Beyond Nolan’s Nine-stage Model

Evolution and Value of the Information System of a Technical Office in a

Furniture Factory

Andrés Boza

1

, Javier Llobregat

2

, Llanos Cuenca

1

and Zenon Michaelides

3

1

Research Centre on Production Management and Engineering (CIGIP), Universitat Politècnica de València, Spain

2

School of Informatics, Universitat Politècnica de València, Spain

3

Management School, University of Liverpool, U.K.

Keywords: Information System, Nolan’s Model, Smart Factory, Technical Office.

Abstract: This paper reviews the evolution of information systems. Nolan’s Model has been reviewed and a new

Smart Era seems to be arising. The model has been used to analyse the development stages of a technical

office’s information system in a furniture factory. The necessarily changing business model in the company

throughout the ages has been analysed from the perspective of the contribution of the technical office’s

information system to its main business process.

1 INTRODUCTION

Companies are constantly changing due to the strong

competitiveness of the markets. Transformations in

their organizational structures, in their business

models, in their facilities or in simple or complex

business processes have required in many cases the

addition of information systems involved in each

case. Companies have been incorporating new

technologies, making greater use of them and

performing different styles of management over time

in order to maximize the value of investment in

information systems (IS). Although this evolution of

the information systems in the company has not

always produced the expected results (Nijland,

2004) or has not used adequate tools and

methodologies to successfully measure the IT value

(van Wingerden, D., 2008).

This paper reviews the Information System

evolution in organizations based on Nolan’s nine-

stage model (Nolan, 1992) (Mutsaers, 1998) to pass

through three different Eras.

A case study of the evolution of the IS of a

Technical Office in a furniture factory is presented.

The fundamental role of these information systems

covers from design to manufacturing, in order to

achieve new products, efficient production and/or a

flexible factory.

The paper is structured as follows; section two

deal with the value of the IS for organizations and

section three reviews the evolution of IS. Section

four presents a new scenario that is emerging in a

disruptive way: Industry 4.0. The case of the

evolution of the IS in a technical office in a furniture

Factory is included in section five. Finally, the

conclusions are presented.

2 INFORMATION SYSTEM

VALUE FOR ORGANIZATIONS

Renkema and Berghout (1997) define value as the

sum of financial and non-financial consequences.

Benefits refer to all positive consequences of an IS

investment and sacrifices to all negative

consequences. Lucas (1999) includes in the

Information Technology (IT) value all financial,

non-financial, direct, indirect, tangible and

intangible contributions from investments in IT, i.e.

he takes into account financially quantifiable

contributions but also other contributions perceptible

by the user in the result of the processes to calculate

the value of the IS.

