The Use an Electric Vehicle as a Power Source

Kristýna Friedrischková, David Vala and Bohumil Horák

VSB – Technical University of Ostrava, 17.listopadu 15, Ostrava Poruba, 708 33, Czech Republic

Keywords: Electric Vehicle, Home Electric Grid, Traction Battery, Transfer Energy.

Abstract: Electric cars are becoming a serious competition for the common artificial fuel driven cars in small city

agglomerates and short distances. With the new developments on the field of state-of-art accumulators,

electric cars are becoming much more that just a single use items, but can serve a number of roles. One of

them is possibility to use excessive energy stored in the batteries and its rerouting from the car to other

systems (such as offices, family houses, lighting etc.). This brief article is making a suggestion on usage and

lifecycle of traction batteries, interconnection of the house and its electric car. Additionally, logic and

control of such a transfer processes is put to the test for conclusion, that the electric car can be used as both

the mean of transportation as well as energy source while in the meantime its primary function is not

dampened at all.

1 INTRODUCTION

Due to increasing number of cases where local

energy sources are disrupted by climatic changes or

by due to human interventions, there is ever

increasing need for independent energy and heat

sources. Also related to those, there is a high

demand for "clean energy sources" and small energy

producing units that are capable of sustaining local

establishments, such as family houses etc. Hand in

hand with these demands, there is also a pressing

need to properly store unused energy for later usage

by the residents or users.

1.1 Electric Energy

Electrical energy for charging electric vehicles can

be removed from the public grid or the local

(domestic) alternative and renewable sources.

The most common alternative and renewable

sources of electricity are photovoltaic systems. The

cost of acquisition is continually reduced and impact

on the environment in terms pollution CO

2

is

minimal in the active part of their lives.

