Design of i-Fields System Component: Computer Model of

Oil-Recovery by Polymer Flooding

D. Zh. Ahmed-Zaki, S. T. Mukhambetzhanov and Т. S. Imankulov

Al-Farabi Kazakh National University, al-Farabi ave., 71, Almaty, Kazakhstan

Keywords: Polymer Flooding, Surfactant, i-Fields, Smart Fields, Parallel Program.

Abstract: This article describes the issues and approaches the design and development of distributed high-

performance system for analysis of oil fields within the i-fields (smart fields) concept. The system is based

on hydrodynamic model of collaborative filtering of oil, water, gas, polymer solution and the surfactant,

taking into account influence of temperature. Built a 3D numerical parallel algorithm and web-based

platform for data analysis and calculation on a supercomputer. Obtained distribution of the main

technological parameters: distribution of pressure, saturation of each phase, the concentration of surfactant

and polymer, and temperature.

1 INTRODUCTION

Nowadays there are many approaches to develop

software systems for the analysis and development

of oil and gas fields (software.slb.com, rfdyn.com).

But the problem of creating fields monitoring

systems in real-time, modelling and optimal control

of field development began to appear only in recent

years due to the development of information

technologies. Particularly interesting approach for

the development of information systems - smart

fields, i-fields, e-fields and other. These systems are

mainly aimed at solving problems of "continuous"

optimize of operations on oil field: location,

quantity, and planning new wells. For the

implementation of such advanced technologies in

large and complex oil and gas fields require detailed

research data on the methods of drilling / plug wells

(horizontal, inclined and multilateral), with sensors

(pressure, inflow, temperature, etc.) in the borehole

Figure 1: A “Closed-loop intelligent field” scheme (Smart

Fields Consortium, Stanford University, USA).

geophysical measurements. In this case, there is an

acute demand for the need of modelling and

monitoring in real time to aid decision making and

optimal management/exploitation involving the

latest equipment and hardware/software systems.

Synthesis of the above, in the form of

implementation of the "closed-loop intelligent

(smart) field" is shown in Figure 1

(smartfields.stanford.edu). As can be seen in the

figure, the cycle consists of two basic components:

planning / forecasting and modeling processes into

reservoir on oil field. In this paper, we consider it is

the second component. Within the framework of

implementation of these components, project authors

will design and develop distributed high-

performance analysis system of oil and gas fields

within i-fields concept with modern mathematical

models of three-phase flow in porous media and

computational algorithms with three-dimensional

visualization of data to monitor them in real time.

Surfactant and polymer flooding are the effective

chemical EOR methods. There are various

interactions between the surfactant and the reservoir

fluids, such as adsorption, interfacial tension,

wettability (Babalyan, 1983). Surfactants are used to

reduce the interfacial tension between crude oil and

reservoir water and increase the mobility of

"trapped" oil in the pore space. Polymer injection

method is used to reduce water mobility and

increase water viscosity. Decreasing the

permeability of the water phase increases flooding

510

Zh. Ahmed-Zaki D., T. Mukhambetzhanov S. and Imankulov T..

Design of i-Fields System Component: Computer Model of Oil-Recovery by Polymer Flooding.

DOI: 10.5220/0005572905100516

In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2015), pages 510-516

ISBN: 978-989-758-123-6

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

efficiency and significantly improves quality of

displacement (Lake, 1989; Sorbie, 1991). The paper

Imankulov, 2014 describe the problem of oil

displacement process by polymer injection, and

compares the results of numerical experiments using

gellan and polyacrylamide, a change in viscosity of

the aqueous phase is taken as a linear function and

does not depend on temperature.

At present, the combined methods of enhanced

oil recovery are used. One such method is surfactant

flooding in combination with water soluble

polymers. Surfactant and polymer are injected into

the reservoir, then, push oil to the production wells

by pumping water. This method shows higher

recovery rate comparing with using surfactant and

polymer alone (

Fathaddin

, 2011; Rai, 2013 ).

