Analysis Comparison of Cost and Time of Concrete and Paving Block

Jobs in the Implementation of Village Road Development using

Village Fund Budget

Indra Jaya

1

*, Andy Putra Rambe

1

1

Department of Civil Engineering, Faculty of Engineering. Universitas Sumatera Utara, Padang Bulan, Medan 20155,

Indonesia

Keywords: Concrete, paving block, Cost, Time.

Abstract: Minister of finance regulation No.93/PMK.07/2015 concerning procedures for allocation, distribution,

monitoring and evaluation of village funds regulates in more detail the use of village funds. The purpose of

this research is to analyze the cost and time of alternative selection of concrete materials and paving blocks

in carrying out the construction of village roads. The research used was a field study/ direct observation.

Collecting secondary data such as wage and basic material standards and budget of village fund for concrete

road works. Collecting primary data such as survey of paving block prices, survey of basic wage and material

prices, coredrill, concrete quality testing and paving blocks, mix design paving block. In 2017, The 1 m

2

unit

price of paving block work was cheaper by IDR.25472 than concrete road with the same quality. The 1 m

2

unit price of paving block work was cheaper by IDR.163588 than the existing concrete road. In 2018, The 1

m

2

unit price of paving block work was cheaper by IDR.32693 than concrete road with the same quality. The

1 m

2

unit price of paving block work was cheaper by IDR.132944 than the existing concrete road. The

conclusion in this research, paving block is 2 times cheaper than concrete material, and Concrete material is

4 times faster than paving blocks.

1 INTRODUCTION

The amount of the village funds budget distributed to

more than 74 thousand villages requires strict

supervision, but the lack of state civil apparatus

(ASN), supervision in the low field.

Until now the total circle of the Village Fund reached

62 cases, while in the process of investigation reached

48 cases (liputan6, 2018).

Village funds can be used to build village road

infrastructure. Until 2017, the total funds available to

finance village funds were 127.74 trillion for 74,910

villages that received assistance. The details in 2015

were IDR 20.76 trillion, 2016 IDR 49.98 trillion, and

2017 IDR 60 trillion (coverage 6, 2018)

This research is useful to provide technical

justification for the Village Head as the highest

official of the Village Government in implementing

the construction of village roads with an alternative

selection of concrete materials and paving blocks

seen from the aspect of cost and time.

2 LITERATURE REVIEW

2.1 Concrete Block

In accordance with SNI 03-0691-1996, concrete brick

is a composition of building materials made from a

mixture of portland cement or similar hydraulic

adhesives, water and aggregate with or without other

additives that do not reduce the quality of the concrete

brick. Concrete brick classification according to SNI

03-0691-1996, is Quality A, concrete brick is used for

roads. Quality B, concrete brick is used for the

parking lot. Quality C, concrete bricks are used for

pedestrians. Quality D, concrete bricks are used for

parks and other uses.