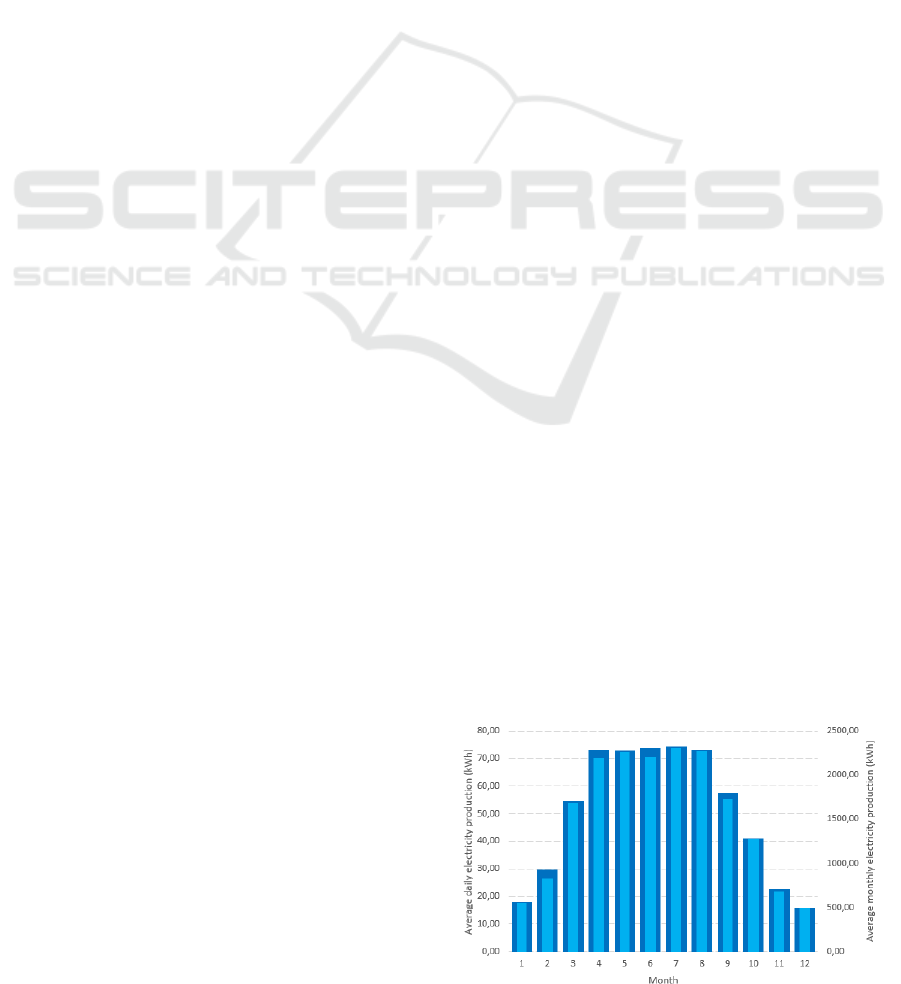

1.1.1 Design PV Plant

During the design of the PV plant we need to

establish basic facts as a surface roof, orientation,

angle of the panelling, type panels and their

efficiency and power. The design monocrystalic PV

plant is on the roof library, Technical University of

Ostrava (49.8314019N, 18.1622161E).

We need to use the surface of the roof (96m

2

),

orientation (south) and angle of the panelling (35°).

In case of installation of the panels with power of

120 Wp we will need 160 pcs. of them and installed

power will be 20 kWp. Interactive Maps, 2015.

As it is obvious from the previous data,

photovoltaic systems are producing energy during

times we cannot utilize it directly and would be

wasted (9 AM to 6 PM). Therefore we need

technologies that would store this energy with

minimal losses.

For accumulation of gained energy, we can use:

Electrochemical batteries;

Capacitors and supercapacitors;

Byproduct (ex. heat, cold, hydrogen, etc.);

Mechanical and hydraulic accumulators.

Figure 1: Average electricity production PV plant.

Interactive Maps, 2015.

164

Friedrischkova K., Vala D. and Horak B..

The Use an Electric Vehicle as a Power Source.

DOI: 10.5220/0005532401640170

In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2015), pages 164-170

ISBN: 978-989-758-122-9

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

1.1.2 Family House Energy Consumption

Energy consumption of family house is dependent

on many different home appliances, but due to better

access to state of the art products, consumption can

be better distributed and lowered (side demand

management).

Days when most consumption was created by

heating and water management are over, almost 50%

of the current consumption is created by home

appliances that are becoming more and more

common in most homes. Some of them, like a

fridge, needs to be turned on and connected 24/7,

others can be connected when needed (oven,

microwave and others). Haluza, M., TZB info, 2012.

Figure 2: Graphical balance of the consumption.

As it was said before, some appliances needs to

be plugged in all the time (fridge, freezer, alarm

etc.), while others are used only when needed or

allowed by the user or the technology (side demand

management).

Figure 3: The consumption appliances - washing machine.

Due to connect households to a three-phase

network, the individual phases are measured

separately so we can decipher the individual electric

circuits. Together with the schedule of individual

daily tasks that depend on electricity (appliances),

can be decipher consumption relatively detailed.

Channel 1 measured - kitchen appliances and

lighting equipment, channel 2 - heating, channel 3 -

hot water. Friedrischkova, K.,Workshop, 2014.

Customs and behavior of the members of

particular household differs during workdays (most

consumption happens during 2 PM to 8PM) and

Figure 4: Consumption in house with 4 family members.

Customs and behavior of the members of

particular household differs during workdays (most

consumption happens during 2 PM to 8PM) and

weekends (most consumption happens during 7 AM

to 12 AM). Friedrischkova, K.,Workshop, 2014

The weekly consumption in house with 4 family

members is average 25kWh.

1.1.3 Electric Vehicle

In connection with this main idea, research and

development was conducted during the period of

2009 - 2012, involving commercial co-investigators,

on electric drive unit. This project included four

prototypes of vehicles (K0-electric vehicle for

suburban traffic, K1- electric vehicle for long range,

K2 - electric vehicle with Range Extender to extend

the range, K3 - hybrid vehicle, into which it is

possible to build in various types of sources

(batteries, range extender for LPG, CNG, petrol,

diesel or hydrogen)). Horak, B., Proceedings of the

14th International Scientific Conference Electric

Power Engineering 2013.

The implemented experiments then

demonstrated that vehicles consume an average of

10kWh/100km.

