An Intelligent Defect Detection Method of Small Sized Ceramic Tile

Using Machine Vision

Linjie Yang, Mina Chong, Qiming Li and Jun Li

Quanzhou Institute of Equipment Manufacturing, Chinese Academy of Sciences, China, Quanzhou, 362200

E-mail: kidylj@fjiram.ac.cn, junli@fjiram.ac.cn

Keywords: Ceramic Tile, Defect detection, Size Parameters, Patch Strategy, Machine Vision, Chromatism Detection,

Abstract: Quality control of small sized ceramic tile is an important part for manufacturing enterprise. To improve the

efficiency and precision of ceramic tile defect detection, an intelligent detection method is proposed in this

paper. Firstly, the noise is eliminated by image pre-processing,and the geometric primitive of ceramic tile

is taken as benchmark. Meanwhile, the nearest neighbor algorithm is adopted to search measurement point,

and the size parameters are calculated by Euclidean distance. Then, local defect feature of chromatism is

obtained by patch strategy and composite contour mask. It is necessary to merge potential block to recover

original appearance of defects. Finally, the optimized parameters from feature distribution and a

discriminant function are utilized to achieve target defect detection. The experimental results show that the

method has good detection effect and high real-time performance.

1 INTRODUCTION

With the development of automation and artificial

intelligence, AVIS(Automated Visual Inspection

System) for ceramic tile is becoming increasingly

popular due to its low cost maintenance and high

accuracy. However, most of assembly line of

ceramic tile in China still adopt traditional manual

detection method because of the limitation of

automatic technology. It will inevitably bring about

the inspection errors and visual fatigue

during the process (Boukouvalas C, 1995; Karimi M

H, 2014).

Generally, the defect detection of ceramic tile is

an important step for the whole of assembly line,

because it ensures the quality of product. In the

AVIS, if a inspection task is accomplished

automatically by computers, the efficiency and

reliability of detection process are greatly improved.

Specially, for small specification of ceramic tile

which situate under the large FOV (Field of View),

the detection system requires high-speed and real-

time. Thus, designing an effective method based on

a AVIS is very important for ensuring quality of

ceramic tile.

In last few years, image processing has been

widely applied in many aspects of manufacturing.

However, few methods are applied in actual

production, in particularly the defect detection of

ceramic tile. H. Elbehiery proposed a method of

quality control for ceramic tile by integrating a

visual control stage. However, it only works well in

the defect of textured surfaces (2005). Andrade

utilized infrared images and Artificial Neural

Network to solve the issue of automatic inspection

of ceramic tile, and the performance of the technique

has been evaluated theoretically and experimentally

in laboratory, but the system has not been applied in

practical production (Andrade, 2011). Ehsan Golkar

proposed a model which allows ceramic tile

companies to perform quality inspection without

costly artificial measuring tools, and this method can

be applied in different situations of manufacturing

production line systems (2011). Cristina Costa

presented a phase correlation based algorithm for the

automatic surface inspection of ceramic tile for fault

detection, and the algorithm can be used to register

the reference and test images (2000). However, there

are very few methods have been proposed for the

defect detection of small specification ceramic tile.

In order to solve the aforementioned limitations,

a defect detection method for ceramic tile based on

the machine vision is proposed in this paper. The

works of size measurement and chromatism

detection are completed under the large FOV and

complex environment, and the proposed method

Yang, L., Chong, M., Li, Q. and Li, J.

An Intelligent Defect Detection Method of Small Sized Ceramic Tile Using Machine Vision.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 427-433

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

427

utilizes the techniques of gradient sharpening,

nearest neighbor searching algorithm, parameters

optimization, color space, geometric primitives and

composite mask etc. In the experiments, extensive

test data is provided for the subsequent quality

evaluation.

This paper is organized as follows, the overall

frame of both platform and algorithm is given in

Section II. In Section III, the strategy of image pre-

processing is illustrated in detail. The method of size

measurement is introduced in Section IV and the

chromatism detection is discussed in Section V.

Finally, the experiment and conclusion of our work

are summarized in the last two sections.

