Industrial Optimal Operation Planning with Financial

and Ecological Objectives

Camille Pajot

1

, Benoit Delinchant

1

, Yves Maréchal

1

, Fredéric Wurtz

1

, Lou Morriet

1

,

Benjamin Vincent

2

and François Debray

2

1

Univ. Grenoble Alpes, CNRS, Grenoble INP*, G2Elab, 38000 Grenoble, France

2

CNRS, LNCMI, F-38000 Grenoble, France

{benjamin.vincent, francois.debray}@lncmi.cnrs.fr

Keywords: Energy Planning, MILP Optimization, District, Energy Efficiency, Co

2

Emissions.

Abstract: As energy transition is fundamental to have a chance to fight climate change, every stakeholder concerned

by energy should be able to get a better knowledge of the consequences of these actions. However, it could

be very complex to understand energy problematics without being an expert. This article focuses on giving

the possibility to an energy intensive consumer of a district to make decisions about its energy planning

while taking into account its specific operating constraints. A practical case has been studied in a heat

recovery project to help the experiments planning of a research laboratory according to the thermal needs of

the district. At first, the energy planning only aims to reduce its electricity consumption bill. In a second

time, we consider re-using the thermal power from processes cooling. Then, two energy planning were

realised: reducing district CO

2

emissions and reducing district supply cost. Finally, trade-offs between these

two goals have been studied. The work is based on mixed-integer linear optimization models (MILP)

gathered into a Python library to provide a modular decisions tool for energy stakeholders.

1 INTRODUCTION

More and more modeling approaches and tools

emerge for the district-scale energy systems

(Allegrini et al., 2015). However, district energy

models focus more on simulation or design

optimization (Schütz .et al., 2016) than on energy

management optimization. Our objective was to

develop an optimization tool to help energy

stakeholders to make decisions about district energy

management with technical, financial,

environmental and social aspects.

Lots of the emerging district tools are based on a

bottom-up methodology gathering thermal buildings

models to create a district one (Lauster et al., 2014),

(Jimeno et al., 2015) while we aim to create a single

multi-energies representation with production,

conversion and consumption.

Before the district scale, energetic optimisation

has been studied at the urban level through lots of

optimization techniques (Keirstead et al, 2012), (Z.

Shi et al., 2017). Best et al. provide genetic

optimization models for supply and demand of

heating, cooling, and electricity (Best et al., 2015),

while Shabanpour-Haghighi et al. use heuristic

algorithm through the modified teaching–learning

based optimization (MTLBO) in order to minimize

the fuel cost in multi-carrier energy network

(Shabanpour-Haghighi et al., 2015

). Finally, a lot of

them preferred a Mixed Integer Linear Programming

(MILP) approach, as B. Morva et al. who optimized

both design and operational aspects of an urban

energy system (Morva et al, 2016).

In our study, several objectives will be presented:

reducing an energy supply bill, reducing CO

2

emissions of a district and reducing the heating

supply cost of a district. Therefore, the presented

problems require a formulation of energetic,

economic and CO

2

flux, what generates hundreds of

variables. In order to easily deal with a large amount

of variables, we are working on MILP formulation.

214

Pajot, C., Delinchant, B., Maréchal, Y., Wurtz, F., Morriet, L., Vincent, B. and Debray, F.

Industrial Optimal Operation Planning with Financial and Ecological Objectives.

DOI: 10.5220/0006705202140222

In Proceedings of the 7th International Conference on Smart Cities and Green ICT Systems (SMARTGREENS 2018), pages 214-222

ISBN: 978-989-758-292-9

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 INDUSTRIAL ENERGY

PLANNING TO MINIMIZE

ENERGY SUPPLY BILL

For industries and other energy intensive users, the

energy bill strongly affects their operation. From

simple operation schedules based on lower prices to

energy management policies, planning the energy

repartition to stay competitive becomes crucial.

In France, Energy Intensive Industries (EII) such

as steel, chemical and microelectronics’ industries or

paper mills can be directly connected to the

transmission system (Rte&Vous Le Mag, 2018). In

this case, electrical access and supply are two

separated contracts. With temporal repartition of

prices at several scales, the associated pricing is

more complex than a simple electrical cost for

standard consumer (Clients.rte-france.com, 2018).

At its Grenoble site, the National High Magnetic

Field Laboratory (LNCMI) offers static magnetic

fields up to 36 T, thanks to several magnets supplied

by a 24 MW electrical power station (LNCMI,

2017). The mean consumption during a day of

experiment is 6 MW (one fourth of the maximum

value), while the annual consumption for this

laboratory is typically around 14 GWh leading to an

important electricity bill. This should be taken into

account when experiments on magnetic fields are

planned, task which is currently handled manually.

Our study case focuses here on minimizing the

electricity bill considering specific operating

constraints and complex pricing structure.

2.1 Energy Pricing for Energy

Intensive Industries

2.1.1 Pricing Structure for French Electrical

Transmission System Access and

Supply

As explained before, EIIs have direct access to the

electrical transmission network. For those, electricity

access is not included into the supply and requires

subscribing two different contracts:

• The TURPE: French price for accessing

the public transmission system of

electricity

• An electrical supply contract

The TURPE pricing for LNCMI has an hourly-

seasonal structure (price variations at different time

scales: seasonal to hourly), which can be presented

as follows (Table 1).

