Model of Formation Graphene from Graphite with Ammonia

H. Sitohang

1

, N. Pasaribu

1

, R. Siburian

1*

C. Simanjuntak

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan

Keywords: Graphene, Graphite, FTIR, Hummer’s Method.

Abstract: The reaction mechanism of commercial graphite using ammonia reducing agents has been carried out based

on Hummer's modification method. The purpose of this study was to determine the reaction model of graphene

formation and characterization using an infrared spectrophotometer (FTIR). The results showed that the

characterization using infrared spectrophotometer (FTIR) analysis on graphene oxide showed a ring

consisting of three one oxygen atom or called an epoxy group (C-O-C) at a number wave

1396 cm

-1

which

reacted with ammonia thus replaced by the availability of CN groups in wave numbers

1033 cm

-1

on

graphene. This happens due to the deoxygenation process. These data proved that graphene can be synthesized

from graphite using ammonia reducing agents.

1 INTRODUCTION

Graphene is believed to be a promising material in the

future (1). Graphene is a two-dimensional carbon

from the structure of graphite. Graphene has various

extraordinary properties, such as mechanical

resistance, strength and elasticity, thermal and

electrical conductivity and high surface area (2,3).

That is, graphene can replace other materials and

applications. By laboratory, graphene can be

produced from a simple, high-quality and inexpensive

method. Graphene characterization produced

approaches the theoretical parameters namely

electron mobility (2.5 × 105 cm2 V-1s-1) (4),

Young's modulus 1 TPa and 130 GPa intrinsic

strength (5,6), high thermal conductivity (> 3000 W

mK-1) (7), optical absorption πα = 2.3% (α =

structural stability) (8), can react with various gases

(9), ability high density of electric current (1000 times

that of Cu) (10) and has a functional chemistry (11).

Graphene is also called a magical material (11) and

can be deposited on special substrates such as

hexagonal boron nitride (4, 13). Thus, graphena will

be of particular concern to be applied to the industry.

Thus, the production of graphene on a large scale

becomes the target of scientists.

2 MATERIALS AND METHODS

2.1 Materials

The materials used are: Graphite; strong acids,

oxidizing agents and ammonia reducing agents.

2.2 Synthesis of Graphene Oxide

A total of 0.2 g of graphite powder were fed into a

250 mL erlenmeyer, then 0.2 g of NaNO3 and 15 mL

of 96% H2SO4 were added. The solution is stirred for

2 hours. Furthermore, the Erlenmeyer containing the

mixture was placed in an ice container and added

gradually 1 gram of KMnO4 then stirred for 24 hours.

After stirring for 24 hours, 20 mL 5% H2SO4 and 1

mL H2O2 30% were added to the solution and stirred

for 1 hour. The solution is confused with a speed

centrifuge of 6500 RPM for 20 minutes to separate

the filtrate and supernatant. Then into the solution

added 25 ml distilled water and messed up using a

centrifuge with a speed of 6500 RPM (Rotor

PerMinute) for 20 minutes. The solution was

transferred to a beaker glass and added with 100 mL

distilled water and then ultrasonicated for 5 hours,

then allowed to cool and produced graphene oxide.

1036

Sihotang, H., Pasaribu, N., Siburian, R. and Simanjuntak, C.

Model of Formation Graphene from Graphite with Ammonia Reduktor.

DOI: 10.5220/0010096210361038

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

1036-1038

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2.3 Synthesis of Graphene

The second graphene oxide solution was added with

10 ml of ammonia then stirred for 72 hours. The

solution was filtered and dried at 80ºC for 24 hours

and characterized by using XRD, FTIR, and SEM-

EDX.