Elaborated study on transport services in Ostrava

showed that the average vehicles daily driving

distance is up to 50km. The remaining energy

(14kWh) in a vehicle can be used for other purposes.

Figure 5: A prototype electric vehicle KaipanVoltAge K0.

TheUseanElectricVehicleasaPowerSource

165

Figure 6: Consumption of electricity electric vehicle

depending on the distance and temperature.

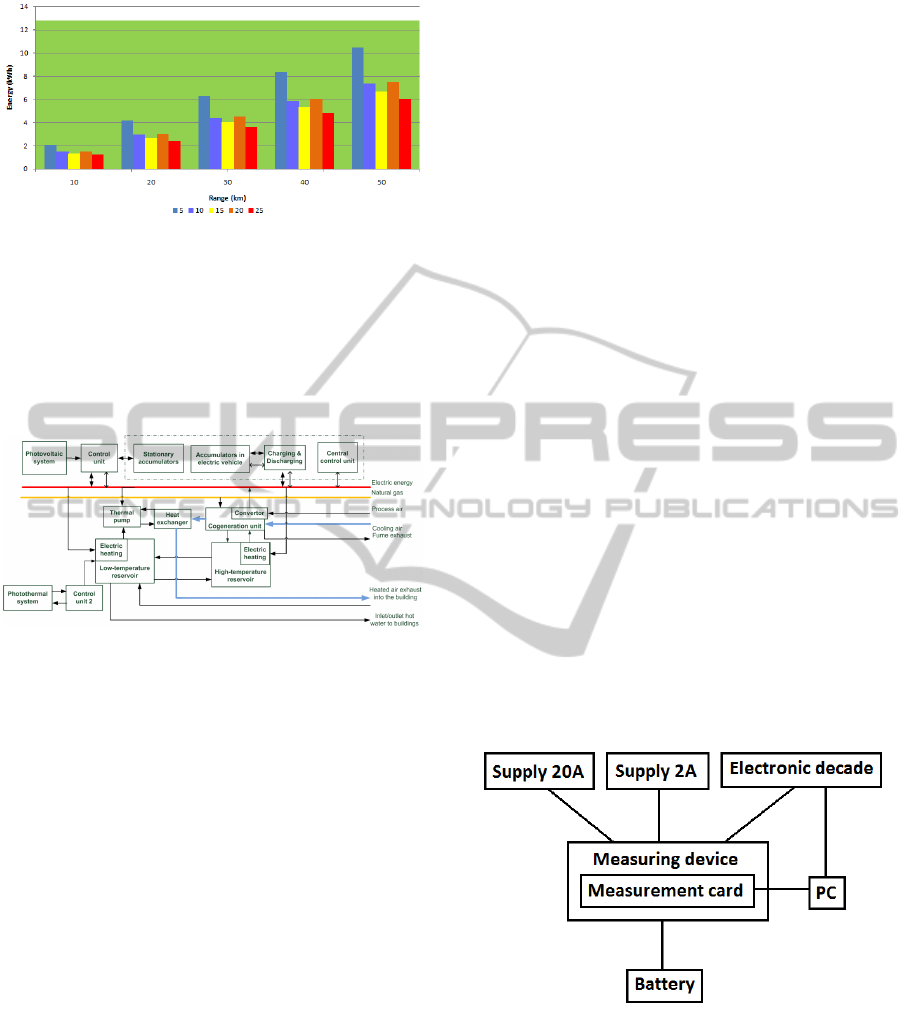

1.1.4 Energy Implemented Household

These alternative sources covered own consumption

of the house to more effectively manage energy

processes in the household (washing the dishes in

the dishwasher, laundry, water heating, etc.).

Figure 7: Block diagram of the concept of energy-

independent family house.

This control requires a certain amount of

prediction on the side electric vehicle and

consumption household. This control system should

to avoid unwanted situations which could endanger

or limit the functionality of named household.

The consumption in a household can be

planning. This system is called Side Demand

Management (SDM) and allows the usage

management by postponing consumption.

Friedrischkova, K.,Workshop, 2014.