This work aims to study the mathematical model

of oil displacement by polymer-surfactant flooding,

which is considers the influence of temperature

effects and dependence of polymer/surfactant

solution viscosity on agents concentration and water

salinity. Development of sequential/parallel

computational algorithm for solution of 3D problem

using MPI and CUDA technologies.

2 MATHEMATICAL MODEL

2.1 Mathematical Model of Polymer

and Surfactant Flooding

Several physical and chemical processes influence

the properties of the polymer/surfactant and

polymer/surfactant solution. For example, viscosity

of injected solution depends on various factors, such

as reservoir temperature, concentration of

polymer/surfactant in solution and water salinity and

etc. The model considers following assumptions:

- the porous media and fluid are incompressible;

- gravitational forces are not taken into account;

- the two-phase flow (aqueous, oleic) is subject of

the Darcy’s law;

- water, polymer, surfactant and salt are fully

mixed;

- adsorption of the polymer affects only on the

relative permeability of the aqueous phase;

- dissolution of polymer and surfactant in oil is

very small.

Based on the above assumptions, we can write

the mathematical model of two-phase flow in porous

media.

Mass conservation equation for aqueous and

oleic phases (Akhmed-Zaki, 2012) is:

+

(

)

=

(1)

+

(

)

=

(2)

+

=1

where – porosity,

,

–water and oil

saturations,

,

- source or sink,

,

–

velocity of the water and oil phases, which is

expressed by the following law:

=−

(

)

, = , (3)

(

)

,

– relative permeability and viscosity of

fluids,

– absolute permeability.

Polymer and surfactant concentration and salt

transport equations can be written as (Babalyan,

1983):

+

+

=

(4)

(

+

)

+

+

(

+

=

(

+

)

(5)

(

)

+

(

)

=0 (6)

where

,

– polymer and salt concentrations in

aqueous phase,

,

–surfactant concentration in

aqueous and oleic phases,

,

– polymer and

surfactant adsorption functions,

,

,

–

polymer and surfactant coefficients.

Heat transfer equation:

(

1−

)

+

(

+

)

+

(

)

+

(

)

=

(

1−

)

+(

+

)

(7)

where

,

,

– specific heat of water, oil and

rock,

,

,

– density of water, oil and rock,

,

,

– coefficients of thermal conductivity.

Flory-Huggins equation can represent a

mathematical relation which describes the

dependence of water phase viscosity on

concentration of salt, surfactant and polymer. This

dependence, which takes into account temperature

changes can be written as (Flory, 1953):

=

1 + (

+

+

+

)

−

( −

)

(8)

=

1 −

( −

) (9)

Designofi-FieldsSystemComponent:ComputerModelofOil-RecoverybyPolymerFlooding

511

where

,

,

,

,

,

,

– nondimensional

constants.

−initial viscosity of oelic phase,

−

reservoir temperature.

Relative permeability curves are taken as

follows:

(

)

=

.

;

(

)

=(1−

)

.

The type of the polymer and surfactant

determines their adsorptions degree. Langmuir’s law

can represent the relation between adsorbed

polymer/surfactant and polymer/surfactant

concentration in the solution (Babalyan, 1983):

=

1+

where −Langmuir’s constant.

Permeability reduction factor

can be

described as follows (Wegner, 2012):

=1+(

−1)

- residual reduction factor.

Initial and boundary conditions are:

|

=

,

=

,

=

,

|

=

,

|

=

,

=

(10)

|

=

|

=

= 0;

=∙

;

=∙

;

−

+

∙

=

∙̃

; (11)

−

+

∙

=

∙̃

;

+

∙

=0;

Pressure equation obtained is by adding (1) and (2):

(

)

+

(

)

=0 (12)

Correctness of the proposed model was

confirmed by two stages of verification (Imankulov,

2014):

- comparison of numerical results with

laboratory experiments;

- and with results of calculations on

hydrodynamic simulator Eclipse 100.

