Picking Process Variability in Small and Medium-Sized Enterprises:

State of the Art and Knowledge Modeling

Daniel Hilpoltsteiner

1

, Stephanie Bäuml

2

and Christian Seel

1

1

Institute for Project Management and Information Modelling, Landshut University of Applied Sciences,

Landshut, Germany

2

Technology Centre for Production and Logistics Systems, Landshut University of Applied Sciences, Landshut, Germany

Keywords: Process Variability Modelling, Order Picking Process, Knowledge Management, Information Modeling,

Adaptive Process Modeling.

Abstract: Information modelling is an established standard for knowledge representation in companies. However, small

and medium-sized companies (SME) often lack the resource to use it for their own purpose. In this paper a

solution to model business process variability in order picking processes is discussed. Therefore we did a

knowledge extraction from different companies using a questionnaire, expert interviews and workshops with

different experts from the field of production logistics in SME has been done. Based on their knowledge

different variants of order picking processes in SME were defined and put together in an adaptive process

model. Using configuration terms to enrich the adaptive process model allows the distinction between these

different variants. Based on different influencing factors a specific process variant can be generated from the

process model using element selection and further process optimizations including introducing new technol-

ogies can be made.

1 INTRODUCTION

Knowledge management is an important component

for the documentation of business processes and at

the same time the starting point for the digitization

strategy in companies besides the reduction of waste

in the processes (Becker et al., 2012). The non-use of

employee knowledge is wasteful and of crucial im-

portance for operational processes. Shared

knowledge is the basis for process improvements,

prevention of knowledge loss (e.g. employee fluctua-

tion, demographic change) and support of learning

and coaching processes.

The analysis of the actual situation and the mod-

elled processes are the basis for the identification of

strengths and weaknesses in the process and for the

elaboration of development potentials. In addition to

the core processes which create value in the company,

there are also so-called support processes (Becker et

al., 2012). One of these support processes in manu-

facturing companies is logistics with order picking as

a sub-process. In this paper we focus on picking pro-

cesses in SME, because they are an important part of

the value chain. The preparatory activities of logistics

staff in this process reduce waste in the value-adding

production process. The production employees do not

have to collect their goods themselves, which short-

ens distances and reduces access times to the neces-

sary goods (Womack et al., 2006).

Information modeling is a well-established stand-

ard for knowledge representation in companies (Seel,

2010). Expert interviews and results from a question-

naire in various SME showed a deficit in workflow

documentation using information modeling tech-

niques. In practice, problems arise when dealing with

model variants. Problems in the management of busi-

ness process variants can be seen in many industries

and application areas for example in logistics or pro-

ject management (Timinger and Seel, 2016).

Creating a separate model for each variant, which

differ only in a few details, will lead to great effort in

model maintenance, expansion and inconsistencies.

Instead we can combine multiple process variants to

an adaptive process model and extract concrete vari-

ants based on defined influence factors. Constructing

an adaptive information model helps to reduce effort

in maintenance and inconsistencies.

The purpose of the paper is to answer the follow-

ing research questions related to knowledge manage-

ment through information models in the field of order

picking processes. Furthermore technologies are pre-

sented which can enhance the order picking process.

120

Hilpoltsteiner, D., Bäuml, S. and Seel, C.

Picking Process Variability in Small and Medium-Sized Enterprises: State of the Art and Knowledge Modeling.

DOI: 10.5220/0006896901200127

In Proceedings of the 10th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2018) - Volume 3: KMIS, pages 120-127

ISBN: 978-989-758-330-8

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

RQ1 How is knowledge management of picking

processes implemented in SME?

RQ2 How can information modeling support

knowledge management in picking pro-

cesses?

The article is divided into the following sections:

At first, the state of research is presented as related

work. Subsequently, the research methodology used

and the structure of the empirical study are discussed.

The next chapter presents the results from the empir-

ical study. Chapter Variability modeling in picking

processes presents the different variants of infor-

mation modeling and explains the resulting adaptive

information model in picking processes. An evalua-

tion of the results completes the contribution.

2 RELATED WORK

According to the VDI (Association of German Engi-

neers), a picking process is defined as (Verband

Deutscher Ingenieure, 1994) "assemble a partial

quantity (assortment) from total quantities of goods

based on requirements (order)".