2 REALIZATION

The use electric vehicles as a backup energy source

for houses requires high quality and stable battery.

The most commonly traction batteries the used in

electric vehicles are Lithium Iron Phosphate.

Phosphate based technology possesses superior

thermal and chemical stability which provides better

safety characteristics than those of Lithium-ion

technology made with other cathode materials.

Lithium phosphate cells are incombustible in the

event of mishandling during charge or discharge,

they are more stable under overcharge or short

circuit conditions and they can withstand high

temperatures without decomposing. When abuse

does occur, the phosphate based cathode material

will not burn and is not prone to thermal runaway.

Phosphate chemistry also offers a longer lifecycle.

Phosphates significantly reduce the drawbacks of

the Cobalt chemistry, particularly the cost, safety

and environmental characteristics. Once more the

trade off is a reduction of 14% in energy density, but

higher energy variants are being explored.

Due to the superior safety characteristics of

phosphates over current Lithium-ion Cobalt cells,

batteries may be designed using larger cells and

potentially with a reduced reliance upon additional

safety devices.

The performance of Lithium Ion cells is

dependent on both the temperature and the operating

voltage. If thresholds are exceeded may be partially

or permanent damage to the cells or even their

destruction. WOODBANK COMMUNICATIONS,

2005.

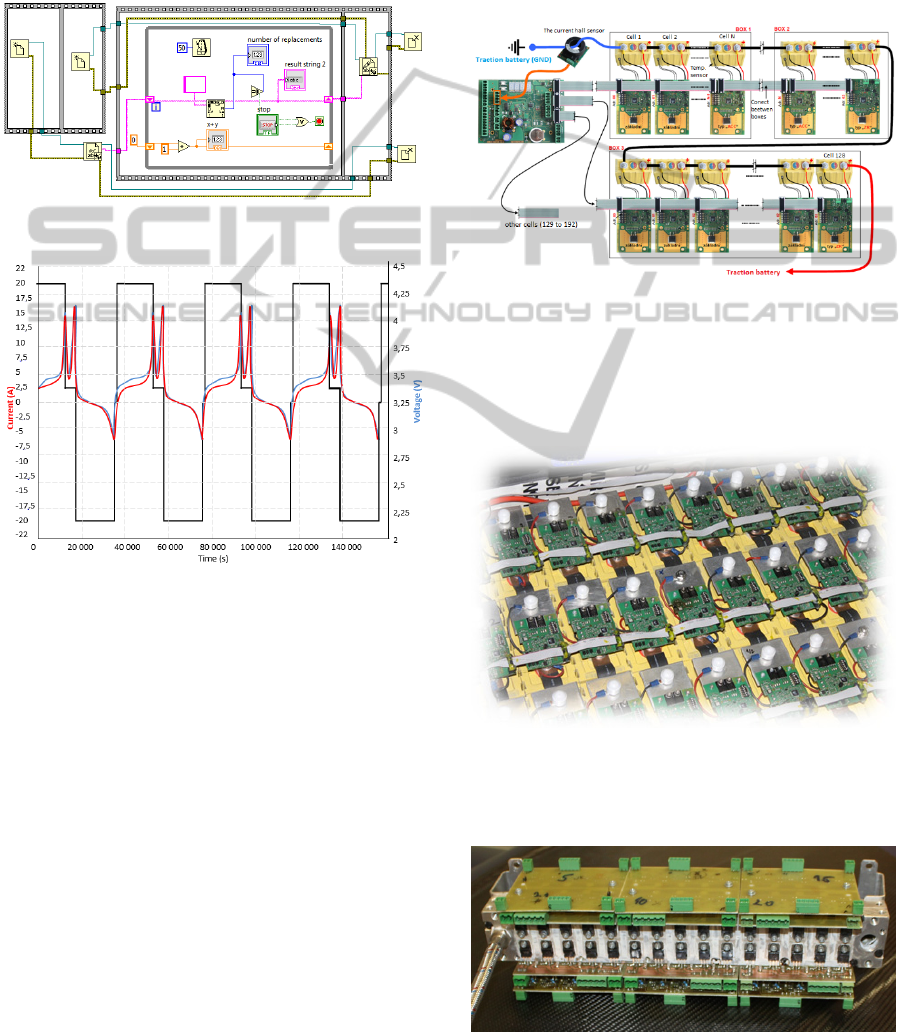

2.1 Testing the Battery Cell LiFePo

Testing of the battery is performed during cyclic

charging and discharging while balancing the

system. Use it to determine the number of cycles the

batteries hold until they have the appropriate

characteristics. It consists of laboratory resources,

electronic measuring decade and computer.