In our study, only the three major components of

the price have been modeled: the power part

(subscription), the energy part and the taxes (see

equations 1, 2 and 3 below).

Power_part : b

k

= b

1

* Ps

1

+ ∑

k>1

b

k

(Ps

k

-Ps

k-

1

)

(1)

Energy_part : c

k

= ∑

k

c

k

E

k

(2)

Total electricity cost = Power_part +

Energy_part + Taxes

(3)

Moreover, according to the TURPE, the

subscribed power has to respect the following rule:

Ps

k

≤ Ps

k+1.

(Clients.rte-france.com, 2018)

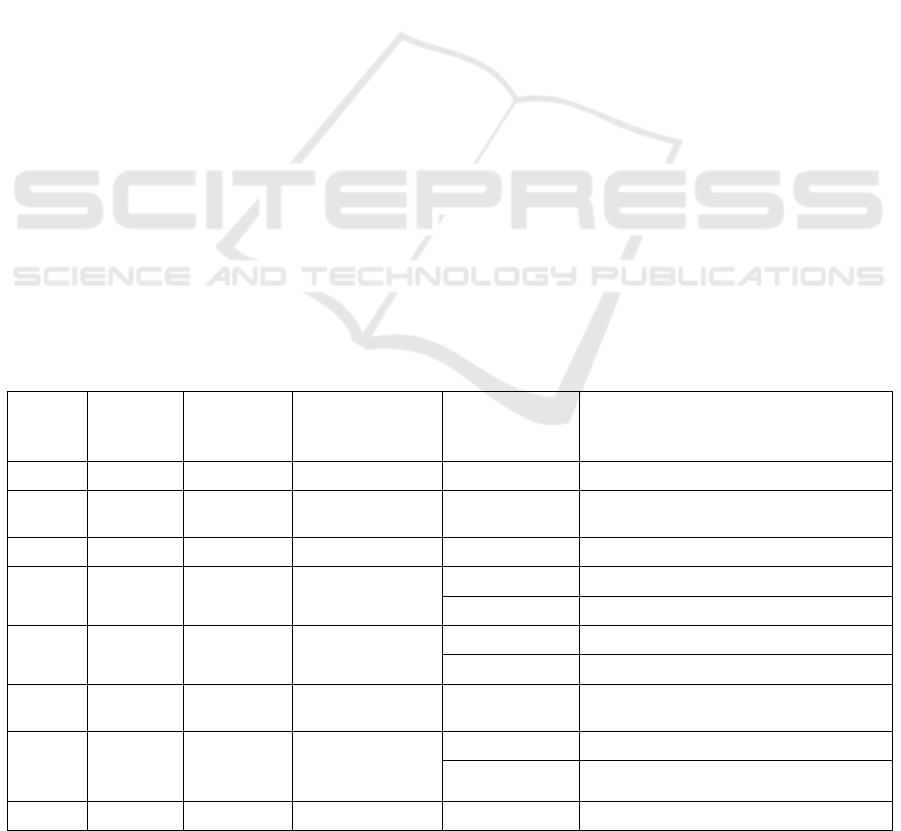

Table 1 : TURPE 4 pricing structure.

Time

period

b

k

[€/kW/y

]

c

k

[c€/kWh]

Monthly

period

Day type Hour range

k=1

9.24

3.01

Dec., Jan., Feb.

Working

9:00-10:59 / 18:00-19:59

k=2 8.5932 2.73 Dec., Jan., Feb. Working

7:00 - 8:59 / 11:00 – 17:59

20:00 - 22:59

k=3

6.6528

2.26

March, Nov.

Working

7:00– 22:59

k=4

5.1744 1.59

Dec., Jan., Feb.

Working

0:00 - 6:59 / 23:00 – 23:59

Non-working 0:00 – 23:59

k=5 4.2504 1.22 March, Nov.

Working

0:00 – 6:59 / 23:00 – 23:59

Non-working

0:00 – 23:59

k=6 3.696 1.37

Ap., May, June,

Sept., Oct.

Working 7:00– 22:59

k=7 1.9404 0.86

Ap., May,

June, Sept.,

Oct.

Working

0:00 - 6:59 / 23:00 – 23:59

Non-working 0:00 – 23:59

k=8

0.924

1.08

July, August

All

0:00 – 23:59

Industrial Optimal Operation Planning with Financial and Ecological Objectives

215

Where:

b

k

:

Price for the capacity defined by time

interval k and the tariff version

Ps

k:

Subscribed power for time interval k

c

k:

Price for the energy for time interval k and

the tariff version concerned

E

k

:

Active energy extracted over the year during

time interval k, expressed in kWh

Energy supply prices are based on electrical

consumption forecasts for each price period (same

pricing repartition as TURPE). This contractual

commitment forces the LNCMI to estimate its

electrical load repartition by time period one year

ahead explaining the energy planning need for an

entire year. As mentioned before, this work is

realised by a member of the LNCMI, who could

benefit from the developed tool.

2.1.2 Operation Constraints

Each big consumer has its own operating

constraints: some industries cannot ever stop their

process, whereas some others can only operate on

working days for instance. Understanding and being

able to describe these particulars needs is very

important to get a plausible energy planning.

Therefore, a part of our work was to translate

common constraints into easy Python objects and

thus enrich the possibilities of the decision tool.

As an industry, LNCMI has operating

constraints. In its case, it is estimated that it cannot

handle experiments more than 16 hours per day

(considering for instance the time required between

experiments). Moreover, the laboratory is closed

several days per year (two weeks starting at

Christmas’ Eve) and should be working all other

days.

