Preparation of Nano-silica Dioxide Modified Cellulose Acetate (CA)

Membranes for Enhanced Performance in Forward Osmosis Process

Haiyang Jin

1,2,3

, Li Lin

1,2,*

, Min Liu

1,2

, Qingyun Li

1,2

, Zhuo Huang

1,2

, Xianqiang Tang

1,2

and Ping Yu

3

1

B

asin Water Environmental Research Department, Changjiang River Scientific Research Institute, Wuhan, Hubei, 430010,

People's Republic of China

2

Key Lab of Basin Water Resource and Eco-Environmental Science in Hubei Province, Wuhan 430010,

China

3

College of Chemistry and Molecular Sciences, Wuhan University, Wuhan, Hubei, 430072 People's

Republic of China

Email: linli1229@hotmail.com

Keywords: Forward osmosis, membrane modification, nano silica dioxide, cellulose acetate

Abstract: Nano-silica dioxide (nano-SiO

2

) modified cellulose acetate (CA) membranes for forward osmosis (FO)

were prepared by phase inversion via immersion precipitation technique. Nano-SiO

2

particles were added

into the casting solution of CA, 1, 4-dioxane, acetone, lactic acid and methanol to improve the FO

membranes performance. Different percentage of nano-SiO

2

(2, 4 and 6 wt. %) of CA composite

membranes were cast. The modified membranes were characterized by various methods to probe the

membranes structure and surface properties. The FO performances were also evaluated for the modified

membranes compared to the non nano-SiO

2

membranes. The surface hydrophilicity, porosity and tensile

strength of nano-SiO

2

CA membranes were improved with the increment of the percentage of nano-SiO

2

added to the CA. The morphological studies showed that the addition of nano-SiO

2

significantly changed

the surface properties of the CA membranes. The FO performance was evaluated using 1M NaCl solution as

feed solution and purified water as draw solution. The nano-SiO

2

CA membranes showed better water flux

and reverse salt flux in the range of 2–6 wt. % nano-SiO

2

content than original CA membranes. These

encouraging results suggested that nano-SiO

2

CA membranes displayed potential to be further developed for

FO applications.

1 INTRODUCTION

Forward Osmosis (FO) is the transportation of water

across a selectively permeable membrane from a

region with higher water chemical potential to a

region with lower water chemical potential. This

process is driven by a difference in solute

concentrations across the membrane which allows

passage of water but rejects most solute molecules

or ions. Due to its inherent advantages, such as low

energy expenditure, low membrane fouling, high

water recovery, simple configuration and equipment

and etc, forward osmosis process was extensively

studied by scientists for a variety of applications in

science and engineering (

Cath et al., 2006;

Shuaifei et al., 2012

). Now, its applications have

showed potential values in seawater desalination,

wastewater treatment, food and pharmaceuticals

processing, controlling drug release, and electrical

power generation (

Shuaifei et al., 2012; Achilli et

al., 2009

), etc.

However, there are some problems which limit

the use of FO, such as flux decline caused by

internal concentration polarization, lack of proper

draw solute and effective recovery. Recent works

have focused on reducing internal concentration

polarization and seeking optimal draw solute. The

internal concentration polarization which occurs

within the support layer is the major limiting factor

causing the decline of water flux (

McCutcheon and

Elimelech, 2006

). The influence of internal

concentration polarization on FO water flux has

been investigated by different modeling techniques

and the solution-diffusion theory (

Shuaifei et al.,

2012

). A variety of draw solutes/solutions,

including magnetic and/or hydrophilic nanoparticles

Jin, H., Lin, L., Liu, M., Li, Q., Huang, Z., Tang, X. and Yu, P.

Preparation of Nano-silica Dioxide Modified Cellulose Acetate (CA) Membranes for Enhanced Performance in Forward Osmosis Process.

In Proceedings of the International Workshop on Environment and Geoscience (IWEG 2018), pages 163-169

ISBN: 978-989-758-342-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

163

and organic compounds (Kim et al., 2012;

McCutcheon et al., 2005

), have been investigated

in FO process.

