Effect of Initial Characteristic on Promoting the Pozzolanic Reaction

in Soil Solidification Work

Ernesto Silitonga

1

, Rachmat Mulyana

1

, Hamidun Batubara

1

, Enny Sinaga

1

, Jintar Tampubolon

1

1

Department of Civil Engineering, Universitas Negeri Medan, jl.. Willem Iskandar Pasar V, Medan, Indonesia

Keywords: Initial characteristic, Pozzolanic Reaction, Particle size distribution, Mineralogical characteristic, Unconfined

compressive strength.

Abstract: The effect of binders on concrete admixture has been investigated for several years. Pozzolanic reaction has

been known for its ability to enhance the concrete performance. Pozzolanic reaction needs various parameters

to provide an additional concrete performance. The physical, and mineralogical characteristic on the

pozzolanic reaction has its different impact on enhancing concrete performance. The main goal of this study

is to determine which characteristics that influence the most to the concrete strength performance. Two

different type of fly ash are used as pozzolanic binder each fly ash has its initial properties Particle size

distribution of fly ash is realized in goal to identify the physical characteristic, Mineralogical characteristic

is determined with XRD test. The effect of the addition of the pozzolanic binders is identified with UCS test.

The test result identified that the particle size distribution is the most influenced properties. The binder with

higher available CaO content produces greater concrete strength. The binder with higher percentage of SiO

2

,

Fe

2

O

3

and Al

2

O

3

provides higher UCS value than binder with CaO content.

1 INTRODUCTION

The used of pozzolanic binders such as fly ash, silica

fume in concrete work has been popular for decade.

Due to its initial characteristics the pozzolanic binders

is known for its capability to increase the concrete

performance. Several studies have been done

concerning this pozzolanic binders. Work realized by

Fernandez (Fernández-Jiménez, Palomo and Criado,

2005) studied the effect of microstructure of alkali

activated of fly ash. The study shows that due to its

microstructure, alkali activated of fly ash can increase

the strength of the sample. Becquart.(Bernal, 2011) in

his research working on slag (can be considered as a

fly ash). bottom ash as a binder to enhance the

performance of the admixtures. The mineralogical

properties of the bottom ash are helping to provide the

needs of pozzolanic reaction to reacts and produces

additional strength to the sample. In this study the

slag is subjected to alkali activation process.

Beside in concrete work, fly ash is used in soil

stabilization work. Silitonga (Silitonga, Levacher and

Mezazigh, 2010) added fly ash to stabilized dredged

sediment from port of Cherbourg. The heavy metal

content of this dredged sediment is very high, and

block the cement hydration to provides the strength.

The present of the fly ash in the admixtures shows an

increase of unconfined compressive strength on

stabilized soil. Due to its micro filler capability, the

fly ash contributes additional strength. A study

conducted by Weber (Weber, 2015) investigated the

characteristic of soil derived from fly ash after the

revegetation process. This study determine the effect

of revegetation process on stabilized soil with fly ash.

Another previous work using fly ash as a soil

stabilization binder is done by Goswani (Goswami

and Mahanta, 2007) tried to identify the properties of

the soil stabilized by fly ash. The leaching test is

realized to determine the influence of the fly ash on

soil stabilization process. Previous study on

mechanical and microstructure characteristic of alkali

activated fly ash is done by Komljenovic. This study

shows the effect of characteristic of each fly ash on

strength development gained. (Komljenović,

Baščarević and Bradić, 2010)

Other pozzolanic binder such as silica fume is

also known for its capability to produces additional

strength. Study done by (Pfeifer, 2010) working on

effect of silica fume oh high performance concrete.

The experiment result shows that the addition of silica

fume produces a significant strength increase on

unconfined compressive strength. Silitonga (E.

258

Silitonga, E., Mulyana, R., Batubara, H., Sinaga, E. and Tampubolon, J.

Effect of Initial Characteristic on Promoting the Pozzolanic Reaction in Soil Solidification Work.