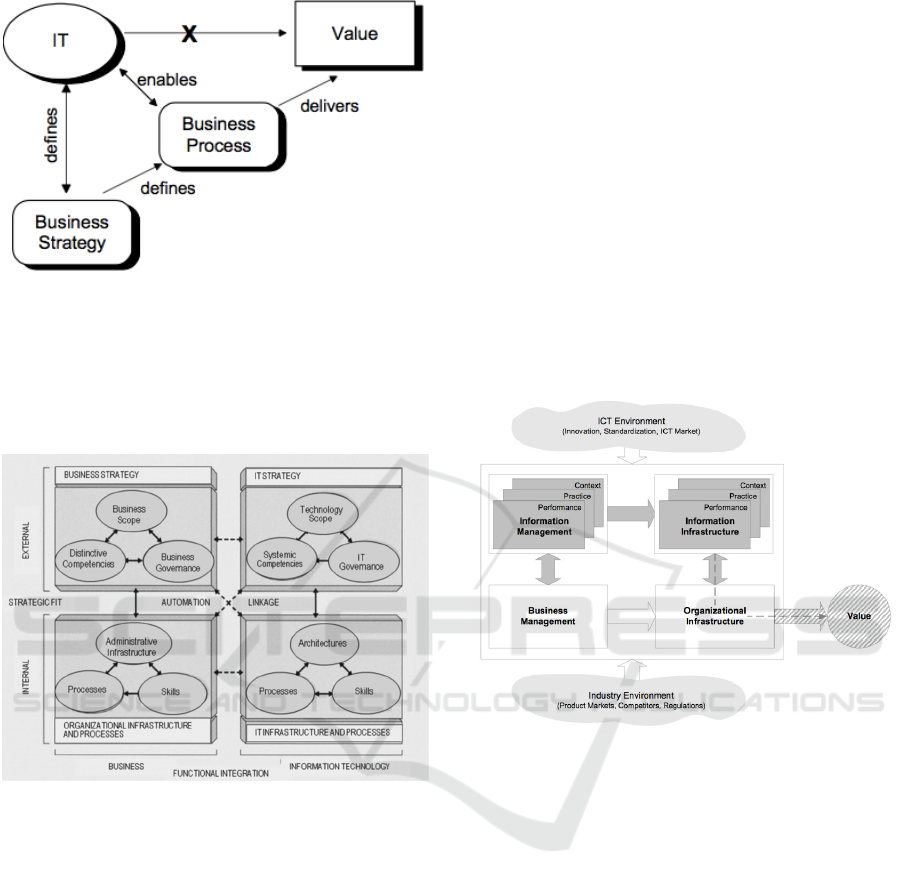

So, IT benefits are indirect (Figure 1).

Boza, A., Llobregat, J., Cuenca, L. and Michaelides, Z.

Beyond Nolan’s Nine-stage Model - Evolution and Value of the Information System of a Technical Office in a Furniture Factory.

DOI: 10.5220/0006373503770384

In Proceedings of the 19th International Conference on Enterprise Information Systems (ICEIS 2017) - Volume 1, pages 377-384

ISBN: 978-989-758-247-9

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

377

Figure 1: Explanation of the IT productivity paradox

(Wigand, 1998 ; referenced by Teubner, 2005).

Henderson & Venkatraman (1993) in their

“Strategic Alignment Model” present the influence

of information systems on business and a proper

alignment with business.

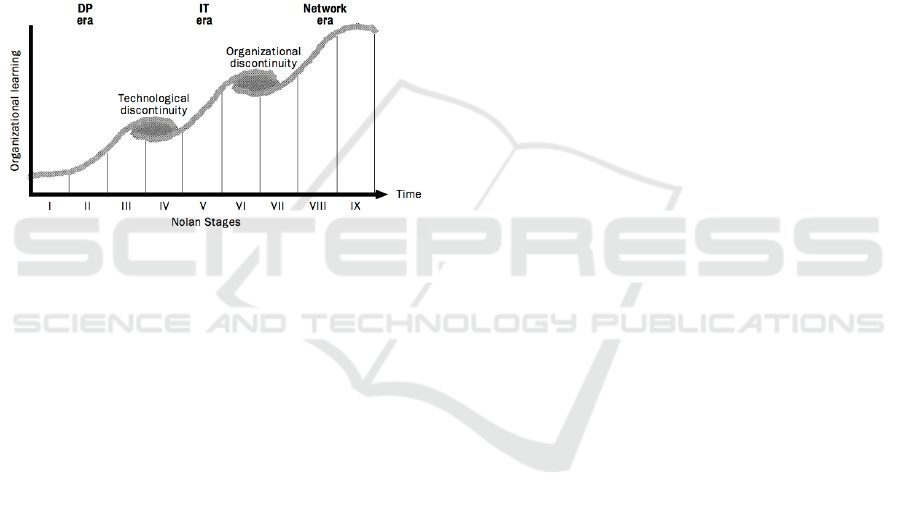

Figure 2: Strategic Alignment Model (Henderson and

Venkatraman, 1993).

The Strategic Alignment Model (SAM) makes a

distinction between the external perspective of IT

(IT strategy) and the internal focus of IT (IT

infrastructure and process). It is composed of four

quadrants that consist of three components each.

These 12 components define what each quadrant is

as far as alignment is concerned. All the components

working together determine the extent of alignment

for the company being assessed (Henderson and

Venkatraman, 1993; Papp, 2001; Sakka et al., 2010).

The four quadrants are (Henderson and

Venkatraman, 1993):

Business strategy at the external level of the

business domain. It is structured by three

components: business scope, business

competencies and business governance.