In the early study, reverse osmosis (RO)

membranes were tested for FO process. But they

showed low water flux due to the internal

concentration polarization caused by the porous

support layer. Hence, a perfect FO membrane should

consist of a single active layer without any support

layer (

Wang et al., 2010). However, the lack of

mechanical strength may limit its applicability.

Chung’s group developed flat-sheet CA-based

membranes comprised double- skinned layers that

were able to eliminate internal concentration

polarization (Zhang et al., 2010;

PhuongNgaNguyen et al., 2013

). However, the

membranes showed low water flux due to the

additional resistance to water transport. Thi Phuong

Nga Nguyen et al. prepared CTA/CA FO

membranes to improve water flux (

Smitha et al.,

2004

), but relatively high reverse solute flux (RSF)

limits the application of the membranes. It is

necessary to prepared FO membranes with high

water flux and salt rejection for practical application.

Introducing inorganic particles into membrane

materials has shown potential to improve the

permeability and selectivity of membrane (Sairam

et al., 2011

). Nano-silica dioxide (nano-SiO

2

) is

one of the most important new high-tech ultra-fine

inorganic materials and has lots of particular

characteristics: the particle size of 20±5 nm, the high

specific surface area of 640-700m

2

/g and superior

thermal and chemical stability. Besides, the rich

hydroxyl groups on the surface of nano-SiO

2

can

form hydrogen bonds with the hydroxyl groups of

polymer chains. In a word, nano-SiO

2

plays an

irreplaceable role in many subjects due to its

particular characteristics (

Liu et al., 2004)].

In this research, nano-SiO

2

are added into the CA

casting solution of 1,4-dioxane and acetone with

additives of lactic acid and methanol to prepare the

new nano-SiO

2

modified cellulose acetate (CA)

membranes for FO application. Membranes are

prepared by phase inversion. Subsequently, the new

nano-SiO

2

modified CA membranes are

characterized in different ways and compared with

CA membranes without nano-SiO

2.

The influences

of the content of nano-SiO

2

on the membrane

performance are also discussed.

2 MATERIAL AND METHODS

2.1 Materials

CA(54.5 ~ 56.0wt. ﹪ acetyl) were purchased from

Sinopharm Chemical Reagent Co., Ltd and used

without further purification. 1, 4-dioxane

(≥99.5%purity), acetone (≥99% purity), lactic acid

(≥99%purity) and methanol (≥99.8% purity) were

obtained from Sinopharm Chemical Reagent Co.,

Ltd. Sodium chloride (NaCl, 99%purity) and

deionized water were used for membrane

performance testing. Nano-silica dioxide (7nm) was

from Sinopharm Chemical Reagent Co., Ltd and

used for modifying. Disodium carbonate (Na

2

CO

3

,

Sinopharm Chemical Reagent Co., Ltd) was used as

an effluent for ion chromatography (ICS-900,

Dionex, CA, USA).

2.2 Preparation of Flat-sheet CA-based

Membrane and Nano-SiO

2

Modified CA Membrane

Flat-sheet membranes were prepared by phase

inversion. The casting solution contained CA

polymers dissolved into 1, 4-dioxane and acetone

with additives of lactic acid and methanol (

Sairam

et al., 2011

). The solution was kept in a round flask

sealed with a glass stopper to prevent evaporation of

the solvents. The solution was homogenized by

using a mechanical stirrer (JJ, Yitong Electron Co.,

Ltd, China). The casting solution was then cast on a

glass plate by using an 100mm thick casting knife in

a constant temperature (set up at 25℃) and humidity

(70% relatively humidity) room. After evaporation

of the solvent for 30s, the casting film together with

the glass plate was immersed in a coagulation bath

of 1±0.3℃ deionized water. The membrane was

then stripped off the glass plate and kept in a bath of

deionized water at room-temperature (20℃), which

was changed every 4h for 24h to wash out the

solvents. Then the membrane was stored in

deionized water for performance testing.