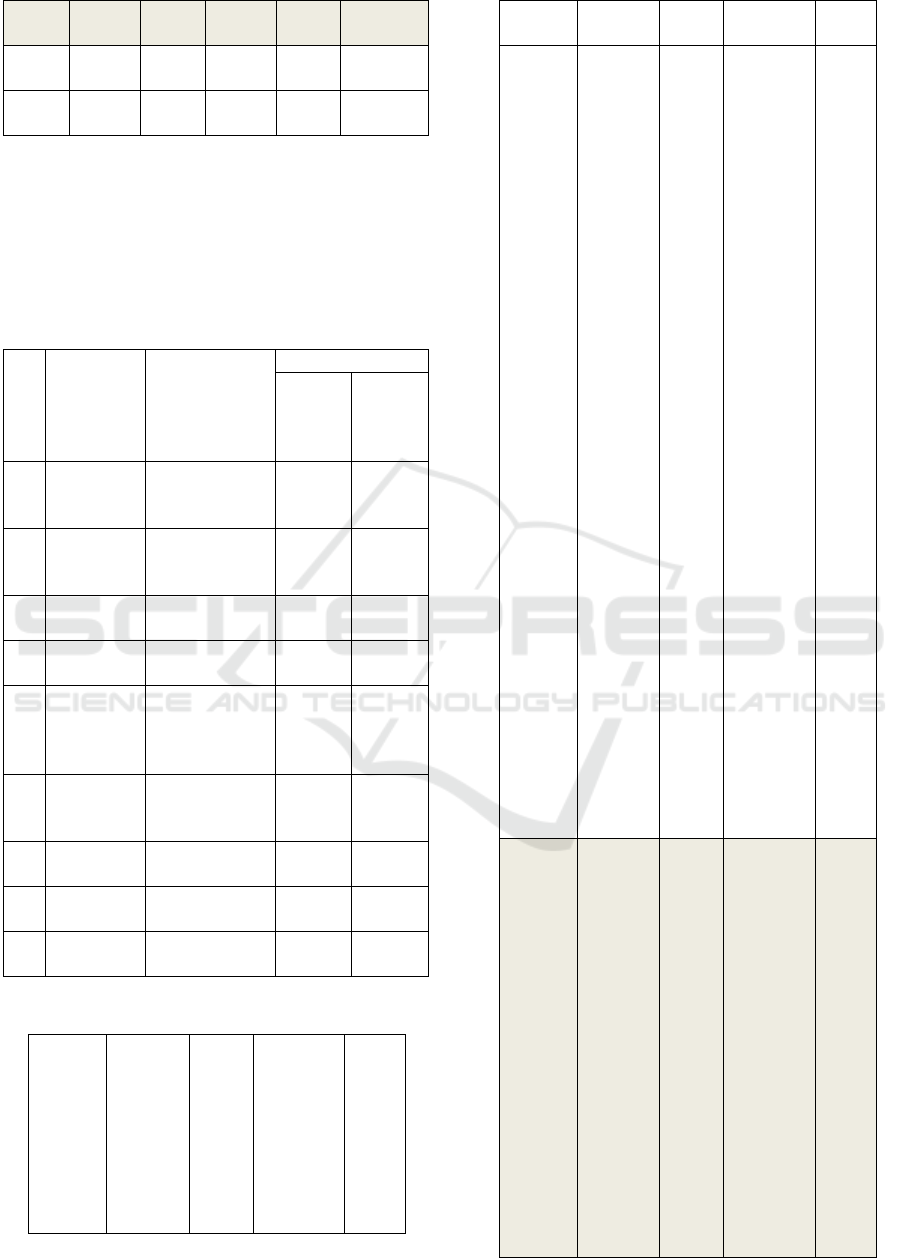

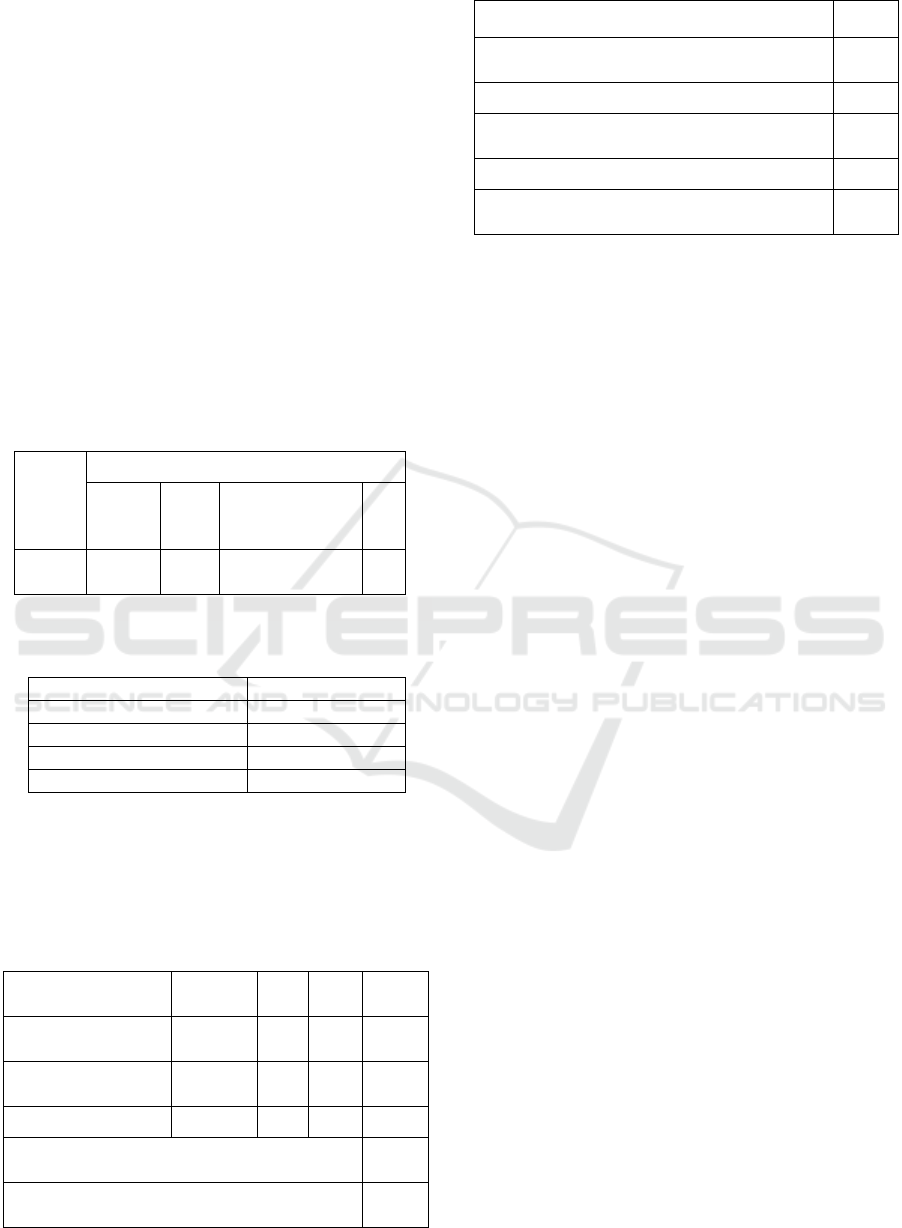

Table 1: Paving Specification according SNI 03-0691-1989

Quali

ty

Compressi

ve Strength

kg/cm

2

Abrasion

Resistance

mm/minute

Absorpti

on %

Avera

ge

Lowe

st

Avera

ge

Lowe

st

368

Jaya, I. and Rambe, A.

Analysis Comparison of Cost and Time of Concrete and Paving Block Jobs in the Implementation of Village Road Development using Village Fund Budget.

DOI: 10.5220/0010099403680374

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

368-374

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

I

40

0

340 0.090 0.103 3

II

30

0

255 0.130 0.149 5

II

I

20

0

170 0.160 0.184 7

2.2 Paving Block for Rural Roads

Sharma, P. and Kumar, B.R. 2016, “Cement Concrete

Paver Block For Rural Roads”, TROI, Volume-3,

Issue-2, ISSN: 2393-8374. India.