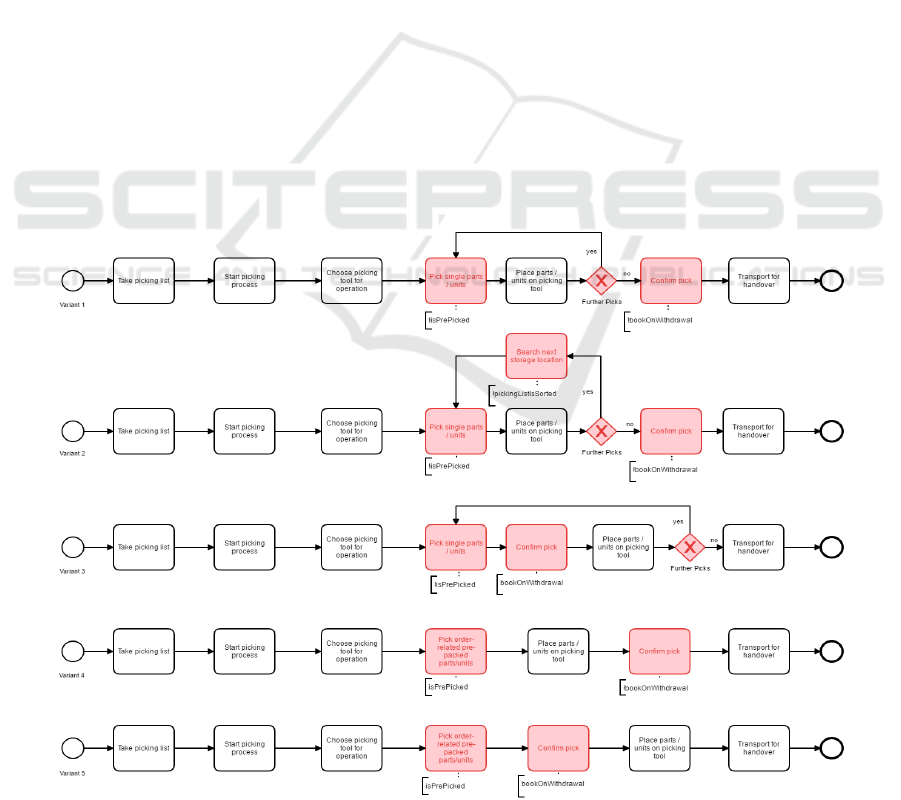

The picking processes of the participating SME in

the transfer project were analyzed which are con-

ducted according to the "man to goods" picking sys-

tem. The three building blocks defined by GÜNTHNER

(Günthner et al., 2009) are preparation, picking pro-

cess and follow-up were analyzed. In accordance with

VDI guideline 3590, the order picking process is di-

vided into the following sub-tasks: specify transport

information, transport goods to preparation area, pro-

vide goods for picking, specify pick information,

picker move to preparation area, picking goods, de-

liver pick, confirm pick, transport collection unit for

hand over (Figure 1). The main focus of this paper

lies on the picking process itself, because no variants

were found during preparation and post processing of

the picking.

For the examined SME, information is provided

exclusively by means of a picking list. This form of

information provision is the most widespread one

(Günthner et al., 2009). All relevant order data is

listed in the picking list. Among other things, the ar-

ticle, its storage location and quantity is listed. If the

individual items on the picking list are sorted by lo-

cation, it is referred to as a guided picking list. In con-

trast to an unguided picking list, which leads to longer

picking times through not optimized routes.

The prerequisite for process improvements are

described and modeled processes in the form of infor-

mation models (Becker, 2007). Consistently man-

aged, complete information models can also lead to

an improvement in knowledge transfer within the

company. As already mentioned in the introduction,

problems often occur with variants in business pro-

cesses in various industries and applications, such as

logistics, automotive and project management (Tim-

inger and Seel, 2016). If one maintain each of these

variants, which differ only in partial steps, in a sepa-

rate information model, their consistent maintenance

leads to increased effort and an increased risk of in-

consistencies. It makes sense to combine variants of

a process in a single adaptive information model in

order to achieve a reduction in effort. An adaptive or

configurable information model contains different

variants of a process in a single information model.

Variant management is a permanent and ubiqui-

tous problem in information modelling and the state

of current research (La Rosa et al., 2017). The general

goal of variant management is to combine several

variants of the same domain in one model. This can

be adjusted by adding or removing parts of a model.

The existing approaches consider configurable nodes,

element annotation, specialization through various

activities and adapted model fragments. The greatest

scope of research comprises the element annotation,

where predicates are linked to elements of a customi-

zable process model through annotation. (Becker et

al., 2003; Delfmann, 2006).