The compositions of casting solution were of

13.4 wt. % CA, 53.2 wt. % 1, 4-dioxane, 18.4 wt. %

acetone, 6.8 wt. % lactic acid and 8.2 wt. %

methanol. The nano-SiO

2

were added into the

solution in different contents (2, 4 and 6 wt. %) and

were dispersed by stirring for 8h at room

temperature. The resultant solution was prepared for

phase inversion after eliminating air bladder by

IWEG 2018 - International Workshop on Environment and Geoscience

164

sonic oscillating. The nano-SiO

2

modified CA

membranes are denoted as CAN-2, CAN-4 and

CAN-6 assigned to their nano-SiO

2

content.

2.3 Characterization of Membrane

Structure and Surface Properties

Scanning electron microscopy (SEM) was used to

acquire the cross section and top surface imaging of

membranes to determine the morphological

properties. The SEM analysis was performed using

FEI Quanta 200 from Holland and operated at 15

KV. Every membrane sample was dried under

vacuum for 24h to dehydrate it for preparing SEM

samples. Membranes were fractured in liquid

nitrogen to clearly scan the cross-section image. The

membranes were coated with a gold layer for

observation by a sputter coater. Furthermore, energy

dispersive spectrometer (EDS) was used to collect

the elemental composition of membranes.

Attenuated total reflectance spectroscopy (ATR-

FTIR) was used to analyze the chemical changes of

the membranes in this study. Nicolet AVATAR 360

FTIR Spectrophotometer together with an ATR

accessory (ZnSe crystal) was used to collect the

spectra. The incidence angle was 45

o

and each

spectrum was recorded using 32 scans at a resolution

of 4cm

−1

in the region between 400 and 4000 cm

−1

.

OMNIC 8.2 software was used to record the spectra,

correct their baselines, normalize the spectra and

find the peaks.

Contact angle measurements were conducted by

dynamic contact angle instrument (DSA100,

KRŰSS GmbH, Hamburg, Germany). Contact angle

indicates the hydrophilicity and the smaller angle

indicates the better hydrophilicity. Every membrane

sample was dried under vacuum for 24h before

measurement. Two replicates were used, and five

drops per replicate were measured.

Membranes porosity(Ɛ) was calculated from the

equations below (

Wang et al., 2010):

wet dry w

wet dry w dry p

(m - m )/ρ

ε 100

(m - m )/ρ (m /ρ )

=×

+

(1)

Where m

wet

and m

dry

are the mass of the hydrated

and dried samples, ρ

w

and ρ

p

are the density of water

and polymers at a dried state respectively. The

relative density of the CA polymers used is 1.31

g/cm

3

according to the reagent instructions.

Mechanical properties (e.g., tensile strength) of

the CA membranes and modified nano-SiO

2

CA

membranes were measured using a universal tensile

testing machine (AGS-J, Shimazu, Japan). Every

membrane sample was dried under vacuum for 24h

before measurement. The elongation velocity was 2

mm/min with an initial gauge length of 15 mm.

2.4 Performance Testing

The prepared membranes were tested in FO mode

using a test cell with 30.25cm

2

effective area (width,

6.5 cm; length, 6.5 cm). Either feed solution or draw

solution was kept in a 2L tank. Both solutions were

circulated at a rate of 15 L·h

−1

in a closed loop by

using two diaphragm pumps (PLD-2203, China).

The draw solution was placed on a weighing balance

and the feed solution was placed on a platform at the

same height to eliminate any gravitational effects.

Feed solution was Purified water from a Milli-Q

system(18M Ω cm) and draw solution was 1M

sodium chloride (NaCl). Both of the volume of the

solutions was 1L. Membrane performances were

assessed by measuring permeate water flux (J

w

) and

reverse salt flux (J

s

).

The permeate water flux (J

w

) was calculated

through the increment of the weight of the draw

solution because of the water permeated over the

membrane during the FO testing. The change of the

weight was obtained by the weighting balance which

the draw solution was placed on. Corresponding, the

feed solution was put on a platform at the same

height to eliminate any gravitational effects. The

calculation equation of water flux was as follows.