2 THE OVERALL FRAME

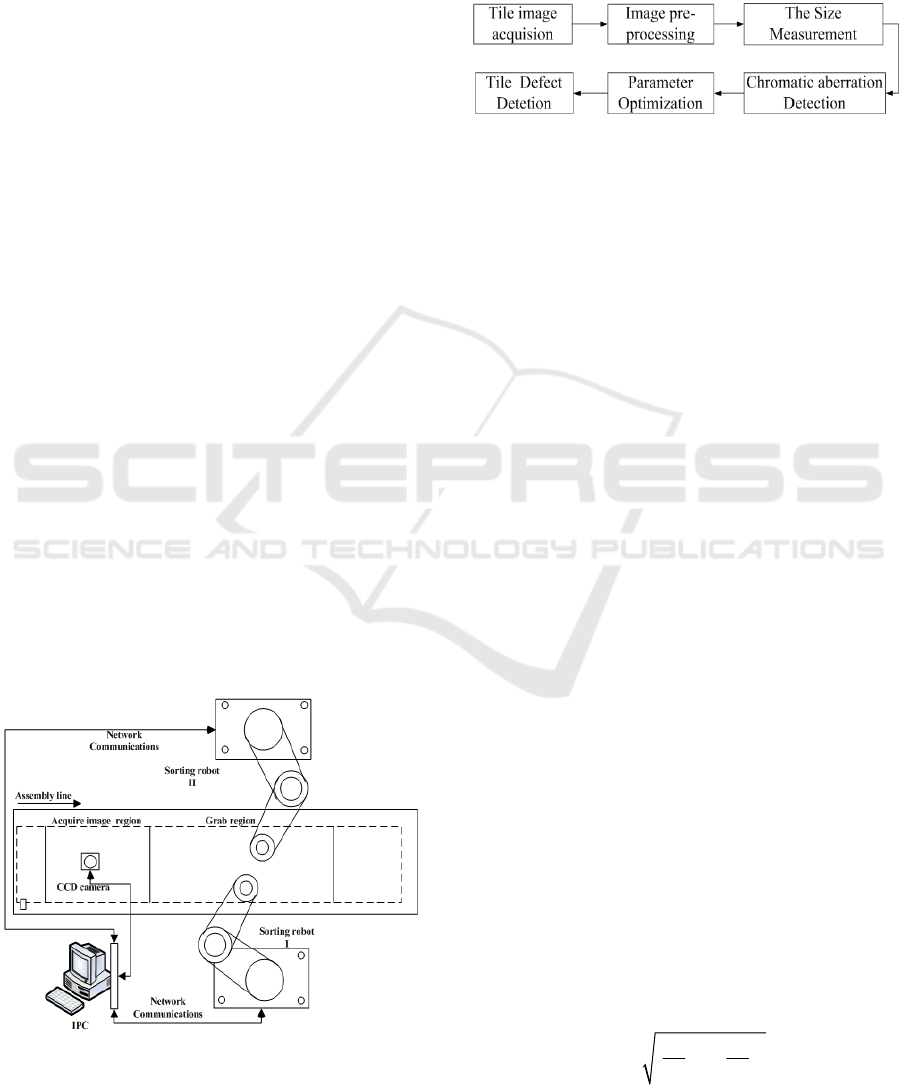

2.1 Hardware Platform

In our method, the locating and sorting system

mainly consists of IPC (Industrial Personal

Computer), CCD industrial camera, LED light,

EPSON robot, image processing software etc. The

overall platform is shown in Fig. 1, the whole

assembly line is divided into acquire and grab region

for the task. Firstly, the standard parameters are

acquired and stored into the database offline through

the feature model. When the visual system is

initialized, the location packet is imported to system

automatically. The center coordinates of the ceramic

tiles are obtained by location system with the

proposed algorithm, Subsequently, the coordinate

datas through system calibration are sent to the each

CSARA robot by network communication separately

(Ashraf M A, 2011; Lan M I, 2007).

Figure 1: The platform of defect detection and sorting

2.2 The Algorithm Flow

The algorithm of defect detection is achieved by

four steps in our work: image pre-processing, size

measurement, chromatic aberration detection and

parameter optimization, the main process is shown

in Fig. 2.

Figure 2: The algorithm flow of defects detection

(1) The image pre-processing consists of

sharping the image and extracting the contour.

