Towards a Self-balancing Machine Velocity Production Line

for Energy Saving

E. Garcia

1

and N. Montes

2

1

Ford Spain, Poligono Industrial Ford S/N, CP 46440, Almussafes, Valencia, Spain

2

Department of Physics, Mathematics and Computing, University CEU Cardenal Herrera,

CP: 46115, Alfara del Patriarca, Valencia, Spain

Keywords:

Energy Saving, Predictive Control, Velocity Control, Robot Arm, Manufacturing Lines.

Abstract:

The present study analyzes how to re-balance a real world manufacturing line for energy saving by means

of machine velocity reduction. Without loss of generality, the paper is focused in Industrial Robot (IR) lines

where the velocity of each robot is properly tuned using a predictive control technique. It predicts the IR

idle time for the next cycle based on the model line knowledge, the mini-term sub cycle time measurements

and simulation techniques. The proposed predictive control technique is tested off-line, using a real world

welding line model located at Factory Ford, Almussafes (Valencia). Also an estimation of the stored energy

is computed by means of an experimental test developed in a real welding unit. A discussion on how to

implement it in a real line is done at the end of the paper.

1 INTRODUCTION

A production line is a set of sequential operations

established in a factory whereby materials are put

through a refining process to produce an end-product

that is suitable for onward consumption; or compo-

nents are assembled to make a finished article. Be-

cause of the high investment and running costs in-

volved, the design of such lines is of considerable im-

portance, (O.Battaa, 2013). There are a large num-

ber of crucial decisions to be made in flow line de-

sign as, product design, process selection, line lay-

out configuration, line balancing, machine selection,

available technology, etc. Usually, these problems are

considered one at a time because of their complexity,

(O.Battaa, 2013). The last and crucial step in the pro-

cess design is the line balancing, (O.Battaa, 2013).

Here tasks are assigned to the workstations and re-

sources that will be employed on the line. Due to the

relevance of this task, a large number of researchers

have been working on this topic, (O.Battaa, 2013).

Depending on industrial environments, there are solu-

tions to a number of product models, line layout, tasks

and their attributes, workstations and their attributes,

etc, see (O.Battaa, 2013).

Recently, the pressure to reduce energy consump-

tion in the industry is growing due to increasing costs

of electricity and resources. The motor vehicle in-

dustry alone in the U.S. spends about 3.6 billion Dol-

lars on energy annually, (C.Galitsky, 2008). There-

fore, the energy saving goal is a key point for the

industry and also for the governments as the Euro-

pean Union, (Comission, 2016). For that reason, in

the production line balancing problem, energy sav-

ing is a crucial goal recently. Primary research ef-

forts on manufacturing energy savings have focused

on developing individual energy efficient machines.

(G.Mouzon, 2008b), (G.Mouzon, 2008a), pointed out

that if instead of leaving the non-bottleneck machines

idle, they were turned off until needed, then 80%

savings on total energy consumed on idle, start up,

and shut down could be achieved. However, there

are significant amounts of energy required for ma-

chine startup. This suggests that energy saving ef-

forts focusing solely on updating individual machines

or processes may be missing a significant, and per-

haps a bigger, opportunity i.e., system-level changes

and coordinated control (Q.Chang, 2013). It is due

to production lines are a complex dynamic system

with interdependence among different machines and

unscheduled events like downtimes, breakdown and

other random disturbances, (Q.Chang, 2013). Most

current manufacturing execution systems (MES) have

no module or function to deal with energy man-

agement during operation, which means that a huge

amount of energy is wasted during the machine block-

568

Garcia, E. and Montes, N.

Towards a Self-balancing Machine Velocity Production Line for Energy Saving.

DOI: 10.5220/0006430405680575

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 2, pages 568-575

ISBN: Not Available

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

age and starvation without production, making the en-

ergy efficiency really low. Leaving a non-bottleneck

machine idle due to lack of multiple operation states

setting seems to be a routine and regular operating

practice in the industry. In (Z.Sun, 2011) considers

that modern machines or motors systems have multi-

ple adjustable power states instead of traditional ON,

OFF states. The power state is maintained on the ON

level when it is processing parts; while the power hi-

bernation mode may be triggered when it is detected

to be starved or blocked. In (L.Li, 2013), The inter-

actions between the adopted energy control decisions

and system state evolutions are modelled by Markov

decision process (MDP).The decision is to adjust the

energy mode for each machine according to not only

current states but also possible evolutions of system

states in the future. In (Z.Zhou, 2013), a heuristic

method considering throughput bottleneck detection

for real time electricity demand response under the

production constraint is introduced.