2.2 Numerical Method

For numerical calculation, consistency of units and

order of variables are important. Therefore, a system

of equations (1) - (12) is converted to a

dimensionless form. To solve these equations, an

explicit scheme is used (Samarskii, 1989). First of

all, fluid properties and physical parameters of

reservoir are set. Further calculations are conducted

in the following order:

- distribution of pressure;

- saturation (by the known distribution of

pressure);

- distribution of salt, surfactant and polymer

concentrations;

- distribution of temperature in the reservoir;

- aqueous phase viscosity, depending on salt,

surfactant and polymer concentrations is

recalculated;

- aqueous phase permeability considering the

polymer adsorption is recalculated.

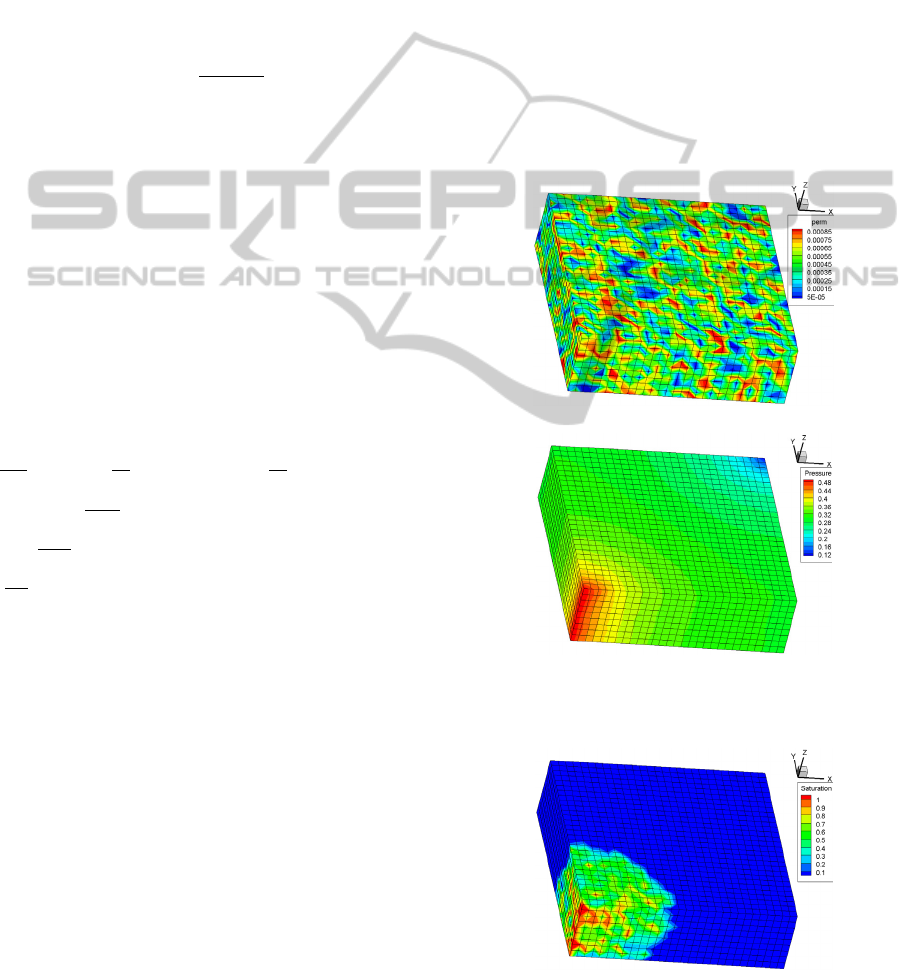

The results of numerical calculations for non-

isothermal oil displacement are shown in the

following Figures 2-7.

(a)

(b)

Figure 2: (a) Permeability field; (b) distribution of pressure.

Figure 3: Distribution of water saturation at different

moments of iteration times.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

512

Figure 3: Distribution of water saturation at different

moments of iteration times (cont.).

Figure 4: Distribution of the polymer concentration in the

aqueous phase at different moments of iteration time.

Figure 5: The distribution of the surfactant concentration

in the aqueous phase at different moments of iteration

times.

Figure 5: The distribution of the surfactant concentration

in the aqueous phase at different moments of iteration

times(cont.).

