Study on Performance Test Method of Solar Assisted Gas

Heating System

Y Wang

1,2

, W X Gao

2,*

L Yang

2

, W Y Zhou

2

and Q Wang

2

1

School of Environmental Science and Engineering, Tianjin University, Tianjin,

No.92 Weijin Road, China

2

North China Municipal Engineering Design&Research Institute CO., LTD., Tianjin,

No.16 Guiyuan Road, China

Corresponding author and e-mail: W X Gao, wenxuegao@163.com

Abstract. In this study, a test method for thermal performance of solar assisted gas heating

system was taken as research object, basing on the existing relative test standards in China,

test system was set up, and test parameters and test method for thermal performance of the

heating system were put forward. Daily useful energy captured by solar collector, heat output

of the gas boiler, heat loss rate and energy efficiency coefficient of system were proposed to

analysis the thermal performance of the hybrid system.

1. Introduction

In view of the thermal performance test of solar assisted gas heating system, the relevant regulations

and standards, available in China, were mainly concentrated in a single heat source or very few

combined heating systems. Among them, for solar water heater, the relevant national and industrial

regulations and standards were mainly related to the basic standards, technical conditions,

performance evaluation standards, solar collector, water storage tank, supplementary heat source and

so on, thereinto the main standards for performance test were shown in Table 1. For gas boiler,

current performance test was carried out mostly according to the standards “Gas-fired heating and hot

water combi-boilers” (GB 25034-2010) and “Minimum allowable values of energy efficiency grades

for domestic gas instantaneous water heaters and gas-fired heating and hot water combi-boilers” (GB

20665-2015), principle product standards were shown in Table 2.

For solar assisted gas heating system, the existing standards were insufficient for the integrated

test indexes and interaction between different heat sources can not be truly reflected. At the same

time, in Europe energy labelling and ecodesign requirements for space heaters, combination heaters,

packages of space heater, temperature control and solar device and packages of combination heater,

temperature control and solar device were issued in 2013 [1-4], that provided a reference for the test

of multi-energy hybrid heating system.

Wang, Y., Gao, W., Yang, L., Zhou, W. and Wang, Q.

Study on Performance Test Method of Solar Assisted Gas Heating System.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 189-193

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

189

Table 1. Principle test regulations and standards for solar water heaters in China.

Number of standard

Name of standard

GB 50495-2009

Technical code for solar heating system

GB/T 25966-2010

Specification of domestic solar water heating systems with electrical auxiliary

heat source

GB/T 6424-2007

Flat plate solar collector

GBT 17581-2007

Evacuated tube solar collectors

GB/T 23889-2009

Specification of air source heat pump assisted domestic solar water heating

systems

GB/T 4271-2007

Test methods for the thermal performance of solar collectors

Table 2. Principle test standards for gas water heater in China.

Number of standard

Name of standard

GB6932-2001

Domestic gas instantaneous water heaters

GB18111-2000

Gas storage water heater

GB25034-2010

Gas-fired heating and hot water combi-boilers

GB20665-2015

Minimum allowable values of energy efficiency grades for domestic gas

instantaneous water heaters and gas-fired heating and hot water combi-boilers

2. Test system

The solar assisted gas heating system studied in this paper consisted of a solar heating unit and a gas

heating unit. In order to carry out the test for thermal performance of the system, a solar assisted gas

heating test platform was set up. The test devices and arranged test points were shown in Table 3 and