1.1 Energy Saving in Industrial Robots

One of the areas in which a significant amount of en-

ergy can be saved in manufacturing process is in in-

dustrial robots (IR). For example, the energy needed

during the production of cars is approximately 8%,

(D.Meike, 2011b). Therefore, the primary goal of

the optimization is to minimize the energy consump-

tion of a robotic cell for a given production rate by

changing the robot speeds, positions, order the oper-

ations and applying the robot power saving modes,

(L.Bukata, 2016). However, energy consumption re-

duction for IR can be achieved at different stages of

a manufacturing systems’ developments: During pro-

duction planning, commissioning process, or at opti-

mization stages, see (P.Matthias, 2015). At the pro-

duction planning stage, engineers are more flexible

with optimizing the process and defining a strategy

for reducing energy consumption, for example, by op-

timizing IR operation schedule, (D.Meike, 2011b) or

by optimizing IR parameters, like the speed and accel-

eration of the robots, (D.Meike, 2011a), (A.Kovetski,

2008). At the commissioning stage, reducing energy

consumption can be conducted by eliminating wait-

ing and iddle time of IR but manufacturing produc-

tivity must be considered. At the optimization stage,

the engineers cannot change the hardware apparatus

or the production rate. Therefore, the energy reduc-

tion must be done by releasing the actuator brake

earlier and implementing optimal trajectories using

time-scaling methods, (D.Meike, 2014), (P.Matthias,

2015), (S.Riazi, 2016).

1.2 Real World Line Balancing

Problems

Although many solutions for reducing the energy con-

sumption of IR have been provided, majority of them

are focused in primary stages. Optimizing the mo-

tion planning of IR can reduce energy consumption

but less interesting for practical point of view and

only effective for an IR manufacturers, (P.Matthias,

2015). Optimizing the operating parameters is a rela-

tively new method but is only effective in the produc-

tion planning stage, while the productivity rate at the

manufacturing system is planned, (P.Matthias, 2015).

In the end, an expert team designs the line, based on

all of these parameters and defines the maximum pro-

duction rate, adjust the IR parameters, program the

trajectories, schedule the tasks, etc. However, dur-

ing the lifespan of the line, which could be decades,

the line suffers a lot of changes due to market de-

mand with new products or models manufactured in

the same line, new technologies like for instance a

new robot arm that can run more faster than when

the line was designed, deteriorating systems that af-

fect the throughput and also produce a dynamic bot-

tleneck behaviour, etc, see (E.Garcia, 2016).

Many of the Operational Research approaches as

well as energy saving strategies implicity assume that

the problem to be solved involves a new, yet-to-be

build assembly line or yet-to-be-build-factory. How-

ever, the vast majority of real-world line balancing

tasks involve existing lines, (E.Falkenauer, 2005). In

fact, the target line tipically needs to be re-balanced

rather than balanced.

1.3 Previous Works

In (E.Falkenauer, 2005) was defined that each work-

station have its own identity, meaning that the work-

stations in the real world are indeed not identical.

The same concept was deep analyzed in our previous

works where not only the workstations are not identi-

cal, but also the components that form each machine

are different and do not have the same behaviour in

each cycle time repetition.The literature classify the

data used in the production line analysis into long-

term and short-term. Long-term is mainly used for

process planning, while short-term focuses primar-

ily on process control. In (E.Garcia, 2016), short-

term was divided into two new terms, mini-terms and

micro-terms, see Figure 1.

A mini-term may be defined as a part of the ma-

chine, in a policy preventive maintenance or a break-

down, which could be replaced in an easy and faster

maneuver than other machine sub-division. A micro-

Towards a Self-balancing Machine Velocity Production Line for Energy Saving

569

Figure 1: From micro-term to Long-term.

term is defined as each of the mini-term sub-division.

It could be divided to the level of depth that the user

requires. Therefore, the probabilistic cycle time of

each machine or station is a concatenation of the

probabilistic mini-terms and micro-terms times where

each could have a different probability distribution.

In (E.Garcia, 2016), (E.Garcia, 2017) was pro-

posed an experimental setup to measure the most

common mini-terms of a welding unit. In this case,

the welding unit is divided into three mini-terms, the

motion of the robot arm, the motion of the welding

clamp and the welding task, see Table 1. The tests de-

veloped in (E.Garcia, 2016), (E.Garcia, 2017), allow

us to measure the sub-cycle times for each mini-term

at the start (Table 1,test 0) and near to the end of the

lifetime of some particular machine component. The

deteriorated components were selected at the weld-

ing line at Ford Motor Factory located at Almussafes

(Valencia) with some particular pathologies which are

not detectable by the machine control systems or by

the maintenance workers. The pathologies are; the

stiffness of a proportional valve (Table 1,test 1), the

pneumatic cylinder wear, galling or communication

inside the stem (Table 1,test 2), the loss of the wire

insulation in a transformer (Table 1,test 3), the loss

of pressure in a pneumatic circuit (below the alarm

value) (Table 1,test4) and the loss of the robot speed

(Table 1,test5).

Test 0 demonstrates that the line components have

Table 1: mini-terms for a welding unit (µ,σ) with (Test 0)

and without deterioration (Test 1-5).