Figure 8: Block diagram testing devices for charging and

discharging batteries.

The testing device serves as charging and

discharging power through electronic decade. One of

the charging sources has to charge using the large

current and a second small current. Charging a small

current is used for charging multiple batteries and is

only used to recharge the batteries when charging

and battery balancer has limits. Discharge electronic

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

166

decade can be firmly set on the discharge current or

adjusted continuously according to the required

parameters during the discharge.

The process control computer is used to program

measuring card in LabVIEW. Measuring card

controls the measuring device and the relay to

switch between charging and discharging of the

battery.

KAZARIK, J., 2010.

Figure 9: The measurement program for testing batteries.

Figure 10: Lifetime battery cells.

On the Figure 10 is showing that charging has

two parts - charging of battery and balancing of

battery. For charging 9 Amps were used from mains

(i.e 2 kW - limited by local power net). After the

first, cell of traction battery charged to charging

voltage (in this case 3.8V) the charger was switched

by balancing subsystem to balancing mode (i.e less

than 2.5A) next it is possible to observe cyclical

interruption of balancing current. This is caused by

necessity of heat transfer from balancing module to

the cooling medium (air) and also give a time to

chemistry of battery to better absorption of energy

(pulse charging).

Furthermore, long-term tests of the battery cells

were performed in order to verify of capacity

decrease by 10% after 3000 cycles which was

declared by manufacturer.

One of the main things extending the life time of

the battery is a battery management system.

2.2 Battery Management System

One of the main functions of the BMS is to keep the

cells operating within their designed operating

window. This is not too difficult to achieve using

safety devices and thermal management systems. As

an additional safety factor, some manufacturers set

their operating limits to more restricted levels

indicated by the dotted lines. MGM COMPRO.

Figure 11: Battery management system in electric vehicle.

MGM COMPRO.

There is however very little the BMS can do to

protect against an internal short circuit. The only

action that can be taken to protect it, is strict process

control of all the cell manufacturing operations.

Figure 12: Installed BMS.

BMS systems developed by the company MGM

compro didn’t fulfill function properly due to poor

cooling system.

Figure 13: BMS VSB TUO water cooling.

TheUseanElectricVehicleasaPowerSource

167

BMS system designed for VSB Technical

University of Ostrava is cooled by water and thus

there is no overheating of the control elements of

balance units.

Individual self-balancing / measuring units are

connected to the individual battery cells and are

controlled by the basic management unit, which

constantly communicate.

The control unit, besides controlling balancers,

also mediates the measurement of voltage,

temperature, currents, safety disconnect,

communicate with charger, communication with the

controller (s) engines, communication with the

operator.