DOI: 10.5220/0010082402580262

In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches (ICOSTEERR 2018) - Research in Industry 4.0, pages

258-262

ISBN: 978-989-758-449-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Silitonga, 2017) (Ernesto Silitonga, 2017) tried to

stabilize a heavy metal contaminated sediment. Silica

fume is used to encounter the high percentage of

pollution in dredged sediment. The studies

demonstrate that the addition of Silica fume can

increase the strength of the stabilized soil than others

samples.

2 MATERIALS AND METHOD

Pozzolanic binder used in this study is fly ash. Two

type fly ash is added in to the admixture. To

determine the influence of the initial characteristics,

two types of fly ash (FA1 and FA2) are utilized in this

experiment. Each fly ash has its own physical and

mineralogical characteristic. The Soil is `taken from

Harbor of Cherbourg Basse Normandie Franc. The

soil sampling is realized from 4 locations (HoC_1,

HoC_2, H0C_3, and HoC_4.

2.1 Initial Characteristic of Materials

Initial Characteristics of binders are devised in two

types. Physical type and mineralogical type. Physical

characteristic is represented by particle size

distribution size determined with Laser

Granulometric Diffractometer. The Mineralogical

characteristic is determining with XRD test.

2.1.1 Particle Size Distribution

Particle size distribution is one of the most important

strong point of the pozzolanic binders. Due to its fine

particle size distribution, fly ash can penetrate and fill

the empty space in the microstructure and increase the

strength of the sample.

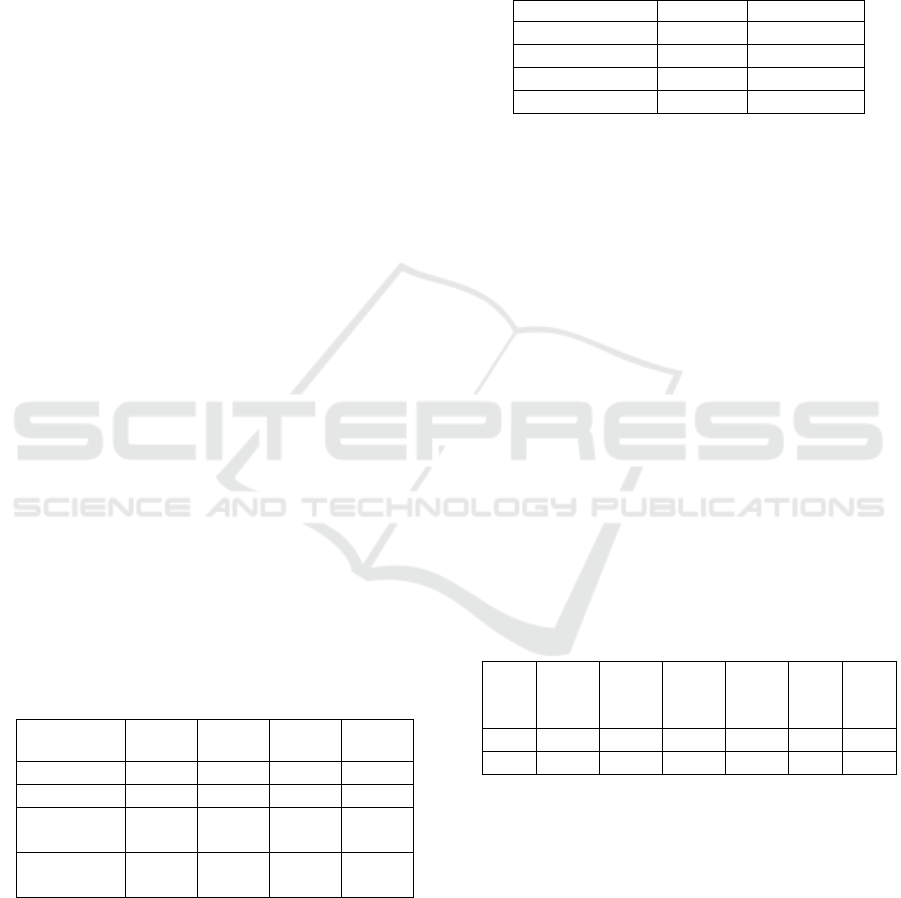

Table 1: Particle size distribution of the untreated soill

Parameters

HoC_

1

HoC_

2

HoC_

3

HoC_

4

D50(µm)