Where is the change of the weight of the

draw solution, is the water density, Am is the

effective membrane area and is the time of

testing.

RSF (reverse salt flux) was defined as the mass

of NaCl diffusing from the draw solution to the feed

solution per unit time per unit membrane area during

FO testing. The mass of NaCl was obtained through

the concentration of chloride ions in each solution

which was determined by ion chromatography. 10

mL samples of both solutions were collected for

determination before and after the testing. The

calculation equation of RSF was as follows:

()

(

2

w

w

J /h or LMH2)

Am t

ρ

Δ

=⋅

××Δ

lm

wΔ

ρ

tΔ

2

s-NaCl

w

J = (g/m h) (3)

Am t

⋅

×Δ

Preparation of Nano-silica Dioxide Modified Cellulose Acetate (CA) Membranes for Enhanced Performance in Forward Osmosis Process

165

Where w is the mass of NaCl, Am is the

effective membrane area and is the time of

testing.

The membrane performances were tested in AL-

FS (active layer facing feed solution) orientation.

Data were recorded after running of the system for 5

min to stabilize water flux and the testing time was 1

h. All the tests were conducted at 25℃and repeated

three times to minimize experimental error.

3 RESULTS AND DISCUSSIONS

3.1 FO Membrane Morphologies

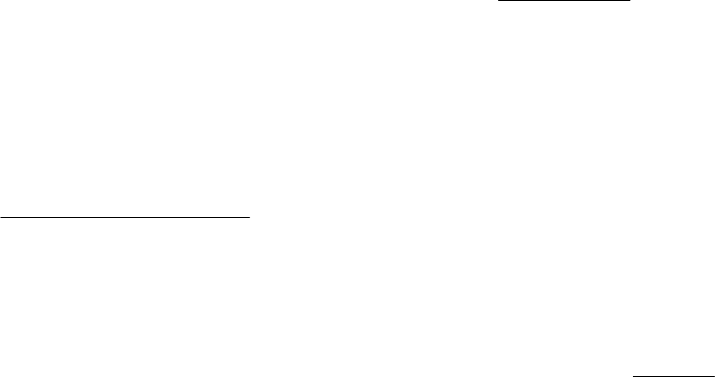

Figure 1: SEM cross sectional micrographs of CA

membranes prepared with: (a) 0 wt. % nano-SiO

2

, (b) 2

wt. % nano-SiO

2

, (c) 4 wt. % nano-SiO

2

and (d) 6 wt. %

nano-SiO

2

and amplified SEM cross sectional micrographs

of CA membranes prepared with: (e) 0 wt. % nano-SiO

2

,

(f) 2 wt. % nano-SiO

2

, (g) 4 wt. % nano-SiO

2

and (h) 6

wt. % nano-SiO

2

。

In the text, Figure 1 (a) to Figure 1 (d) shows the

cross-section morphology of CA membranes

prepared with different content of nano-SiO

2

in the

casting solution. The SEM images indicated that the

asymmetric structure of the membranes was not

changed by the presence of nano-SiO

2

. All the

membranes show the asymmetric structure of

compact cortical layer and porous support player

containing the finger-like structures. The Figure 1

(e) to Figure 1 (h) shows the amplified images of the

finger-like structure of the membranes and show that

the large pores appear gradually on the surface of the

support layer increase with the increment of the

content of nano-SiO

2.

The reason is that the addition

of nano-SiO

2

delays the process of the phase

separation during the preparation of membranes,

which plays an important effect on the membrane

structure.

