Micromachining of Materials using Femtosecond Laser Pulses

A Parametric Study

K. Garasz

1

, M. Tański

1

and J. Mizeraczyk

1,2

1

Institute of Fluid-Flow Machinery Polish Academy of Sciences, Gdansk, Poland

2

Faculty of Electrical Engineering, Gdynia Maritime University, Gdynia, Poland

1 RESEARCH PROBLEM

In the presented research, I have undertaken the

problem of femtosecond laser interactions with

matter, under various laser pulse parameters and

considering a wide group of materials, i.e. metals,

plastics, graphene, silicon. There is a considerable

interest in the precise material micro and

nanomachining with ultrashort laser pulses. It is well

established, that the quality of ablation process with

femtosecond laser is much better than when using

long pulse lasers. The use of femtosecond laser

pulses creates an attractive opportunity for high

quality micromachining of many groups of materials

and opens an interesting field in fundamental

research. The objective of the fundamental research

proposed within this research is a complex study of

the physical phenomena occurring during short-

pulsed (femtosecond) laser interactions with matter.

Although the research topic itself is very popular in

the scientific community, it is relatively little

elucidated. A better examination of the effects of

electromagnetic irradiation on the materials in the

femtosecond regime will provide a better

understanding of the subject. The experimental

results obtained from this project and theoretical

considerations will provide a verification of the

existing theories on laser-matter interactions.

Additionally, the experimental investigations will be

carried out on novel materials, i.e. graphene.

I have specifically taken under investigation the

laser ablation phenomena, which occurs during

a highly energetic laser irradiation of the material

and results in detachment of microparticles from the

material. The physics of the ablation process in an

ultrashort laser pulses regime differs from the

ablation caused by the long (nanosecond and

picoseconds) laser pulses. The nature of the process

is more complex with the short pulses and the

complete, research based understanding of the

phenomena is not available yet.

2 STATE OF THE ART

Since the development of mode-locked lasers,

ultrashort pulse durations became available,

allowing measurements in the femtosecond range.

The next significant advance in laser technology was

the development of chirped pulse amplification

(CPA) technique (Strickland and Mourou, 1985;

Mourou, 1997). Pulse energies in the mJ range are

easily obtained via CPA. The CPA technique also

allows the pulse duration to be varied from a few

femtoseconds to even nanoseconds, while keeping

all other beam parameters constant. Through this

technique, (Liu et al., 1997), studied the ablation

dynamics with pulse width varying from 10 ns to

100 fs and observed a decrease in the ablation

threshold with decreasing pulse duration. However,

the details of the physical mechanisms behind

femtosecond laser ablation were still far from

complete understanding.

A numerous groups studied the ablation

processes analytically and numerically. Many

models have been proposed to explain various

aspects of the femtosecond ablation process

including: ultrafast laser pulse absorption by solid

targets, femtosecond heating, expansion, stress

generation, defect capture and formation of periodic

surface structures on surfaces (Anisimov et al.,

1999; Peterlongo et al. 1994, Emelyanov and Babak,

2002).

The experimental and theoretical investigations

lead to some improvement in the physical

understanding of the ultrafast laser ablation process.

The dynamics of the ablation process can be roughly

divided into several stages: energy absorption,

energy transfer to the lattice and subsequent material

removal. The first step of the ablation process is

deposition of energy into the material. The primary

absorption mechanism involves excitation of

electrons from the valance to the conduction band

and free carrier absorption. The interband excitation

can occur through nonlinear processes, such as

3

Garasz K., Ta

´

nski M. and Mizeraczyk J..

Micromachining of Materials using Femtosecond Laser Pulses - A Parametric Study.

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

multiphoton and avalanche ionization, with high

enough laser intensity. Nonlinear absorption is very

important in femtosecond interaction due to the high

intensity of the incoming radiation (Sokolowski-

Tinten and Von der Linde 2000). During the laser-

mater interaction all of the processes occur

simultaneously and it is difficult to estimate the

contribution of each one. Due to the complexity of

the process, it is also difficult to calculate or

measure the effective penetration depth of the

radiation.