Test Robot arm Clamp

Motion Motion Welding

0 (1,0.11) (0.42,0.47) (1.44,0.84 )

1 (1,0.18) (0.43,0.51) (4.05,10.9)

2 (1,0.13) (1.41,3.42) (1.14,5.99)

3 (1,0.19) (0.46,0.54) (1.76,0.91)

4 (1,0.16) (1.56,3.74) (1.29,5.08)

5 (1.3,0.16) (0.41,0.46) (1.45,0.85)

its own identity and do not have the same behaviour

in each repetition. Moreover, the line components,

cylinders, transformers, etc, are deteriorated during

their lifetime. Therefore, the probabilities, mean and

variance changes, modifying the productivity rate and

defining a new alternative for predictive maintenance,

see (E.Garcia, 2016), (E.Garcia, 2018).

2 NUMERICAL CASE EXAMPLE

2.1 Welding Line Case

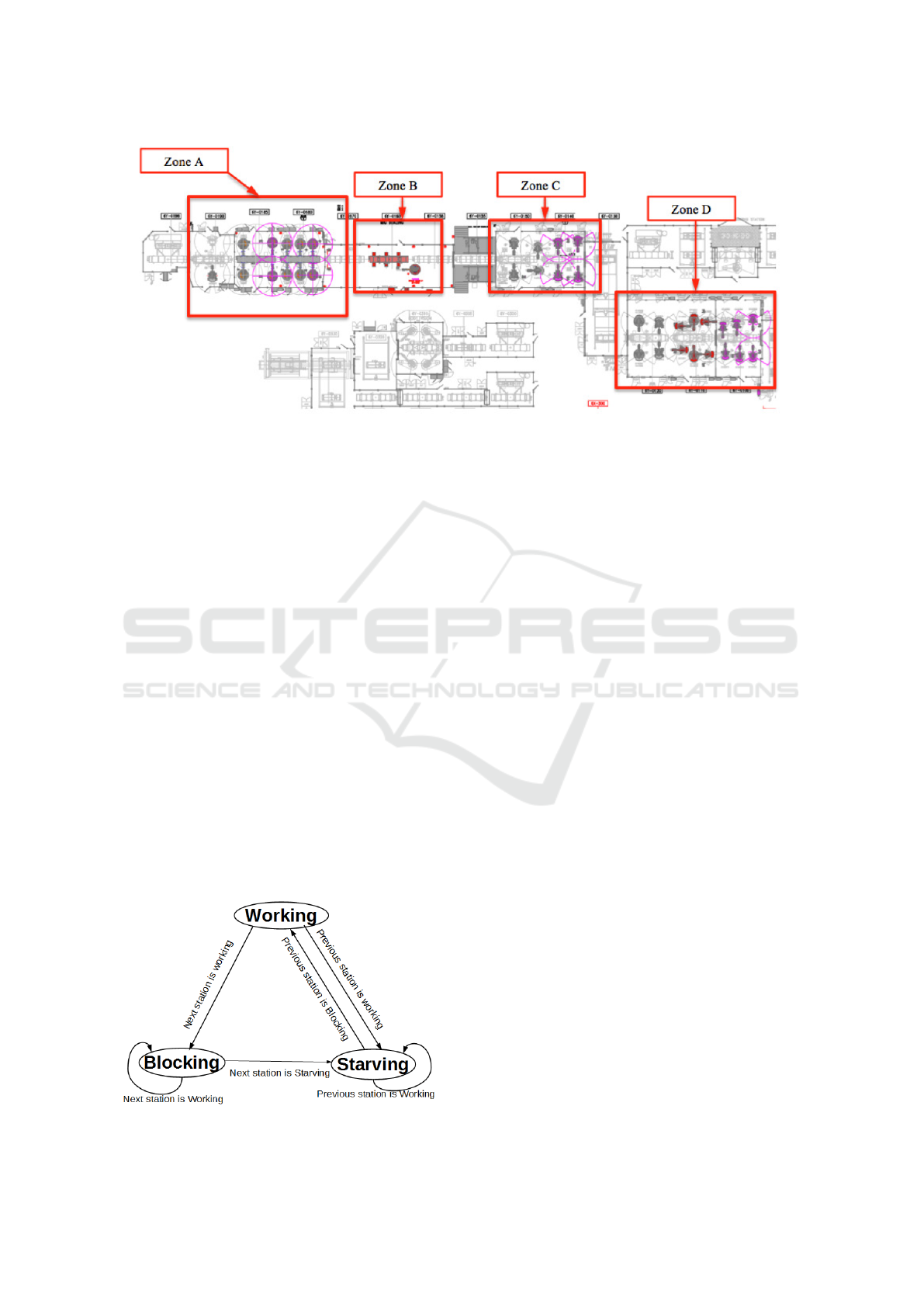

In order to test and illustrate our proposal, a real

welding line located at Ford Almussafes (Valencia)