On the other side, quality of life at work is

currently taken into account without being strictly

formalized, by avoiding too many nights and

weekends of work. To do so, the current planning is

created with energy limits on the corresponding time

periods. For instance, maximum values are fixed for

some time periods including nights and non-working

days as k=4, k=5 and k=7.

In our study, to avoid an experiment planning

only focused on electricity prices, these current

energy limits will be directly translated into

optimization constraints (see equations 5 to 8).

2.2 Optimization Problem Formulation

2.2.1 Daily Steps Model

For a yearly study, an hourly step could lead to

heavy formulations due to the amount of decision

variables. To avoid computational issues in case of

complex problems, we went for a daily step when

we aim to optimize an annual energy planning.

However, as the price may change during the

day, we expressed the daily energy consumption as

consumption at a fixed equivalent power and

deducted the equivalent operating hours, according

to equation 4.

op

h

(t) = e

in

(t) / p

eq

(t)

(4)

This deduction of an equivalent number of

operating hours is fundamental to evaluate the

consumption cost of the day, taking intra-day prices

variation into account. Indeed, LNCMI expenses are

calculated as follows:

expense

lncmi

(t) = p

eq

∑

k

c

k

* op_h

k

(t)

(5)

∑

k

op_h

k

(t) = op

h

(t)

(6)

Where:

e

in

(t):

Electrical consumption for the day t

p

eq

:

Equivalent power of the LNCMI

(6MW)

op

h

(t):

Equivalent number of operating hours

for the day t

op_h

k

(t):

Number of operating hours at price c

k

for the day t

2.2.2 Translation of Operating Constraints

into Energetic Constraints

According to the use of the magnets, each

experiment led in the LNCMI consumed a different

amount of electricity. By knowing by advance the

experimentations planned on the following year, it

becomes possible to evaluate the annual electrical

consumption to come. For the year 2107, it has been

estimated at 14 GWh, leading to equation 7:

∑

t

e

in

(t) = 14000000 for t in {0; 364}

(7)

As written before, the LNCMI closes annually

for two weeks, but the installation is working all the

others days with a minimal value of 0.5 hours per

day, leading to the equations 8 and 9. The minimal

value of 0.5 daily operating hours has been set from

an energetic point of view, forcing the installation of

consuming at least 3MWh per day (see equation 4).

SMARTGREENS 2018 - 7th International Conference on Smart Cities and Green ICT Systems

216

e_in

lncmi

(t) = 0 for t in annual closure

(8)

op_h

lncmi

(t) ≥ 0.5 for t not in annual closure

(9)

Finally, the next equations translate LNCMI

choices to avoid high electricity prices, while

considering the quality of life at work. Indeed, the

equation 9 expresses the fact that no power

subscribing was taken for time periods tp

1

and tp

2

, in

order to limit energy costs and avoid a bill increase.

In the other hand, as explained in 2.1.2, quality of

life at work is considered into the energy planning.

Limits are fixed in terms of energy minimums

or/and maximums for some pricing time periods and

are based on the LNCMI experience. If we call tp

k

the time period corresponding to the TURPE period

at price c

k

, the constraints are expressed as follows

in equations 10, 11, 12 and 13.

∑

t

e

in

(t) = 0 for t in tp

1

and tp

2

(10)

∑

t

e

in

(t) ≤ 2000 for t in tp

4

(11)

∑

t

e_in

lncmi

(t) ≥ 500 for t in tp

3

(12)

∑

t

e

in

(t) ≤ 1500 for t in tp

5

(13)

∑

t

e

in

(t) ≤ 6600 for t in tp

7

(14)

2.2.3 Objective Formulation

In this case study we aim to reduce the LNCMI

electricity bill by optimizing its consumption

planning under specific constraints. The expressions

of these constraints were expressed above, so that

the objective formulation is:

Minimize ( ∑

t

expense

lncmi

(t) )

(15)

With expense

lncmi

expressed in equation 5.

2.3 Results

2.3.1 Optimal and Previous Planning

Comparison

The current LNCMI energy planning is based on a

compromise between consuming low prices

electricity and avoiding too many working nights

and weekends. To allow a comparison between

optimal and usual planning (created manually),

values chosen for the 2017 year are shown in the

second column of Table 2. The energetic values are

expressed in MWh, while the electricity prices have

been normalised regarding to the maximal value for

a confidentiality purpose.