The energy transfer from electrons to the lattice

occurs via carrier-phonon scattering on a timescale

estimated from several hundred femtoseconds to

a few picoseconds, depending on the material. Since

the electrons and lattice are not in equilibrium, this

situation is often described by a two temperature

model, where a distinction is made between the

electron and the lattice temperature (Chichkov et al,

1996). The energy transferred to the lattice leads to

rapid thermal or nonthermal melting (Tom et al.,

1988). Since the timescale for mass transport is

significantly longer than for non-thermal or even

thermal melting, the melted material is left at near

solid state densities and a high initial temperature.

The subsequent processes of material removal have

been described in terms of transient thermal

processes. Following melting, the hydrodynamic

expansion of the ablated material begins a few 100

ps after the initial excitation (Sokolowski-Tinten et

al., 1998). In spite of numerous investigations the

fundamental mechanisms leading to the material

removal are still rather poorly understood. Several

different ablation mechanisms were identified in

theoretical investigations including: spallation,

explosive boiling and vaporization (Zhigilei and

Garrison, 2000; Perez and Lewis, 2002; Shafer et al.,

2002, Ivanov and Zhigilei, 2003).

Spallation occurs at a fluence slightly exceeding

the ablation threshold, and refers to ejection of

a complete layer of material induced by material

fracture due to internal stress buildup brought on by

constant volume heating. At a higher fluence, or in

materials where spallation might not apply, the

expansion of material can occur through phase

explosion. In phase explosion, the melted material

enters a liquid-gas metastable state during expansion

and homogenous nucleation of gas bubbles sets in,

leading to formation of a heterogeneous phase of gas

and liquid droplets. Phase explosion is believed to be

the primary mechanism in femtosecond ablation

below the threshold for plasma formation (Perez and

Lewis, 2003). At a high enough excitation fluence

the surface layer of the material can be completely

atomized and material removal proceeds by process

vaporization.

The entire ablation process occurs on time scales

of several tens ns. Ablation experiments are usually

performed with laser beams that have a near

Gaussian spatial profile, therefore energy deposition

varies across sample surface.

The ablation process mechanisms briefly

described above depends, on the one hand, on the

laser radiation parameters, such as pulse duration,

wavelength, pulse energy, repetition rate or

irradiation time, and on the other hand – material

properties, i.e. absorption coefficient or thermal

conductivity (Chichkov et al, 1996).

In laser – irradiated material sample, a various

features, such as crater profiles, ablated volume,

local changes in crystallography and chemistry,

surface modifications can be related to various

dynamical mechanisms and the ablation threshold

and ablation rates can be readily obtained from the

analysis of the final state of material. Together with

a detailed observation of the laser generated plasma

plume during ablation, the results of the proposed

research project will provide a complex

understanding of the laser-matter interaction

mechanisms in the ultrashort pulse region.

3 OUTLINE OF OBJECTIVES

As previously mentioned, the physics of laser

ablation is strongly dependant on the material type

and is still an object of interest of many research

groups worldwide. It has been established, that the

character of the physical mechanisms occurring

during the laser ablation is different for the typical,

often investigated materials, such as plastics or thin

metal foils, and different in case of specific or novel

materials, such as graphene or silicon. With these

non-typical materials, the character of laser-matter

interactions doesn’t match the theoretical

explanations found in the literature.

Exploring the physical mechanisms during laser

irradiation is crucial for the full understanding of the

laser ablation phenomena. In the ultrashort pulse

region, the most significant mechanisms are: liquid

phase explosion due to the heterogenic and

homogenic heating, due to the subsurface heating

and the ablation plasma interactions with the

material surface in so called Knudsen layer. Apart

from the liquid phase ablation, the phenomena can

also occur through direct sublimation. In that case,

the most important ablation mechanisms are:

spallation, fragmentation, charge separation due to

PHOTOPTICS2015-DoctoralConsortium

4

avalanche and multiphoton ionization and coulomb

explosion. The contribution of these particular

mechanisms depends on the laser radiation

parameters and material properties. Because of the

complexity of the ablation process, a complete

theory describing the laser-matter interactions in

ultrashort pulse region has not been developed yet.

The results of this research project will provide a

deeper knowledge about the contribution of the

different ablation mechanisms in the ablation

process and their dependence on laser radiation

parameters, which will contribute in a coherent

theory of ultrashort pulse laser-matter interactions.