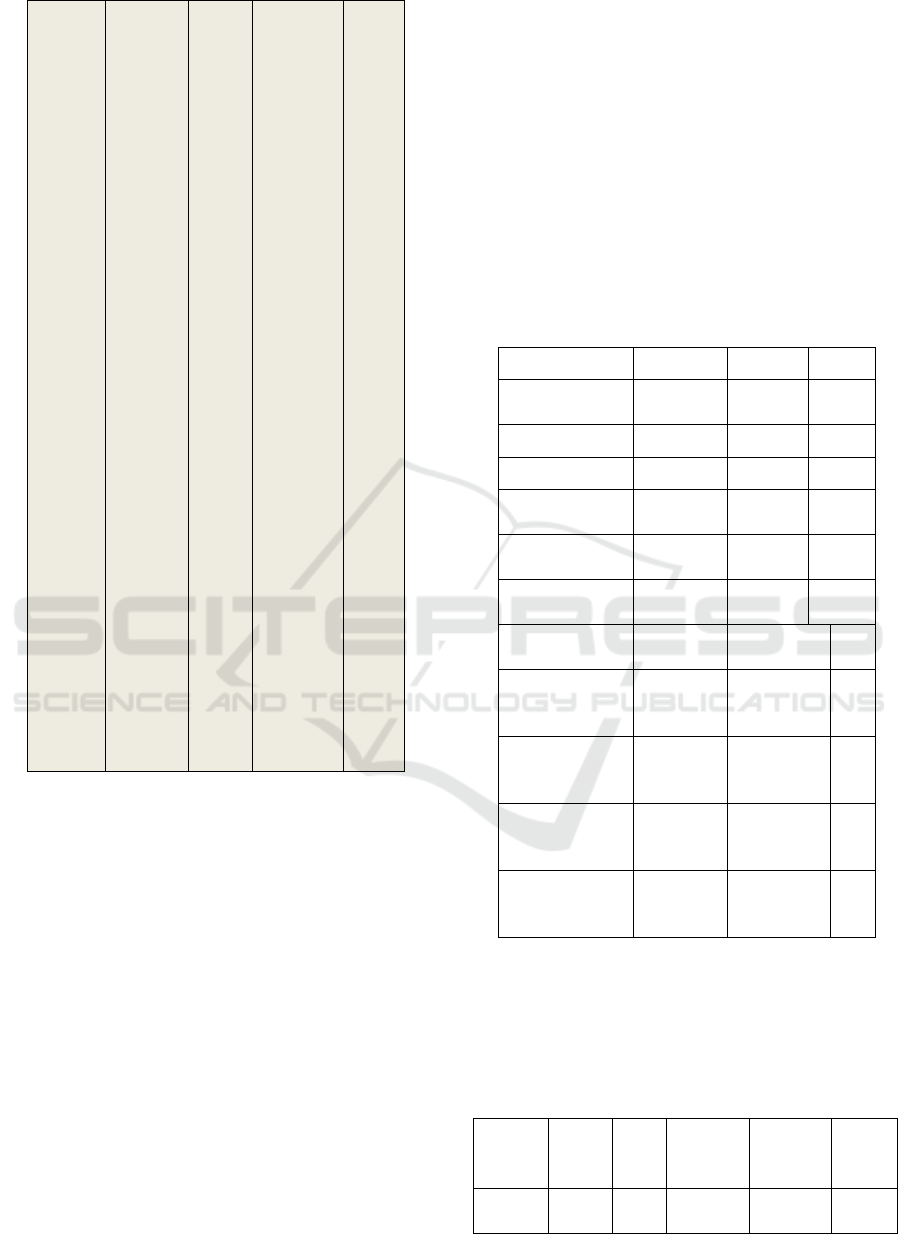

Table 2: Dimensions and tolerance recommended for

paving blocks

.N

o

Dimensio

ns

Recomended

values

Tolerance limit

Thickn

ess

<100

mm

Thickn

ess

>100

mm

1 Width, W

To be specified

by

manufacturer

±2mm ±3mm

2 Length, L

To be specified

by

manufacturer

±2mm ±3mm

3

Thickness,

T

50 to 120 mm ±3mm ±4mm

4

Aspect

ratio (L/T)

Maximum 4.0 +0.2 +0.2

5

Arris/Cha

mfer

Minimum:5m

m

Maximum:7m

m

±1mm ±1mm

6

Thickness

of wearing

layer

Minimum:6m

m

+2mm +2mm

7

Plan Area,

Ast

Maximum:0.0

3mm

2

+0.001

m

2

+0.001

m

2

8

Wearing

face area,

Minimum 75%

of plan area

-1% -1%

9

Squarenes

s

Nil ±2mm ±3mm

Table 3: Value of paving blocks for traffic category

Grade

Design

ation of

Paver

Blocks

Specifie

d

Compre

ssive

Strengt

h of

Paver

Blocks

at 28

Traffi

c

Categ

ory

Recomm

ended

Minimu

m Paver

Block

Thicknes

s in mm

Traff

ic

Exa

mple

s

Appl

icati

on

Days

N/mm

2

M-30 30

Non

Traffi

c

50

Buil

ding

prem

ises,

mon

ume

nt

prem

ises,

lands

cape

s,

publi

c,

gard

en/pa

rks,

dom

estic

drive

rs,

paths

and

patio

s,

emba

nkm

ent

slope

s,

and

stabil

izati

on

area

etc.

M-35 35

Light

Traffi

c

60

Pede

stria

n

plaza

s,

shop

ping

com

plex

ramp

s, car

parks

,

offic

e

drive

ways

,

housi

Analysis Comparison of Cost and Time of Concrete and Paving Block Jobs in the Implementation of Village Road Development using

Village Fund Budget

369

ng

colo

nies,

offic

e

com

plexe

s,

rural

roads

with

low

volu

me

traffi

c,

farm

hous

es,

beac

h

sites,

touri

st

resor

t

local

auth

ority

foot

ways

,

resid

entia

l

3 RESEARCH METHODOLOGY

3.1 Direct Observation

The research used was a field study/ direct

observation.

3.2 Collecting Secondary Data

Collecting secondary data such as wage and basic

material standards and budget of village fund for

concrete road works, in year 2017 and 2018.

3.3 Collecting Primary Data

Collecting primary data such as survey of paving

block prices, survey of basic wage and material

prices, coredrill work, concrete quality testing and

paving blocks, mix design paving block of K-350.