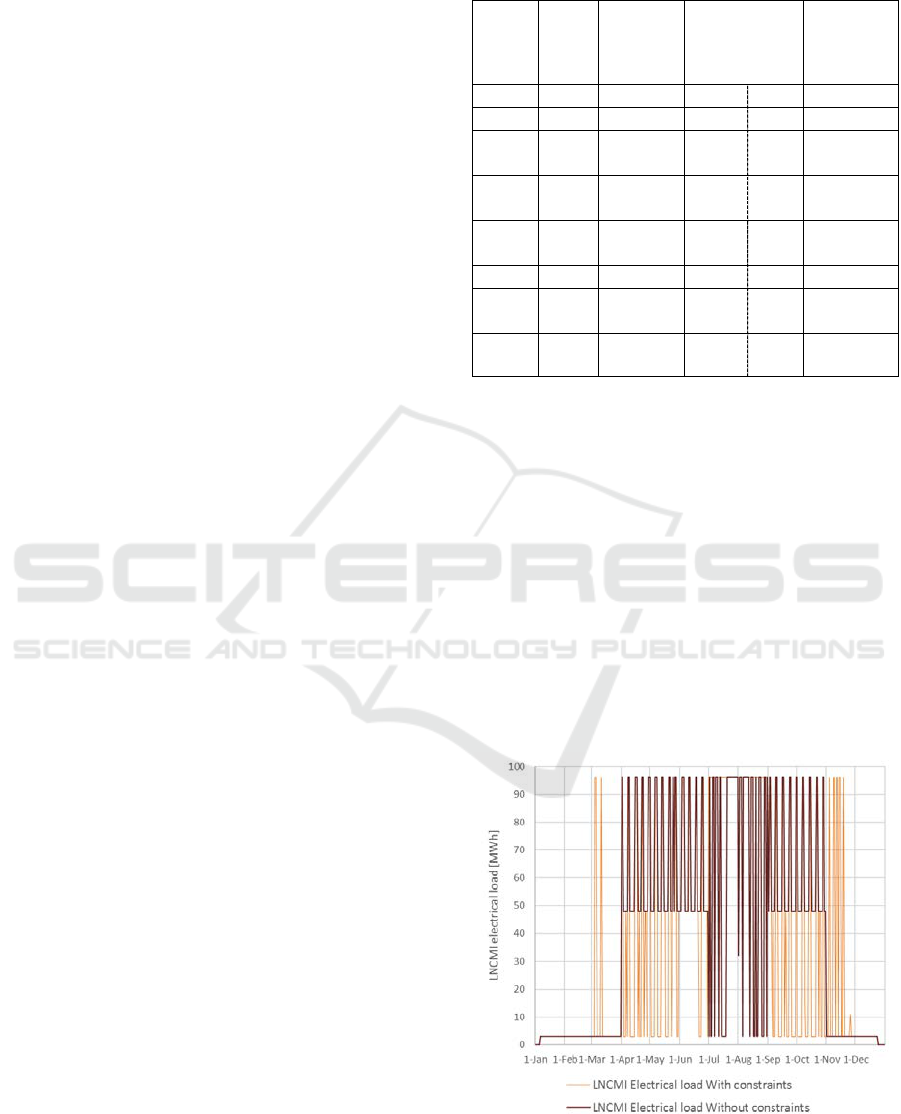

Table 2: Comparison between current and optimized

LNCMI energy planning.

Time

perio

d

Elec.

price

[pu]

2017

Planning

Optimization

Results

Constraints

Results

without

constraint

s

1

1.00

0

= 0

0

0

2

0.98

0

= 0

0

0

3

0.83 180

≥

500

500 0

4

0.65 1 200

≤

2000

234 234

5

0.56 1 420

≤

1500

714 183

6

0.67

250

None

0

0

7

0.48 6 600

≤

6600

660

0

9648

8

0.55 4 350 None

595

2

3935

As a first approach, we considered the

optimization problem as a minimization of the

electricity bill under constraints. Energetic planning

for this optimization can be found in the fourth

column next to the energetic constraints taken into

account (equations 9 to 13). We can notice that some

of the constraints are reached (see values in red), so

that we can hope to get better results in terms of

electrical bill reduction if we relax the constraints.

These results led us to the second approach,

without the energetic constraints put in place

manually, but not corresponding to a real constraint

of the installation, in opposite to the annual closure

for instance. Results of this optimization are shown

in the last column of Table 2 and Figure 1.

Figure 1: LNCMI electrical consumption from

optimization results.

Industrial Optimal Operation Planning with Financial and Ecological Objectives

217

These values complete results from the first

approach, by giving several indications as:

• As suspected, forcing the electrical

consumption to zero for the first two price

periods is not necessary because of high

prices.

• Relaxing the two periods where limits are

reached can significantly change the energy

repartition.

For a better understanding of the impact of the

relaxation of energy limitations, we will focus on the

objective, which is the LNCMI electricity bill

reduction.

In the first approach, the bill reduction with the

new energy planning is estimated of 0.4%. Even if

this diminution seems low, we have to keep in mind

that our problem is more constrained than the

current energy planning. Indeed, it has been wished

that at least 500 MWh would be planned during the

fourth time period, while only 180 MWh are

currently planned. In the second approach, the bill

reduction reaches 4.6%, but the impact on working

conditions is not taken into account, as we relaxed

the associated constraints.

2.3.2 Conclusion and Prospects

The energy planning of an EII allows us to use its

consumption flexibility to adjust its operation.

Moreover, it could also help the consumer to

identify which constraints are the more restrictive

from an economic point of view. However, it is

important to keep in mind what impact could have

the relaxation of restrictive constraints (less working

quality in our case).

It has been shown that this first modeling could

be used to minimize the energy bill with a defined

pricing, but we can also imagine using it to compare

financial gains associated with different energy

supply contracts. Nevertheless, these two

applications have as sole goal to serve economical

interest of one particular actor, while we could

imagine considering other goals.

A prospect for this decision tool could be to

explicitly quantify the social impact of energy

planning to realise multi-objectives optimizations

and to help to choose a compromise between these

two interests. Another one would be to use this

flexibility into more ambitious projects and serve

general interest at district scale.