We will also expand the existing knowledge base

with novel materials. The conditions of the ablation

process, such as pulse energy, wavelength or

repetition rate need to be determined separetly for

each of the investigated materials. The main

difference from the nanosecond ablation sums up in

a fact, that the radiation energy absorbed by the

material remains stored in a very shallow layer,

predefined by the optical absorptive properties

(Chichkov et al, 1996; Dowden 2009).

Femtosecond lasers of high repetition rates have

not yet been fully examined for interactions with

materials. One of the experiments were carried out

by [17], taking into consideration a few significant

parameters at once, i.e. pulse repetition rate, limited

to megahertz range, at an average laser power level

and fixed wavelength. During these studies,

numerous problems have appeared, such as

instability of the laser pulse energy and power

fluctuations. Although the fiber solid state laser was

used, so far the researchers have failed to take full

advantage of CPA amplified lasers laser-matter

interactions investigations, mostly because of the

low repetition rates used (Dowden 2009; Tan and

Dalili, 2009).

A femtosecond laser in our laboratory, not only

provides the opportunity to achieve a wide range of

repetition rates, but also can offer a stable output

power at different levels. Very strong focusing of the

laser beam by an advanced optical system will

provide a high pulse energy and will eliminate the

problem of power fluctuations. Furthermore, the

possibility of generating three different wavelengths

of UV, VIS, IR range will allow to perform the

research using a single laser, while the other

radiation parameters will remind constant. Whereas

most of the short pulse lasers applied in the research

offers a pulse duration in the range of several tens of

femtoseconds, our laser generates 500 fs pulses,

what places it in the subpicosecond range, a range

which we find a far more interesting from the

scientific point of view. Working with a several

hundred femtosecond pulses creates an unique

opportunity to observes the ablation mechanisms in

the border area between long and ultrashort laser

pulses.

4 METHODOLOGY

The laser micromachining of materials will be

carried out using a prototype diode-pumped

Yb:KYW fiber laser, developed within a research

project by prof. Radzewicz’s Laser Centre group

from Institute of Physical Chemistry PAS (Fig. 1).

The use of fiber laser technology among other

femtosecond laser technologies is very beneficial.

No thermal problems within the active medium

occur, high average power and temporal stability is

obtained.

Figure 1: Yb:KYW laser construction.

The source of a high power femtosecond pulses

in our laser is the Yb:KYW crystal-based oscillator

with a z-type resonator. A passive mode-locking

technique is used for pulse synchronization, which is

implemented with a semiconductor saturable

absorber mirror (SESAM). In a SESAM-type

construction the absorber mirror is a periodic

structure (diffraction grating), reflecting light due to

Bragg diffraction phenomenon. The Yb:KYW

crystal is pumped with a single-mode laser diode

with a 980 nm wavelength. The fundamental

wavelength of the output beam generated by the

oscillator is 1030 nm (3 nm FWHM), but also

second (515 nm) and third (343 nm) harmonic can

be generated. From the oscillator output,

femtosecond pulses go directly to the amplifier. Due

to the high peak power values in a single pulse,

significant damages of the optical elements can be

caused during the amplification process. Therefore,

chirped pulse amplification (CPA) technique needs

to be applied. Stretched pulses pass through the

electro-optic modulator (Pockels cell) that reduces

the repetition frequency. This allows us to modulate

pulse repetition rate from kilo to megahertz range.

The typical operating range of the laser is 100 – 900

MicromachiningofMaterialsusingFemtosecondLaserPulses-AParametricStudy

5

kHz. At the Pockels cell output, the beam is

amplified in two stages, which provides a better

efficiency of the pumping process. The photonic

fiber with a large diameter ytterbium doped core is

used in both stages. Laser diode pumping to the core

is continuous at a wavelength of 976 nm. At

maximum power of the laser diode we obtain the

amplified beam power at the level of 50 W in the

fundamental beam. M

2

factor, an important measure

of beam quality is at maximum power, 1.27. These

parameters are proved to be very promising in the

laser material processing. The output pulse length of

the laser is 500 fs, which is close to the so-called

subpicosecond region, which opens a new,

interesting field of research for the short-pulsed

laser-matter interactions.