4 RESULT AND DISCUSSION

4.1 Material and Wage Standard Unit

Price

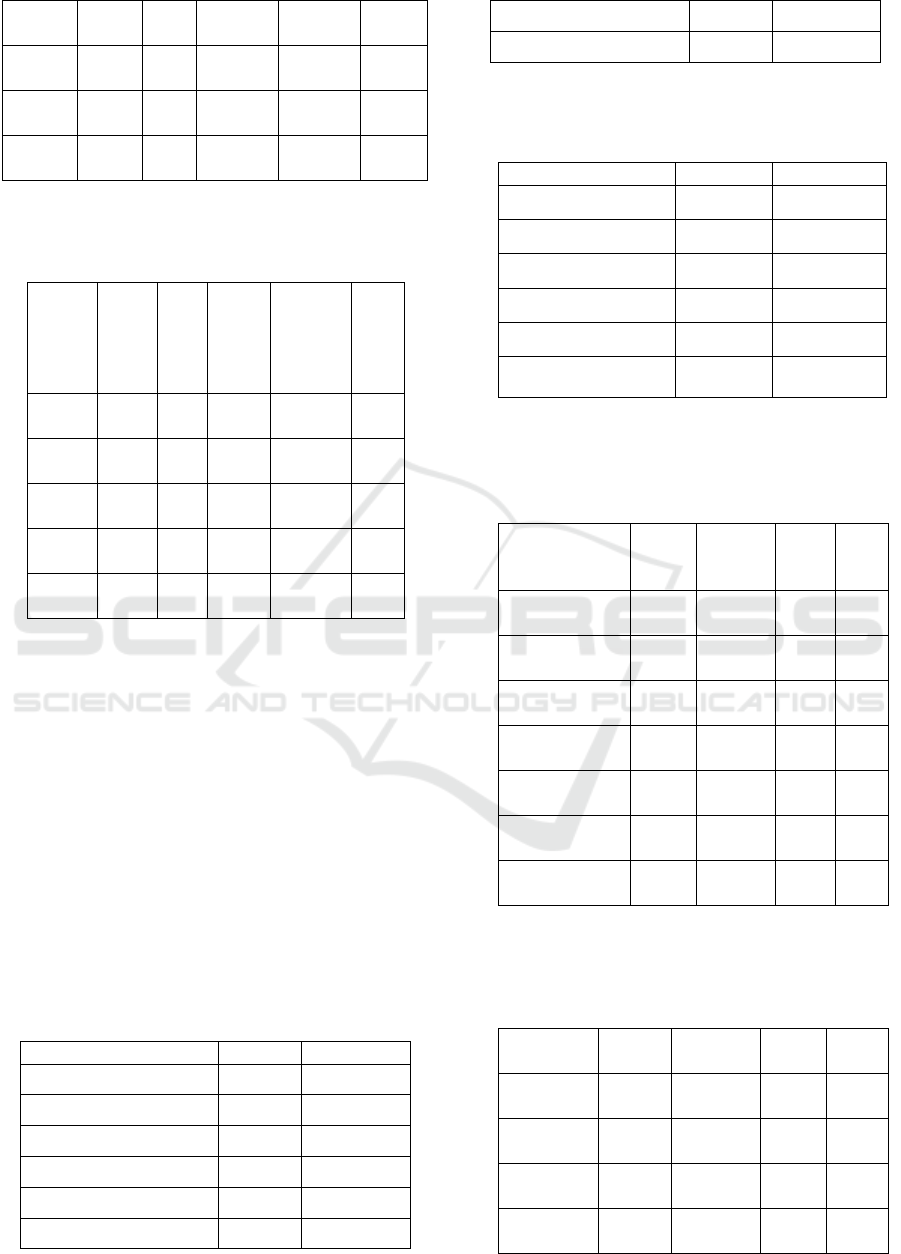

Table 4: Material and wage standard unit price

Description Unit 2018 2017

Portland

cement

kg 1485 1438

Sand m

3

63525 53763

Fine aggregate kg 42 33

Split size 2-

3cm

m

3

490875

39050

0

Gravel (Max

.30mm)

kg 320 255

Split size 0,5-

1cm

m

3

508200

39050

0

Paving Blok

thickness 6 cm

pcs 1600

15

00

Worker man day 90000

86

25

0

Bricklayer

man day 120000

11

50

00

Head man day 130000

12

65

00

Foreman man day 135000

13

22

50

Price of paving block with thickness 6 cm was

IDR.1600 in 2018.