8.4

10.2

7,6

9,6

<2 µm (%)

1.7

2.9

3.3

1.9

2 à 63 µm

(%)

76.4

72.9

77.8

79.8

> 63 µm

(%)

21.9

24.2

18.9

18,4

The particle size distribution is realized with the

help of Laser Granulometric Diffractometer, this

machine is used because of the fine particle size of

soil and the fly ash. With this machine the particle

size less than 2 µm can be identified. The result of

Laser Granulometric can be seen in table 1. The result

shows that the particle size distribution of the material

(soil) taken from 5 different locations is in the same

class. The majority percentage of the particle is

classified between 2 à 63 µm. This result proves the

homogeneous of the soils. The homogenous of the

soil will help the analysis of the result.

Table 2: Particle size distribution of the fly ash

Parameters

FA1

FA2

D50(µm)

12

17,5

<2 µm (%)

16.4

7.40

2 à 63 µm (%)

80

89

> 63 µm (%)

3.8

3.8

The particle size of fly ash is described in Table

2, this result shows that the particle size of the fly ash

is larger than common fly ash that used in the concrete

work. This is because the fly ash utilized in this study

is a raw fly ash from coal mining. These fly ashes are

not commercialized yet. The goal of using this raw fly

ashes is to identify its potential use. Normally, the

majority percentage of the particle size of the fly ash

is <2 µm. The Majority of the particle size of fly ashes

used in this study is around 2 à 63 µm. From this

result it can be assumed that

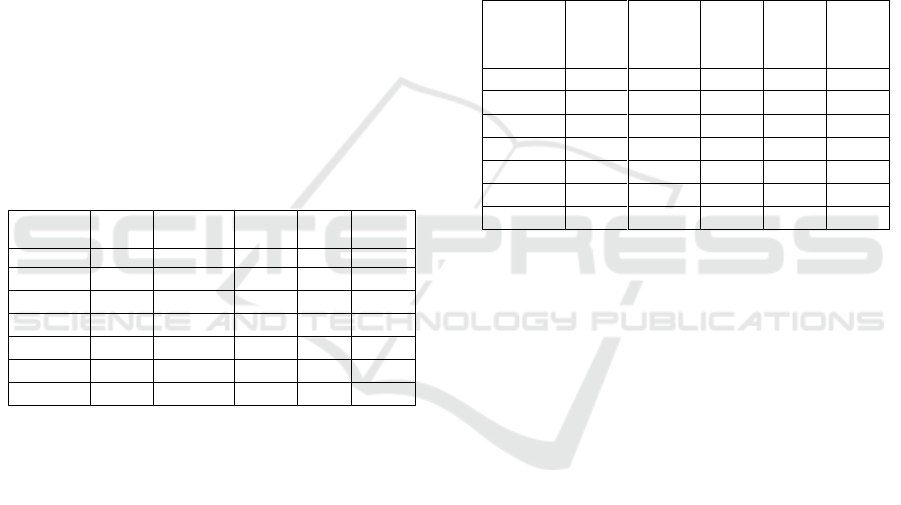

2.1.2 Mineralogical Characteristic

Determine the quantity of the mineral on the binder is

the main goal of this test. The quantity of the binder

plays an important role on strength development. The

Mineralogical characteristic is identified using XRD.

The mineralogical characteristic of fly ashes is

described in table 3

Table 3: Mineralogical characteristic of fly ash

Na

me

SiO

2

(%)

Fe

2

O

3

(%)

Al

2

O

3

(%)

CaO

Total

(%)

CaO

free

(%)

SO

3

(%)

FA1

45

9

20

9

1

5

FA2

21

2

12

36

14

16

From table 3 we can that fly ash named FS_1 has

more SiO

2,

Fe

2

O

3

and Al

2

O

3

than FS_2. On the other

hand, FA_2 consist more CaO total then FA_1. The

result of study done by Silitonga, (Silitonga, 2018)

stated that SiO

2,

Fe

2

O

3

and Al

2

O

3

content plays an

important role on improving the engineering

performance of stabilized soil. Comparing the

mineralogical characteristic test and previous study, t

we can assumed that FA_1 will produces higher

strength than FA_2. On the other hand, FA_2 possess

higher CaO than FA_1. Silitonga in his study used fly

ash (Silitonga, Levacher and Mezazigh, 2009) on

Effect of Initial Characteristic on Promoting the Pozzolanic Reaction in Soil Solidification Work