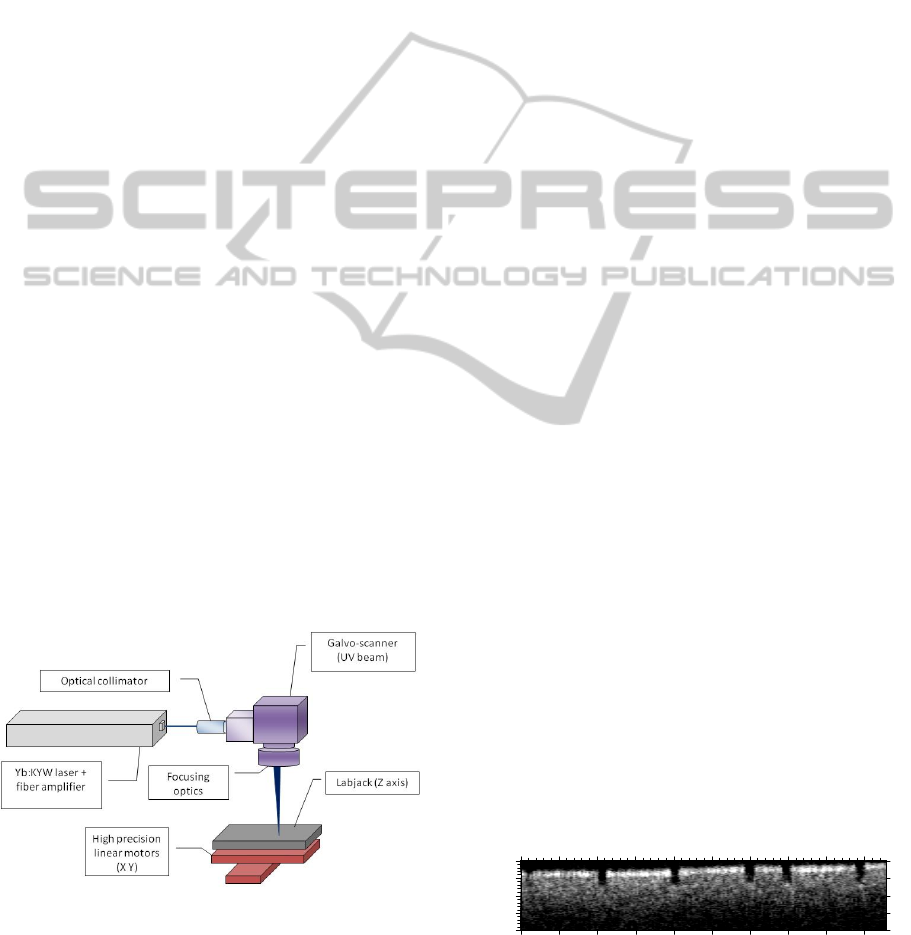

From the laser output, the beam is passing

through the optical collimator and focusing system,

containing of mirrors and lenses adequate for the

applied laser wavelength. Microscopic lenses can be

applied to obtain a higher laser fluence. The concept

of the micromachining implies, that the output

femtosecond laser beam, after passing through the

optical collimator, will be directed into the

positioning system. To move and focus the UV laser

beam on the surface of the workpiece, an optical

scanner with focusing lens is used. The scanner is

equipped with two galvanometric mirrors that

deflect the laser beam, making it possible to move

according to a given pattern in the XY plane.

A dedicated control software, supporting HPGL files

is provided to create patterns. A telecentric lens is

used to focus the beam as it provides a uniform

beam interaction with material in the whole scanning

area. The samples are put on the z-axis adjustable

table, directly beneath the scanning area, on the

exact level of the laser beam focus (Fig.2).

Figure 2: The experimental setup.

A Yb:KYW femtosecond laser offers high

repetition rates and stable power level, as long as the

possibility of generating three different wavelengths

of UV, VIS, IR range, which allows the

micromachining processes at full spectrum of laser

radiation. For the IR and VIS experiments, the

galvo-scanner cannot be applied. Instead, two high-

precision linear motors are provided to move the

sample in the XY plane and a separate focusing

optics, dedicated for the given wavelength range, is

used.