Figure 6: Distribution of the salt concentration in the

aqueous phase at different moments of iteration times.

Figure 7: The temperature distribution at different

moments of iteration times.

Designofi-FieldsSystemComponent:ComputerModelofOil-RecoverybyPolymerFlooding

513

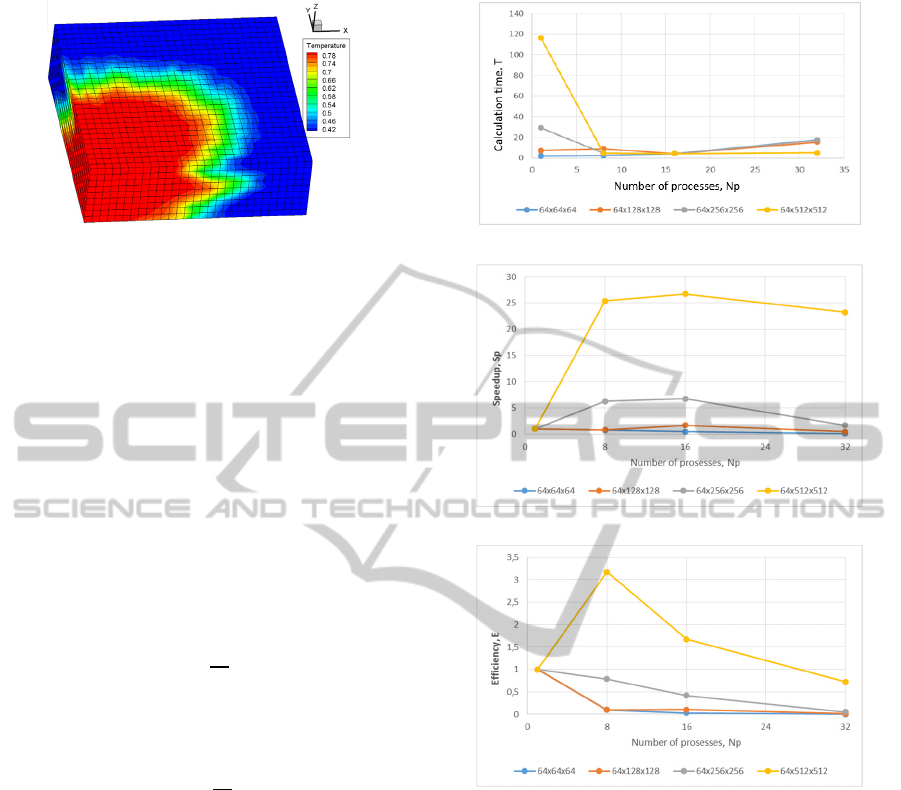

Figure 7: The temperature distribution at different

moments of iteration times (cont.).

For parallelization of this algorithm, the

computational domain is divided into partially

overlapping subdomains, calculations in which are

performed independently of each other. After each

iteration, it is necessary to make the exchange of

data at the boundaries of the subdomains (Matkerim,

2013). The above method was implemented using

MPI technology.

The speedup and efficiency of parallel algorithm

on the 64х64х64, 64х128х128, 64х256х256,

64х512х512 grids are investigated.

Speedup of parallel algorithm is estimated as the

ratio computing time on a single processor

to

computing time on p processors

:

=

the efficiency of parallel algorithm is estimated as

ratio of speedup to the number of processors :

=

As you can see from Figure 8, the computing time of

serial code very large in comparison with the

parallel code at large computational grids. Also, you

will notice that, when the number of processes

exceeds 16, speedup and efficiency of the algorithm

decreases. This is because an increase in the number

of processes is increases number of data exchanges

between processes. Therefore, the computing time

increases, since these exchanges are also takes time.

Accordingly, we can see that high efficiency can

only be achieved on large grids, as on such grids loss

of time on data exchanges between processes are not

significant.

(a)

(b)

(c)

Figure 8: (a) Calculation Time, Speedup (B) and

Efficiency (C) of Parallel Algorithm for Different Grid

Sizes and on Different Process Numbers.