259

enhancing the soil contaminated b heavy metal. The

result of this study stated that the fly ash with CaO

content produces higher unconfined compressive

strength than fly ash with lower CaO content. On this

point of view, we assumed that the fly ash FA_2 will

provides higher strength than FA_1. This theory will

be confirmed by the result of this study.

2.1.3 Formulation

The soil utilized has very high-water content (70-

80%), before the treatment begins, the soil subjected

to the dewatering process. The dewatering process is

realized with the help of the sun (in open area). After

the water content reach the point needed, the soil

crushed int to the small pieces and mixed with binders

with various composition. The formulations of the

binder are presented in Table 4. Several compositions

were designed to identify the effect of binders with its

special characteristics. The sample without any

binder content (PS) is realized as a guide to determine

binder effect. Various percentage of fly ash is realized

to verify the effect of the amount of binder.

Table 4: Particle size distribution of the untreated soil

Name

Sand

(%)

Cement

(%)

Lime

(%)

FA1

(%)

FA2

(%)

PS

15

5

5510FA1

15

5

5

5

-

5515FA1

15

5

5

15

-

5520FA1

15

5

5

20

-

5510FA2

15

5

5

10

5515FA2

15

5

5

-

15

CMT

15

8

5

-

-

3. RESULT AND ANALYSIS

3.1 Unconfined Compressive Strength

The unconfined compressive strength is realized to

determine the engineering performance. This test is

realized at five different time of curing ages (7, 14,

28, 60 and 90 days). The sample is subjected with

simple compression machine. The result of

unconfined compressive strength is given in table 5.

As shown in table 5, the sample without any binders

(PS), the unconfined compressive strength value is

not available, this result because of the sample is to

weak to be subjected to compressive strength test.

The strength development pattern of sample

without any binder (PS) is not very significant,

especially after 28 days of curing age. This result

shows that increase of the strength after the

solidification process is very low. The strength value

at 90 days (0.79 MPa) is not fulfil the requirement as

a material in road pavement work. At teen curing age

(728 days) Sample with only cement content (CMT)

that provides highest compressive strength compared

to other samples. This result obtained because of the

quick hydration of cement, as soon as the water

introduce in to the cement, directly the hydration

cement starts and produces According to study done

by Silitonga in his previous study (Silitonga.,

2018)the hydration of cement continuously provides

significant development of compressive strength until

60 days, at 90 days the development strength becomes

insignificant.

Table 5: Unconfined Compressive strength test

Name

7 days

Mpa

14

days

Mpa

28

days

Mpa

60

days

Mpa

90

days

Mpa

PS

-

0.6

0.75

0.7

089

5510FA1

08

0.9

1.16

1.4

1.8

5515FA1

0.3

0.9

1.15

1.6

2.1

5520FA1

0.7

08

1.2

1.4

2

5510FA2

-

0.6

0.75

0.7

0.8

5515FA2

0.7

0.81

1

1.6

1.88

CMT

0.8

0.97

1.24

1.3

1.35

On the other hand, the sample mixed with pozzolanic

binder (fly ash) starts to show a significant increase

of compressive strength. According to Mertens,

(Mertens, 2009) the pozzolanic reaction reaches its

maximum reaction is after 60 days of curing age. This

confirm the result, where the compressive strength

value of all the sample with fly ash start exceed the

strength value of sample consists only with cement

(CMT). This result because of the excess of fly ash

content in the soil. Due to its fine particle size

distribution, a role of fly ash as a filler is very

important on enhancing the engineering performance.