The presented micromachining setup provides

a 2 μm micromachining accuracy and allows to

perform a wide variety of the machining processes:

cutting, scribing, engraving, structuring, drilling and

dicing.

The laser, together with the optical focusing

system and high precision positioning setup are the

most important tools to achieve our research goals

and have already proven a very high-quality of the

results.

Evaluation of the experiment results is based

mostly on the microscopic images. The stereoscopic

metallographic microscope (up to 200x

magnification) and Carl Zeiss Scanning Electron

Microscope (magnification up to 1000x) are used for

crater dimensions, line width, HAZ range and derbis

measurement for most of the materials. These tools

are adequate, but not sufficient for the detailed

sample analysis, especially when it comes to

transparent or nonconductive materials, the exact

crater depth measurements or investigating changes

in the inner structure of the material. Additionally,

a confocal laser Olympus LEXT microscope or the

Optical Coherence Tomography System (OCT) is

used. The confocal laser microscope is a powerful

tool for sample diagnostics with a < 1 µm resolution,

performing non-contact 3D observations and a fast

image acquisition.

The OCT system I am using, was build and

designed at the faculty of Electronics,

Telecommunications and Informatics, Gdańsk

University of Technology. This diagnostics tool is

available to us due to the collaboration with the

GUT’s Optoelectronic department. This is still a rare

used and an innovative approach to research

methodology, when it comes to laser-matter

interaction diagnostics. The microscopic images

Figure 3: A PS-OCT image of the microcraters after

Nd:YAG nanosecond laser micromachining of alundum

ceramics.

Shift [μm]

Depth [μm]

0

50

100

150

200

0 100 200 300 400 500 600 700 800 900

PHOTOPTICS2015-DoctoralConsortium

6

allows the observation of the surface modifications,

roughness or derbis, as well as crater size, line width

or aspect ratio of the material. Using the OCT

technique, it is also possible to cross-examine the

material, thus resulting changes in its structure at the

full penetration depth of laser radiation (Fig. 3).

5 STAGE OF THE RESEARCH

On an early stage of the research, laser beam

characteristics were carefully measured, in order to

ensure the best knowledge of the laser beam

parameter range, accuracy and stability and to

provide the maximum quality of the laser

micromachining processes. During this experiments,

spatial and temporal characteristics of both, focused

and unfocused laser beam were examined, as long as

the Rayleigh range and minimum spot diameter.

These values are crucial for accuracy of the further

experiments. The stability of the spatial position of

the laser beam will was determined. In order to

perform the parameter examination, a Spiricon

SP620U beam analyzer was used, together with a set

of adequate filters and lenses. The output power

level and the temporal power stability of the laser

beam was measured using Thorlabs PM200 power

meter with a S350C probe (measurement range:

10mW – 40W). Additionally, a spectroscopic study

of the laser beam was performed. The spectral

characteristics of the femtosecond laser beam were

measured using MAYA11734 spectrometer and

Andor Mechelle spectrometer. To maintain the

optimal laser parameters, measurements were taken

on the laser output and inside the laser, on the

oscillator output, with the fundamental beam and

both of the harmonics.

The most important aim of the research is to

investigate femtosecond laser interactions with a

variety of materials under a wide range of laser

irradiation parameters, and to determine laser

ablation mechanisms. Thus, the next step in the

work plan is irradiating the material samples with

single and multiple laser pulses with different

variables, such us: pulse energy (laser output power

is up to 50 W in the fundamental beam), pulse

repetition rate (100 kHz to 900 kHz), wavelength

(1030 nm / 515 nm / 343 nm), irradiation time, etc.

All the experiments are to be carried out with

a single femtosecond laser (detailed description can

be found in the methodology chapter), which

ensures a complexity of the research and guarantees

constancy of the invariable parameters in each step.

As a reference, I also plan to use a long pulsed

(nanosecond) laser, available in our laboratory and a

short pulsed femtosecond laser from the Institute of

Solid State Physics, available through our research

collaboration with the Bulgarian Academy of

Sciences. Especially the latter can bring a significant

contribution to the research, providing a 35 fs and

120 fs pulse width and low repetition rates (1 – 10

kHz), with a wavelength in the close IR range.

