The Effects of Exfoliated Graphite Concentration on Sensing

Properties of Chitosan/Exfoliated Graphite Film Crosslinked with

Glutaraldehyde

I. Nainggolan

1

, P. Faradilla

1

, T. I. Nasution

2

, H. Agusnar

1

1

Chemistry Department, Faculty of Mathematics and Natural Science, Universitas Sumatera Utara, Medan 20155,

Sumatera Utara, Indonesia

2

Physics Department, Faculty of Mathematics and Natural Science, Universitas Sumatera Utara, Medan 20155, Sumatera

Utara, Indonesia

Keywords: Chitosan, Exfoliated Graphite, Glutaraldehyde, Films, Sensors.

Abstract: In this study, chitosan/exfoliated graphite (CEG) sensors were used for formaldehyde detection in various

concentration i.e. 1 ppm; 1,5 ppm; 2 ppm; 5 ppm; and 10 ppm. The sensors were fabricated using

electrodeposition method to form film sensors. The cross-linking agent is glutaraldehyde, it was used to

enhance the life time of CEG film sensors. The effect of exfoliated graphite concentration on sensing

properties of CEG film sensors has been proven by improvement on response and sensitivity of sensors when

the concentration of EG increased. Formaldehyde solution was dropped onto chitosan/EG film sensor and the

response of the chitosan/EG film sensors toward formaldehyde was recorded as output voltage. The

measurement result of maximum output voltage from chitosan/EG film sensors is greater than chitosan

sensors for 10 ppm formaldehyde. Increasing on concentration of formaldehyde made the output voltage

of the sensors increased.

1 INTRODUCTION

The control on utilization of formalin by goverment

is weak (Noordiana, 2011). Formalin is a forbidden

food as stated in The Food Regulation. According to

WHO standards in 2002, the maximum formalin

content contained in food was 1 mg/l equivalent to 1

ppm (WHO, 2002).

Chitosan is biopolymer which produced by treating

seafood waste and it functions as an attractive sensitive

material. Chitosan easily can be modified to be used as

an effective sensitive material due to modification of the

chitosan structure, excellent film-forming ability,

adhesive, high heat stability (Yang, 2013). The high

solubility in acidic media makes chitosan easily

deposited onto a substrate to form film (Sun, 2011). The

use of thin films of chitosan continues to expand in

various industries such as industrial biotechnology,

.

environmental, agricultural industries etc. (Majety,

2000). The advantages of non-porous film layers offer

high selectivity, permeability and mechanical strength

(Kanti, 2004).

Graphite is produced naturally or synthetically.

Graphite is a crystalline carbon which is highly

conductive (with an electrical conductivity of 10

4

S/cm). Graphite’s derivative called exfoliated

graphite or expanded graphite could be a filler for

producing conductive materials. The electrical

conductivity of exfoliated graphite is high. Exfoliated

graphite has a good affinity for organic compounds

(Debelak, 2007). Neat graphite (NG) can be

converted to intercalated or expandable graphite

through chemical oxidation in the presence of

concentrated acid such as H

2SO4 or HNO3. Expanded

graphite is then obtained by exfoliation and expansion

of graphite by heating in a furnace above 600

o

C

(Demitri, 2015). Surface area and bulk density

essentially affect the physicochemical and physical

properties of carbon materials. Exfoliated graphite

can be also synthesized from graphite oxide (OG)

(Buchsteiner, 2006).

Nainggolan, I., Faradhilla, P., Nasution, T. and Agusnar, H.

The Effects of Exfoliated Graphite Concentration on Sensing Properties of Chitosan/Exfoliated Graphite Film Crosslinked with Glutaraldehyde.

DOI: 10.5220/0010103810871090

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

1087-1090

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1087

Most of current techniques to detect fomaldehyde

are sophisticated equipment, expensive and time

consuming. So, it is highly desirable to develop a

sensitive and easy-to-use method for formaldehyde

detection.

2 MATERIALS AND METHOD

2.1 Materials and Instruments

Materials used in this research are chitosan powder

supplied by Sigma–Aldrich (medium molecular

weight), graphite, glutaraldehyde, CH

3COOH 2%,

H

2SO4(p), HNO3(p), CoCl2 0,01 M, KSCN 1 M and

HCl 2 N (Merck).