3 RESULTS

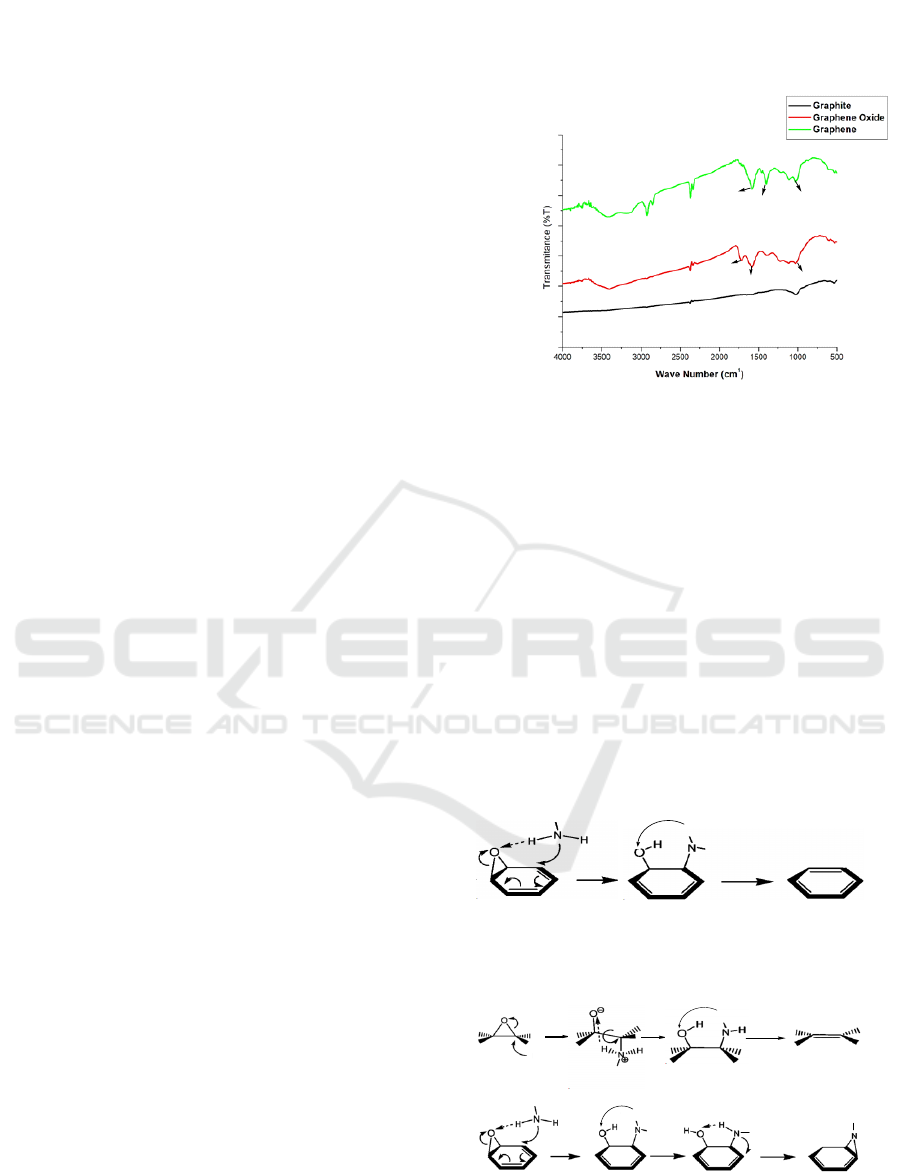

Characterization using FTIR was carried out to

determine changes in functional groups before and

after the oxidation process in graphite, the synthesis

of graphite oxide, graphene oxide and graphene and

to determine the interaction between graphene and

ammonia reducing agents. FT-IR analysis using

Shimadzu IR Prestige-21 tool was carried out in the

wave number range of 500-4500 cm

-1

. All samples

were analyzed in the form of smooth curls. In Figure

1 shows that the peak wavelength FT-IR has occurred

in graphite, graphene oxide and graphene.

In the Graphite FT-IR spectrum, the wave number

1581cm

-1

shows the bond between the aromatic group

C = C, and the presence of a support group in another

wave number that appears at peak 1026 cm

-1

which is

the bond between C-C. Based on the data in Figure1

it can be seen that graphite only has the structure C =

C (π bond) and C-C.

In the FT-IR spectrum of Graphene Oxide has

formed bonds between oxygen and hydrogen (OH)

groups occurring at wave numbers 3402 cm1, a weak

absorption spectrum occurring at wave numbers

1705.07 cm-1 indicates the bond between C = O of

the carboxylic acid group ( COOH), the spectrum of

the wave number is formed by the aromatic group C

= C in the wave number 1581 cm

-1

and there is also a

weak spectrum at wave number 1396 cm

-1

indicating

the bond between C-OH or CO (epoxy) bond at 900-

1300 cm

-1

.

In the Graphene FT-IT spectrum shows the

appearance of absorption peaks in the wave number

1033 cm

-1

which indicates the bond between C-N.

The wavelength range~ 900 cm

-1

is the range of wave

numbers for epoxy groups (C-O) (Li, et al, 2008).