So far, the laser micromachining experiments

were carried out in the UV and IR range. For the 343

nm beam, a various scanning velocities, number of

repetitions, output power levels and different

radiation time were tested, while performing cutting,

scribing and drilling. For the 1030 nm, laser scribing

and drilling was examined with variable power,

repetition rate and radiation time. Not only the laser

radiation parameters, but also material properties

have strong effect on laser micromachining and

ablation mechanisms, therefore all of the

experiments were carried out on metals (stainless

steel with different surface finish, aluminum of

various thickness, nickel, copper, bronze, zinc,

titanium) and plastics (PTFE, polypropylene,

polycarbonate, acetal, nylon). A closer attention was

given to silicon wafers, graphene on copper and

ceramic pieces.

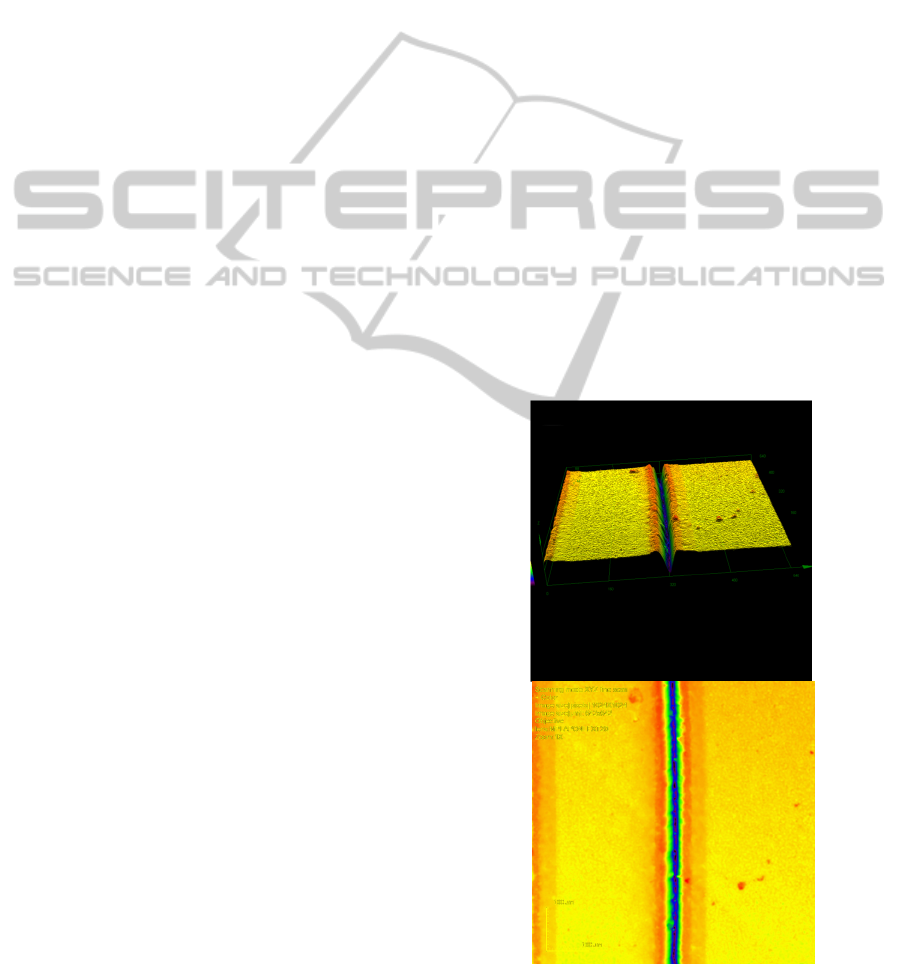

Figure 4a: Si wafers sample after laser scribing, images

from the confocal Olympus LEXT microscope.

MicromachiningofMaterialsusingFemtosecondLaserPulses-AParametricStudy

7

Figure 4b: Si wafers sample after laser cutting,images

from the Zeiss SEM microscope.

Pre diagnostics of the of the micromachining results

was performed using the metallographic microscope.