Organisational infrastructure and processes

that form the internal level of the business

area. This domain is composed of three

components: administrative infrastructure,

skills and business processes.

IT strategy at the external level of the IT

domain. It is structured by three components:

technology scope, systemic competencies and

IT governance.

IT infrastructure and processes that form the

internal level of the IT area. Likewise, it is

formed by three components: IT architecture,

IT skills and IT processes.

Nevertheless, as indicated above, the value is

materialized through the business processes.

Teubner (2005) represents it as shown in the

following figure:

Figure 3: IT Productivity Framework – IT21 (Teubner,

2005).

A correct evolution in the ICT Environment

aligned with the Industry Environment has brought

value to the organization.

3 EVOLUTION OF THE

INFORMATION SYSTEM IN

THE ORGANIZATION

As technology advances, so does the role it plays in

organizations.

Thorp (1998) presents the evolution of

information systems with only three stages:

Automation of Work. The emphasis is placed

on operational efficiency, not on doing things

differently.

Information Management. IT was increasingly

applied to provide information to support

ICEIS 2017 - 19th International Conference on Enterprise Information Systems

378

improved decision making, to move it “closer

to the customer” and to support new service

and product design. Benefits moved beyond

operational efficiency to operational and

tactical effectiveness.

Business Transformation. As more and more

computing power is distributed, and as

advanced communications capabilities

continue to erase the constraints of time and

distance, the very nature of businesses, and

even entire industries, are being redefined.

Benefits have moved beyond operational and

tactical effectiveness to strategic effectiveness

and positioning.

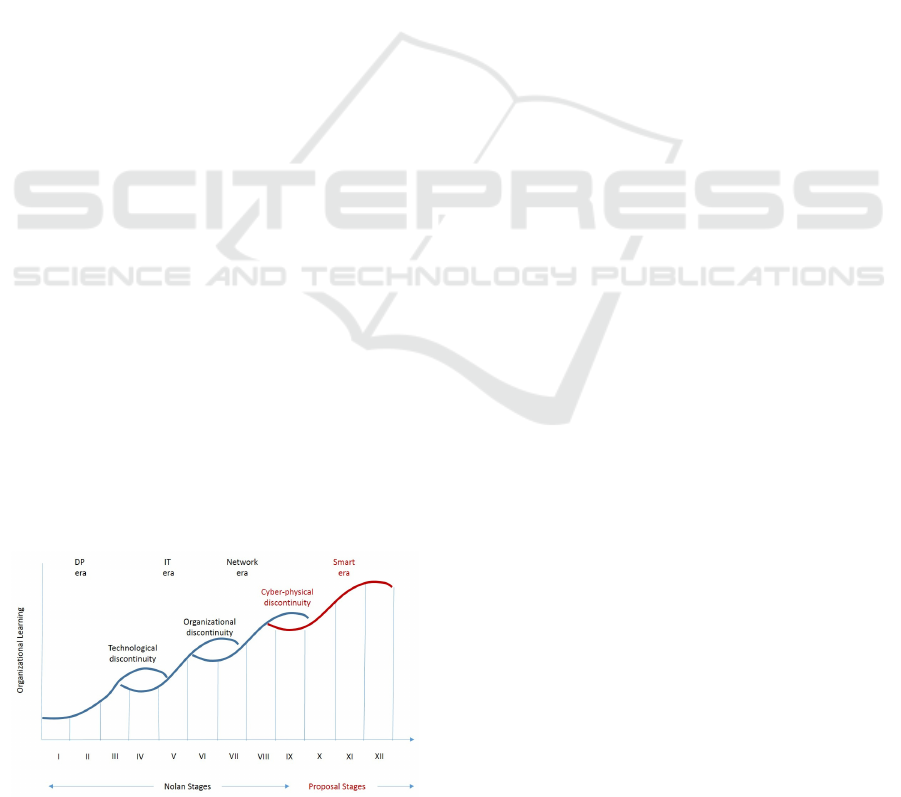

Nolan (1992) presents the evolution in three "Eras"

with three stages in each Era (Mutsaers, 1998).

Figure 4: Nolan Stages (Mutsaers, 1998).

Data Processing (DP) Era : Management of the

organization begins to pay attention to the

phenomenon of automation.