(2) The size measurement mainly adopts

geometric primitives of contour and nearest

neighbor algorithm to search segmentation points.

(3) Chromatic detection is conducted based on

HSV color space, patch strategy and composite

mask to obtain local defect features of color.

(4) Gaussian model is adopted to obtain the

optimized standard parameters from the sample

feature distribution.

3 THE IMAGE RFEPROCESSING

Due to the perturbation from environmental

condition and noise of acquisition systems, the

image quality of ceramic tile is inevitably degraded.

It is necessary to highlight the concerned target and

enhance image contrast. Related works of improving

image quality have completed base on the both

hardware and software in this paper.

Firstly, the annular LED light and obscura are

adopted to construct the stable inspection

environmental. Moreover, an improved gradient

sharpening method is introduced to ensure that the

targets edge will not be over-smoothed.

The conventional sharpening algorithms will not

be discussed in this part (Lan M I, 2007). The

contour of detection target is a fundamental task for

subsequent detection algorithms, and the improved

sharpening method for ceramic tile will be

introduced later. For the image f(x,y), the gradient

of pixel (x, y)indicates the maximum change in

this location, and its magnitude G

M

[f(x, y)] is

defined by

22

[f(x, y)] ( ) ( )

M

f

f

G

x

y

∂∂

=+

∂∂

(1)

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

428

In order to reduce the computational cost, the

absolute value is adopted to replace the traditional

square operation, and the gradient modulus value is

formulated as .

[f(x, y)] (x, y) (x 1, y 1) (x 1, y) f(x, y 1)

M

Gff f=−++++−+

(2)

The pixel value is directly replaced by the

gradient value in the traditional method, by doing so,

it could result in some weaknesses with ? image

original information. Therefore, the gradient

sharpening has been improved by setting threshold

judgment in our work, and the specific formula is

'

11

''

22

[f(x, y)] [f(x, y)] T

[f(x, y)] (x, y) T (x, y)

(x, y)

MM

M

GTG

Gf fT

fother

⎧

+≥

⎪

=− ≥

⎨

⎪

⎩

(3)

'

[f(x, y)]

M

G

is the final value after above mapping,

and its maximum value is 255. T’

1

denotes a low

threshold which is used to highlight the dark details.

When the

'

[f(x, y)]

M

G

is greater than T’

1

, its value is

increased by T

1

, which can enhance the object edge.

Similarly, T’

2

denotes a high threshold, and it

restrains light regions. Based on the above analysis,

the regions in the original image with high pixel

value are retained while its dark details are enhanced

by equation 3. And the modified method increases

the contrast between the edge information and

backgrounds.

The image pre-processing is an essential step to

obtain accurate target contour. The median filter is

used to reduce the noise of image firstly. Both

the Otsu algorithm and Canny edge detection (Jiao,

2007) are used in pre-processing step to highlight

target edge, and also 8 Freeman chain code is

adopted to acquire ceramic tile contour (Galba T,

2014; Kerautret B, 2014).

4 THE SIZE MEASUREMENT

The indicators of the target size measurement are

defined as the upper width(UW), lower width(LW),

left height(LH), right height(RH), integrity(IN) and

edge straightness(ES), which cover the basic shape

features of the ceramic tile. The steps of the

measurement method mainly include two parts:

acquiring segmentation points and calculating size

parameters.

4.1 Acquiring The Segmentation Points

The most methods for ceramic tile size measurement

are given which takes its corner as the theoretical

segmentation points. However, it is difficult to

acquire stable and accurate corner location by

traditional algorithm in industry (Boukouvalas C,

1995; Karimi M H, 2014). Another strategy obtains

the intersections between borders by fitting linear of

target edges, and this method refers to these

intersections as segmentation points which are

obviously deviated from engineering practice.