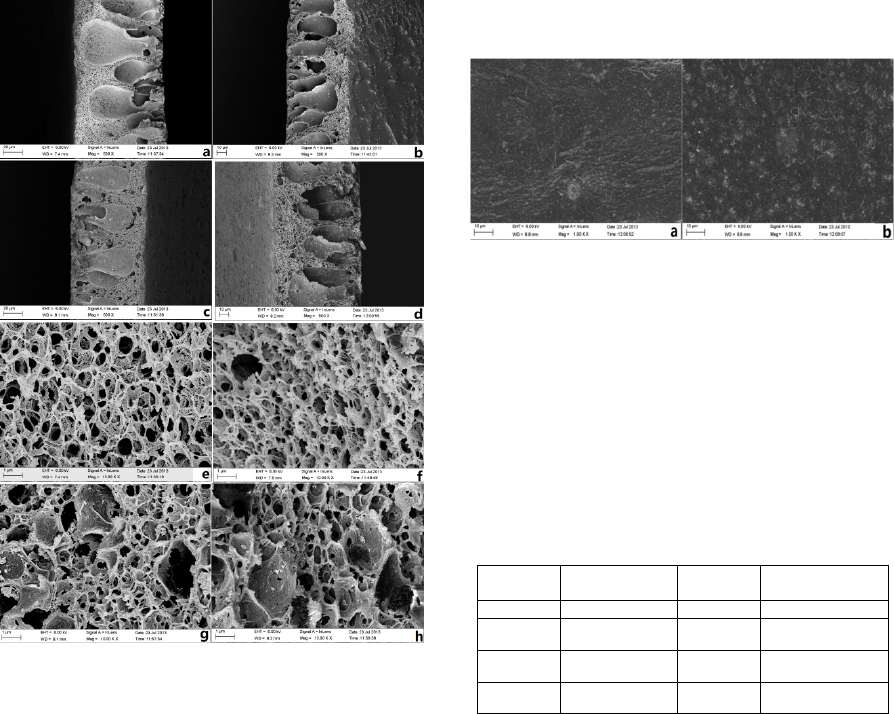

Figure 2: SEM micrographs displaying the top surfaces of

CA membranes prepared with: (a) 0 wt. % nano-SiO2 and

(b) 2 wt. % nano- SiO2.

Figure 2 shows the surface morphologies of CA

membrane (a) and modified CA membranes

prepared with 6wt. % nano-SiO

2

in the casting

solution (b). The particles can be clearly seen on the

surface of the membrane when the nano-SiO

2

are

added in the casting solution.

Table 1: Contact angle, porosity and mechanical strength

of prepared FO membranes.

Membrane Contact angle (°) Porosity (%) Tensile strength

(MPa)

CA 67.1±0.72 47.52 6.17

CAN-2 54.1±0.83 52.20 7.79

CAN-4 49.3±0.21 57.57 8.63

CAN-6 43.6±0.54 61.64 9.22

Table 1 indicates the surface contact angles,

porosity and tensile strength of CA membranes

prepared with different content of nano-SiO

2

(0, 2, 4

and 6 wt. %). The contact angle of membranes

tΔ

IWEG 2018 - International Workshop on Environment and Geoscience

166

declined with the increase of the content of nano-

SiO

2

, suggesting that the hydrophilicity of CA

membrane surface was improved with the increment

of the content of nano-SiO

2

. This is due to the

silicon hydroxyl groups on the membrane structure

by the presence of nano-SiO

2

in the CA polymer

system. Meanwhile, the porosity of membranes

increased with the increase of the content of nano-

SiO

2

. This is because pores were formed when the

nano-SiO

2

added in the casting solution filtered out

of the main body of the membrane during the phase

inversion (

Lin et al., 2012). The tensile strength of

the membranes was also improved with the increase

of the content of nano-SiO

2.