Stages 1. Initiation: an organization becomes

acquainted with automation. 2. Contagion: There is

an increase in the need for other sorts of systems. 3.

Control: Owing to the spread of automation

throughout the organization and the failures

encountered in this, there exists a need for control of

the automation activities and emerging costs.

Information Technology (IT) Era: A breaking

point appears because of a technological

discontinuity. The business environment has

changed enormously. In the IT era, companies are

typically process-oriented, and separate business

units are organised according to markets, product-

lines or geographic areas.

This era includes the stages: 4. Integration:

Companies use IT to enable new methods of doing

business. Integration of applications and different

technological platforms are key. Old systems must

be replaced to facilitate integration. 5. Architecture:

New system development activities are focused on

achieving highly-strategic business objectives, such

as integration with suppliers and customers. As a

consequence, the involvement of top-management is

increasing rapidly. 6. Demassing: Business unit

management assumes full responsibility for the

business strategy and the related deployment of IT.

This leads to a shift in the application of IT, from a

technological phenomenon, driven by IT experts, to

a strategy-driven management resource.

Network Era: The increasing pressure from the

business organisation for ever-more tailor-made

functionality from information systems makes it

necessary to create an applications portfolio that is

both flexible and stable at the same time.

This Era includes the stages: 7. Functional

Infraestructure: The focus was on integration of

systems; now the name of the game is integration of

flexible modules of functionality and network

connectivity. 8. Tailored Growth: When the

functional infrastructure is in place, including

server-type of information systems, the focus will

shift to the expansion of the functional support for

users. 9. Rapid Reaction: The expansion stage is

now over and the main activity is to adapt the

functionality as the highly dynamic business teams

change.

The transition from the DP to the IT Era is

accompanied by a Technological discontinuity.

From the IT to the network Era an Organisational

discontinuity occurs. However, a new discontinuity

arises for IS related to new technologies such as big

data, cloud computing, wireless sensor networks or

the Internet of things. In addition, this set of new

proposals has been “tagged" for the industry as

Industry 4.0.

4 INDUSTRY 4.0

The production system will have a new development

with a higher level of automation of the production

lines due to the new intelligent systems, with the

ability to learn and make their own decisions. In the

Industry 4.0, sensors, machines, workpieces and IT

systems will be connected along the value chain

beyond a single company (Rüßmann et al., 2015).

Industry 4.0 promotes, among other things,

autonomous decision-making, interoperability,

agility, flexibility, efficiency and cost reductions.

This is the reason by which many companies are

aiming to implement the technologies and concepts

related to “Industry 4.0”. However, current research

about “Industry 4.0” is diverse, limited and clearly

insufficient regarding its implementation in

operational levels of the production processes

Herman et al. (2015) defines Industry 4.0 as a

Beyond Nolan’s Nine-stage Model - Evolution and Value of the Information System of a Technical Office in a Furniture Factory

379

collective term for technologies and concepts of

value chain organization”. This new paradigm seems

to mark the future roadmap, leading to the fourth

industrial revolution (Erol et al., 2016).

According to Gilchrist (2016), the Industrial

Internet (Industry 4.0) is a coming together of

several key technologies in order to produce a

system greater than the sum of its parts. The

Industrial Internet provides a way to get better

visibility and insight into the company’s operations

and assets through integration of machine sensors,

middleware, software, and backend cloud compute

and storage systems. Therefore, it provides a method

of transforming business operational processes by

using as feedback the results gained from

interrogating large data sets through advanced

analytics. Four Main Characteristics of Industry 4.0

are: i) 1. Vertical integration of smart production

systems ii) Horizontal integration through global

value chain networks iii)Through-engineering across

the entire value chain and iv) Acceleration of

manufacturing.

Perez et al. (2017) identified eight main different

features of the term “Industry 4.0”: Virtualization,

Interoperability, Automatization, Real-time

availability, Flexibility, Service Orientation and

Energy efficiency. These features are being

supported by these technologies/concepts: Cyber-

Physical Systems (CPS), Internet of Things/Services

(IoT/IoS), Smart Data and Smart Factory.

