest that silica shell is successfully formed on

the magnetic nanoparticles surface. The spectrum of Fe

3

O

4

@SiO

2

-NH

2

(Figure 1c) showed several

signals appeared in the area of 1450-1560 cm

-1

and 2250-2345 cm

-1

which are related to C-H

stretching modes of the propyl groups. These bands conformed that the Fe

3

O

4

@SiO

2

was by

3-Aminopropyltriethoxysilane successfully modified. In the spectrum a band at 1630 cm

-1

associated

to C=N stretching vibration [24], and some weak bands at 3066-3040 cm

-1

and 1400-1500 cm

-1

assigned to stretching vibrations of aromatic rings were observed in Figure1(d). These bands

confirmed the successful anchoring of Schiff base ligand. The band at 1615 cm

-1

(Figure 1d)

indicated the coordination of C=N group of complexes with Mn. Also, a new absorption band at 529

cm

-1

was assigned to Mn-N band [25].

4000 3600 3200 2800 2400 2000 1600 1200 800 400

Wavenumber(cm

-1

)

Transmittance(a.u.)

(a)

(b)

(c)

(d)

1615

3066

1091

Figure 2. The FT-IR spectrum of (a)Fe

3

O

4

(b)Fe

3

O

4

@SiO

2

(c)Fe

3

O

4

@SiO

2

-NH

2

and (d) Fe

3

O

4

@

SiO

2

[(EtO)

3

Si-L

2

]/Mn.

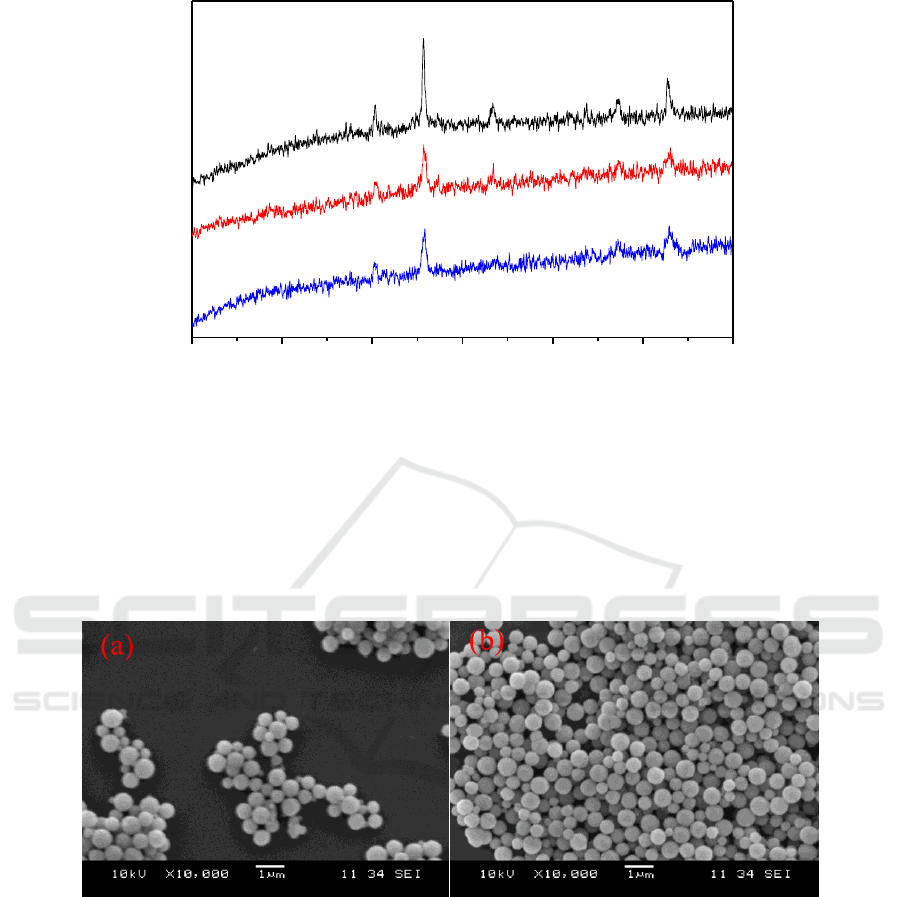

3.2.2. XRD. From the XRD spectra of the samples in Figure 3, the characteristic diffraction peaks of

the Fe

3

O

4

nanoparticles could be observed at 2θ=29.91, 35.41, 43.11, 57.21, and 62.81°, which can

be assigned to cubic spinel phase of Fe

3

O

4

[26]. However the main peaks of Fe

3

O

4

@ SiO

2

and Fe

3

O

4

@ SiO

2

[(EtO)

3

Si-L

2

]/Mn exhibit no obvious changes compared to Fe

3

O

4

, which confirmed that the

coating and grafting process didn’t induce any phase change of the Fe

3

O

4

.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

412

10 20 30 40 50 60 70

2/degree

(a)

(b)

(c)

29.91

35.41

43.11

57.21

62.81

Intensity(a.u.)