This effect as filler has very significant impact on

strength gained especially at teen curing age (7-28

days). As cement hydration starts to reacts and harden

the sample, the fly ash penetrates in to the

microstructure and fulfil the empty space. Due to

these two processes at teen age of curing time, explain

why sample with only cement content (CMT) shows

the highest compressive strength. From the quantity

of the binder point of view, we can observe that at

teen curing age, the sample with the highest (20%)

content of fly ash shows the lowest compressive

strength value. As mentioned before that the role of

fly ash as a filler is the most important effect at 7-14

days of curing age. Sample with 20% fly ash, has a

problem to mix because of the excess of the quantity

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

260

of fly ash. Besides that, because of the present of high

quantity of material with fine sediment (fly ash) the

specific surface of the sample increase.

From the point of view of different type of fly

ash (with each different initial characteristic), we can

observe that, at teen age curing time (7-28 days)

sample with fly ash FA_1 shows higher compressive

strength value than sample with FA_2. As mentioned

in previous paragraph that at 7-28 days of curing age,

the most important role of binder is as a filler. This

filler effect is very influenced by the particle size of

the binder (fly ash). Compared the result of particle

size distribution and Unconfined compressive

strength test (presented in table 2 and 5), we can

conclude that, the sample possess the particle size

with greater quantity of particle with size of <2 µm

(FA_1) produces higher compressive strength.

Silitonga in his research working on fly ash with

different particle size (Silitonga, Matondang, 2018).

This result of this study done by Silitonga, shared the

same patterns with the result above. Pozzolanic

binder with higher percentage of particle size <2 µm

produces higher strength (especially compressive

strength).

The unconfined compressive strength result at

60-90 days curing age presents different pattern than

the previous curing age. (7-28 days). At 60 days, the

pozzolanic reaction assumed already reach its

maximum reaction. At this age, the sample with fly

ash content produces higher compressive strength

value than sample consist only with cement (CMT).

The pozzolanic reaction need more time to reach its

maximum reaction, on the opposite the cement

hydration already finish reacts, because there is no

more calcium and the silicate available in the cement.

On the other hand, due to its pozzolanic reaction, the

produced of C-S-H and C-A-H, that enhance the bond

between the particle and automatically provide

additional strength of the admixture. As long as the

pH of the environment reach 9 or more, the

pozzolanic reaction can always proceed. The pH

value 9 release the calcium and the silicate that

available in the soil, and with the help of CaO then

form C-S-H and C-A-H, which plays an important

role on increasing the strength by strengthen the

microstructure of the sample.

Unlike at teenage curing time (7-28 days), the

mineralogical characteristics of the fly ash plays

important role at this age of curing (60-90). At

previous chapter (table 3) we can observe that the

named FS_1 has more SiO

2,

Fe

2

O

3

and Al

2

O

3

than

FS_2. On the other hand, FA_2 consist more CaO

total then FA_1. The unconfined compressive

strength result proves that the sample with FA_2

possess higher strength value than FA_2. This result

confirms that the present of SiO

2,

Fe

2

O

3

and Al

2

O

3

promotes the pozzolanic reaction better than the CaO

content. The present of the SiO

2,

Fe

2

O

3

and Al

2

O

3

on

fly ash, provides substance to initiate the pozzolanic

reaction. Beside the amount of SiO

2,

Fe

2

O

3

and Al

2

O

3

that available in the soil, the present of SiO

2,

Fe

2

O

3

and Al

2

O

3

on the fly ash helps to provides for

pozzolanic reaction. The CaO content also provides

CaO for initiate the pozzolanic reaction. Based on this

result we can confirm that the content of the SiO

2,

Fe

2

O

3

and Al

2

O

3

on the binders has greater influence

than the present of CaO.

4 CONCLUSIONS

The main goal of this study is to determine which

initial characteristics that affect the pozzolanic

reaction on enhancing the engineering properties of

the sample. The physical characteristic is represented

by particle size distribution and the mineralogical

characteristic is identified by XRD test. The physical

properties show that, due to its finer particle size, the

fly ash (FA_1) has a higher possibility to increase the

strength than FA_2. According to the mineralogical

test, FA_1 has more SiO

2,

Fe

2

O

3

and Al

2

O

3

than

FA_2, on the opposite the FA_2 has more CaO

content than FA_1. Each result has a possibility to

increase the engineering performance. In order to

confirm this theory, unconfined compressive strength

is realized. The Analysis of this compressive strength

devised in two period of time, teen age of curing time

)7-28 days and long-term condition (60-90 days). The

result demonstrates that, binder with finer particle

size distribution has higher engineering performance

(compressive strength) than other. The result of long-

term period of time demonstrate that, the present of

SiO

2,

Fe

2

O

3

and Al

2

O

3

on the mixture plays more

important role to enhance the strength than the

content of CaO. We can conclude also that with

addition of fly ash, the soil utilized can be used and

fulfil the criteria to be reused in as material in road

construction.