4.2 Budget of Village Fund Concrete

Road Works

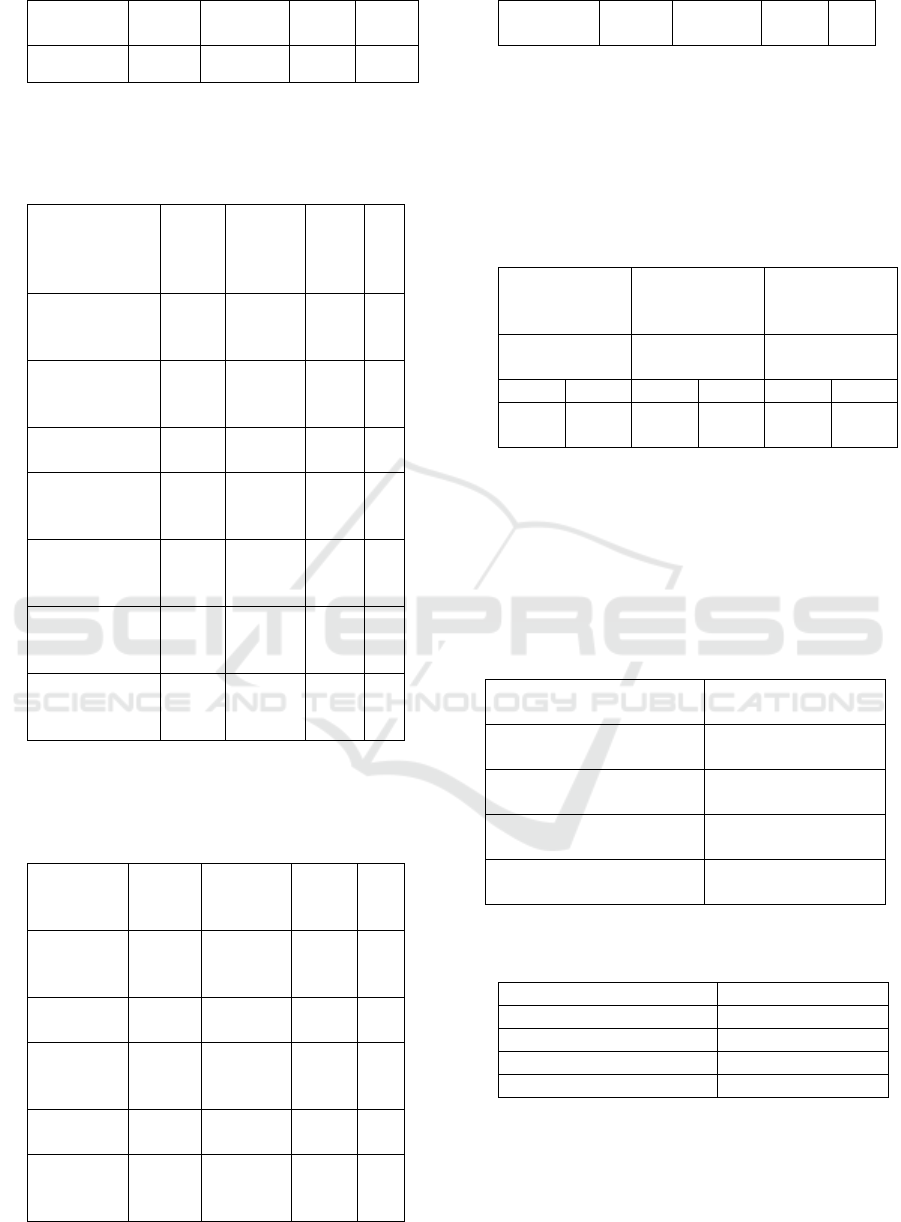

Table 5: In Year 2017

Locati

on

Lengt

h (m)

Wid

e

(m)

Thickne

ss (cm)

Budget

(Rp)

Cost

/m

2

(Rp)

I 160 2.3 15

954920

00

25948

9

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

370

II 105 2.3 15

647230

00

26800

4

III 100 2.0 15

673000

00

33650

0

IV 100 2.0 15

673000

00

33650

0

V 150 1.0 15

540160

00

36010

7

Cost average /m2 for five location was IDR.312120

in 2017.

Table 6: In Year 2018

Locati

on

Leng

th

(m)

Wi

de

(m)

Thic

kness

(cm)

Budget

(Rp)

Cos

t

/m

2

(Rp

)

I 175 2.0 15

974315

00

278

376

II 425 2.0 15

253664

000

298

428

III 50 2.0 15

297830

00

297

830

IV 215 2.0 15

130722

000

304

005

V 100 1.5 15

405130

00

270

087

Cost average /m2 for five location was IDR.289745

in 2018.

4.3 Direct Survey in the Field

Based on direct surveys in the field in 2018, the price

of 1 block paving with a size of 21x10.5x6cm in 3

locations in a row is in IDR.1200; IDR.1400;

IDR1500, and Wage of worker was IDR.90000/day,

Sand was IDR.50000/m

3

, Portland cement was

IDR.52000/zak 40 kg, Split size 0,5-1cm was

IDR.280/kg.

4.4 Unit Price of Work Refers SNI

2013

Table 7: Unit Price of Concrete Work K-350

Description Unit Coefficient

Worker man day 2.100

Bricklayer

man day 0.350

Head man day 0.035

Foreman man day 0.105

Portland cement kg 448.0

Fine aggregate kg 667.0

Gravel (Max .30mm) kg 1000.0

Water liter 215.0

Table 8: Unit Price of Paving Block Work Size of

21x10,5x6cm

Description Unit Coefficient

Bricklayer man day 0.250

Head man day 0.025

Worker man day 0.500

Foreman man day 0.025

Paving block Pcs 45.00

Sand m

3

0.050

4.5 Unit Price in 1 m

2

of Work

Table 9: Unit price of 1 m

2

Concrete K-350 with thickness

15 cm, In 2017

Description Unit

Coeffic

ient

Basi

c

price

Am

oun

t

Worker

man

day

2.1

8625

0

181

125

Bricklayer

man

day

0.35

1150

00

402

50

Head

man

day

0.035

1265

00

442

8

Foreman

man

day

0.105

1322

50

138

86

Portland

cement

kg 448 1438

644

000

Fine aggregate kg 667 33

217

13

Gravel (Max

.30mm)

kg 1000 255

254

620

Table 9 shown that unit price of 1 m

2

Concrete K-350

with 15cm thickness, it was IDR.174003

Table 10: Unit price of 1 m

2

Paving block Size of

21x10,5x6cm, In 2017

Description Unit

Coefficie

nt

Basic

price

Amou

nt

Bricklayer

man

day

0.25

11500

0

28750

Head

man

day

0.025

12650

0

3163

Worker

man

day

0.5 86250 43125

Foreman

man

day

0.025

13225

0

3306

Analysis Comparison of Cost and Time of Concrete and Paving Block Jobs in the Implementation of Village Road Development using