The value of Industry 4.0 has been approached

by Schuh (2014) not only on its impact on

production processes but also on indirect

departments by deriving individual activities which

lead to a growth in productivity and therefore

competitiveness.

All this leads us to think that it seems necessary

to define a new Era beyond those already defined by

Nolan. That new Era could be called the Smart Era

and should be associated with the new

functionalities, technologies and concepts exposed

previously.

Figure 5: Extended Nolan Model.

5 CASE STUDY: NOLAN’S ERAS

IN THE INFORMATION

SYSTEM OF A TECHNICAL

OFFICE IN A FURNITURE

FACTORY

5.1 Context

5.1.1 Furniture Sector

The furniture market has traditionally been very

cyclical and is sensitive to the economic

conjuncture. Indeed, the furniture industry has been

one of the most severely hit by the recent economic

downturn in Europe. After a peak in 2007, total

industry production has decreased by more than 14%

and total sector employment decreased by 20%

between 2007 and 2011. This has accelerated an

underlying restructuring process common to other

low-tech industries (such as clothing and textiles).

Nowadays one strength in this sector is “the advance

in furniture production technology” and an

opportunity is “ the growing demand for high

technology and knowledge intensive jobs” so

information systems and information technology are

crucial in this new environment. (EU commission,

2014).

5.1.2 Technical Offices in Furniture

Industries

Technical offices in the furniture industry sector

(and indeed its Information Systems) are

functionally interrelated to the commercial and

purchasing departments, and mainly to the

production area.

In addition, as part of an organization that is

immersed in an unstable and changing sector

environment, its activity needs to be able to adapt to

new business models, new markets and forms of

production, new technologies and machinery, new

products and customers; so that the organization can

maintain high levels of productivity and profitability

to stay in this competitive market.

Decisions about new product production and the

required changes (or incorporation) in infrastructure

are important not only for a possible growth of its

market share, but also for the continuity of the

business, because an important part of the success

depends on a suitable implementation of these

decisions. In this sense, continuous develop of its

information system and a successful investment in

ICEIS 2017 - 19th International Conference on Enterprise Information Systems

380

new IT solutions are also crucial to optimize this

area of the company.

In this case study, the factory manufactures

bathroom furniture and the technical office is in

charge of different services to: i) ensure a proper use

of the resources and information systems of the

factory used for production. ii) ensure the security

and reliability of the systems, iii) capture orders,

design products, define technical information,

produce computer files for CNC (Computer

Numeric Control) machines and optimize

production.

The quality strategy of this technical office is

summarized in the following sentence: '' providing

our internal users with services and data that satisfy

their needs and expectations, designing,

implementing and executing reliable processes”. The

main areas under this technical office are shown in

the following figure:

Figure 6: Main areas under this technical office.

5.2 Value Provided by the Technical

Office’s Information System

As discussed above, it is difficult to attribute the

financial performance of the productivity for the IS

in the technical office because this performance is

also a consequence (and subject to the influence) of

other factors, such as the management of the

production or other CEO decisions. The IS of the

technical office, by itself, cannot be evaluated in

isolation but it can be evaluated in combination with

other processes within the context of the production

area.

The evolution over the years of the IS in this

technical office has involved an increase in

investment in hardware, software and user training.

As IS for the technical office have become more

advanced, the level of exigency in the use of it,

generally associated with its inherent high

technology, has also been more sophisticated. Thus,

over the last few years, the ways in which these IS

can add value to the organizations have risen to

become essential to increase the benefit of the

organization.

5.3 Evolution of the Information

System

The three Eras defined by Nolan are presented in

relation to the evolution of the technical office in the

company studied. The Parts Processing Era, the

Batch Manufacturing Era and the Mass

Customization Era are shown respectively associated

with the DP Era, IT Era and Network Era.

5.3.1 Part Processing Era - Data Process

Era

This era started with the first years of existence of

the factory. This was a period in which, once

acquired the means of production that allow the

automation of processes, the unique objective was

improving the efficiency that this production

automation entails. This did not imply changes in the

traditional functional hierarchy of the organization.

1st Stage: Initiation. At this stage, the focus was

on reducing costs and improving ratios and scale

factors thanks to the automation of the production

processes supported by the technical office. It had a

merely operational point of view.