3 COMBINED OPTIMIZATION

OF ENERGY CONSUMPTION

AND DISTRICT HEATING

On the one hand, for lots of energy experts, energy

efficiency will be one of the keys of a successful

energy transition (Smartgrids-CRE, 2017), so that

energy losses reduction becomes more and more

important. On the other hand, Joule losses in

industrial processes can lead to temperature

problems and lots of EIIs are forced to put in place

cooling installations to evacuate generated heat. One

way of reducing our total energy consumption

consists in the heat losses re-use to supply heating

demand instead of simply trying to evacuate it.

Well-known examples are datacenters (ADEME,

2015), but it could be achieved on the LNCMI

installation with its annual consumption of 14 GWh

and its cooling installation (which evacuates almost

12 GWh of heat). Therefore re-using calories from

LNCMI magnets cooling to complete the heat

supply of a district (annual load of 21GWh) instead

of dissipating it into the neighbour river is studied in

the project Valocal (C. Pajot et al., 2017).

3.1 Carbon Footprint for Heating

Supply

Our first case study aims to reduce the carbon

footprint of a district by minimizing the CO

2

emission generated to cover the heat load of

buildings connected to a heating network. This

reduction of greenhouse gases emissions will be

realised thanks to the choice to solicit either the

electrical network or the heating network offer by

re-using LNCMI Joule losses.

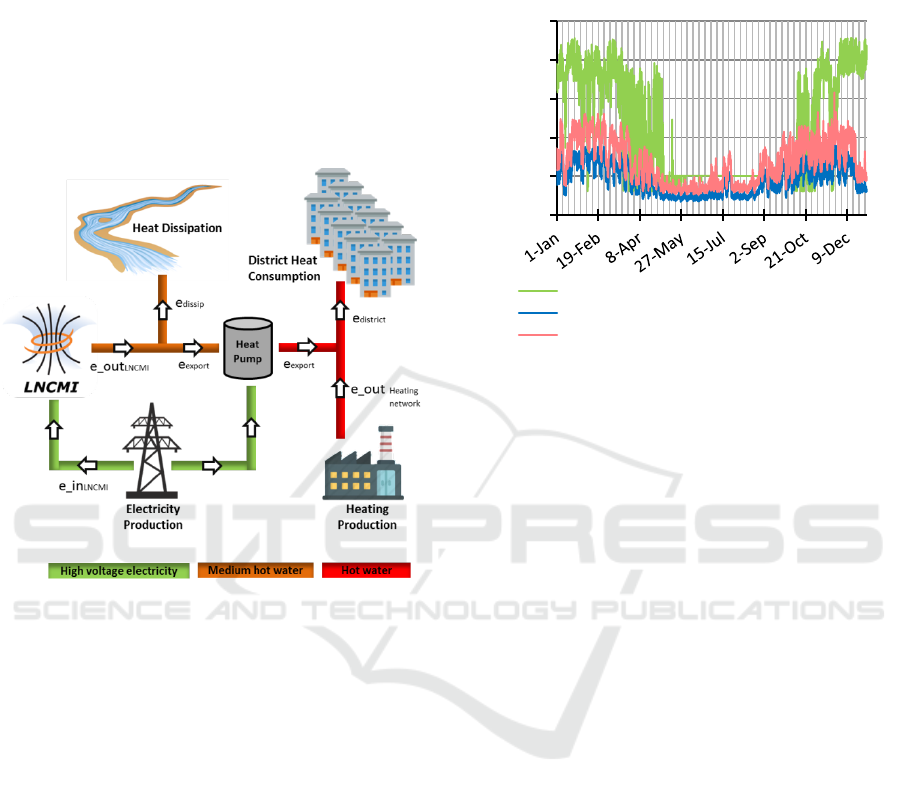

3.1.1 Energetic Model

Indeed, from an energetic point of view, the LNCMI

could be considered as a conversion unit between

electricity and heat with a conversion rate depending

of temperature conditions. To simplify the problem

and focus on power flows only, we modeled the

LNCMI process with a fixed electrical to thermal

conversion rate of 85% (mean value of thermal

losses observed in real conditions).

e_out

LNCMI

(t) = 0.85 * e_in

LNCMI

(t)

(16)

The previous operating constraints were kept and

a thermal dissipation model was added as a flexible

consumption (see Figure 2). Heating power provided

by the LNCMI can be either dissipated through this

SMARTGREENS 2018 - 7th International Conference on Smart Cities and Green ICT Systems

218

flexible consumption unit or exported to the heating

network as expressed in equation 16:

e_out

lncmi

(t) = e

dissip.

(t) + e

export

(t)

(17)

e

export

: export to the district heating network

e

dissip

: the variable dissipated heat

The energy networks (heating and electrical)

were modeled as production units with limitations

on maximal power delivered corresponding to

network maximal power flux.

Figure 2 : Schematic diagram for district energetic model.

In our study case, we don’t consider the

possibility of load variations (load shifting, load

reduction, etc.), so that the district heating

consumption was modeled as a fixed load

corresponding to a representative year.

3.1.2 Environmental Model

3.1.2.1 French Electrical Emissions

The French electrical system is well known for its

low CO

2

emission, due to its high share of nuclear

power (72% of the 2016 electrical production (RTE,

(2016)). Moreover, this massive nuclear power

integration into the electrical mix has affected the

heating sector with one of the highest electrical

heating share among European countries, so that

fossil fuel production units are only started to

provide supply for load peaks (see French electricity

network CO

2

emission during a year in Figure 3).