To annotate the configuration terms on the elements

of the information model, the configuration procedure

"element selection by terms" is used (Becker et al.,

2003). The problem with this method is not the con-

figuration of the models themselves, but rather the

consistent and efficient construction of the infor-

mation models. After executing an element selection,

the result is a meta-model based model projection that

only contains elements whose terms are evaluated to

true (Delfmann, 2006). A similar but simplified ap-

proach to meta-model based model pro jection is the

evaluation of the information models using configu-

ration terms (Seel, 2017). These are annotated to the

elements of the model and ensure the extraction of in-

dividual variants from the adaptive process model.

Figure 1: Reference picking process in BPMN 2.0 based on VDI3590.

Picking Process Variability in Small and Medium-Sized Enterprises: State of the Art and Knowledge Modeling

121

3 RESEARCH METHOLOGY

The paper follows the design science research para-

digm proposed by HEVNER et al. (Hevner and Chat-

terjee, 2010). According to them two complementary

research paradigms have been established in the field

of information science. A distinction is made between

behavioral and construction-oriented research. The

former is based on the formation and verification of

theories about artifacts. This also includes the search

and empirical validation of hypotheses. The aim of

the paradigm is to test the correctness based on the

empirical suitability of theories. Design science, on

the other hand, is based on the engineering approach

and focuses on the construction and evaluation of de-

veloped artifacts. The latter can be implementations,

methods, models and languages.

The first research question (RQ1) is based on an

empirical study and is assigned to behavioral re-

search. A questionnaire was issued to the companies

involved in the technology transfer project. After

evaluation of the questionnaire, a structured interview

guideline was developed and expert interviews were

conducted with four SME using the interview guide-

line. In addition, there is an “intelligent logistic sys-

tems” working group consisting of specialists and

managers from different SME and large companies in

the region. This enables an interactive exchange of

technical and expert knowledge on various problems

in production logistics. The structure of the question-

naire, the structured interview guideline and the

working group is explained in more detail in the fol-

lowing chapter Structure of the empirical study.

The second research question (RQ2) is answered

with the help of the construction oriented paradigm.

This involves modeling the companies picking pro-

cesses in BPMN 2.0 and transferring them into an

adaptive information model. The picking process var-

iants and the adaptive information model represent ar-

tifacts of the design science process. An evaluation is

ensured regarding to the completeness and function-

ality of the adaptive information model in comparison

to the collected picking process variants.

4 STRUCTURE OF THE

EMPIRICAL STUDY

The results of this chapter are based on an empirical

study in form of a quantitative approach using a ques-

tionnaire (Meuser and Nagel, 2009). In the question-

naire various information about the companies were

requested including general company information

such as the number of employees, the type of produc-

tion and the industry they belong to. Further questions

dealt with the self-assessment of companies in certain

areas such as production logistics, applied technolo-

gies and the degree of digitization. In addition, the

characteristics of information modeling and its com-

plexity in the company were queried. More precise,

the consistency of information modeling, the fre-

quency of adaptations to information models, but also

the access possibilities of the employees were ques-

tioned. In addition, they were asked about modeling

languages and tools used in the company as well as

the responsibility for information modeling. The

questionnaire included closed questions, semi-open

and open questions. The last ones were used to obtain

more detailed statements in certain areas. The results

of the questionnaire serve as initial indications and

are incorporated into the structured interview guide-

lines for the expert interviews. The quantitative ap-

proach is supported by a qualitative approach in form

of expert interviews with staff from the four SME par-

ticipating in the EDRF Project and workshops with

specialists and managers from production logistics.

Expert interviews in four companies were used to

determine the picking process variants and the factors

influencing the process. The structured interview

guidelines were discussed with employees and man-

agers. It was divided into the three parts: knowledge

management in the company, consideration of the

picking process including influencing factors and

their impact on process variants. The findings on the

picking processes in the SME serve as a basis for the

developed artifacts, which are presented in the chap-

ter Variability modeling in picking processes. This in-

cludes influencing factors for the picking process and

the resulting variants. After the parts of the empirical

study have been shown, the results are presented in

the following chapter.

5 RESULTS OF EMPIRICAL

STUDY

A questionnaire as described in the previous chapter

was sent to 23 cooperating companies. At the end of

the survey, the response rate was 70 percent. Nearly

all companies are affiliated to the NACE (Nomencla-

ture Générale des Activités Économiques dans les

Communautés Européennes)-Codes for manufactur-

ing industry and the spectrum ranges from very small

companies to global players. Some relevant infor-

mation are shown in Figure 2.