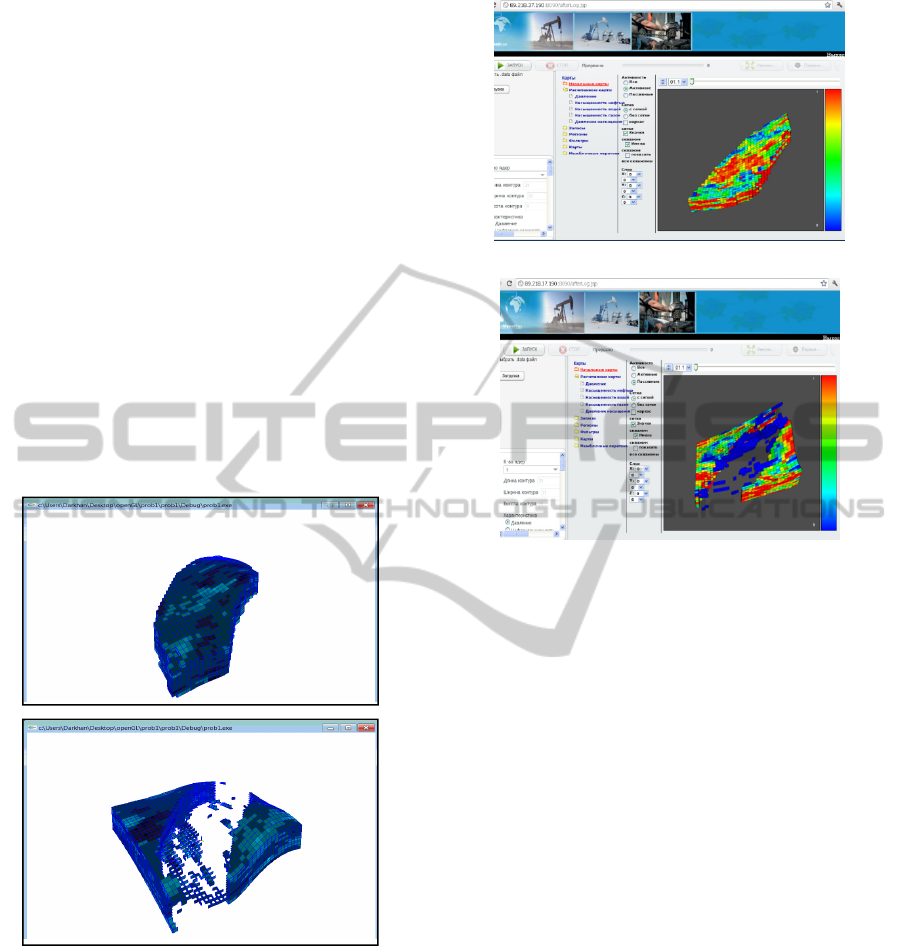

2.3 3D Web Hydrodynamic Simulator

The system represents interactive package for

analysis and estimation of technological problems of

hydrodynamic simulation of oil and gas fields. The

basis of the produced program complex the modern

scientific developments which allow to use

heterogeneous multiprocessing computer facilities at

their limit. Because of this it is possible to

demonstrate high efficiency of calculations. The

system is initially developed as an interactive

package - Web applications on the basis of client-

server architecture models of MVC – Model View

Controller type. The possibility of automatic

connection and start of calculations on a

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

514

supercomputer is presented. The user can observe

calculation results in real-time, manage calculation

process and also modify model online.

Visualization module of three-dimensional

reservoir loads the data from special format text

files, reads geological model from them and

provides visualization of this model in the form of

three-dimensional contour.

The visualization module is presented in two

ways:

1) As a desktop application which uses hardware

resources of the client computer and is not integrated

into the basic program. It is implemented using

OpenGL graphics platform and C++ programming

language (figure 9).

2) As a Web-module running on the server

(supercomputer) and partially using hardware of

graphics subsystem of client computer. Visualization

is carried out on the basis of WebGL graphical

technology, with JavaScript, HTML5 web-

technologies (figure 10).