Oven, Furnace, hot plate, magnetic stirrer, printed

circuit board (PCB), centrifuge, an ultrasonic, a set of

FTIR Shimadzu IR prestige-21 and a set of XRD

Shimadzu XRD-6100 were used as tools to perform

the

material preparation and material characterization.

2.2 Preparation of Chitosan Solution

Chitosan powder was dissolved in acetic acid 2% then

stirred using a magnetic bar for 24 hours at room

temperature to prepare the chitosan gel.

2.3 Preparation of Exfoliated Graphite

Exfoliated graphite was prepared using graphite and

it was mixed with nitric and sulfuric acid for 24 hours.

Then, it became intercalated graphite. The mixture

was filtered and washed until the pH became neutral.

Exfoliated graphite was dried in an oven. Then the

intercalated graphite compound was subjected

thermal shock to temperatures of 900

o

C.

2.4 Preparation of Chitosan/Exfoliated

Graphite Solution

Exfoliated graphite 400 mg was added into chitosan

solution and stirred for 1 hour then sonicated. After

that, the solution was centrifuged 5000 rpm to collect

supernatant solution for chitosan/EG film sensors

fabrication.

2.5 Preparation of Chitosan/Exfoliated

Graphite (EG) Film Sensor

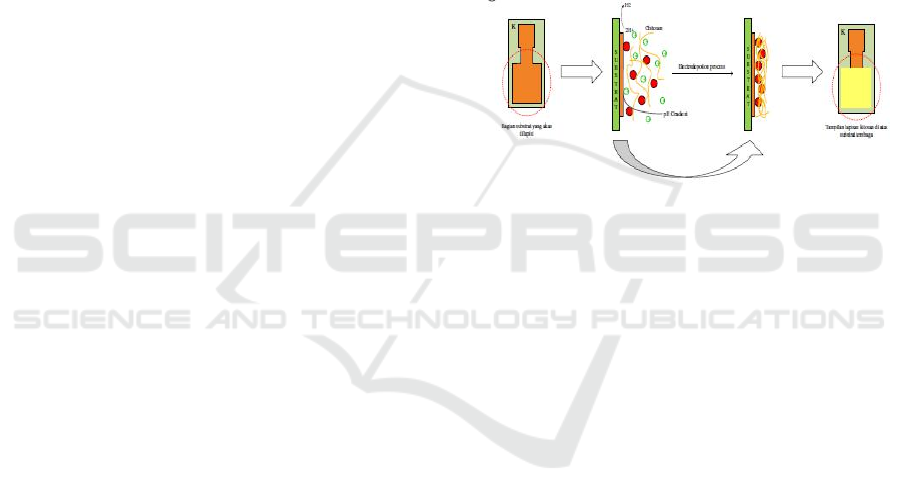

Chitosan/exfoliated graphite film sensors were made

by chitosan/EG solution using electrodeposition

method. The substrate of the sensor used is a printed

circuit board (PCB). The electrodeposition process is

illustrated as in Figure 1. The supplied voltage was

fixed at 2,5 volts. Then it left to dry for 5 minutes at

105

o

C in an vacuum oven. Chitosan/EG films were

cross-linked using glutaraldehyde 25%. CoCl

2 0,01

M was used as a template to protect amine groups.

KSCN 1 M is a solution to remove the template and

HCl 2 N was used to ensure the template is

completely removed. Formaldehyde solution was

varied into 1 ppm; 1,5 ppm; 2 ppm; 5 ppm; and 10

ppm. Formaldehyde solution was dropped onto

chitosan/EG film sensors and it was detected by

amperometric method. The output voltage was

displayed based on the characteristic of the film

sensor. The response of the sensor towards

formaldehyde was recorded as output voltage.

Figure 1. Electrodeposition Process of Chitosan/EG film

sensor.

3 RESULTS AND DISCUSSION

Chitosan would assemble onto the PCB surface when

it is positively charged in acidic conditions to form

chitosan sensor. Exfoliated graphite was found

improving the sensitivity of chitosan film sensor. The

addition of glutaraldehyde as crosslinking agent

improved the lifetime of chitosan/EG. The output of

chitosan/EG sensors was in the potential voltage.