The key findings from the questionnaire on

knowledge management and information models in

KMIS 2018 - 10th International Conference on Knowledge Management and Information Sharing

122

the companies are as follows (RQ1). In general, the

questionnaire shows that information models and

knowledge in the company are insufficiently main-

tained and rarely updated. At the same time, two

thirds of those companies are committed to an estab-

lished continuous improvement process. As a result,

the level of knowledge modeled in the company and

the actual situation of the processes differ. It is very

important to maintain changes to workflows in infor-

mation models in a timely manner, but only about

40 % of the companies provide timely maintenance

for their information models. The majority of those

involved consider the advantages of consistently

maintained information models in the areas of real-

time error detection, congestion management or weak

points in process chains to be important. Problems in

these areas can only be solved if processes in the com-

pany are modeled and correspond to the actual situa-

tion. However, only one company has indicated that

it uses a standardized modeling language to map its

business processes. However, modeled processes are

the starting point for optimizing processes and avoid-

ing errors (Becker et al., 2012). In addition, well-

structured processes can reduce manual workflows

and the resulting media disruptions, thereby creating

greater transparency and leading to a more flexible

reaction to changes.

Another insight of the questionnaire was that em-

ployees have insufficient access to information mod-

els in the company, if they exist. Around half of the

companies surveyed stated that they regularly train

their employees. These shortcomings lead to a higher

probability of errors in the processes. In order to be

able to detect errors in processes, a modeled process

is necessary, but regular process assessments (certifi-

cations) are also useful (Schmelzer and Sesselmann,

2013). According to the results of the questionnaire,

evaluations of the processes never take place or only

take place irregularly, which makes it difficult to

identify deviations between the processes described

and the actual situation in the companies.

Based on the results of the questionnaire, the

structured interview guide as presented in the chapter

Structure of the empirical study was developed. This

served as the basis for the expert interviews in the

companies. The results from the second and the third

part of the structured interview guide are presented in

the chapter Variability modeling in picking processes.

The expert interviews on the subject of knowledge

management in the four SME showed that knowledge

is predominantly documented in text form via work

instructions and made available to employees either

via the intranet or in printed form at the workplace.

Furthermore, structured documentation of the picking

processes was found in two out of four companies. In

one company it was the requirement of the certifica-

tion institution and in the other a necessity to train

new employees. In the latter there are considerations

to realize the knowledge about Wiki-based

knowledge management system. Another result of the

Figure 2: Results from the questionnaire.

0 2 4 6

not at all

a little

intermediate

rather consistent

very consistent

consistent use of information models (n=13)

0 2 4 6 8

not at all

very uncommon

yearly

quarterly

in case of changes

not specified

maintainance of information models (n=17)

0 5 10

not at all

irregular

regular (defined period)

not specified

training on information modeling (n=17)

0 2 4 6

not at all

infrequently

regular (defined period)

commonly

on demand

not specified

frequency of process assessments (n=15)

Picking Process Variability in Small and Medium-Sized Enterprises: State of the Art and Knowledge Modeling

123

questionnaire is that employees generally have a

deeper knowledge of the work processes as docu-

mented in information models. In addition,

knowledge is unevenly distributed across several em-

ployees within the same department. The reasons for

the incomplete preparation of knowledge in the com-

panies are: Added value from knowledge manage-

ment for the company is not recognized, information

modelling is not recognized as a value-adding activ-

ity, expenditure for the survey of complex processes

cannot be mapped with the available resources in

SME. Complex processes result from several influ-

encing factors in the picking process, which means

that there are several different variants of the same

process. In order to enable companies to maintain

their business processes in information models due to

their limited resources, it is proposed to combine the

different variants of one process into a single adaptive

process model.

6 VARIABILITY MODELING IN

PICKING PROCESSES

Using the reference picking process according to

Günthner et al., an actual state analysis of the existing

picking processes in the four SME was conducted.

This chapter deals with the results from the picking

process and information modeling from the expert

interviews.

During the analysis, it became apparent that the

documentation of work processes in the company is

scarce and employees have only limited access to it.