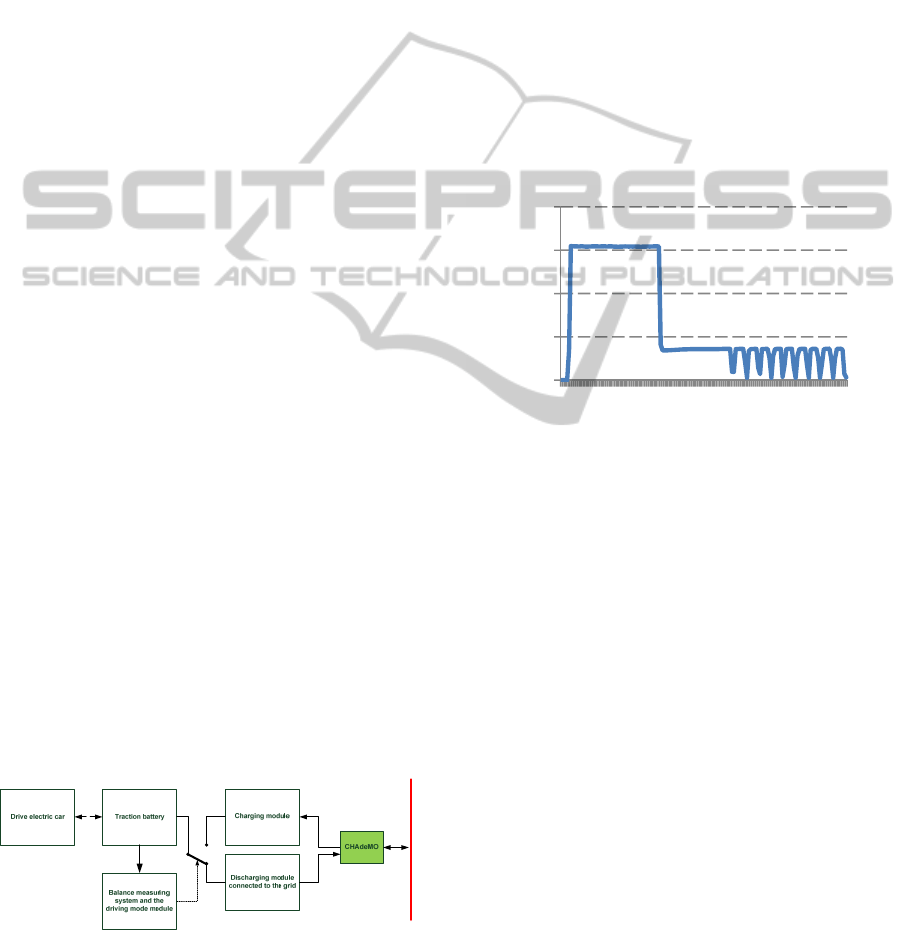

2.3 Connections Electric Vehicle with

House

Depending on the usage, renewable and alternative

sources a very good aspect of electric vehicle

traction battery to store excessive energy. Systems

placed in both automobiles and houses are

communicating and as such allowing for effective

charging and discharging of traction batteries based

on the needed range of the car, supplementary need

of the house grid and such.

For this to be possible bidirectional transmission

of electric power it is necessary to use a special

protocol to be integrated into components that can

be deployed in both electric and house system. One

possibility is to use commercially available

CHAdeMO protocol.

This protocol ensures transmission of DC

electrical power from accumulators in a electric

vehicle to the houses electrical grid, where the

energy is converted to AC for home usage.

These electric vehicles are carrying sophisticated

route planning system that includes advanced

measuring, computing and storage. This system is

able to guarantee possibilities of using this vehicle

for transportation even if the vehicle is connected as

part of energetic system of the building and part of

its energy is discharged to cover energy demands.

Figure 14: Block diagram of the internal concept electric

vehicle and its connection to the electricity grid house.

Through the CAN communication network

which is included in CHAdeMO standard, data are

transferred from the vehicle to the building control

system which then route the energy as required. This

control system is able to cover all energy demands

of building by combining different renewable

alternative energy sources and electrical appliances

without necessity to be connected to the public grid.

2.4 Charging of the Electric Vehicle

Traction batteries in the electric vehicle are equipped

by integrated charger and balancing subsystem to be

able to store electric energy. This type of charger has

been subjected to series of tests in severe conditions

including eg. EMC, EMI, electric safety etc. This

charger is able to charge up 100A to 100 LiFePo cell

battery pack.

Figure 15: Charging electric vehicle.

In our experiment,the current for charge was 9A.

It is optimal for the used battery (LiFePo - 40Ah)

and a typeBMS of electric vehicles KaipanVoltAge

K0.

2.5 Discharging of the Electric Vehicle

to the Grid

The concept described above was experimentally

verified by the connection of electric vehicle to the

infrastructure of family house. Measurement was

aimed to different setting of discharging circuit and

mainly on several limitations of discharging of

traction battery of electric vehicle. For the testing the

minimum voltage has been setup for the traction

battery to the 319 V and maximum power to the

mains to the 2 kW

The graph shows the progress of power

limitation depending on the state of stress on the

battery.