Figure 3. The X-ray diffraction patterns of (a) Fe

3

O

4

(b) Fe

3

O

4

@SiO

2

(c) Fe

3

O

4

@

SiO

2

[(EtO)

3

Si-L

2

]/Mn.

3.2.3. SEM. The image in Figure 4 showed the morphology change in the modification process. The

image of the production after coating showed less smoothing than before, which may cause by the

coating process. This could confirm the coating modification process might be successful. And after

coating showed some agglomeration piece that might be the SiO

2

.

Figure 4. SEM images of Fe

3

O

4

before (a) and after coating modification (b).

3.3. Catalyst activity tests

Table 1 showed performance of homogeneous catalyst and heterogeneous catalyst in selectivity

oxidation of benzene methanol. From the blank experiment, the influence of the 1, 2, 3 to the catalyst

could be excluded. Through comparing the entries 4 with 5, the little reduction of performance

happened, which might be related with the loading amount of homogeneous catalyst. In the

modification process, the loading amount was limited, so the catalysis effect decreased. Compared

with other reports literature, The reaction conversion rate relatively lower. We will continue to study

the catalyst performance.

Schiff-Base Complexes Immobilized on the Fe3O4@SiO2 for Selective Oxidation of Benzyl Alcohol

413

Table 1.Test of catalysis performance.

Entry

Catalyst

Conversion (%)

Selectivity (%)

1

L

2

0.78

96.0

2

Fe

3

O

4

@SiO

2

1.2

97.2

3

Mn-acetate

7.5

95.3

4

Mn-L

2

74.1

98.6

5

Fe

3

O

4

@ SiO

2

[(EtO)

3

Si-L

2

]/Mn

71.2

97.5

3.4. Catalyst life tests

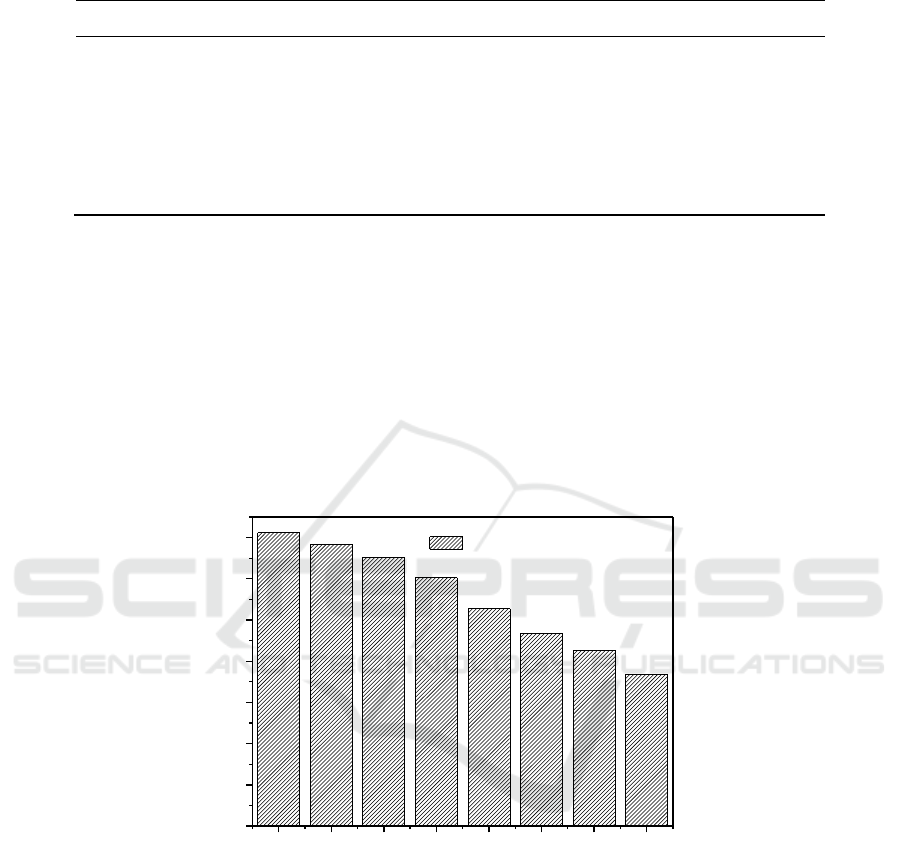

Figure 5 shows the catalyst life in the recycle process. In the experiment, the recovered

heterogeneous catalyst can be reused for at least 5 times at the same reaction conditions without great

loss of activity. After 5 times reused, the damage of coating layer and the small part of

polymerization of the Schiff base complexes may cause the decrease gradually. However the

performance of the homogeneous catalyst reduced apparently in the recycle process, and they almost

deactivated after the 4 times. So the immobilization can efficiently enhance the recycle capacity of

the catalyst. Although catalyst can be reused eight times, and closed to reported literature, but the

catalytic performance of falling fast, we will continue to further research.