In cases where documentation exists in text form, de-

viations can partly be determined by process changes

between the time of the process documentation and

the actual situation in the company. Various variants

of the picking processes were identified, which differ

only in partial steps. Factors influencing the process

included a sorted and unsorted picking list, order-re-

lated and order-neutral picking, and technology-sup-

ported picking confirmation. The influencing factors

mentioned in Figure 3 in BPMN 2.0 determine the

variants of the picking process (RQ2). These were

collected in cooperation with the technical experts of

the companies. The different variation steps are

marked in red in the information model.

Variant 1 is a classic order-neutral picking

process using a sorted picking list, without any

technological support during goods withdrawal. The

withdrawal is confirmed at the end of the process by

posting all items in the ERP system (Enterprise

Resource Planning). Variant 2 differs from Variant 1

in using an unsorted pick list. Therefore, the

additional process step "Search next storage location"

Figure 3: Overview of the collected picking process variants.

KMIS 2018 - 10th International Conference on Knowledge Management and Information Sharing

124

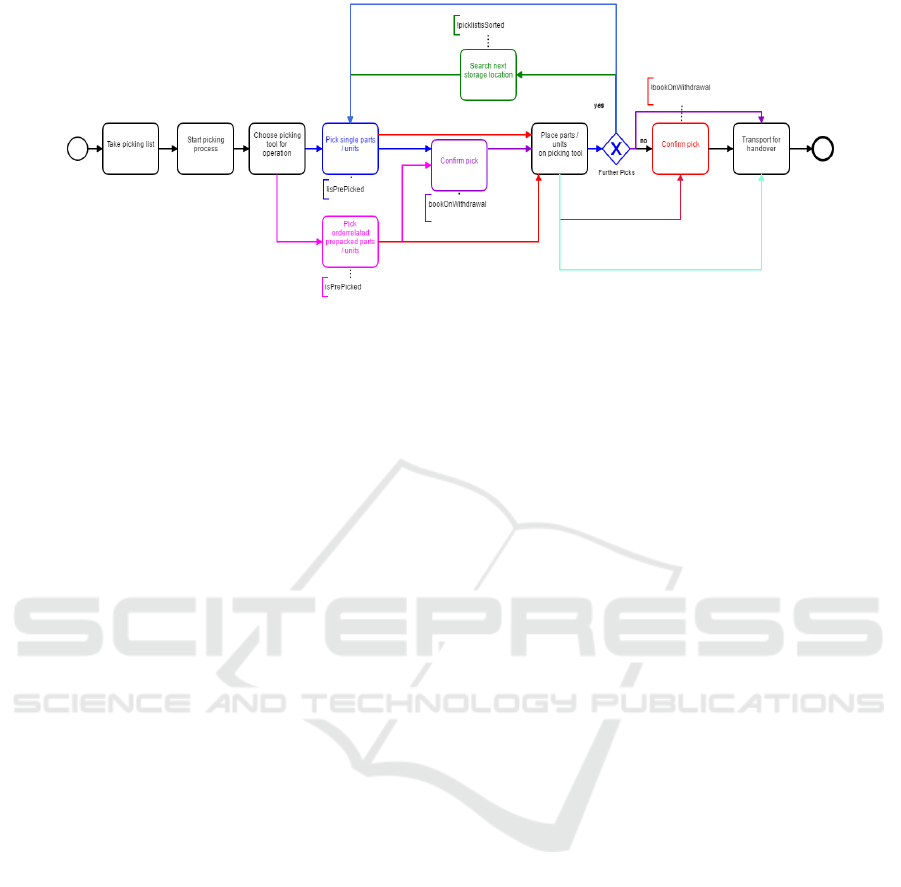

Figure 4: Adaptive Information model, which includes all variants from Figure 2.

is included. Variant 3 describes a process that

provides technological support for the picking

confirmation. Withdrawal is acknowledged in real

time by using technologies pick-by or barcode

scanning technologies. The fourth variant describes

an order-related picking process in which the goods

for an order have already been pre-packed. The fifth

variant describes the order-related picking process,

which, like variant 3, is supported by a technology for

picking confirmation. The variants presented are only

an excerpt of the situation found in the four SME.

Further variants were found when using different

picking aids and in hybrid approaches to order-related

and order-neutral picking lists. The modelling and

description of all further variants would go beyond

the scope of the article and would not show any

further insights for solving the above-mentioned

problem.