Actually, the real tile corner is circle

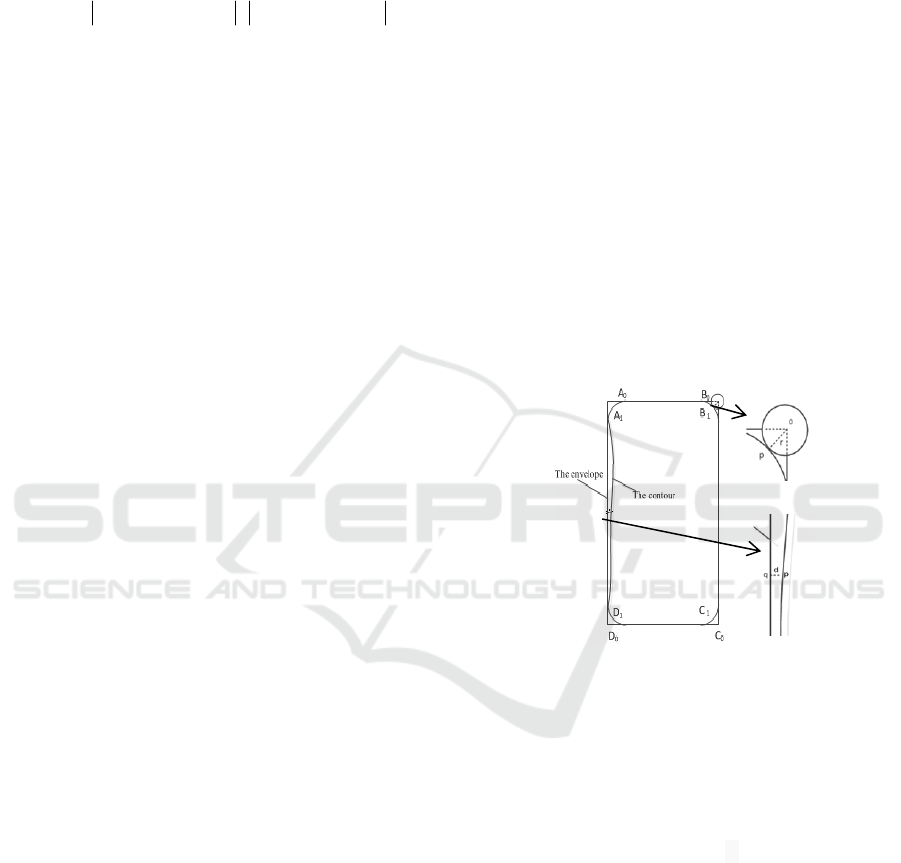

transitional region as shown in Fig. 3. A nearest

neighbor algorithm based on the oblique external

envelope is proposed to solve the problem

of points

segmentation

. The oblique external rectangle is an

ideal geometric primitive for ceramic tile, and the

geometric characteristic changes with the fitting

target. Furthermore, its shape property is not

affected by the target rotation and translation.

Figure3: The envelope and segmentation points of contour

How to break the closed ceramic tile contour is

the core content in this work. Taking partial enlarged

detail from upper-right corner of Fig.3 as example.

B

0

is the benchmark of the oblique external

rectangle, and B

1

is the corresponding segmentation

point of B

0

on the closed contour. r is the minimum

radius of the contour spatial neighborhood. The

nearest neighbor algorithm used for point position

segmentation is shown below.

An Intelligent Defect Detection Method of Small Sized Ceramic Tile Using Machine Vision

429

Table.1: The nearest neighbor search algorithm

Nearest neighbor search algorithm

Intput:O(x

0,

y

o

), r=r

0,

step=s , flag=false,

discri{(p(r),C(i)};

Output: Return Flag{ true, false };

1. count=0;

2.for all r do

3.r=r

0+

step;

4. if discri{(p(r),C(i)} satisfy T;

5. Flag=true;

6. else

7. Flag=false;

8. Break;

9. return Flag

The related Parameter description are illustrated

below.

(1) O(x

0

, y

0

): Envelope reference point;

(2) r: Neighborhood radius,the value is

initialized r

0

=2;

(3) Step: Radius step represents the minimum

precision of searching, and its value is set as 1;

(4) Flag :Test mark, it is initialized as false;

(5) discri{}: Discriminant function, it determines

whether the point are within the setting

neighborhood;

(6)T: Discrimination rules.

4.2 Size Parameter Calculation

The coordinates of segmentation points A

1

,B

1

,C

1

and D

1

on the ceramic tile contour are obtained

according to the process discussed in the above

section

. Subsequently, the length of the line

segments L

A1B1

, L

C1D1

, L

A1D1

, L

B1C1

are

calculated as the ceramic tile parameters of the

upper width, lower width, left height and right

height by Euclidean distance

respectively.