That is why we decided to study the subject of

energy carbon footprint from a dynamic point of

view (ADEME, 2014).

For both of the production units modelling

energy networks, a dynamic CO

2

emission rate was

defined corresponding to the daily mean value (see

‘Electricity’ and ‘Heat’ curves on Figure 3).

Figure 3: Dynamic CO

2

emission from energetic

(electrical and heat) production.

3.1.2.2 Additional emissions

Moreover, temperature levels need to be increased to

reach those of the heating grid. Therefore, the

resulting electrical consumption increase needed to

feed a heating pump was also considered. As before,

we consider temperature variations to be negligible

and make the hypothesis of a constant ratio. After a

technological benchmark realised in the Valocal

project, the heat pump was chosen with a coefficient

of performance equal to 3.25.

Therefore, if we consider the CO

2

emissions

related to the entire conversion chain of electrical

consumption into heat production, we have to add

the CO

2

emission from the electrical consumption of

the heat pump to the electrical consumption to the

LNCMI electrical consumption converted into heat

and exported into the heating network.

For each thermal kWh exported, 1/0.85 electrical

kWh was consumed by the LNCMI and an extra

1/3.25 electrical kWh was consumed by the heat

pump leading to an equivalent CO

2

emission rate

(see ‘Electricity conv. into heat by LNCMI’ on

Figure 3) expressed as follows:

co

2eq rate

(t) = co

2elec rate

(t) * (1/0.85 + 1/3.25)

(18)

For reminder, the objective in this case study is

to reduce the carbon footprint of the district by

minimizing the CO

2

emission of the heating

network. To simplify, we introduced an equivalent

CO

2

emission rate (equation 16) for thermal energy

provided by LNCMI cooling system, so that

0

50

100

150

200

250

CO2 emissions [g/kWh]

Heating network

French electrical network

Electricity conv. Into heat by LNCMI

Industrial Optimal Operation Planning with Financial and Ecological Objectives

219

objective can be formulated as:

Minimize ∑

t

CO

2district

(t)

(19)

Where: CO

2district

(t) = co

2eq rate

(t) * e

export

(t)

+ co

2heat rate

(t) * e_out

heating network

(t)

(20

)

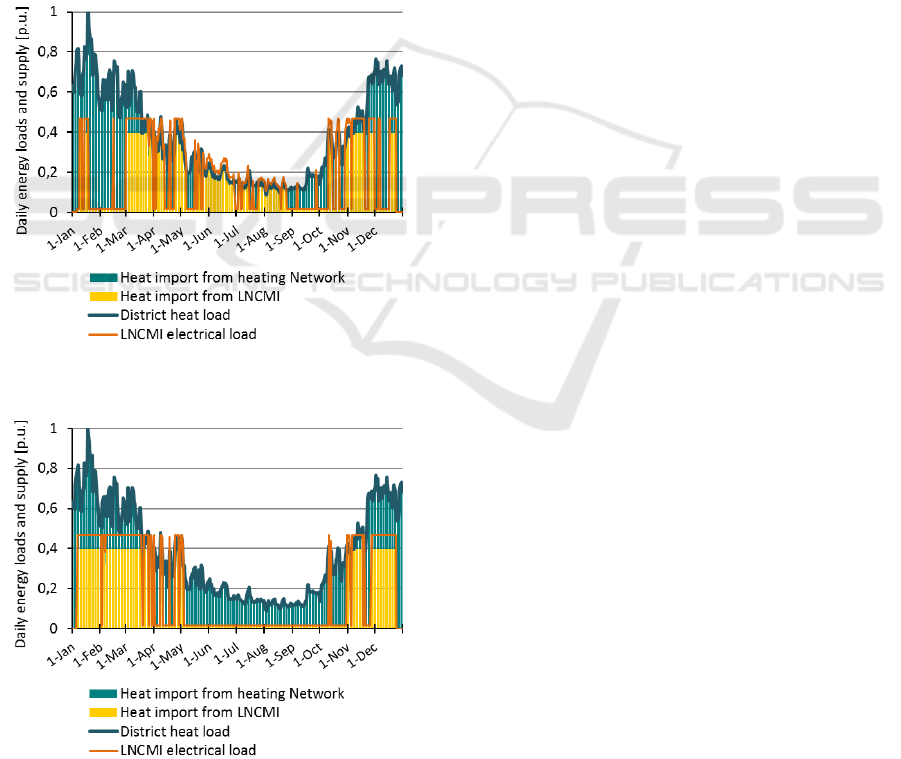

3.1.3 Results and Prospects

As before, we studied two different approaches: with

and without LNCMI energy limitation constraints.

We reached a reduction of CO

2

emission of 28% in

the first case and 35% in the second case.

Unlike the energy bill reduction problem, we can

notice that energy limitations are less restrictive in

order to minimize CO

2

emission. However, the

energy repartition changes a lot between

optimizations with or without energy limitations (see

Figure 4 and Figure 5).

Figure 4: District energy flows repartition with LNCMI

constraints taken into account.

Figure 5: District energy flows repartition without LNCMI

constraint.

In section 2, we optimized energy planning in

order to reduce the electricity bill and demonstrated

that the currently used energy planning was already

a good optimization as we reduced the bill with and

without energy constraints of respectively 0.4% and

4.6%. This first case aimed to help a single

stakeholder, while we focused on the global interest

through an ecological optimization in 3.1.