It is clear to see that an increased effort is in-

volved in the maintenance of information models if a

company has to maintain all these variants in separate

information models. When process changes occur to

the same parts of the picking process (shown black in

Figure 3), all affected information models must be

modified. Inconsistencies can occur if certain infor-

mation models have been forgotten. If companies are

certified, these inconsistencies can lead to deviations

in the certification assessment and inconsistencies

should therefore be avoided.

To solve this problem, it is proposed to combine

the five variants in an adaptive information model.

Using the configuration terms, which are annotated to

the elements of the model, any original variant can be

generated by an algorithm. This algorithm was imple-

mented in a software tool and can be accessed via an

online repository (Bitbucket, 2018; Hilpoltsteiner et

al., 2018). Figure 4 shows the constructed adaptive

information model, which represents an artifact of the

Design Science process. The adaptive model was en-

riched with configuration terms, which were added to

the individual elements and edges. A configuration

term as used in the model is shown below. The con-

figuration term gets interpreted by the software tool

and returns the result of the expression. Only ele-

ments with the Boolean result true remain in the

model. In the current solution this leads to redun-

dancy regarding to edges.

[pickingListIsSorted] == false &&

[isPrePicked] == false

Altogether three configuration variables were

used in the adaptive information model. They can be

displayed and maintained in a separate overview. Us-

ing an additional function of the software tool, all el-

ements can be colored which have an identical con-

figuration term. As a rule, the variants can already be

identified by this. This approach poses problems,

when several variants dependent on each other. For

example, the process step "Place parts / units on pick-

ing tool" causes problems because it can be achieved

by both incoming process steps with different vari-

ants.

7 EVALUATION

The aim of the design science process is to create ar-

tifacts that solve a practical problem (Hevner and

Chatterjee, 2010). One of the core activities of the De-

sign Science process is the evaluation of the created

artifact to prove and justify its usefulness (Peffers et

al., 2007). To demonstrate the usefulness of the de-

signed artifact it is examined whether all originally

determined variants are present in the adaptive infor-

mation model and can be generated using configura-

tion terms. As a first indicator for the correctness of

the adaptive information model, the number of colors

Picking Process Variability in Small and Medium-Sized Enterprises: State of the Art and Knowledge Modeling

125

Table 1: Matrix including the used configuration variables

and their relation to the process variants.

can be checked. Elements that occur in all variants are

displayed in black. As already mentioned in the pre-

vious chapter, problems occur when coloring the ele-

ments as soon as the configuration terms differ. The

reason for this problem is that common process steps

can follow two different variants. Therefore, the sub-

sequent configuration term of the process step differs

from both the first and second incoming variants. The

mere check of the correctness of the information

model based on the number of colors can therefore

not be guaranteed in this case. However, the approach

would work well with completely independent pro-

cess variants. On the software side this behavior can

be further optimized. The variable assignments for

the individual variants are defined in Table 1. The in-

dividual variants of the adaptive information model

are written down vertically. By assigning variable

values to variants, one can test whether the individual

information model variants can be generated from the

adaptive information model. The values are inserted

into the evaluation interface of the software tool.