2nd Stage: Contagion. The operation of

Information Systems focused on the satisfaction of

the users because of the reliability of the work

processes associated with the information received.

The top management of the company had, at this

stage, little control over the investment made not

only at the production machinery level, but also in

the hardware, software, and training of technical

office personnel. Investments in highly specific IS

were not formally justified.

3rd Stage: Control. It is inevitable that failures

will occur during the contagion stage. Errors made

by the technical office related to data automation

posed an undesirable risk. Due to the IS costs,

senior management, through the administrative

departments, wanted to exercise greater control over

investments in IS. The Information Systems plan

became one of the control instruments used.

5.3.2 Batch Manufacturing Era -

Information Technology Era

A technological discontinuity appears with the new

software for the optimization of cutting boards,

imbrication of pieces for their milling and a

generation of programs of CNC. Internally, the new

focus of the Technical Office is oriented towards the

Technical

Office

Design

and

Manufacturing

Cut

Edge

Banding

Machining

Assembly

Beyond Nolan’s Nine-stage Model - Evolution and Value of the Information System of a Technical Office in a Furniture Factory

381

effectiveness (once the stage of mere automation had

been passed).

Step 4: Integration. The adoption of a new

business model in the company under study implied,

firstly, the acquisition of a new manufacturing line

to include intermediate stock of parts produced in

optimal batches, and secondly, an important

integration of existing applications into the new

production process. Information Systems were

acquired to achieve the objectives and not only to

reduce costs.

5th Stage: Architecture. The data, so far

dispersed in different applications were considered

at this stage as a critical resource. It is crucial to

develop a corporate data production architecture

fully integrated with the rest of the organization.

Production management increasingly involving

Information Systems, were increasingly integrated

with the production processes.

6th Stage: Demassing. The Technical Office

assumed greater control of the company's production

processes and the IS related with the technical office

activities.

5.3.3 Mass Customization Era – Network

Era

The increasing pressure for competence and the

market conditions due to the economic crisis in the

last years have forced a new change in the

organization: Mass Customization. Specifically, the

technical office faced the challenge of a mass

customization production according to customer

preferences. The technical office was managed as a

vital strategic resource for the company.

7th Stage: Functional infrastructure. The

interconnection with other business units of the

organization was strengthened. In particular, the

connection with the commercial area information

system was improved.

8th Stage: Tailored Growth . The new context

implied a demand of request. Users of new

applications implanted by the technical office to

support the organizational changes required new

functionalities.

9th Stage: Rapid reaction. The new

functionalities available are used to adapt quickly to

the new business context: the new customized

demand of the clients, and the changed production

system. The technical office, equipped with flexible

and configurable information systems, can create

and adapt orders, make launches to production with

different criteria, according to the guidelines

imposed by the organization.

5.3.4 Smart Era

New technologies are knocking at the door of

technical offices. In the case of this company in the

furniture sector i) the creation of prediction models

using information collected plant WSN and

exploiting the information using big data, ii)

Intelligent use of RFID technologies iii) Advanced

CAD / CAM systems.

These new technologies offer new insights and

value to the company. We can talk about a new Era

and new stages in near future. These stages can be

incorporated into Nolan’s model. The following

table summarises the three Eras defined by Nolan

and their relation to the evolution of the technical

office in the company studied. The new Smart Era

and the new stages proposed have also been

incorporated.

6 CONCLUSIONS

Organizations have invested progressively in

improving their information systems. The result of

such investments (as value for the organization) is

difficult to identify due to the influence of other

aspects in the organization. In addition, another

handicap is that this value is materialized indirectly

through the organizational infrastructure and

specifically by its business processes.

Despite these difficulties, organizations have

continued to invest in information systems and these

systems have evolved over time.

Nolan's 9-stage model is a classic in describing

such evolution. The 9 stages are grouped in three

Eras: Data Processing Era, Information Technology

Era, and finally, the Network Era. However, a new

discontinuity point seems to be arising with the

arrival of new proposals like big data, cloud

computing, the internet of things or the general term

Industry 4.0. This new era could be named the Smart

Era.

We have analysed these aspects for a technical

office in a furniture Factory.