Nevertheless, we can now wonder how the

LNCMI is impacted by these ecological

considerations. In the first case, the electricity bill of

the LNCMI increases by 21% and reaches 39% of

raise when we remove the LNCMI energy

limitations. In these cases, why would the LNCMI

be the one to pay the CO

2

emissions reduction?

Moreover, the electricity cost to feed the heat pump

was not included into the increases, while some

stakeholders would have to pay for it.

These results raise an issue: how to guarantee no

economic effect on the heating consumer bill, while

guaranteeing no LNCMI electricity bill increase

either?

3.2 Reduction of a District Heating

Supply Cost

One of the main issues in energy transition is to

mitigate our environmental impact without leading

to an uncontrolled raise of energy prices for the

consumer. How to do so, when we have the

possibility to produce at low price with energies as

coal with a strong impact on global warming for

instance?

That is the problem we address in this last case

study at a district scale. Our aim is to add a financial

modeling to our previous case study to find

compromises between ecologic and economic points

of view.

3.2.1 Financial Model

We found previously that LNCMI electricity bill

could increase when we reduced the CO

2

emission.

However, we did not define any economic model to

compensate this bill augmentation.

Here, we decided not to model the financial

transactions between the heat supplier and the

LNCMI to keep all types of remuneration possible.

To do so, we considered the LNCMI as a heating

production unit with an energy production cost.

The production cost of 1 thermal kWh is

estimated as the electrical consumption cost of the

heat pump added to the increase of LNCMI bill

regarding to the current one. LNCMI expense model

SMARTGREENS 2018 - 7th International Conference on Smart Cities and Green ICT Systems

220

is usable for any energy unit connected to the

transmission grid under the condition of providing

an equivalent power of consumption. Nevertheless,

applying this particular point to the heat pump could

lead to an over-estimation of its electricity

consumption cost. We preferred here an average

approach as studied on the ecological study case,

with a mean dynamic cost of electricity.

3.2.2 Which Trade-off between Divergent

Interests?

Optimization focused on district energy heating cost

only can lead to a reduction of 8.3% with the

LNCMI energy limitations. This result seems to say

that we get a margin to lower the CO

2

emission of

the district without increasing energy cost for the

consumer. Our last case study aims to verify this

assumption.

For this purpose, we combine financial and

ecological objectives into a single one as follows

with a coefficient α to weight the objectives:

Minimize:

α ∑

t

CO

2district

(t) / CO

2max

+

(1-α) ∑

t

Ct

district

(t) / Ct

max

(21

)

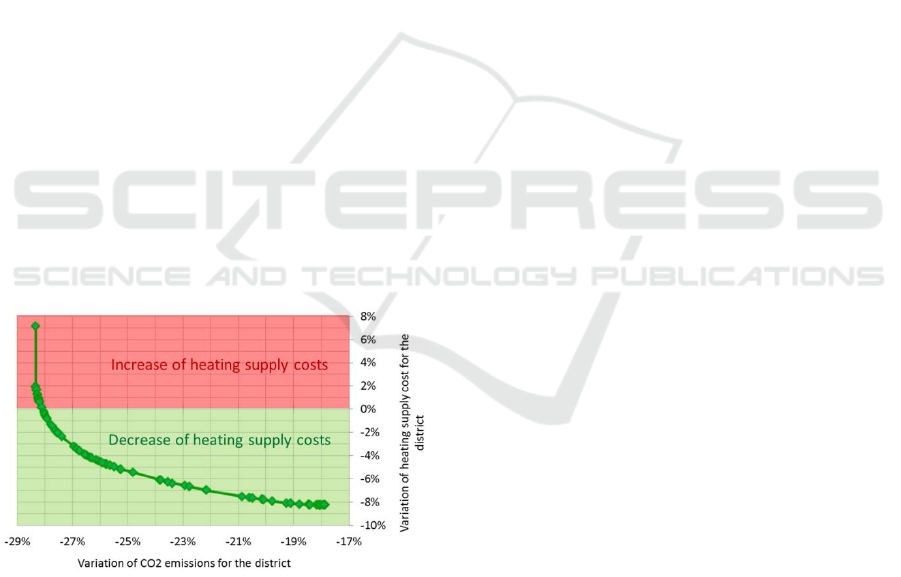

Results obtained with α-values in [0; 1] showed

that with great use of LNCMI flexibility, we could

achieve both of the goals previously set: CO

2

emission reduction and heating supply cost

reduction (see the Pareto diagram Figure 7).

Figure 6: Pareto diagram for CO2 emission and heating

supply bill reduction.

The abscissa shows the impact on CO

2

emission

compared to the current estimation, while the y-axis

represents the financial objective with the variation

of heating supply cost (positive values when cost

increases and negative ones when it decreases). We

can observe on the Figure 6, the two extreme points

corresponding to each objective. When alpha equals

0, the optimization is only financial and we reach the

8.3% of savings announced before. In the other

hand, when alpha equals 1, we recognized the 28%

of CO

2

emission reduction from the environmental

optimization in 3.1.

If we consider only the results leading to supply

cost decreases, we can see that reducing CO

2

emissions is possible without increasing the energy

supply and can even lead to supply savings.

However, these savings do not consider the

investment costs to re-use the LNCMI thermal

losses. That is why one of the outlooks for the use of

this decision tool could be the study of return of

investment in the case of heat recycling.