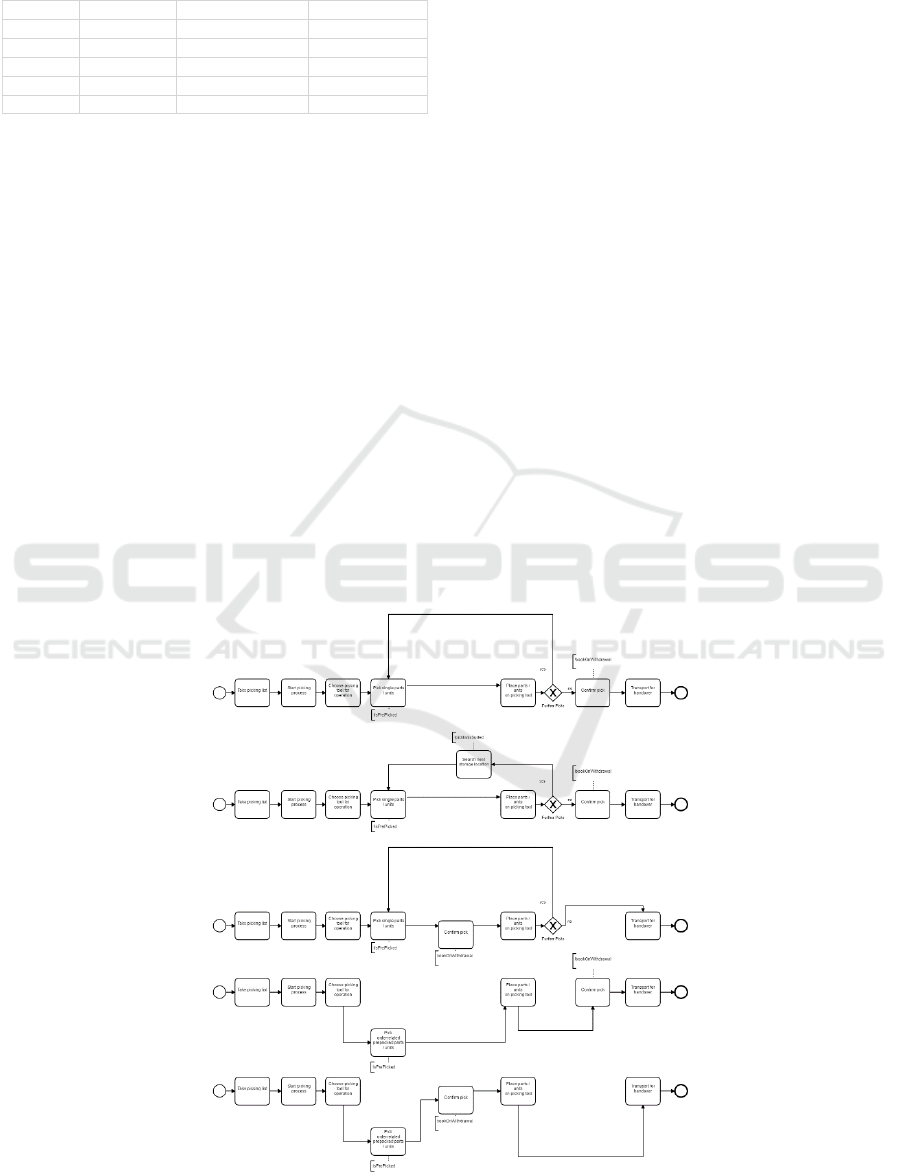

Figure 5 shows the generated information models

from the software tool. On closer inspection, all five

generated variants are technically correct. Only their

optical appearance differs by the positioning of the el-

ements and the edges, because the absolute positions

from the adaptive information model are used. Com-

mercial software already offers possibilities to auto-

matically align elements after changes.

By creating the adaptive information model, the

effort for the administration and maintenance of in-

formation models could be reduced, because only one

information model must be maintained. This will also

reduce the risk of inconsistency after changes to var-

iants. However, it should be noted that the introduc-

tion of configuration terms in the adaptive infor-

mation model leads to a higher complexity of the

model.

8 CONCLUSION

In this paper the two research questions RQ1 and RQ2

have been answered. The first question dealt with the

state of the art of knowledge management in picking

processes in SME (RQ1).

It was found that knowledge management in SME

is insufficiently established in order picking. The rep

Figure 5: All generated variants from the software tool.

isPrePicked bookOnWithdrawal pickingListIsSorted

Variant 1 false false true

Variant 2 false false false

Variant 3 false true true

Variant 4 true false true || false

Variant 5 true true true || false

KMIS 2018 - 10th International Conference on Knowledge Management and Information Sharing

126

resentation of knowledge in information models is

also weak. Furthermore, it was discovered that

knowledge is unequally distributed among employ-

eesin the same department and that access to the in-

formation models is not guaranteed across the depart-

ment. The documentation of knowledge and its acces-

sibility is essential to avoid errors. Also errors in the

processes themselves or potentials for optimizations

can often only be recognized if these have already

been documented in advance. The questionnaire and

the interviews with experts showed that there is po-

tential for development in SME. Among other things,

the modelling of business processes due to variations

was considered complex. Especially the documenta-

tion of these process variants is important to achieve

a holistic representation of the process flows.

As part of the empirical study, expert interviews

were conducted in four SME. Various factors have

been identified that influence the order picking pro-

cess in SME. Together with the companies, these var-

iants of the picking processes were documented. With

the help of adaptive information modeling, an artifact

was created from these process variants as part of the

design science process. Using this artifact, the support

of knowledge management in SME through infor-

mation modeling was demonstrated (RQ2). Specifi-

cally, variants of the picking process were collected

and modelled in four SME. Based on the influencing

factors, the adaptive information model was extended

by configuration terms. Through using element selec-

tion by terms, all process variants found in the com-

panies in Figure 3 can be recreated. The correctness

of the information model and the software tool that

executes the element selection by terms was proven

in the evaluation of this paper.