0

3

6

9

12

9:38 10:08 10:38 11:08 11:38 12:08

Current (A)

Time (hh:min)

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

168

Figure 16: Discharging electric vehicle.

3 CONCLUSIONS

Usage of the new technologies and energy sources

are a viable way for the people to get rid of the

dependancy on international companies and state

regulatory charges.

Weather profile, property size, location,

orientation, these are just few things we need to take

into account and together with appliances and

behavioral statistics of the occupants it is much

easier to create a proper list of energy sources and

their optimal implementation. Most common method

of self sustained renewable energy is photovoltaic,

but with its impractical energy generation times, we

need to establish a way to store that energy for later

use in more convenient time schedules. Part of the

way to increase efficiency is to combine storage of

the energy with backtracking it back into public

electrical grid.

Most convenient method is backtracking of the

energy into the public grid, but only in case, that the

buyout price is higher than selling price.

Unfortunately it is not a rule and different countries

have different approach to renewable energy sources

that delivers into the public grid, which needs to be

taken into account. We also need to understand that

backtracking is not without its own risks and it can

easily affect whole parts of the public grids if done

improperly. There are lot of cases of public grid

overloads and pullouts due to uncontrolled energy

distribution from photovoltaic sources and this

problems are multiplying at an alarming rate these

days.

One of the way to utilize all the generated energy

is to store it into accumulation units. We can find a

lot of possible candidates for this function, starting

with electrochemical accumulators, capacitors,

supercapacitors up to the byproducts such as

hydrogen, heat or cold. All of the variants above are

a significant financial investments and they all bring

their own issues, most commonly energy losses.

Thanks to the boom of automotive industry, we

could say, that most advanced and also easily

accessible are electrochemical accumulators that in

state of the art can go through up to 8k cycles with

20% capacity drop and without memory effect.

In case of combined ecological and economical

approach we can go as far as purchase of the

electromobile, that when price considered surpasses

the standard middle class vehicle, but its running and

maintenance costs are very low and has no demands

on special treatments. Also it can be used as a

supplemental accumulation unit for the family house

that, in case of the implementation of the

sophisticated control system, will then operate both

as consumer and supplier of the energy into the

family house grid and can compensate for energy

generation inconsistencies.

Some experts do claim that this way of storing

energy into mobile solutions is contra productive,

because of the fact, that in most times that there is an

energy production peak, the electromobile is usually

away from the house. In this case we need to take

into consideration fact, that both car and houses

energy center can be in constant communication via

remote access. Only necessity in this case is the

connection of the car into public grid, which then

may be used as a "transfer medium".

Obvious disadvantage of this technology is its

entry costs, that varies based on the technologies

used, where return rate is from 6 to 12 years or

more. Also a big issue may be laws and regulations

of the particular country, as well as common

approach to this technology.

ACKNOWLEDGEMENTS

This project was supported by European sources

within the project Pre-seed activities VSB-TUO II -

Energy, CZ.1.05/3.1.00/13.0317. And the work was

partially supported by Grant of SGS No. SP2015/42,

VSB - Technical University of Ostrava, Czech

Republic.

REFERENCES

Horak, B., Minarik, D., Friedrischkova, K., Vala, D.,

Kazarik, J.: The development of drive units for electric

cars KaipanVoltAge. Proceedings of the 14th

International Scientific Conference Electric Power

Engineering 2013. VŠB – TU Ostrava 2013. 978-80-

248-2988-3.

0,0

0,4

0,8

1,2

1,6

2,0

2,4

1

13

25

37

49

61

73

85

97

109

121

Power to the grid (kW)

Sample

TheUseanElectricVehicleasaPowerSource

169

Urban, H.: Eigenverbrauchimhaushalt und integration

eines E-Fahrzeuges, EMobile plus solar Nr.89/2013

page 27-32. Schletter GmbH [cit. 2014-02-12].

Available from: http://www.schletter.de.

Haluza, M., Macháček, J.: Spotřeba elektrické energie

domácností, predikce a potenciální úsporypomocí

BACS. TZB info: Technická zařízení budov [online].