The value of the investments in information

systems in this office cannot be evaluated in

isolation, since this is mainly conditioned by the

influence of the productive area.

The evolution of the Information System of the

Technical Office has been associated with changes

in its production context, in particular Part

Processing – Data Processing Era, Batch

Manufacturing - Information Technology Era, and

Mass Customization – Network Era

ICEIS 2017 - 19th International Conference on Enterprise Information Systems

382

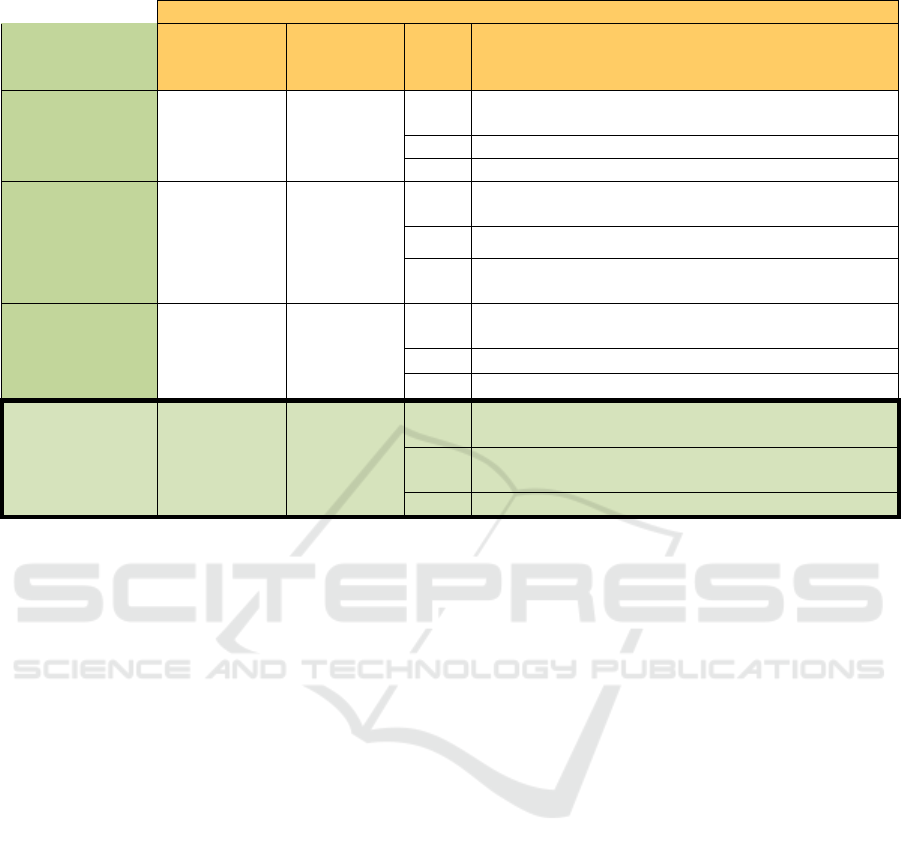

Table 1: Beyond Nolan’s nine-stage Model.

PRODUCTION SYSTEM EVOLUTION AND STAGES IN THE CASE STUDY

INFORMATION

SYSTEMS

EVOLUTION

Production

system

Objective Stage Description of the stage meaning at the company

Data

Processing

Era

Part

Processing

Efficiency

1

Focus on reducing costs and improving ratios and scale

factors

2 Little control over the investment

3 Information systems became as a control instrument

Information

Technology

Era

Batch

Manufacturing

Effectiveness

4

New business model

IS help to achieve the objectives

5 Data considered as a critical resource

6

The technical office increase the control over the

production system and the information system

Network

Era

Mass

Customization

Strategic

alignment

7

Technical office Increase collaboration with other areas

of the company

8 Request of work to manage new requirements

9 Quick response to needs

Smart

Era

Intelligent

Manufacturing

Visibility,

transparency

and

intelligence

10

Seamless communication between IS and business (all

the areas and partners in the company)

11

Self-competences (including self-estimation, self-

assessment and self- adaptation)

12 Accurately and immediate decisions

This evolution has been key i) to automating

manufacturing processes; ii) for the optimal

management of the information from the tactical

point of view (efficacy and efficiency of the

processes); and iii) to transform the business

adapting it to the new business models of the

company. In addition a wave of new technological

proposals are arriving as precursor of a new Smart

Era.