is used, see Figure 2. In a real welding line like

this, there are welding workstations where, each one

has welding stations working in parallel and some-

times in serial. Each welding station makes some

welding points in the same cycle time. It is possi-

ble to find 1,2,4 or at least 6 welding station in the

same workstation, where each one makes up to 19

welding points. In our particular case, our welding

line has 8 workstations where workstation 1,5 and 6

have 4 welding units,workstations 2,4,7 and 8 have

6 welding stations and workstation 3 has 1 welding

unit, see Figure 3. The welding line was installed

in 1980. The staff group that designed the line de-

fined the maximum running capacity, ECR (engineer-

ing running capacity), 60 JPH (Jobs Per Hour). How-

ever, the plant engineers have another maximum run-

ning capacity, that is the ERR (engineering running

rate), in this case defined in 51 JPH. Nowadays, this

line welds 68 different models and variants. Different

car models with 3,5 doors with or without solar roof,

etc. Obviously, from 1980 to today, the line suffers a

lot of changes and updates, new models and variants

are appear and old models and variants disappeared,

most advanced robot arms and welding units are in-

troduced, etc. Therefore, the line is re-balanced, if it

is possible, when new update occurs.

Figure 2: Welding line at Ford Almussafes (Valencia).

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

570

Figure 3: Welding line layout.

2.2 Welding Line Modelling

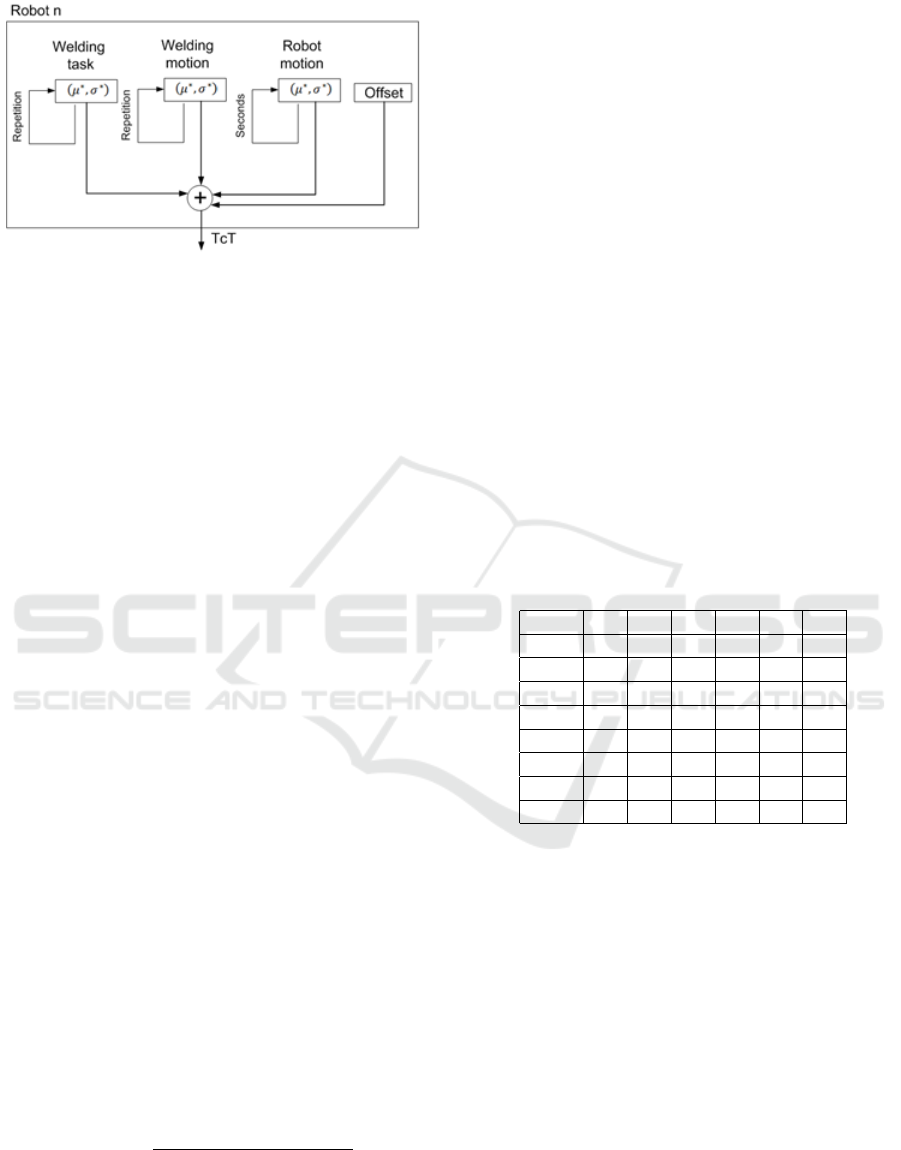

The welding line was modeled taking into account

the mini-terms subdivision. that is, the motion of the

robot arm (the time that the robot is in movement),

and the number of welding point for all the 68 differ-

ent models and variants, see (E.Garcia, 2016), Anex

4. Also in (E.Garcia, 2016), Anex 4, there is the off-

set, time that a particular robot is awaiting for another

robot in the same workstation and the transfer time,

the required time to move the car body to the next

workstation, (12 seconds). With this model and us-

ing a computer simulation explained below, the pro-

ductivity rate was re-computed in, (E.Garcia, 2016)

,(E.Garcia, 2017), taking into account the variability

and the production schedule.