The crater diameter, depth and aspect ratio, the heat

affected zone range and debris were measured. For

more advanced result analysis, the confocal laser

microscope, SEM and OCT will be used. These

techniques will provide the ability to measure such

features, as: measurement of transparent layers,

micro roughness profiles, sample thickness or

measurements of micro areas and surface analysis

with high resolution. The results for some of the

measurement methods are represented by a silicon

sample after laser cutting on Fig.4.

With the collected data, the laser fluence [J/cm

2

]

is calculated for each experiment and the

dependence of crater measurements, HAZ, line

width, etc. on laser and material parameters is

investigated.

The effects of the laser pulse parameters on

ablation threshold, heat accumulation, ablation

efficiency, cold and hot ablation mechanisms and

the amount of liquid phase occurring during the laser

irradiation will be studied for materials mentioned

above. The specific material parameters, like

absorption rate or heat conductivity will be included

as a significant variables. The results will be

discussed against theoretical models and other

experimental results, in order to determine most

probable physical phenomena during laser-matter

interactions for short pulse irradiation.

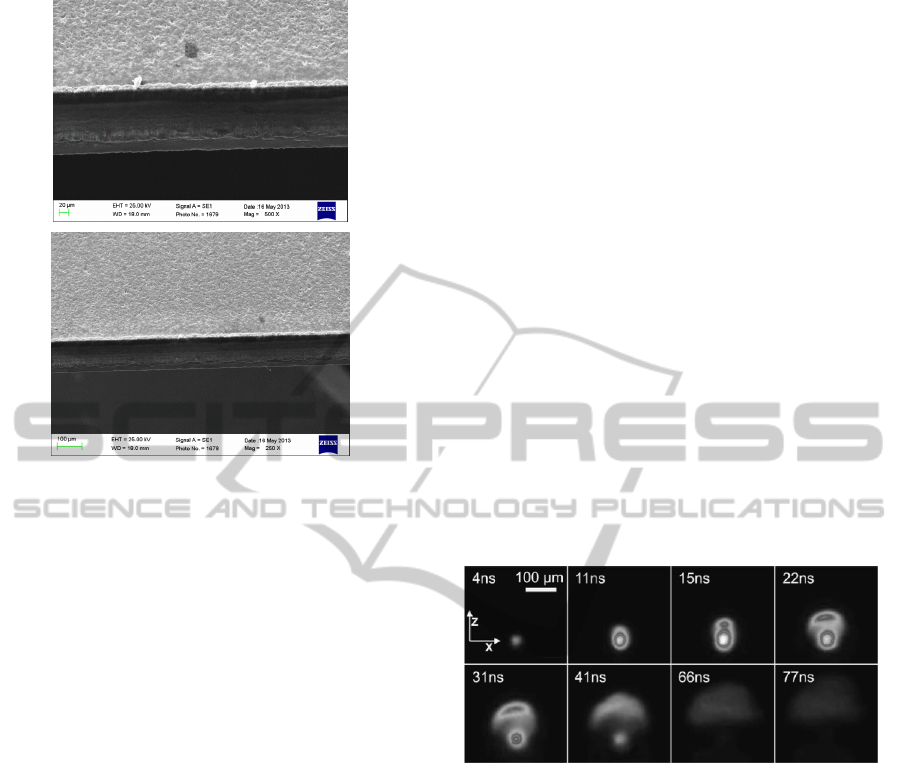

For the complex understanding of the laser

ablation mechanism, the next work plan step is an

investigation of the laser generated plasma plume.

The plasma plume consists of particles, atoms,

clusters, ions and electrons, detached from the

material surface during laser irradiation. A time-

resolved spectroscopic study of the ablation plasma

and the dynamics of the expansion of ablation

plasma will be performed. The spectroscopic study

will be carried out with a Mechelle spectrometer,

whereas the expansion dynamics observation will be

done with an Intensified CCD (ICCD) camera with a

very short time of exposure. The use of the ICCD

camera will allow us to observe the formation and

the evolution of the plasma with a very high

temporal resolution (Fig.5).

The experimental results will provide

a knowledge about the shape of the plasma plume on

an early stage of development (plasma onset) and

the velocity of the plasma front expansion. The

spectroscopic study will allow to determine an

excitation time of atoms and ions forming a plasma

plume. Based on this results, an electron temperature

of plasma and its ionization degree can be

concluded.