1 2 3 4 5 6 7 8

0

10

20

30

40

50

60

70

Conversion (%)

Recycle times

Fe

3

O

4

@ SiO

2

[(EtO)

3

Si-L

2

]/Mn

Figure 5. Catalyst life test.

4. Conclusions

In this work we have shown that heterogeneous catalyst made by anchoring the metal Schiff-base on

the magnetic nanoparticles coated by silica have excellent performance in the reaction of selective

oxidation of benzyl alcohol. The catalyst can be reused for at least 8 times without great loss of

activity. Due to the magnetic nature of the support, the catalyst was separated simply by applying an

external magnet. It is not only reduced the pollution of organic solvent used in the recycle process,

also is good to the practical application in industry.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

414

Acknowledgement

Financial supports from the Science and technology planning project of Guangdong Province (No.

2014A020216045, 2013KJCX0081) are gratefully acknowledged.

References

[1] Matsui S and Fujita T 2001 Catal. Today 66 63-73

[2] Willingh V, Gavin, Abbo H S and Titinchi S J J 2014 Catal.Today 227 96-104

[3] Farzaneh F, Majidian M and Ghandi M 1999 J. Mol. Catal. A: Chem. 148 227-233

[4] Musie G, Wei M, Subramaniam B, and Busch D H 2001 Coord. Chem. Rev. 219

789-820

[5] Fehring V and Selke R 1998 Angew. Chem. Int. Ed. 37 1827-30

[6] Suga H, Fudo T, and Ibata T 1998 Synlett. 1998 933-935

[7] Che C M, Kwong H L, Chu W C, Cheng K F, Lee W S, Yu H.S and Cheung K K 2002 Eur. J.

of Inorg.Chem. 2002 1456-63

[8] Kowalak S and Balkus K J 1992 Collect. Czech. Chem. Commun. 57 774-780

[9] Lee K Y, Kawthekar R B and Kim G J 2007 Bull Korean Chem. Soc. 28 1553-61

[10] Li G, Chen L, Bao J, Li T and Mei F 2008 Appl.Catal. A: General 346 134-139

[11] Sharma P, Lazar A and Singh A P 2012 Appl. Catal. A: General 439 101-110

[12] McCue A J, Urgast D S, Wells R P, and Anderson J A 2014 Catal. Commun. 43 159-163.

[13] Zhang L, Wang T, Liu P 2012 Chem. Eng. J. 187 372-379

[14] Lee S J, Jeong J R, Shin S C, Kim J C and Kim J D 2004 J. Magn. Magn.Mater. 282

147-150

[15] Chin A B and Yaacob I I 2007 J. Mater. Process.Technol. 191 235-237

[16] Wan J, Chen X, Wang Z, Yang X and Qian Y 2005 J.Cryst. Growth 276 571-576

[17] Miguel-Sancho N, Bomati-Miguel O, Roca A G, Martinez G, Arruebo M and Santamaria J

2012 Ind. Eng. Chem. Res. 51 8348-57

[18] Niederberger M. Acc. 2007 Chem. Res. 40 793-800

[19] Kim E H, Lee H S, Kwak B K, and Kim B K 2005 J. Magn. Magn.Mater. 289 328-330

[20] Zhu D, Mei F, Chen L, Li T, Mo W and Li G 2009 Energy Fuels 23 2359-2363

[21] Reddy G R, Balasubramanian S and Chennakesavulu K 2014 J. Mater. Chem. 2 15598-15610

[22] Chen D, Xu R 1998 Mater. Res. Bull 33 1015-21

[23] Wan J, Chen X, Wang Z, Yang X and Qian Y 2005 J. Cryst.Growth 276 571-576

[24] Arshadi M and Ghiaci M 2011 Appl. Catal. A: General 399 75-86

[25] Chen L, Li B and Liu D 2014 Catal.Lett. 144 1053-61

[26] Kong L, Lu X, Bian X, Zhang W and Wang C 2010 ACS Appl. Mat.Interfaces 3 35-42

Schiff-Base Complexes Immobilized on the Fe3O4@SiO2 for Selective Oxidation of Benzyl Alcohol

415