Chitosan/EG film sensors showed good sensitivity

and long lifetime in measurement with various

concentration of formaldehyde. The measurements

were repeated three times. The output voltage of

chitosan/EG film sensors when detecting

formaldehyde are reported in Table 1.

Table 1 shows the output voltage of chitosan/EG

film sensors when the sensor’s surface was exposed

to formaldehyde with various concentration. The

output voltage of the sensor indicates the sensitivity

of chitosan/EG film sensor during detecting various

concentration of formaldehyde. The output voltage

values were within the range of 0,421 V to 0,589 V for

1-10 ppm of formaldehyde. The highest output voltage

(0,589 V) was observed when chitosan/EG film sensor

exposed to 10 ppm formaldehyde, while the lowest

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1088

output voltage (0,421 V) was observed at 1 ppm

formaldehyde. If it is compared to chitosan sensor which

gave output voltage 0.143 V when the sensor was

exposed to 1 ppm of formaldehyde. As shown by the

table, increasing concentration of formaldehyde shows

the increasing of output voltage.

Table 1: The output voltage of crosslinked chitosan/EG

film sensor towards formaldehyde.

Formaldeh

y

de

Avera

g

e of Output

Concentration (ppm) Volta

g

e (V)

1

0,421

1,5

0,434

2

0,447

5

0,504

10

0,589

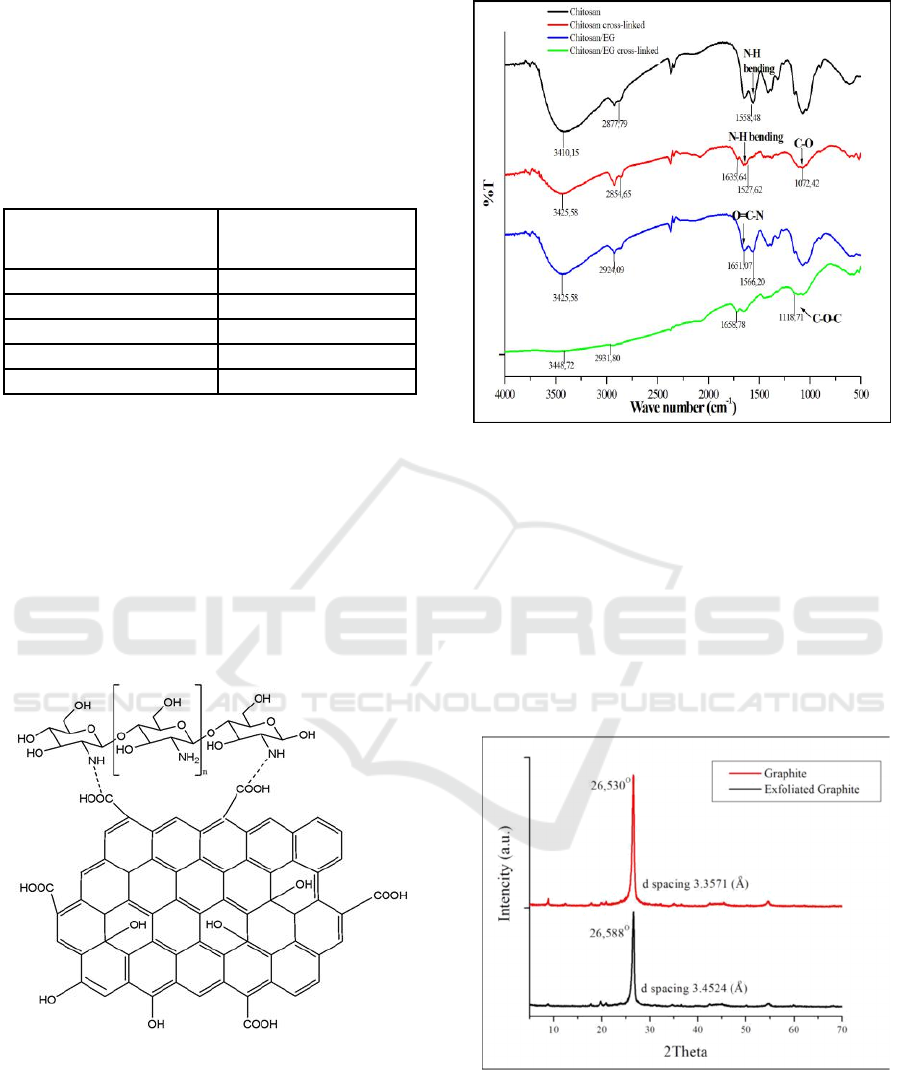

FTIR studies confirmed the successful of

crosslinking of chitosan and chitosan/EG with

glutaraldehyde as displayed in Figure 2. The peak at

1072,42 cm

-1

shows stretching vibration of –C-O-

from chitosan and glutaraldehyde. The absorption

band at the wave number 1651,07 cm

-1

is the O=C-N

group which proves that exfoliated graphite binds to

chitosan. Wave number of 1118.71 cm

-1

is a

stretching of C-O-C bridge which proves cross-

linkage between chitosan/EG and glutaraldehyde.

Figure 2: The FTIR spectrum of chitosan, chitosan/EG,

crosslinked chitosan and crosslinked chitosan/EG films.

The interaction between exfoliated graphite and

chitosan formed hydrogen bonding between

carboxylic acid of exfoliated graphite and amine

group of chitosan. The illustration of the reaction can

be seen in Figure 3.

Figure 3: Reaction between chitosan and exfoliated

graphite

The XRD patterns of graphite and exfoliated