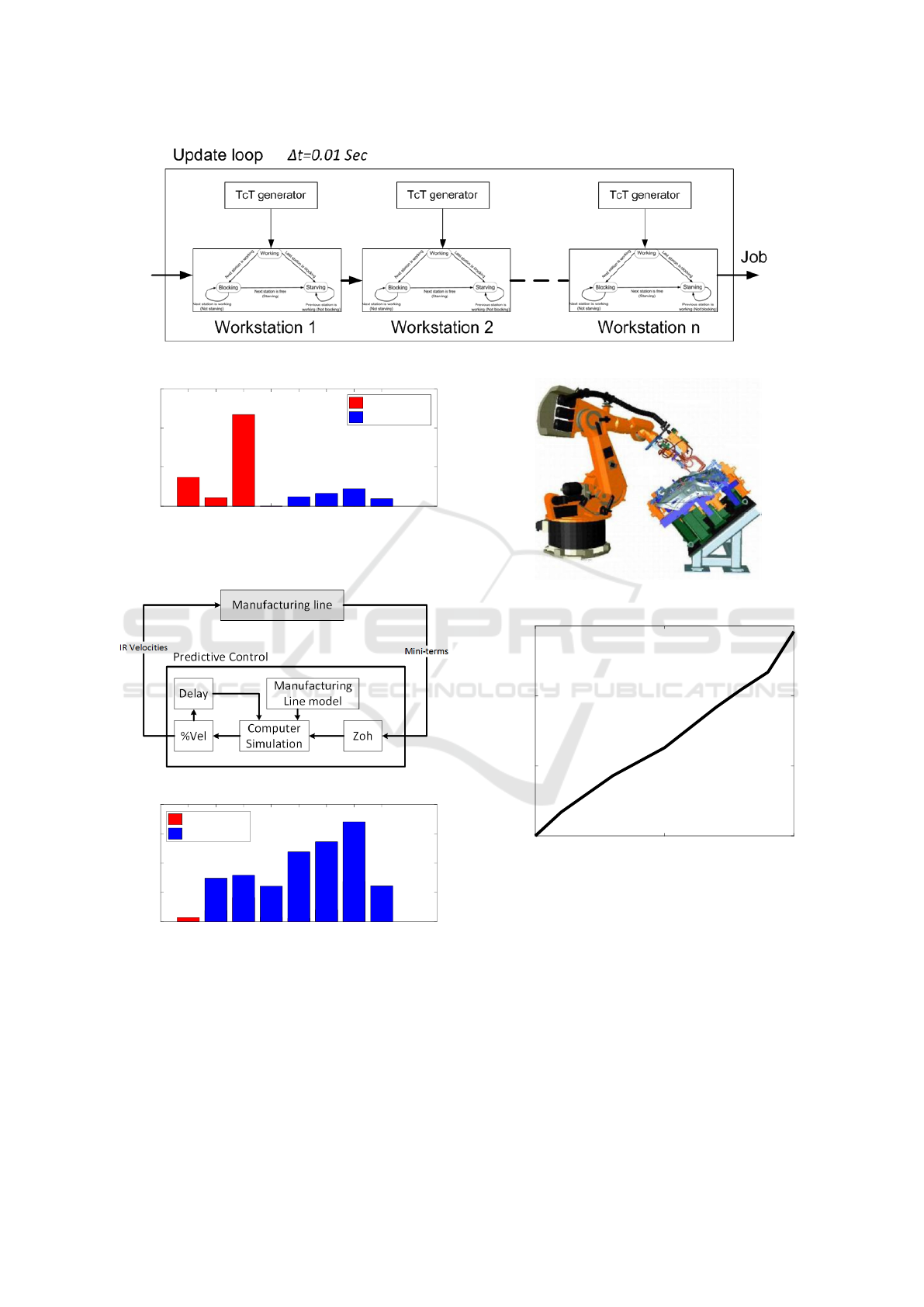

2.3 Welding Line Simulation

The common way to simulate a production line is

to use a simplified machine state, see Figure 4, with

three possible states, Working, Starving and Blocking.