REFERENCES

Bernal, S. A. et al. (2011) “Effect of binder content on the

performance of alkali-activated slag concretes,”

Cement and Concrete Research. doi:

10.1016/j.cemconres.2010.08.017.

Fernández-Jiménez, A., Palomo, A. and Criado, M. (2005)

Effect of Initial Characteristic on Promoting the Pozzolanic Reaction in Soil Solidification Work

261

“Microstructure development of alkali-activated fly ash

cement: A descriptive model,” Cement and Concrete

Research. doi: 10.1016/j.cemconres.2004.08.021.

Goswami, R. K. and Mahanta, C. (2007) “Leaching

characteristics of residual lateritic soils stabilised with

fly ash and lime for geotechnical applications,” Waste

Management, 27(4), pp. 466–481. doi:

10.1016/j.wasman.2006.07.006.

Komljenović, M., Baščarević, Z. and Bradić, V. (2010)

“Mechanical and microstructural properties of alkali-

activated fly ash geopolymers,” Journal of Hazardous

Materials. doi: 10.1016/j.jhazmat.2010.04.064.

Mertens, G. et al. (2009) “Pozzolanic reactions of common

natural zeolites with lime and parameters affecting their

reactivity,” Cement and Concrete Research. Elsevier

Ltd, 39(3), pp. 233–240. doi:

10.1016/j.cemconres.2008.11.008.

Pfeifer, C. et al. (2010) “Investigations of the pozzolanic

reaction of silica fume in ultra high performance

concrete (UHPC),” International RILEM Conference

on Material Science, III, pp. 287–298.

Silitonga, E. (2017) “Experimental Research of

Stabilization of Polluted Marine Dredged Sediments by

Using Silica Fume,” in MATEC Web of Conferences.

doi: 10.1051/matecconf/201713801017.

Silitonga, E. (2017) “Stabilization / solidification of

polluted marine dredged sediment of port en Bessin

France, using hydraulic binders and silica fume,” IOP

Conference Series: Materials Science and Engineering,

237(1). doi: 10.1088/1757-899X/237/1/012031.

Silitonga, E. (2018) “Impact of pozzolanic binder addition

on stabilization of polluted dredged sediments on its

potential reuse as a new material resource for road

construction in Basse Normandie, France,” IOP

Conference Series: Materials Science and Engineering,

309(1). doi: 10.1088/1757-899X/309/1/012062.

Silitonga, E., Sitompul, H., et al. (no date) “Effect of

Mineralogical and Physical Characteristic of

Pozzolanic Binders on Enhancing Strength in Soil

Improvement Work.”

Silitonga, E., Matondang, Z., et al. (no date) “Effect of The

Available Amount of CaO in Pozzolanic Binders on

Enhancing Physical Characteristic of Concrete.” IOP

Conference Series: Materials Science and Engineering,

Silitonga, E., Levacher, D. and Mezazigh, S. (2009)

“Effects of the use of fly ash as a binder on the

mechanical behaviour of treated dredged sediments,”

Environmental Technology, 30(8), pp. 799–807. doi:

10.1080/09593330902990089.

Silitonga, E., Levacher, D. and Mezazigh, S. (2010)

“Utilization of fly ash for stabilization of marine

dredged sediments,” European Journal of

Environmental and Civil Engineering, 14(2). doi:

10.1080/19648189.2010.9693216.

Weber, J. et al. (2015) “Properties of soil materials derived

from fly ash 11years after revegetation of post-mining

excavation,” Catena. doi:

10.1016/j.catena.2015.05.016.

ICOSTEERR 2018 - International Conference of Science, Technology, Engineering, Environmental and Ramification Researches

262