Village Fund Budget

371

Paving

block

pcs 45.0 1500 67500

Sand m

3

0.05 53763 2688

Table 10 shown that unit price of 1 m

2

Paving block

Size of 21x10,5x6cm, it was IDR. 148532

Table 11: Unit price of 1 m

2

Concrete K-350 with thickness

15 cm, In 2018

Description Unit

Coeffic

ient

Basi

c

price

A

m

ou

nt

Worker

man

day

2.1

9000

0

18

90

00

Bricklayer

man

day

0.35

1200

00

42

00

0

Head

man

day

0.035

1300

00

45

50

Foreman

man

day

0.105

1350

00

14

17

5

Portland

cement

Kg 448 1485

66

52

80

Fine aggregate Kg 667 42.0

28

22

2

Gravel (Max

.30mm)

Kg 1000 320

32

00

69

Table 11 shown that unit price of 1 m

2

Concrete K-

350 with 15cm thickness, it was IDR. 189494

Table 12: Unit price of 1 m

2

Paving block Size of

21x10,5x6cm, In 2018

Descriptio

n

Unit

Coefficie

nt

Basic

price

A

mo

unt

Bricklayer

man

day

0.25

1200

00

30

00

0

Head

man

day

0.025

1300

00

32

50

Worker

man

day

0.5

9000

0

45

00

0

Foreman

man

day

0.025

1350

00

33

75

Paving

block

pcs 45.0 1600

72

00

0

Sand m

3

0.05

6352

5

31

76

Table 12 shown that unit price of 1 m

2

Paving block

Size of 21x10,5x6cm, it was IDR.156801

4.6 Comparison of the Unit Price of

1 M

2

Village Fund Budget for

Concrete Roads with Paving Block

Table 13: Comparison of the unit price of 1 m2 Village

Fund Budget for concrete roads with Paving Block

Village Fund

Budget

SNI 2013

Concrete K-

350

SNI 2013

Paving block

Concrete

thickness 15cm

Concrete

thickness 15cm

Size of

.21x10,5x6 cm

2017 2018 2017 2018 2017 2018

31212

0

28974

5

1740

03

1894

94

1485

32

1568

01

Table 13 shown that price of paving block is 2 times

cheaper than concrete material.

4.7 Quality Testing on the Road That

Exists and in Paving Blocks on the

Market

Table 14: Average Strength of coredrill On Existing Road

Location-1 : Length 150 m,

Wide 1 m

105,58 kg/cm

2

Location-2 : Length 100 m,

Wide 2 m

112,01 kg/cm

2

Location-3 : Length 100 m,

Wide 2 m

109,36 kg/cm

2

Location-4 : Length 105 m,

Wide 2,3 m

118,45 kg/cm

2

Location-5 : Length 160 m,

Wide 2,3 m

119,58 kg/cm

2

Table 15: Average Strength of Paving Blocks On The

Market

Location-1 151,0 kg/cm

2

Location-2 156,9 kg/cm

2

Location-3 153,9 kg/cm

2

Location-4 148,0 kg/cm

2

Location-5 152,9 kg/cm

2

Coredrill is carried out on a concrete road in the 2017

budget year. It aims to find out the quality installed.

From the table 14 and tabel 15 shows that the quality

of the concrete road is installed under the quality of

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

372

the paving block on the market. This shows that poor

supervision of concrete road works.

4.8 Recommendations for Composition

of Paving Block Refers to the

Requirements of SNI 03-0691-1996

Paving block is used for roads in accordance with the

requirements of SNI 03-0691-1996 are using K.350,

Water absorption from testing on average 3 units of

paving blocks should not exceed 6%.

Mix design is a way to get the composition as required

by SNI 03-0691-1996.

In the table below we show the results of the paving

block Mix design K-350.

Table 16: Recommendations for composition of paving

block

Qualit

y

Paving Block Composition (kg/m

3

)

Cemen

t

Sand

Coarse

Aggregate

W

at

er

K-350 303.2

873.