First of all, let us to define a serial production line

with three stations, a,b and c, that are chained in this

Figure 4: Simplified state machine.

order. If station b is in Working state and the work is

finished, it checks station c, if it is in Starving state,

the finished part of product is delivered to it and sta-

tion b is free to receive another job. If station c is

in Working state when station b finishes its work, sta-

tion b changes its state to Blocking, blocking itself

until station c is free. If station b is free to receive an-

other part, it checks the previous station. If station a

is in Working state, station b changes to Starving state

waiting until station a has a part to work on. If station

a is in Blocking state, station b receives the part so, the

state of station b changes to Working and the state of

station a changes to Starving. When simulation starts,

every station state is set to Starving, until the first sta-

tion is set to Working state. The simulation loop runs

at predefined step time (t). For each step time, the cy-

cle time of each workstation decreases until the cycle

time is zero, meaning that the work is finished and the

events are triggered.

In order to simulate the welding line, a chain state

machine simulator is developed, see Figure 6. The

loop is updated with an incremental time of 0.01 sec-

onds. When the cycle time is finished in a particu-

lar workstation, a new cycle time is computed for the

next part, taking into account the car model that will

be manufacture in the next cycle. It is important to

point out that there are different mini-terms and rep-

etitions of each one for each particular car model de-

veloped in a welding line, see figure 5.

In the simulated welding line, a job is always per-

formed in the first workstation, so that the blocking

state cannot be reached in the first station. In addition,

all the finished jobs in the last workstation are retired,

so that the Starving state cannot be reached in the last

workstation. The loop starts with all the stations in

the Blocking state.

The cycle time for each workstation is the max-

Towards a Self-balancing Machine Velocity Production Line for Energy Saving

571

Figure 5: Cycle time computation for each welding unit.

imum cycle time of each welding station that works

in parallel, indicating the slower welding unit and the

bottleneck in a particular workstation.

3 PREDICTIVE CONTROLLING

TECHNIQUE FOR ENERGY

SAVING

In order to test the energy saving algorithm proposed

below, a model, or variant 12 for the (E.Garcia, 2016),

anex 4 is selected. The values of this model are shown

also in the Table 3 of the present paper. If a simulation

is run supposing that the welding line only produces

this model, and the mini-terms are without deteriora-

tion (Table 1,test 0) the production rate is (45.0,1.07),

mean and variance respectively. The simulation also

computes the starving and blocking times, that are

shown in figure 7. As can we see, workstation 4 is

the bottleneck workstation, mainly because, blocking

and starving time are produced at the previous and

later workstations respectively.

Based on blocking and starving times, let us to

define idle time as;

Id

W

k

= Max(S

W

k

,B

W

k

) (1)

where Id

W

k

is the idle time for the workstation W that

manufactured the part in the k instant of time. S

W

k

, B

W

k

are the starving and blocking time the workstation W

that manufactured the part in the k instant of time.

The equation 2 shows how to estimate the minimum

velocity at which each robot could run without loss of

production rate, that is;

%v

W,R

k

=

mR

W,R

Zoh

mR

W,R

Zoh

+ O f f

W,R

+ Id

W

Zoh

(2)

where %v

W,R

k

is the percentage velocity of the

robot R in the workstation W that can be applied for

the part manufactured at the time instant k, O f f

W,R

is

the offset for the robot R at workstation W . mR

W,R

Zoh

is

an estimation of the mini-term robot R at workstation

W . This estimation is done by means of Zoh (Zero

order hold) technique using the next equation;

mR

W,R

Zoh

= mR

W,R

k−1

(3)

Id

W

Zoh

is an idle time estimation for the part that

will be manufactured at the time instant k. This es-

timation is done by means of a computer simulation

technique using the estimated mini-terms, that is;

mCm

W,R

Zoh

= mCm

W,R

k−1

,mCw

W,R

Zoh

= mCw

W,R

k−1

, (4)

where mCm

W,R

Zoh

and mCw

W,R

Zoh

are estimations of the

mini-term clamp for a robot R at workstation W . Also

the velocity reduction applied for the previous part,

k − 1, is taken into account. An schema of the pro-

posed strategy is shown in figure 8.

Table 2 shows the velocity percentages for each

robot at each workstation. With these velocities, the

line is re-balanced and the starving and blocking time

are nearly to zero, see figure 9, maintaining the pro-

duction rate,(45.0,1.07).

Table 2: Velocity percentages for each robot.

W /R 1 2 3 4 5 6

1 52 52 55 56

2 78 79 71 73 85 66

3 23

4 0 0 0 0 0 0

5 80 81 85 85

6 80 81 66 62

7 75 74 75 75 75 75

8 84 84 80 79 83 83

3.1 Welding Line Energy Saving

Estimation

In order to estimate the energy saved with this strat-

egy, the energy consumed for a particular welding

unit at different velocities was done. This experimen-

tal test isolates one welding unit, see Figure 10, where

a current clamp is located at the wire that supplies en-

ergy to the welding unit. The test uses one of the com-

mon trajectory planning programs used in the welding

line. Therefore, the energy consumed by the welding

at different velocities is obtained, see Figure 11.