Figure 9: Desktop application, a) active and b) inactive

blocks of field.

(a)

(b)

Figure 10: Web application, a) active and b) inactive

blocks of field.

To automatically connect and run calculations on

a supercomputer Java interface (MPJ-Express) with

the support of a hybrid parallelization on OpenMP

and MPI is developed

.

3 CONCLUSIONS

A mathematical model of oil displacement process

by polymer-surfactant injection is considered and

solved, taking into account the dependence of

solution viscosity on salt, surfactant and polymer

concentrations and where viscosity of both phase are

depends on temperature.

System of equations is solved using

implicit/explicit methods and following numerical

results were obtained: distribution of pressure,

saturation distribution of both phases, salt, surfactant

and polymer concentration and temperature

distribution in reservoir.

The module of polymer injection analysis of

distributed information system for analysis of oil

field development with operational monitoring in

real time and possibility of computing via remote

access or Internet.

Designofi-FieldsSystemComponent:ComputerModelofOil-RecoverybyPolymerFlooding

515

Proposed simulator has ability to calculate on

heterogeneous intercluster environment using

special NumGrid software.

The polymer injection process into the oil

reservoir for enhanced oil recovery can be modeled

using proposed simulator. Presented results shows

good consistence compared with results of the

hydrodynamic simulator Eclipse (Black Oil).

If you do not use chemicals, you can provide

little economic benefit. But the rejection of the

development of such schemes does not lead to the

desired oil recovery factor. On the one hand,

increasing the concentration of chemicals leads to a

non-linear increase of oil production, and on the

other hand, increase the costs, because the used

chemical reagents are not cheap. Consequently, it is

necessary to choose the optimum concentration of

reagents, for economic efficiency.

REFERENCES

Akhmed-Zaki D. Zh., Danaev N. T., Mukhambetzhanov S.

Т., Imankulov T., 2012. Analysis and Evaluation of

Heat and Mass Transfer Processes in Porous Media

Based on Darcy-Stefan's Model. ECMOR XIII,

Biarritz, France, 10-13 September, 122.

Babalyan G. А., Levy B. I., Tumasyan А. B., Khalimov

E.М., 1983. Oilfield development using surfactants.

Мoscow: Nedra.

Matkerim Bazargul, Darhan Akhmed-Zaki, Manuel

Barata, Development High Performance Scientific

Computing Application Using Model-Driven

Architecture, Applied Mathematical Sciences, Vol. 7,

2013, no. 100, 4961 – 4974.

Fathaddin M.T., Nugrahanti A., Buang N.P., Elraes K.A.

Surfactant-polymer flooding performance in heteroge-

neous two-layered porous media. IIUM Engineering

Journal, Vol 12, No 1, – 2011, – P. 31-38.

Flory P.J., 1953. Principles of polymer chemistry. Cornell

University Press.

Imankulov Timur, Danil Lebedev, Kanat Aidarov, Olzhas

Turar. Design of HPC system for analysis the gel-

polymer flooding of oil fields. Contemporary

Engineering Sciences, Vol. 7, 2014, no. 27, 1531-

1545.

Lake L.W., 1989. Enhanced oil recovery. New Jersey:

Prentice Hall Inc.

Rai K, Johns T. R., Delshad M., Lake W. L., Goudarzi A.

Oil-recovery predictions for surfactant polymer

flooding. Journal of Petroleum Science and

Engineering. – № 112 (2013), – P. 341–350.

Samarskii А. А., Gulin А. V., 1989. Numerical methods.

Moscow: Nauka.

Sorbie K. S., 1991. Polymer improved oil recovery. Boca

Raton: CRC Press.

Wegner J., Ganzer L., 2012. Numerical simulation of oil

recovery by polymer injection using COMSOL.

Proceeding of the COMSOL conference, Milan.

www.software.slb.com/products/foundation/Pages/eclipse.

aspx.

www.rfdyn.com/ru/technology/

www.smartfields.stanford.edu/about.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

516