Overall, adaptive information models can support

SME in documenting their expert knowledge. Espe-

cially in processes with many variation steps, adap-

tive information modeling enables a more compact

option for long-term digitalization of knowledge,

which requires less effort in maintenance and man-

agement. Above all, the possibility of optimizing pro-

cesses on the basis of the documented processes has

great advantages.

ACKNOWLEDGEMENTS

The technology transfer project "Competence Net-

work Intelligent Production Logistics" is funded by

the European Regional Development Fund (ERDF) -

Operational Program "Investment in Growth and Em-

ployment" Bavaria 2014 - 2020.

REFERENCES

Becker, J. (Ed.) (2007). Reference modeling. Heidelberg:

Physica-Verl.

Becker, J., Knackstedt, R., Kuropka, D., & Delfmann, P.

(2003). Konfiguration fachkonzeptioneller Referenz-

model. WI. (2003), 901–920.

Becker, J., Kugeler, M., & Rosemann, M. (Eds.) (2012).

Prozessmanagement: Ein Leitfaden zur prozess-

orientierten Organisationsgestaltung. Berlin,

Heidelberg: Springer Gabler.

Bitbucket. ipimlandshut / ipimmodeler. Retrieved April 26,

2018, from https://bitbucket.org/ipimlandshut/ipim

modeler.

Delfmann, P. (2006). Adaptive Referenzmodellierung:

Methodische Konzepte zur Konstruktion und Anwendung

wiederverwendungsorientierter Informationsmodelle.

Günthner, W. A., Blomeyer, N., Reif, R., & Schedlbauer, M.

(2009). Pick-by-Vision: Augmented Reality unterstützte

Kommissionierung. Garching: Lehrstuhl für

Fördertechnik Materialfluß Logistik (fml) Techn. Univ.

München.

Hevner, A. R., & Chatterjee, S. (2010). Design Research in

Information Systems Theory and Practice. Integrated

Series in Information Systems Volume 22.

Hilpoltsteiner, D., Seel, C., & Dörndorfer, J. (2018).

Konzeption und Implementierung eines Softwarewerk-

zeuges zum Management von BPMN-Prozessvarianten.

In R. Hofmann & W. Alm (Eds.), Wissenstransfer in der

Wirtschaftsinformatik. Fachgespräch im Rahmen der

MKWI 2018 (pp. 15–24). Aschaffenburg: Hochschule

Aschaffenburg, Information Management Institut.

La Rosa, M., van der Aalst, W. M. P., Dumas, M., & Milani,

F. P. (2017). Business Process Variability Modeling: A

Survey. ACM Computing Surveys, 50(1), 1–45.

Meuser, M., & Nagel, U. (2009). Das Experteninterview —

konzeptionelle Grundlagen und methodische Anlage. In

S. Pickel, D. Jahn, H.-J. Lauth, & G. Pickel (Eds.),

Methoden der vergleichenden Politik- und Sozial-

wissenschaft. Neue Entwicklungen und Anwendungen

(1st ed., pp. 465–479). Wiesbaden: VS Verlag für

Sozialwissenschaften / GWV Fachverlage GmbH

Wiesbaden.

Peffers, K., Tuunanen, T., Rothenberger, M. A., & Chatter-

jee, S. (2007). A Design Science Research Methodology

for Information Systems Research, 24(3), 45–77.

Schmelzer, H. J., & Sesselmann, W. (2013). Geschäfts-

prozessmanagement in der Praxis: Kunden zufrieden

stellen ; Produktivität steigern ; Wert erhöhen. München:

Hanser.

Seel, C. (2010). Reverse Method Engineering.

Wirtschaftsinformatik - Theorie und Anwendung.

Seel, C. (2017). Metamodellbasierte Erweiterung der BPMN

zur Modellierung und Generierung von Prozess-

varianten.

Timinger, H., & Seel, C. (2016). Ein Ordnungsrahmen für

adaptives hybrides Projektmanagement. GPM-Magazin

PMaktuell, 2016(4), 55–61.

VDI 3590 (April 1994). Düsseldorf: VDI-Gesellschaft

Fördertechnik Materialfluß Logistik.

Womack, J. P., Jones, D. T., & Roos, D. (2006). The machine

that changed the world. New York, NY:

HarperPerennial.

Picking Process Variability in Small and Medium-Sized Enterprises: State of the Art and Knowledge Modeling

127