2

1046.5

98

.9

Table 17: Strength of Paving Blocks Mix Design K-350

Sample -1 360,20 kg/cm

2

Sample -2 365,12 kg/cm

2

Sample -3 362,17 kg/cm

2

Sample -4 364,14 kg/cm

2

Sample -5 370,04 kg/cm

2

4.9 The Cost of 1 Paving Block Size of

21x10,5x6 cm Refers to the

Requirements of SNI 03-0691-1996

Table 18: Cost of 1 Paving block Size of 21x10,5x6 cm K-

350

Cement 303.2 g

148

5

4501

89

Sand 873.2 g 42.0

3694

6

Coarse Aggregate 1046.5 g 320

3349

39

Water 98.9

--

Cost of 1 m

3

8220

74

Volume of 1 Paving block Size of.21x10,5x6

cm

0.001

32

Number of paving blocks in 1 m

3

756

Cost of material in 1 paving block Size

of.21x10,5x6 cm

1088

1 Worker in a day can produce paving block 500

Cost of worker in 1 day

9000

0

Cost of worker can produce 1 paving block 180

The Cost of 1 Paving block Size of 21x10,5x6

K-350

1268

The table above shows that self-produced paving

blocks are cheaper than the price of paving blocks in

the market.

5 CONCLUSION

1. Paving block is 2 times cheaper than concrete

material.

2. Concrete material is 4 times faster than paving

blocks.

3. The concrete road is suitable to be applied to road

conditions with hilly geographical contour, with

road slope above 10%.

4. Roads with paving blocks are suitable to be

applied to road conditions with flat geographical

contours, with slopes below 10%.

ACKNOWLEDGMENTS

The research is funded by the with university funding

sources (USU Non-PNBP - TALENTA) in 2018.

REFERENCES

Anonim. 2003, “Perencanaan Perkerasan Jalan Beton

Semen”, Pd. T-14-2003, Departemen Pemukiman dan

Prasarana Wilaya, Jakarta.

Anonim, 1996, “Bata Beton (Paving Block)”, SNI 03-0691-

1996, Badan Standarisasi Nasional, Jakarta

Anonim, 1995, “Petunjuk Perencanaan Teknis Jalan Desa”,

No. 007/T/Bt/1995, Direktori Jendral Bina Marga,

Jakarta.

Erwin, R. 2009. “Teknologi Pembuatan Paving Block

Dengan Material FCA (Fine Coarse Aggregate)”,

GAMMA, Volume IV. Malang.

Hulu, Y., Hamdani, H.R. dan Arif, N.M. 2018,

“Pengelolaan Dana Desa dalam Pemberdayaan

Masyarakat Desa”, Jurnal, Pendidikan Ilmu-Ilmu Sosial

USU.

Irawan, A. 2016, “Perencanaan Infrastruktur Jalan

Perdesaan Potensial Kabupaten Lebak Provinsi

Banten” Universitas 17 Agustus 1945, Jakarta.

Analysis Comparison of Cost and Time of Concrete and Paving Block Jobs in the Implementation of Village Road Development using

Village Fund Budget

373

James, E. Dan Prakash, B. 2014, “Permeable Concrete

Block Paving Applications In The United Arab

Emirates”, International Journal Of Engineering Trends

And Technology (IJETT) –Volume 16 Number 5,

ISSN:2231-5381, Dubai.

Mantasa, _______, ”Evaluasi Tebal Perkerasan Beton

Semen Dan Rencana Anggaran Biaya Pada Ruas Jalan

KM. 38 Samboja Ke Sepaku”.

Puwarno, Dan Yulita, A.P. 2008, “Testing Of Concrete

Paving Blocks The BS EN 1338:2003 British And

European Standard Code”, Teknik – Vol. 29 No. 2,

ISSN 0852-1697. Semarang.

Rozi, K., Hamzah, H.M. dan Saifoe, E.U. _______.

”Analisa Perbandingan Metode SNI dan Software MS.

Projek Dalam Perhitungan Harga Satuan Pekerjaan

Penutup Lantai Dan Dinding Serta Pemasagan Paving

Block Untuk Konstruksi Bangunan”, Jurnal,

Universitas Brimajaya, Malang.

Sharma, P. Dan Kumar, B.R. 2016, “Cement Concrete

Paver Block For Rural Roads”, TROI, Volume-3,

Issue-2, ISSN: 2393-8374. India.

Sudarsana, D.K. 2008, “Pengendalian Biaya Dan Jadual

Terpadu Pada Proyek Konstruksi”, Jurnal Teknik Sipil

Vol. 12, No 2, Universitas Udayana, Denpasar.

Wangsadinata, W., Indra, T.A.R., dan Najid. 2014,

“Pemilihan Jenis Perkerasan Jalan Kabupaten

Berdasarkan Kondisi Ekonomi Daerah”, The 17

th

FSTPT Internation Symposium, Jember University.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

374