The contour edge of the ceramic tile is not the

ideal straight line as shown in partial enlarged view

of Fig. 3 . The p is the midpoint of the line, and q

denotes the projection of p on the endpoint straight

line. d denotes the edge straightness, and the least

square method is adopted to fit actual ceramic tile

edge. The system uses this method to fit the contour

between the segmentation points. The maximum

value of the ceramic tile straightness is defined as

ES.

5 THE CHROMATISM ETECTION

The purpose of chromatism detection for ceramic

tile is to sort products whose color differ from

standard sample. Our method uses HSV color space,

patch strategy and composite mask to obtain local

defects of chromatism.

5.1 Color Space

Comparing with other color spaces, HSV is more

closer to model of human visual cortex (Muhammad

B, 2016). Moreover, the component of H and S is

less affected by the environment. The color feature F

is generated based on the weight of the HSV color

space by .

12

()/N

t

FHS

λλ

=×+× (9)

F

t

represents the color feature generated by the I

block. H and S which represent hue component and

saturation respectively. Similarly,

1

λ

and

2

λ

are the

weight of corresponding component. N denotes the

number of pixels traversed in the setting block, and

the weight value

1

λ

=0.7,

2

λ

=0.3 in this paper after

testing.

5.2 Image Patch

Traditional strategy describes color information of

the whole region by evaluating statistic, such as

mean, variance and entropy. However, this method

can not perceive small change and it dilutes effect of

local color information. So the patch strategy for

ceramic tile is introduced to solve above problem.

The uniform block is adopted for local

segmentation in ceramic tile image. It is difficult to

guarantee that the image length and width are

integer multiples of the patch step, so the four types

of patch are produced during the process. The

specific judgment rule is analyzed by equation (10),

and g(i, j) is the discriminant function of boundary

conditions.

1 i Width&&i S Width&& j

2 &&j S && Width

(i, j) 3 &&j S &&i Width&&

iS Width

0

x

y

y

x

Hei ght

j Height Height i

gjHeight

other

<+> <

⎧

⎪

<+><

⎪

⎪

=< +<

⎨

⎪

+>

⎪

⎪

⎩

(10)

S

x

, S

y

are patch step in horizontal and vertical

direction respectively. The smaller the value is, the

higher the patch accuracy is, but the real-time of the

algorithm will be depressed. In general, step value is

adjusted by specific target dimension.

Through the above algorithm, the image patch

for ceramic tile is completed. The problem of patch

scale and surpassing boundary is solved effectivelly,

which provides a new strategy for highlighting the

local chromatic aberration.

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

430

5.3 Compound Contour Mask Operation

When g(i, j)={1, 2, 3}, it is shown that the patch

situates beyond contour boundary of ceramic tile,

and the segmentation ROI unit may not completely

overlap with target boundary. So the feature statistic

which involves external contour brings some errors

in the calculation.

The biggest characteristic of contour mask is

that the ROI of arbitrary shape could be dug, so that

we only care about region strictly which is needed in

image process, while other area will be shielded at

the same time. Another detail which the filling color

of contour mask may be same with the color of

target defect will be focused on in this part. A

composite mask method is used to acquire pure

color feature Ft, and the specific operation is as

follows.

(1) Two images which are the same size as the

acquiring image are initialized and the pixel value of

them is zero. We take images as the parent of the

tiled composite contour mask which are denoted as

M1, M2 respectively;

(2) The contour of ceramic tile is painted in the

M1 and M2 mask images with pixel precision

respectively, and the contour of M1 and M2 is

filled with RGB(255,0, 0) and RGB(0, 255, 255)

pixels.

(3) Then we perform “and operation” on HSV

color space of the images with mask M1, M2

respectively. If the resulted values of operation of

both M1 and M2 are equal to the original color, the

value will be retained to generate F

t

. Otherwise, they

will be ignored.

While the patch situates beyond contour

boundary of ceramic tile, step 3 will be implemented.

The compound contour mask operation can help

system to avoid interference from external contour

pixel.

6 OCATION DISCRIMINANT

6.1 Parameter Optimization

If the standard parameters are obtained directly from

the sample set off-line, the empirical errors are

inevitable in the practical calculation. Thus, the

Gaussian feature distribution is used to optimize the

standard parameters in our method.