REFERENCES

Erol, S., Schumacher, A. & Sihn, W., 2016. Strategic

guidance towards Industry 4.0 – a three-stage process

model. In International Conference on Competitive

Manufacturing, COMA’16.

EU Commission. 2014. The EU Furniture market situation

and a possible furniture products initiative. Executive

Summary. Within Framework Contract

/ENTR/008/006. Brusells

Gilchrist, A. 2016. Industry 4.0. The industrial internet of

things. Apress, New York. ISBN-13, 978-1484220467.

Henderson, J. C., & Venkatraman, H. 1993. Strategic

alignment: Leveraging information technology for

transforming organizations. IBM systems journal,

32(1), 472-484.

Herman, M., Pentek, T. & Otto, B., 2015. Design

Principles for Industrie 4.0 Scenarios: A Literature

Review, Technische Universität Dortmund. Audi

Stiftungslehrstuhl Supply Net Order Management.

Lucas, H. 1999. Information Technology and the

Productivity Paradox: Assessing the Value of

Investing in It. New York: Oxford University Press.

Nijland, M. 2004. Understanding the Use of IT Evaluation

Methods in Organisations. Department of Information

Systems .

Nolan, R., & Koot, W. 1992. Nolan Stages Theory Today:

A framework for senior and IT management to

manage information technology. Holland Management

Review, 31, 1-24.

Mutsaers, E. v. 1998. The evolution of information

technology. Information Management & Computer

Security , 6 (3), 115-126.

Papp, R., 2001. Strategic information technology:

opportunities for competitive advantage. Hershey, PA:

Idea Group Publishing.

Perez, D., Alarcón, F., Boza, A. 2017. Industry 4.0: A

classification scheme. Lecture Notes in Management

and Industrial Engineering (Springer) (In press)

Renkema, T. J., & Berghout, E. W. 1997. Methodologies

for information systems investment evaluation at the

proposal stage: a comparative review. Information and

Software Technology, 39(1), 1-13.

Rüßmann, M., Lorenz, M., Gerbert, P., Waldner, M.,

Justus, J., Engel, P., & Harnisch, M. (2015). Industry

4.0: The Future of Productivity and Growth in

Manufacturing Industries. Retrieved from

https://www.bcgperspectives.com/content/articles/engi

neered_products_project_business_industry_40_futur

e_productivity_growth_manufacturing_industries/

Beyond Nolan’s Nine-stage Model - Evolution and Value of the Information System of a Technical Office in a Furniture Factory

383

Sakka, O., Millet, P.-A., and Botta-Genoulaz, V., 2010.

An OWL based ontology of SCOR model: a

prerequisite for strategic alignment. In: Proceedings of

the 8

th

international conference of modelling and

simulation – MOSIM’10 evaluation and optimization

of innovative production systems of goods and

services, Hammamet, Tunisia: Lavoisier, 1684–1693.

Schuh, G., Potente, T., Wesch-Potente, C., Weber, A. R.,

& Prote, J. P. 2014. Collaboration Mechanisms to

increase Productivity in the Context of Industrie 4.0.

Procedia CIRP, 19, 51-56.

Teubner, R. 2005. The IT21 Checkup for IT Fitness:

Experiences and Empirical Evidence from 4 Years of

Evaluation Practice. European Research Center fro

Information Systems (ERCIS), Working Paper nº 2.

Münster: Westfällische Wilhelms-Universität

Münster.

Thorp J. 1998. The Information Paradox: Realizing the

business benefits of information technology. Toronto,

Canada: MacGraw-Hill Ryerson.

van Wingerden, D. 2008. Benchmarking the

Organizational Benefits of IT: A Practical Approach

(Doctoral dissertation, Erasmus Universiteit).

Wigand, R. 1998. Information, Organization and

Management: Expanding Markets and Corporate

Boundaries. Chichester en al.

ICEIS 2017 - 19th International Conference on Enterprise Information Systems

384