3.2 ATR-FTIR Spectra and EDS of CA

and Nano-SiO

2

Modified CA

Membranes

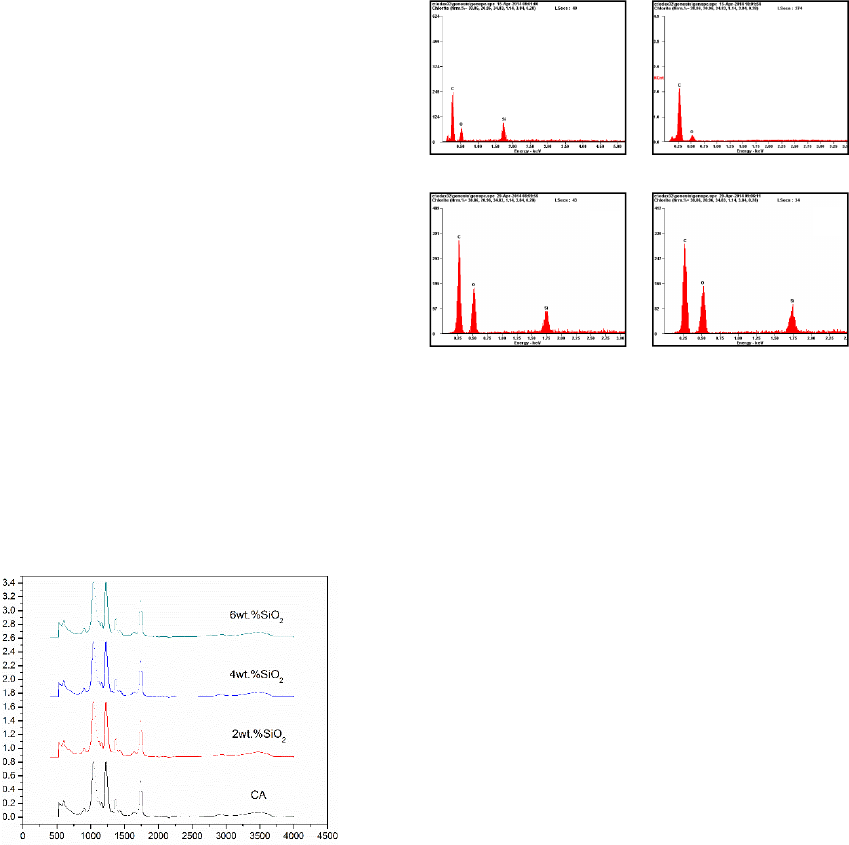

Figure 3 shows the ATR FT-IR spectra of the CA

membranes prepared with different content of nano-

SiO

2

(0, 2, 4 and 6 wt. %). The appearance of peaks

at 1739cm

-1

corresponds to the carbonyl (C=O) of

CA. The appearance of peaks at 1040 cm

-1

and 1228

cm

-1

is assigned to the ether group (C-O-C) of CA.

The appearance of peaks at 3466 cm

-1

corresponds to

the hydroxyl (-OH). There are no characteristic

peaks in relation to silica oxygen group (Si-O-Si)

and silicon carbon group (Si-O-C). It is also

suggested that there is no silicon hydroxyl group (Si-

OH) since the intensity of the peak of hydroxyl (-OH)

is weak.

Figure 3: ATR FT-IR spectra of the CA membranes

prepared with different content of nano-SiO2 (0, 2, 4 and 6

wt. %).

Figure 4 shows the EDS of the CA membranes prepared

with different content of nano-SiO2 (0, 2, 4 and 6 wt. %).

It clearly demonstrates that silicon element exists in the

membrane after modification by nano-SiO2. In addition,

the intensity of the peak of silicon in the EDS increases

with the increase of the content of nano-SiO2. With the

FT-IR results, it can be concluded that nano-SiO2 did not

react with CA to form a new chemical bond. The addition

of nano-SiO2 plays a role of physical blending and nano-

SiO2 consists in the CA organic system as an additive.

Figure 4: EDS of the CA membranes prepared with

different content of nano-SiO2 (0, 2, 4 and 6 wt. %).