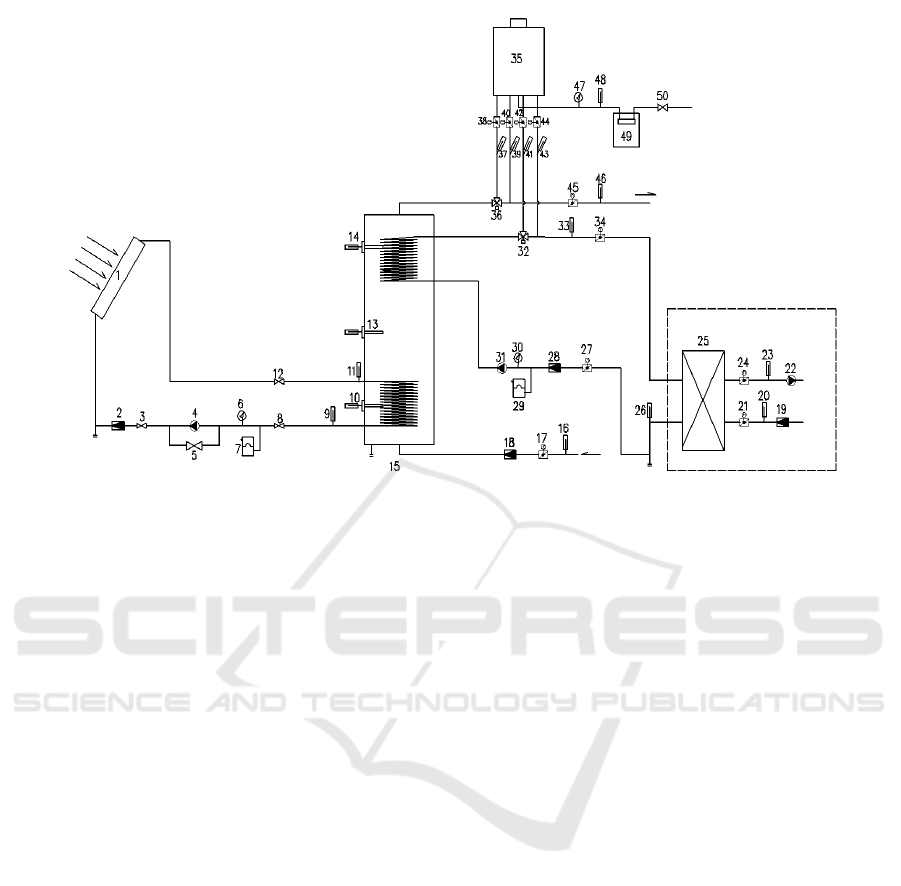

the flow chart of test system in Figure 1.

Table 3. Test devices and test parameters.

Test devices

Test parameters

Electromagnetic

flowmeter

Working mass flow of solar collector, L min

-1

;Water flow of domestic hot water,

L min

-1

; Water flow of space heating loop, L min

-1

;

Wet type

flowmeter

Gas flow, m

3

;

Temperature

sensor

Return water temperature of solar heater, °C ; Supply water temperature of solar

heater, °C ; Leaving water temperature, °C ; Tap water temperature, °C ; Supply

water temperature of space heating, °C ; Return water temperature of space

heating, °C ; Outlet hot water temperature of gas boiler, °C ; Inlet hot water

temperature of gas boiler, °C ; Outlet water temperature of gas boiler in space

heating loop, °C ; Inlet water temperature of gas boiler in space heating loop, °C ;

Water temperature in the upper part of tank, °C ; Water temperature in the middle

part of tank, °C ; Water temperature in the lower part of tank, °C ;

Electricity meter

Electricity consume of system, kwh; Electricity consume of gas boiler, kwh;

Electricity consume of solar collector, kwh; Electricity consume of pump in space

heating loop, kwh.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

190

Figure 1. Test system 1-solar collector; 2,18,19,28- electromagnetic flowmeter;

3,5,8,12,50-regulating valve; 4,22,31-pump; 6,30,47-pressure gauge; 7,29-expansion tank;

9,10,11,13,14,16,20,23,26,33,37,39,41,43,46,48- temperature sensor; 15-water tank;

17,21,24,27,34,38,40,42,44,45- electromagnetic valve; 25-plate-type heat exchanger; 32,36-

three-port valve;35-gas fired heating and hot water combi-boilers; 49-gas flowmeter.

3. Test conditions

Test should include at least 1 day to meet the following conditions: daily solar radiation was 10 MJ

m

-2

≤H≤25 MJ m

-2

; water temperature in the storage tank was t

b1

=15±2°C before test, and that was

t

e1

=50±2°C after; average ambient temperature was 0°C ≤t

ad

≤39°C ; reference gas was selected as test

gas (15°C , 101.3kPa); and the ambient wind speed was v≤4 m s

-1

.

4. Test method

(1) Before the beginning of test, storage tank should be full filled with cold water of 15±0.5 °C , and

solar collector was covered with sun visor.

(2) At the beginning of the test, sun visor was removed, water temperature of storage tank and test

time were started to be recorded; meanwhile outdoor ambient temperature t

ad

, the humidity d and

wind speed v were monitored in real time, and the electricity consumption N

1

and gas using amount

V

g1

were recorded at the same time, as well as the accumulated solar irradiation received by the solar

collector.