graphite are represented in Figure 4. Based on XRD

analysis, the diffraction angles of the graphite forms

peak at 26,530

o

with d-spacing 3,3571 Å while the

diffraction angles of exfoliated graphite forms peak at

26,588

o

with d-spacing 3,4524 Å. It proved that there

was an expansion of the lattice of exfoliated graphite

thus exfoliated graphite was obtained in a greater d-

spacing value than graphite.

Figure 4: XRD of graphite and exfoliated graphite

4 CONCLUSIONS

The electrical testing results of chitosan/EG film

sensors showed that chitosan/EG film sensor was

The Effects of Exfoliated Graphite Concentration on Sensing Properties of Chitosan/Exfoliated Graphite Film Crosslinked with

Glutaraldehyde

1089

potentially capable to detect formaldehyde in various

concentration of formaldehyde. The sensitivity of

chitosan/EG film sensors has been proven by the

different output voltage values when the sensors

exposed to different concentration of formaldehyde.

Increasing concentration of formaldehyde indicated

the increasing on output voltage. The highest output

value (0,589 V) was recorded during detecting 10

ppm of formaldehyde, while the lowest value (0,4217

V) for 1 ppm of formaldehyde. The cross-linking

process of chitosan with glutaraldehyde has been

successfully done and it has been proved by FT-IR

spectrum. The crosslinking improved the lifetime f

the sensors.

ACKNOWLEDGEMENTS

This work was financially supported by TALENTA

USU research grant No. 2590/UN5.1.R/PPM/2018

REFERENCES

Noordiana, N., Fatimah, AB., Farhana, YCB. 2011. Int.

Food Res. J. 18: 125–136

World Health Organization (WHO)., 2002. Formaldehyde.

Concise International Chemical Assessment Document

40. Geneva; 48: 6-7

Yang, Y., Fang, G., Liu, G., Pan, M., Wang, X.,

Kong, L., 2013. Biosens. Bioelectron. 47: 475–

481.

Sun, K., Li, ZH., 2011. Express Polymer Letters 5(4): 342

- 361. Majety, NV., Kumar, R., 2000. Reactive &

Functional Polymers, 46 1-27

Kanti, P., Srigowri., Madhuri, J., Sridhar, S., 2004.

Separation and Purification Technology, 40 259-266

Debelak, B., Lafdi, K., 2007. Carbon 45: pp. 1727-1734

Demitri, C., Moscatello, A., Giuri, A., Rauci, MG.,

Corcione, CE., 2015. Polymers 7 2584–2594

Buchsteiner, A., Lerf,A., Pieper, J., 2006. J. Phys. Chem. B

110 22328-22338.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1090