In order to ensure the accuracy of the standard

parameters, the images of standard and defect-

free sample sets are tested directly to obtain each

parameter. Gaussian distribution is performed on

each element of sample sets.

Mean

j

μ

and standard deviation

j

σ

of each

parameter type are acquired by maximum likelihood

estimation. The

3

δ

principle is used to remove the

part of data which falls outside the model

( 3

μ

δ

− , 3

μ

δ

+ ), and then the optimized standard

parameters are obtained by averaging the processed

data. From statistics point of view, the standard

parameter obtained by distribution model can

eliminate the bad samples, and the data are more

stable.

6.2 Target discriminating

Once target does not meet the discriminantive

requirement as shown in the equation 11, the system

will terminate the judgment immediately to reduce

the determination time.

1

()

0

tj sj j

tj

if f f T

gf

else

⎧

−≤

⎪

=

⎨

⎪

⎩

where j={0,1,2 … } refers to parameter types,

()

g

indicates the discriminant function.

tj

f

is the

parameter of the test online.

s

j

f

is the optimal

standard parameter.

j

T

is the threshold which

determines the tolerance capability of qualified

product. When all the values of the corresponding

()

g

are equal to 1, it is identified as the qualified

product. Otherwise, the program terminates the at

once. The coordinate data is sent to each EPSON

robot by network communication separately.

7 EXPERIMENT

1). In order to evaluate the effectiveness of the

improved sharpening method for the ceramic tile

image, we implement the image pre-processing by

before and after sharpening modification under the

same experimental conditions. Two types of ceramic

tile are used for test. We visualize the performance

improvement in Fig. 4.

Figure 4: The effect before and after of sharpening

(c)

(

d

)

(a)

(b)

An Intelligent Defect Detection Method of Small Sized Ceramic Tile Using Machine Vision

431

It can be seen that the ceramic tile edge with

modification is sharper and the contrast is stronger

than before, which facilitates subsequent size

measurements.

2).We test the stability and accuracy of

measurement method which is provided by section

III, and this method is adopted to measure some

indication for different types of ceramic tile, such as

segmentation points, fitting edges and the extraction

midpoints. The specific effect is shown in Fig.5.

Figure 5: The effect of size measurement

It can be observed that measurement indicators

have a precise fitting effect and it can reflect the

actual shape of the ceramic tile effectivelly. The

indication data of ceramic tile (45mm

×95mm) is

given in table 2, and the measure accuracy is 0.2mm

per pixel .

As seen in Table 2, the indicator of 15 same type

and qualified ceramic tiles are obtained, and the

deviation of resultss is very small. It indicates that

the proposed size measurement method has high

accuracy and stable.

Table 2: The indication data of ceramic tile (mm)

Test order UW LW LH RH IN

ES

1 44.6 44.6 95.2 95.0 0.959 0.2

2 44.8 44.6 94.8 94.6 0.965 0.2

3 45.0 44.8 94.6 94.8 0.958 0.4

4 45.2 45.0 94.6 94.6 0.940 0.2

5 44.8 45.0 94.8 95.0 0.950 0.4

6 44.6 44.8 94.2 94.4 0.954 0.4

7 44.6 44.6 94.6 94.8 0.956 0.2

8 44.4 44.8 94.6 94.8 0.962 0.2

9 44.8 44.6 94.4 94.6 0.965 0.2

10 44.6 44.8 95.2 95.0 0.945 0.4

11 44.6 44.4 95.0 94.8 0.974 0.4

12 45.0 45.2 95.2 95.0 0.978 0.2

13 45.2 45.0 95.0 95.0 0.985 0.2

14 45.2 45.0 95.2 95.0 0.982 0.4

15 44.8 45.0 94.8 94.6 0.965 0.2

Average 44.81 44.81 94.8 94.8 0.962 0.28

Variance 0.239 0.212 0.29 0.18 0.0120 0.09

3). For validating the strategy of chromatism

detection, the defect location detection from

ceramic tile is conducted in this subsection. As

shown in the Fig.6, c,d is the feature changes of a

and b respectively, and the feature F

t

of existing

defect patch is obvious mutation than other patchs.