(3) During the test, flow rate of medium in solar circulation system was set at a constant discharge

between 6 L min

-1

and 10 L min

-1

, and the medium temperature at the entrance and exit of solar

collector, t

in1

and t

out2

, were recorded at least every 15s.

(4) When the solar irradiation accumulated to 10 MJ m

-2

, the combined operation of gas boiler and

solar heater was started; water out from boiler was set at 60°C ; storage tank was equipped with a

mixing pump, water intake and outlet were placed at the bottom and the top of this tank respectively,

mixing pump was run continuously during the whole period of test; when the water temperature in

the middle part of tank arrived at 50°C , gas boiler was closed, the mixing loop was stopped, and the

test was over.

Study on Performance Test Method of Solar Assisted Gas Heating System

191

5. Analysis of thermal performance

5.1. Daily useful energy captured by solar collector

60

1

outiiniiim

n

i

m

s

ttc

Q

(1)

In it, Qs was daily useful energy captured by solar collector, kJ; c

m

was specific heat capacity of the

solar cycle medium, kJ (kg °C )

-1

; ρ

m

was density of the solar cycle medium, kg L

-1

; υ

i

was flow rate

of the solar cycle medium, L min

-1

; τ

i

was measure interval, s.

Converted to the daily useful energy captured by solar collector, Q

s17

, kJ, under daily solar

irradiation of 17 MJ m

-2

, calculated as formula (2),

1

17

17

Ess

HQQ

(2)

In it, H

E

was accumulated solar irradiation received during the test, MJ m

-2

.

5.2. Heat output of the gas boiler

Under dry type flowmeter measuring, gas heat output was converted into gas heat input in the

reference condition according to formula (3); When the wet type flowmeter was used, the gas density

should be corrected by formula (4), and in it d was replaced by d

h

.

2/1

1

15.273

15.288

3.1013.101

3.101

1000

rg

gag

gig

d

d

t

ppp

VHQ

(3)

1

622.0

gassgah

ppppppdd

(4)

In them, Q

g

was heat output of the gas under 15°C , 101.3kPa and dry state, kJ; H

i

was low caloric

value of reference gas under 15°C and 101.3kPa, MJ Nm

-3

; V

g1

was consumption volume of gas, m

3

;

p

g

was gas pressure, kPa; t

g

was gas temperature, °C ; d was relative density of dry test gas,

dimensionless; d

r

was relative density of reference gas, dimensionless; p

s

was saturated vapor

pressure at t

g

, kPa; 0.622 was relative density of water vapor in ideal state, dimensionless.

5.3. Heat loss rate of system

1

1711

1

gsbe

QQtVc

(5)

In it, η was heat loss rate of system, %; c was specific heat capacity of water, kJ (kg °C )

-1

; ρ was

density of water, kg L

-1

; V was volume of storage tank, L; ∆t

e1b1

was temperature rise of water in

storage tank, ∆t

e1b1

=t

e1

-t

b1

, °C .

5.4. Energy efficiency coefficient of system

1

211111

tcegbe

QcVcNtVcCTP

(6)

In it, CTP was energy efficiency coefficient of system, dimensionless; N

1

was electricity

consumption of system, kwh; c

1

was standard coal coefficient of electricity, kg tce kwh

-1

; c

2

was

standard coal coefficient of gas, kg tce m

-3

; Q

tce

was calorific value of standard coal, kJ (kg tce)

-1

.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

192

6. Conclusions

Through the study of test method for thermal performance of solar assisted gas heating system, it

contributed to help consumers to specify the energy efficiency of hybrid heating system, and to

understand the thermal performance of different types of water heaters more directly. Thermal

performance of hybrid system was analysis, test method and test parameters were put forward in this

research, so as to choose heating water equipment more better, and directly promote the energy

efficiency of heating equipment and the application of renewable energy and energy saving

technology.

7. References

[1] European Commission 2013 No.811/2013 Energy labelling of space heaters, combination

heaters, packages of space heater, temperature control and solar device and packages of

combination heater, temperature control and solar device p 77-81

[2] European Commission 2013 No. 812/2013 Energy labelling of water heaters, hot water

storage tanks and packages of water heater and solar device p 123-127

[3] European Commission 2013 No. 813/2013 Ecodesign requirements for space heaters and

combination heaters p 156-159

[4] European Commission 2013 No. 814/2013 Ecodesign requirements for water heaters and hot

water storage p 173-177

Study on Performance Test Method of Solar Assisted Gas Heating System

193