4 CONCLUSIONS

To summarize, we have shown that the developed

decision tool could serve several needs:

• Reducing its energy supply bill under

operation constraints

• Reducing the CO

2

emission of a district

• Reducing the heating supply cost of a

district

With the defined energy limitations, the LNCMI

optimal planning can only reduce by 0.4% the

amount of the energy bill, while this decrease

reached 4.8% when relaxing these limitations.

A multi-objective approach could be studied to

take into consideration both of the financial and

working quality aspect, by adding a social modeling.

Moreover, the LNCMI energy planning could serve

more ambitious projects than only bill reduction as

the Valocal project, which aims to re-use LNCMI

heat losses for building heating.

In this scenario, two goals have been studied

(financial and ecological). Regarding the ecological

optimization, the reduction of CO

2

emissions can

reach 35% and heating supply cost can decrease by

8.8% for a financial optimization. Finally, we have

seen that both goals could be achieved by merging

the two objectives into one.

ACKNOWLEDGEMENTS

The VALOCAL project was funded by the CNRS

Interdisciplinary Mission (MI-CNRS) with support

from the Institute of Sciences and Engineering and

Systems (INSIS-CNRS). The authors thank these

authorities, which have made possible through this

funding to initiate transdisciplinary work on an

Industrial Optimal Operation Planning with Financial and Ecological Objectives

221

original issue of energy optimization.

This work is supported by the French National

Research Agency in the framework of the

"Investissements d'avenir" program (ANR-15-

IDEX-02).

REFERENCES

Allegrini, J., Orehounig, K., Mavromatidis, G., Ruesch, F.,

Dorer, V. and Evins, R. (2015). A review of modelling

approaches and tools for the simulation of district-

scale energy systems. Renewable and Sustainable

Energy Reviews, 52, pp.1391-1404.

Schütz, T., Schiffer, L., Harb, H., Fuchs, M. and Müller,

D. (2017). Optimal design of energy conversion units

and envelopes for residential building retrofits using a

comprehensive MILP model. Applied Energy, 185,

pp.1-15.

Lauster, M., Teichmann, J., Fuchs, M., Streblow, R. and

Mueller, D. (2014). Low order thermal network

models for dynamic simulations of buildings on city

district scale. Building and Environment, 73, pp.223-

231.

Jimeno, A. S., Fonseca, A., 2015. Integrated model for

characterization of spatiotemporal building energy

consumption patterns in neighborhoods and city

districts, Applied Energy, 142, pp.247-265.

Keirstead, James, Jennings, Mark, Sivakumar, Aruna,

2012. A review of urban energy system models:

approaches, challenges and opportunities. Renewable

and Sustainable Energy Reviews, 16, pp. 3847-3866.

Shi, Zhongming, Fonseca, Jimeno A., Schlueter, Arno,

2017. A review of simulation-based urban form

generation and optimization for energy-driven urban

design, Building and Environment, 121, pp.119-129.

Best, Robert E., Flager, Forest, Lepech, Michael D. , 2015.

Modeling and optimization of building mix and energy

supply technology for urban districts, Applied Energy,

159, pp.161-177.

Shabanpour-Haghighi, Amin, Seifi, Ali Reza, 2015.

Simultaneous integrated optimal energy flow of

electricity, gas, and heat, Energy Conversion and

Management, 101, pp.579 – 591.

Morvaj, Boran, Evins, Ralph, Carmeliet, Jan, 2016.

Optimising urban energy systems: Simultaneous

system sizing, operation and district heating network

layout, Energy, 116, pp.619-636.

Rte&Vous Le Mag. (2018). 258 entreprises directement

connectées au réseau RTE : des enjeux XXL. [online]

Available at: http://lemag.rte-et-vous.com/dossiers/

258-entreprises-directement-connectees-au-reseau-rte-

des-enjeux-xxl.

Clients RTE-France. (2016). TURPE 4 : Tarification des

réseaux. [online]. Available at: https://clients.rte-

france.com/htm/fr/mediatheque/telecharge/Comprendr

e_le_tarif_01_08_2016.pdf.

LNCMI. (2017), Laboratoire National des Champs

Magnétiques Intenses [online]. Available at:

http://lncmi.cnrs.fr/spip.php?rubrique17&lang=fr.

Smartgrids-CRE. (2017) L’efficacité énergétique, un

principe structurant de la transition énergétique

[online]. Available at: http://www.smartgrids-

cre.fr/index.php?p=efficacite-energetique.

ADEME. (2015), La chaleur fatale industrielle.

Pajot, Camille, Delinchant, Benoit, Marechal, Yves,

Wurtz, Frédéric, Debray, François, Vincent, Benjamin.

2017. Valorisation optimale de chaleur fatale d'un site

à très forte consommation électrique, Conférence des

Jeunes Chercheurs en Génie Electrique (JCGE),

Arras.

RTE, (2016), Statistiques de production, consommations

et échanges. [online] Available at: http://www.rte-

france.com/fr/article/statistiques-de-l-energie-

electrique-en-france.

ADEME, (2014), Documentation des facteurs d'émissions

de la Base Carbone. [online] Available at:

http://www.bilans-

ges.ademe.fr/static/documents/[Base%20Carbone]%20

Documentation%20g%C3%A9n%C3%A9rale%20v11

.0.pdf.

SMARTGREENS 2018 - 7th International Conference on Smart Cities and Green ICT Systems

222