7.5.2012, [cit. 2014-07-15]. Available from:

http://elektro.tzb-info.cz/8570-spotreba-elektricke-

energie-domacnosti-predikce-a-potencialni-uspory-

pomoci-bacs.

Polanecký, K., Bursa, J.: Jak využívat obnovitelné zdroje

energie, Praktický rádce pro domácnost a obce. 2002

[cit. 2010-05-13]. ISBN 80-902823-6-9.

桥 许

, (names of authors). Modular

charging/discharging system of power battery pack of

multifunctional electromobile [patent].Patent, CN

102025182 A. Uděleno 20.4.2011. [cit. 2014-05-12].

Available from: http://www.google.com/

patents/CN102025182A?cl=en.

Friedrischkova, K., Horak, B., Dočekal,T.: Management

of energy systems combined with renewable or

alternative energy resources.Ph.D. Workshop of

Faculty of Electrical Engineering and Computer

Science. Workshop doktorandů Fakulty

elektrotechniky a informatiky. VŠB - TU Ostrava

2014.

MGM COMPRO, Srovnání balančních systémů.

[6.1.2012]. Available from: http://mgm-

compro.cz/pdf/balancery-srovnani-d120507.pdf.

WOODBANK COMMUNICATIONS LTD,.The

electropaedia [online]. 2005. vyd. South Crescent

Road, Chester, CH4 7AU, (United Kingdom), 2005

[cit. 2015-01-31]. Available from:

http://www.mpoweruk.com/index.htm.

M. Swierczynski, D. Stroe, and et al., “Field tests

experience from 1.6MW/400kWh Li-ion battery

energy storage system providing primary frequency

regulation service,” IEEE 4th European Innovative

Smart Grid technologies, in press, 2013.

B. Dunn, H. Kamath, and et al., “Electrical energy storage

for the grid:a battery of choices,” Science, pp. 928–35,

2011.

Swierczynski, Maciej, Ana-Irina Stan a Remus

Teodorescu. 2013. (6825 - 6830): 6. Available from:

http://ieeexplore.ieee.org/xpl/login.jsp?tp=&arnumber

=6700262&url=http%3A%2F%2Fieeexplore.ieee.org

%2Fiel7%2F6683943%2F6699103%2F06700262.pdf

%3Farnumber%3D6700262.

WEI, Liu. 2013. Introduction to Hybrid Vehicle System

Modeling and Control [online]. The book. Canada [cit.

2015-05-12]. ISBN 978 - 1 - 118 - 30840 - 0.

Available from:

https://books.google.cz/books?id=sVgVbG5WtYkC&

pg=SA5-PA51&lpg=SA5-

PA51&dq=SOC+operating+window&source=bl&ots=

oQktt-

Rhpe&sig=1LtCyjxo2lFDAL7iESge6MtHxjc&hl=cs

&sa=X&ei=XzZQVaDWLIGzUMurgdgO&redir_esc

=y#v=onepage&q=SOC%20operating%20window&f

=false.

Conducted By Group Wps4 - 1050. 2011. Accelerated

Life Testing And Life Prediction Of Lithiu Ion

Batteries Connected To Wind Turbine: Accelerated

life testing and life-time prediction of Lithium Ion

batteries connected to Wind Turbine [online]. Aalborg

University [cit. 2015-05-12]. Dostupné z:

http://projekter.aau.dk/projekter/files/52684684/Repor

t_WPS4_1050.pdf. Student Report. Aalborg

University.

Photovoltaic Geographical Information System –

Interactive Maps [online]. 2015 [cit. 2015-04-15].

Available from:

http://re.jrc.ec.europa.eu/pvgis/apps4/pvest.php.

Kazarik, J., Slanina, Z., Vala, D., Long - Time Battery

Testing. VSB – TU Ostrava, Faculty of Electrical

Engineering and Computer Science, Department of

Cybernetics and Biomedical Engineering, 17.

Listopadu 15, Ostrava - Poruba, Czech republic, 2010.

ICINCO2015-12thInternationalConferenceonInformaticsinControl,AutomationandRobotics

170