With this curve, the estimated energy consumed if

all the welding units work at maximum velocity speed

is 7008 Kwh. Applying the velocity reduction, the

estimated energy consumed is 3007 Kwh.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

572

Figure 6: Welding line simulation.

1 2 3 4 5 6 7 8

WorkStations

0

20

40

60

Time (Sec)

Blocking time

Starving time

Figure 7: Starving and blocking time before velocity reduc-

tion.

Figure 8: Control loop schema.

1 2 3 4 5 6 7 8

WorkStations

0

0.5

1

1.5

2

Time (Sec)

Blocking time

Starving time

Figure 9: Starving and blocking time after velocity reduc-

tion.

4 DISCUSSION. TOWARDS A

REAL-TIME ENERGY SAVING

SYSTEM FOR INDUSTRY 4.0

The present paper treats to define how to develop a

real-time control strategy to re-balance manufactur-

Figure 10: Isolated welding unit.

0 50 100

Velocity (%)

0

50

100

150

Energy (Kwh)

Figure 11: Velocity percentage VS energy in a real welding

unit.

ing lines by means of IR velocity reduction. The first

affair to discuss is the parameter used to re-balance.

As can be explained in the introduction, the vast ma-

jority of the techniques proposed are only valid for

a new line, not an existing one. Changing machine

parameters in real-time could be a solution and, the

velocity and acceleration could be the better one. It is

due to the kinetic energy is the energy used in manu-

facturing plants because the parts are moved parallel

to the floor. In particular for automotive industry,

Towards a Self-balancing Machine Velocity Production Line for Energy Saving

573

Table 3: mini-terms for a model 12.

Robot 1 Robot 2 Robot 3 Robot 4 Robot 5 Robot 6

Workstation 1 Robot motion (Sec) 14 13.26 20.84 16.52 13.72

Welding motion (Units) 9 9 6 6 18 18

Welding task (Units) 9 9 6 6 18 18

Offset(Sec) 0 11 11 0 0 0

Workstation 2 Robot motion (Sec) 24.76 21.26 — — 9.52 11.52

Welding motion (Units) 9 9 — — 18 18

Welding task (Units) 9 9 — — 18 18

Offset(Sec) 0 4 — — 0 0

Workstation 3 Robot motion (Sec) — — 19.56 — —

Welding motion (Units) — — 9 — — —

Welding task (Units) — — 9 — — —

Offset(Sec) — — 0 — — —

Workstation 4 Robot motion (Sec) 13.96 16.54 16.54 17.4 — —

Welding motion (Units) 14 11 11 10 — —

Welding task (Units) 14 11 11 10 — —

Offset(Sec) 0 0 0 6 — —

Workstation 5 Robot motion (Sec) 16.26 15.12 20.68 21.4 — —

Welding motion (Units) 9 8 12 10 — —

Welding task (Units) 9 8 12 10 — —

Offset(Sec) 0 2 0 0 — —

Workstation 6 Robot motion (Sec) 20.26 11.02 14.12 11.34 — —

Welding motion (Units) 9 18 8 6 — —

Welding task (Units) 9 18 8 6 — —

Offset(Sec) 0 0 0 0 — —

Workstation 7 Robot motion (Sec) 11.66 10.10 12.38 8.52 7.52 19.26

Welding motion (Units) 19 15 17 18 18 9

Welding task (Units) 19 15 17 18 18 9

Offset(Sec) 0 0 0 0 0 0

Workstation 8 Robot motion (Sec) 12.24 13.10 12.38 14.10 13.96 15.68

Welding motion (Units) 16 15 17 15 14 12

Welding task (Units) 16 15 17 15 14 12

Offset(Sec) 0 0 0 0 0 0

huge masses as body car are moved, acting as an scal-

ing factor. In addition to that, all the Industrial robots

manufactures provides a velocity control parameter

for a predefined program and can be controlled using

an external input, making easily and cheap the control

system. The second affair is if the IR velocity reduc-

tion is the best choice for energy saving. For instance,

in the welding line analyzed here, it is not clear if is

better to reduce IR velocities or reduce the velocity

conveyor. The first one moves welding units at high

speed, low weight, but the second one moves the body

car, high weight.

The third affair is how to compute the velocity

reduction. The solution proposed in the present pa-

per is only tested for an isolated manufacturing line,

welding line, that produce a single model. Real world

shows that the line produce 68 different models with

a predefined production schedule.

To end up, A Real-time energy saving system that

re-balance the velocity or acceleration needs Indus-

try 4.0. Real world lines have their own entity, even

each mini-term. Real-time monitorization, not only

for the mini-terms but also breakdowns and other real

world facts must be taken into account to re-balance

the velocity successfully without reduce the produc-

tion rate.