Based on these data it can be seen that there has been

a de-epoxidation process. However, the stretch

vibration of O-H at 3410 cm

-1

and the stretching

vibration of C-O at 1404 cm

-1

are still observed due to

the presence of hydroxyl groups and carboxylic

groups even after being reduced by ammonia.

Synthesis of graphene oxide from graphite has

occurred the process of peeling graphite oxide into

graphene oxide by ultrasonication of graphite oxide.

The mechanism of the oxidation reaction can be

stated in equations 1.1 (a) and 1.1 (b).

C=C

(1581 cm

1

)

C-C

(1026 cm

1

)

O-H

(3402 cm

1

)

C=O

(1705 cm

1

)

C=C

(1581 cm

1

)

C-O epoksi

(1118 cm

1

)

O-H

(3410 cm

1

)

C=C

(1581 cm

1

)

C-N

(1404 cm

1

)

C-O

(1033 cm

1

)

Figure 1: FTIR data of Graphite, Graphene Oxide and

Graphene.

This transformation process can only occur under

strong acid conditions, so the presence of sulfuric acid

as well as solvent from graphite also plays a role in

further oxidation processes.

𝐾𝑀𝑛𝑂

4

+ 3H

2

SO

4

→

𝐾

+

+

𝑀𝑛𝑂

3

+

+ 3HSO

4

+

1.1(a)

𝑀𝑛𝑂

3

+

+ Mn

𝑂

4

-

→ M

2

O

7

1.1(b)

(Rizkietal, 2014).

Mechanism of reaction between epoxy and ammonia:

Phase 1:

H

H

H

-H

2

O

-NH

Phase 2:

NH

3

H

H

-H

2

O

-NH

Mn

H

H

H

H

H

-H

2

O

-NH

Model of Formation Graphene from Graphite with Ammonia Reduktor

1037

Phase 3 :

HH

H

-H

2

O

-NH

4 CONCLUSION

Synthesis of graphene oxide with the addition of

ammonia pereductor to produce graphene from

commercial graphite has been successfully carried

out with the modified Hummer's method. The success

of this synthesis is evidenced by the presence of FTIR

data.

Graphene formation reaction model of graphite

and graphene oxide reduction has been obtained

according to FTIR data.

ACKNOWLEDGEMENT

We would like to thankful for “TALENTA”,

Universitas Sumatera Utara, No. 2590/UN5.1

R/PPM/2017, 16 March 2018 who funding supported

on our research.

REFERENCES

Novoselov, K.S., Fal’ko, V.I., Colombo, L., Gellert, P.R.,

Schwab, M.G. and Kim, K. 2012. A road map for

graphene. Nature. 490: 192– 200.

Geim, A. K., and Novoselov, K. S. 2007. The rise of

graphene. Nature Mater. 6: 183–191.

Geim, A. K. 2009. Graphene: status and prospects. Science.

324: 1530–1534.

Mayorov, A.S.et al. 2011.Micrometer-scale ball is tic

transport in encapsulated graphene at room temperature.

Nano Lett. 11: 2396–2399.

Lee, C., Wei, X.D., Kysar, J.W.and Hone, J.2008.

Measurement of the elastic properties and intrinsic

strength of monolayer graphene. Science. 321: 385–

388.

Liu, F., Ming, P. M. and Li, J. 2007. Ab initio calculation

of ideal strength and phonon in stability of grapheme

under tension. Phys. Rev. B. 76: 064120.

Balandin, A.A. 2011. Thermal properties of grapheme and

nanostructured carbon materials. Nature Mater. 10:

569–581.

Nair, R.R.et al. 2010. Fluoro graphene: a two-dimensional

counter part of Teflon. Small. 6:2877–2884.

Bunch, J.S.et al. 2008. Impermeable atomic membranes

from grapheme sheets. Nano Lett. 8:2458–2462.

Moser, J., Barreiro, A. and Bachtold, A. 2007. Current-

induced cleaning of graphene. Appl. Phys. Lett. 91:

163513.

Elias, D.C.et al. 2009. Control of graphene’s properties by

reversible hydrogenation: evidence for graphene.

Science.323: 610–613.

Novoselov, K.S. et al. 2004. Electric field effect in

atomically thin carbon films. Science.306:666–669.

Dean, C.R. et al. 2010. Boron nitride substrates for high-

quality grapheme electronics. Nature Nanotechnology.

5, 722–726.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

1038