The experimental result shows the validity of

chromatism detection.

Figure 6: The effect of chromatism detection

The work of merging potential block is done to

recover original appearance of defects based on

spatial information, and the feature distribution of

patch is given in Fig. 7 . The region of green line

represents that the patch situates beyond contour

boundary.

Figure7: The effect of patch and recovering original

appearance

4).To verify the precision rate of the defect

detection algorithm, 1000 ceramic tiles are used for

detecting and sorting on assembly line. The result

shows that the precision rate of the experiment with

proposed method is 91%, and the detection time is

100 per second, which basically meets the needs of

industrial production.

8 CONCLUSIONS

In this paper, an intelligent defect detection method

of

small sized ceramic tile using machine vision is

proposed in AVIS, and the main works of the

proposed method are summarized as follows.

1).An improved sharpening method is designed

for the image of ceramic tile to improve the edge

sharpness and the contrast.

(a)

(b)

(c)

(d)

(a)

(b)

(c)

(d)

(a)

(b)

(c)

(d)

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

432

2).The geometric primitive of contour is taken as

benchmark. The size parameters are calculated by

adopting the nearest neighbor algorithm and

Euclidean distance. The measure accuracy is 0.2mm

per pixel .

3).The local defect feature of chromatism is

acquired by patch strategy and composite mask, and

the experimental results show that the method has

good detection effect and high real-time

performance.

ACKNOWLEDGEMENTS

This work was supported by Laboratory of Robotics

and Intelligent Systems (CAS

, Quanzhou), and

Fujian Engineering Technology Center of Robot

Intelligent Control. Meanwhile, the work was

funded by Major Special Project of Fujian Province

(No.2015HZ0001-1) and Scientific and

Technological Project of Quanzhou (No.2015G109).

REFERENCES

Boukouvalas C, Kittler J, and Marik R. Ceramic tile

inspection for color and structural defects[J].

Proceedings of AMPT95, 1995, 390-399.

Karimi M H, and Asemani D. Surface defect detection in

tiling industries using digital image processing

methods: analysis and evaluation[J]. ISA transactions,

2014, 53(3): 834-844.

Elbehiery, H., A. Hefnawy, and M. Elewa. Surface

Defects Detection for Ceramic Tiles Using Image

Processing and Morphological Techniques[J]. World

Enformatika Conference, 2005,158-162.

Andrade, R. M. Deeduardo, and A. Carlos. Methodology

for automatic process of the fired ceramic tile's

internal defect using IR images and artificial neural

network [J]. Journal of the Brazilian Society of

Mechanical Sciences & Engineering, 2011,67-73.

Golkar E, Patel A, and Yazdi Ll. Ceramic tile border

defect detection algorithms in automated visual

inspection system[J]. Journal of American Science,

2011, 7(6): 542-550.

Costa C E, and Petrou M. Automatic registration of

ceramic tiles for the purpose of fault detection[J].

Machine Vision and Applications, 2000, 11(5): 225-

230.

Ashraf M A, and Kondo N, Shiigi T. Use of machine

vision to sort tomato seedlings for grafting robot[J].

Engineering in Agriculture, Environment and Food,

2011, 4(4): 119-125.

Lan M I, Hai-Bo X U. Image Mosaicing Based on Edge

Sharping[J]. Application Research of Computers, 2007,

24(5):318-320.

Jiao S, Li X, and Lu X. An Improved Ostu Method for

Image Segmentation[C], International Conference on

Signal Processing. IEEE, 2007:164-166.

Galba T, and Romi K, Baumgartner A. Edge-preserving

partial variable median filtering for fast noise

reduction in CT slices[C]. ELMAR (ELMAR), 2014

56th International Symposium. IEEE, 2014, 1-4.

Kerautret B, and Lachaud J O. Meaningful scales

detection: an unsupervised noise detection algorithm

for digital contours[J]. Image Processing On Line,

2014, 4: 18.

Muhammad B, Abu-Bakar S A R. A hybrid skin color

detection using HSV and YCgCr color space for face

detection[C]. IEEE International Conference on Signal

and Image Processing Applications. IEEE, 2016, 95-

98

.

An Intelligent Defect Detection Method of Small Sized Ceramic Tile Using Machine Vision

433