5 CONCLUSIONS AND FUTURE

WORKS

The present study shows, for the first time, a control

technique to re-balance a manufacturing line for en-

ergy saving. The re-balance is done by means of In-

dustrial Robots velocity reduction. A predictive con-

trol technique is used to estimate it by means of Zero

order hold (Zoh) technique for the real-time mini-term

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

574

measurements. A computer simulation give us an es-

timation of the idle time for the part that will be pro-

duce in the next cycle time.

Future works are focused in three main branches

that we are working in parallel. The first one is to

deeply analyze all the systems that acts in a manu-

facturing automotive industry to determine which is

the better choice to reduce the velocity, based on the

energy saving point of view. The second one is to

improve the technique proposed here for multi-model

lines. In that case, the predictive control must take

into account the production schedule for the velocity

estimation reduction. The last one is to implement a

real setup to test on-line the schema proposed in Fig-

ure 8. In that sense, a real line that produce a single

model could be used to test the efficiency of the tech-

nique proposed in the present paper.

ACKNOWLEDGEMENTS

Authors wish to thank Ford Espa

˜

na S.A and in par-

ticular Almussafes Factory for their support in the

present research.

REFERENCES

A.Kovetski (2008). Velocity balancing in flexible manu-

facturing systems. In Proceedings of the 9th Interna-

tional Workshop on Discrete Events Systems. IEEE.

C.Galitsky (2008). Energy efficiency improvement and cost

saving opportunities for the vehicle assembly industry.

In ErnestOrlando Lawrence Berkeley National Labo-

ratory Report, Berkeley,. CA, LBNL-50939-Revision.

Comission, E. (2016). Energy efficiency. avail-

able: https://ec.europa.eu/energy/en/topics/energy-

efficiency. In European commision. ELSEVIER.

D.Meike (2011a). Analysis of the energy efficient us-

age methods of medium and high payload industrial

robots in the automotive industry. In 10th Int. Symp.

Typical problems in the Field of Electrical and Power

Engineering. IEEE.

D.Meike (2011b). Energy efficient use of robotics in the

automobile industry. In International Conference on

Advanced Robotics (ICAR). ICAR.

D.Meike (2014). Energy efficient use of multirobot produc-

tion lines in the automotive industry: detailed system

modelling and optimization. In Transactions on Au-

tomation Science and Engineering. IEEE.

E.Falkenauer (2005). Line balancing in the real world. In

International Conference on Product Lifecycle Man-

agement. Interscience Enterprises Ltd.

E.Garcia (2016). Analisis de los sub-tiempos de ciclo tec-

nico para la mejora del rendimiento de las lineas de

fabricacion. http://hdl.handle.net/10637/8352, Valen-

cia, 2nd edition.

E.Garcia (2017). A novel predictive maintenance policy

based on the sub-cycle time deterioration effect.(under

review). In Transactions on Automation Science and

Engineering. IEEE.

E.Garcia (2018). Re-computation of the manufacturing pro-

ductivity rate based on real world parameters. a weld-

ing line case. (under review). In Transactions on In-

dustrial Informatics. IEEE.

G.Mouzon (2008a). A framework to minimize total energy

consumption and total tardiness on a single machine.

In International Journal of Sustainable Energy. Taylor

and Francis.

G.Mouzon (2008b). Operational methods for minimization

of energy consumption of manufacturing equipment.

In International Journal of Production Research. Tay-

lor and Francis.

L.Bukata (2016). Energy optimization of robotic cells. In

Transactions on Industrial Informatics. IEEE.

L.Li (2013). Dynamic energy control for energy efficiency

improvement of sustainable manufacturing systems

using markov decision process. In IEEE Transactions

on systems, Man, and Cybernetics systems. IEEE.

O.Battaa (2013). A taxonomy of line balancing problems

and their solution approaches. In International Jour-

nal of Production Economics. ELSEVIER.

P.Matthias (2015). Reducing energy consumption of in-

dustrial robots in manufacturing systems. In Inter-

national Journal of Advanced manufacturing Technol-

ogy. Springer.

Q.Chang (2013). Energy saving opportunity analysis of au-

tomotive serial production systems. In ieee Transac-

tions on automation science and engineering. IEEE.

S.Riazi (2016). Energy and peak-power optimization of ex-

isting time-optimal robot trajectories. In International

conference on automation Science and Engineering.

IEEE.

Z.Sun (2011). Energy consumption reduction for sus-

tainable manufacturing systems considering machines

with multiple-power states. In Proceedings of the

ASME 2011 Int. Manufacturing Science and Engi-

neering Conference. ASME.

Z.Zhou (2013). Real time electricity demand response

for sustainable manufacturing systems considering

throughput bottleneck detection. In International

Conference on Automation Science. IEEE.

Towards a Self-balancing Machine Velocity Production Line for Energy Saving

575