3.3 Determination of FO Performance

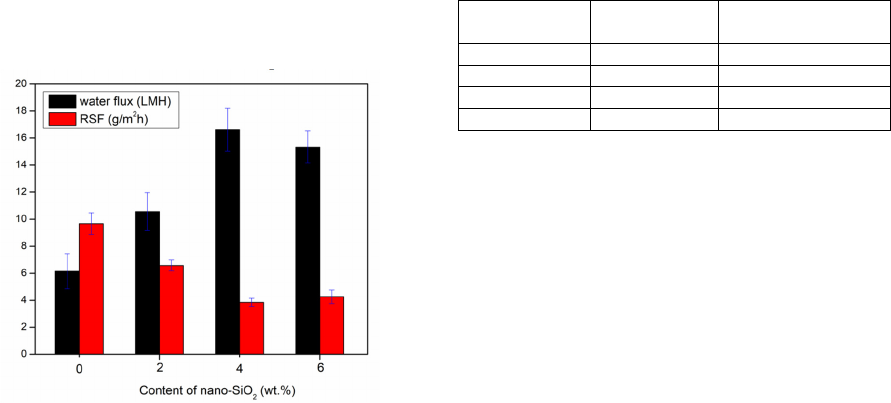

Figure 5 shows the FO performance of CA

membranes prepared with different content of nano-

SiO

2

(0, 2, 4 and 6 wt. %) including water flux,

reverse salt flux and salt rejection and the detailed

data is listed in Table 2. It is worthwhile to note that

the nano-SiO

2

modified CA membranes for FO

exhibits superior separation properties than

unmodified CA membrane. The water permeability

and salt rejection were improved with the increase of

the content of nano-SiO

2

in the CA membrane

structure in the range of 0–4 wt. %. When the

content of nano-SiO

2

increased from 0 wt. % to 4

wt. %, the water flux was improved from 6.15 LMH

to 16.62 LMH and the reverse salt flux declined

from 9.67 to 3.85 g NaCl/m

2

h. The improvement in

water flux of nano-SiO

2

modified CA membranes

could be attributed to the existence of nano-SiO

2

that

forms nanochannels in the top surface of the

membranes. Both inner cores of nanotubes (internal

nanochannels) and the interfacial gap between nano-

SiO

2

and CA polymer at the interface of CA layer

(external nanochannels) create additional passage for

solvent transfer. The latter plays a dominant role

a b

c

d

Preparation of Nano-silica Dioxide Modified Cellulose Acetate (CA) Membranes for Enhanced Performance in Forward Osmosis Process

167

since the internal nanochannels are too thin to

extract water without applying pressure (FO mode).

Moreover, the external nanochannels create direct

and appropriate path in comparison with the inner

cores (

Ma et al., 2012). Also, the presence of nano-

SiO

2

increases the surface hydrophilicity of FO

membranes, which causes improvement of the water

permeation through the modified FO membranes.

The higher salt rejection is caused by the

improvement in surface hydrophilicity, which

promotes the water preferential adsorbing and

decreases reverse salt flux. Reverse salt flux is

proportional to the salt rejection coefficient R (

Cath

et al., 2006

) and the lower reverse salt flux

represents the higher salt rejection (

Ng et al., 2006).

It is worthwhile to note that both of the water flux

and reverse salt flux of the modified membrane

decrease when the content of nano-SiO

2

further

increases from 4 wt. % to 6 wt. %, which might be

attributed to the defect of nano-SiO

2

agglomeration

in the phase inversion process. Hence, the excessive

addition of nano-SiO

2

may not be advisable for FO

applications. In summary, these results specified that

the nano-SiO

2

modified CA membranes exhibit

improved salt rejection as well as water permeability

than unmodified membrane in FO process.

Figure 5: Water flux and reverse salt flux of the CA

membranes prepared with different content of nano-SiO2.

4 CONCLUSIONS

Nano silica dioxide (nano-SiO

2

) modified cellulose

acetate (CA) membranes were prepared. The FO

performance of the modified membranes were

evaluated and compared with those membranes

without nano-SiO

2

. The addition of nano-SiO

2

does

not change the asymmetric structure of CA

membrane. The hydrophilicity, porosity and tensile

strength of the membranes were improved with the

increase of the content of nano-SiO

2

in the CA

polymer system. The nano-SiO

2

did not react with

the CA but consisted in the CA organic system as an

additive according to the FTIR results. The smart

selection of the nano-SiO

2

in order to use in FO

membranes structure caused the formation of

membranes with sufficient separation properties and

FO performance. The water flux and salt rejection

were simultaneously improved in the nano-SiO

2

modified CA FO membranes. However, excessive

addition of nano-SiO

2

might decreased the

permeability and selectivity of the membranes.

Finally, it can be concluded that nano-SiO

2

modified

CA membranes have potential for practical FO

application as a result of their enhanced structural

and separation properties.

Table 2: Water flux and reverse salt flux of prepared FO

membranes.

membrane Water flux J

w

(LMH)

Reverse salt flux J

s

-

N

aCl (g NaCl/m

2

h)

CA 6.15 9.67

CAN-2 10.56 6.58

CAN-4 16.62 3.85

CAN-6 15.34 4.26

REFERENCES

Achilli A, Cath T Y and Childress A E 2009 Power

generation with pressure retarded osmosis: an

experimental and theoretical investigation, Journal of

Membrane Science 343 42–52

Cath T Y, Childress A E and Elimelech M 2006 Forward

osmosis: principles, applications, and recent

developments, Journal of Membrane Science 281 70–

87

Kim T-W, Kim Y, Yun C, Jang H, Kim W and Park S

2012 Systematic approach for draw solute selection

and optimal system design for forward osmosis

desalination, Desalination 284 253–260

Lin W, Zhu T, Li Q, Yi S and Li Y 2012 Study of

pervaporation for dehydration of caprolactam through

PVA/nano silica composite membranes, Desalination

285 39–45

Liu Y-L, Hsu C-Y, Su Y-H, et al. 2004 Chitosan−silica

complex membranes from sulfonic acid functionalized

silica nanoparticles for pervaporation dehydration of

ethanol−water solutions, Biomacromolecules 6(1) 368-

373

IWEG 2018 - International Workshop on Environment and Geoscience

168

Ma H, Burger C, Hsiao B S and Chu B 2012 Highly

permeable polymer membranes containing directed

channels for water purification, ACS Macro Letters

1723–726

McCutcheon J R and Elimelech M 2006 Influence of

Concentrative and Dilutive Internal Concentration

Polarization on Flux Behavior in Forward Osmosis.

Journal of Membrane Science 284(1-2) 237–247

McCutcheon J R, McGinnis R L and Elimelech M 2005 A

novel ammonia–carbon dioxide forward (direct)

osmosis desalination process, Desalination 174 1–11.

Ng H Y, Tang W, Wong W S 2006 Performance of

forward (direct) osmosis process: membrane structure

and transport phenomenon, Environmental Science &

Technology 40 2408–2413.

PhuongNgaNguyen Thi, Eun-TaeYun, In-ChulKim,

Young-NamKwon 2013 Preparation of cellulose

triacetate/cellulose acetate (CTA/CA)-based

membranes for forward osmosis, Journal of Membrane

Science 433 49–59

Sairam M, Sereewatthanawut E, Li K, Bismarck A and

Livingston A G 2011 Method for the preparation of

cellulose acetate flat sheet composite membranes for

forward osmosis—Desalination using MgSO4 draw

solution, Desalination 273 299–307

Shuaifei Zhaoa, Linda Zoua, Chuyang Y. Tangb and

Dennis Mulcahya 2012 Recent developments in

forward osmosis: Opportunities and challenges,

Journal of Membrane Science 396 1– 21

Smitha B, Suhanya D, Sridhar S, et al. 2004 Separation of

organic–organic mixtures by pervaporation—a review,

Journal of Membrane Science 241(1) 1-21

Wang K Y, Ong R C and Chung T-S 2010 Double-

skinned forward osmosis membranes for reducing

internal concentration polarization within the porous

sublayer, Industrial & Engineering Chemistry

Research 49 4824–4831

Wang R, Shi L, Tang C Y, Chou S, Qiu C, Fane A G 2010

Characterization of novel forward osmosis hollow fiber

membranes, Journal of Membrane Science 355 158–

167

Zhang S, Wang K Y, Chung T-S, Chen H, Jean Y C, Amy

G 2010 Well-constructed cellulose acetate membranes

for forward osmosis: minimized internal concentration

polarization with an ultra-thin selective layer, Journal

of Membrane Science 360 522–535

Preparation of Nano-silica Dioxide Modified Cellulose Acetate (CA) Membranes for Enhanced Performance in Forward Osmosis Process

169