Figure 5: The evolution of the laser generated plasma

plume in ambient air at the early stage of its expansion.

Images recorded using an ICCD camera.

6 EXPECTED OUTCOME

The research results will contribute to the deeper

understanding of the laser-matter interaction theory.

I believe that the overall results obtained in this

research will enhance the knowledge of fundamental

phenomena in scientific field of interaction of laser

pulses with matter in ultrashort timescales, in

particular of the ablation mechanisms that take place

in this regime. Based on the experimental results it

will be possible to find the answers to various

problems in this field that are still opened for

academic discussion. I expect that those result will

allow to verify the existing models of ultrafast laser-

matter interactions and extend its applicability for

PHOTOPTICS2015-DoctoralConsortium

8

some materials, which will consequently lead to

progress in the field of micro and nanotechnology.

At present, the potential of creating micro and

nanoscale layers and elements is not fully used and

the lack of knowledge about the interactions of the

electromagnetic radiation with many types of

technologically significant materials is one of the

reasons for this. The practical application of

femtosecond micromachining opens the door to an

entirely new generation of micro device

development, such as MEMS (micro-electro-

mechanical sensors) or Lab-on-a-chip (size of a

credit card micro-chemical laboratory - the latest

trend in medical diagnostics). There is also a number

of candidates for the application area which might

drive femtosecond laser technology into mainstream

industrial use. Some of the sectors include

biomedical devices (stent manufacturing), micro-

optics (micro-lenses, diffractive elements) and

photonics devices (optical waveguides,

telecommunications devices). Non-systemized

knowledge of the optimal micromachining

parameters for a specific material and machining

type (cutting, dicing, engraving, etc.), makes

implementing to the industrial level very difficult

and ineffective and solving this problems might be

one of the outcomes of the proposed research.

REFERENCES

Strickland D., Mourou G., 1985, The Dawn of Ultrafast

Science and Technology at the University of

Rochester, Opt. Commun. 56, 219.

Mourou G., 1997, The Ultrahigh-Peak-Power Laser:

Present and Future, Appl. Phys. B 65.

Liu X., Du. D., Gourou G., 1997, Thermophysical effects

in laser processing of materials with picosecond and

femtosecond pulses , IEEE 1. Quantum Electron. 33,

1706.

Anisimov S. I., Inogamov N. A., Oparin A. M., Rethfeld

B., Yabe T., Ogawa M., Fortov V. E., 1999, Pulsed

laser evaporation: equation-of-state effects, : Appl.

Phys. A, 69, 617.

Peterlongo A., Miotello A., Kelly R., 1994, Laser-pulse

sputtering of aluminum: Vaporization, boiling,

superheating, and gas-dynamic effects, Phys. Rev. E

50, 4716.

Emelyanov V.I., Babak D.V., 2002, Defect capture under

rapid solidification of the melt induced by the action of

femtosecond laser pulses and formation of periodic

surface structures on a semiconductor surface, Appl.

Phys. A 74, 797.

Sokolowski-Tinten, K. Von der Linde D., 2000,

Generation of dense electron-hole plasmas in silicon,

Phys. Rev. B 61, 2643.

Chichkov B. N., Momma C., Nolte S., Van Alvensleben

F., Tunnerman A., 1996, Femtosecond, picosecond

and nanosecond laser ablation of solids, Appl. Phys.

A, 63.

Tom H. W. K., Aumiller G. D., Brito-Cruz C. H., 1988,

Time-Resolved Study of Laser-Induced Disorder of Si

Surfaces, Phys. Rev. Lett. 60, 1438.

Sokolowski-Tinten K., Bialkowski L., Doing M., Cavalieri

A., Von der Linde D., Oparin. A., Mayer-ter-Vehn J.,

Anisimov S. I.,1998, Transient States of Matter during

Short Pulse Laser Ablation, Phys. Rev. Lett. 81, 224,

Zhigilei L. V., Garrison B. J., 2000, Microscopic

mechanisms of laser ablation of organic solids in the

thermal and stress confinement irradiation regimes,

Appl. Phys. 88, 1281.

Perez D., Lewis L. J., 2002, Ablation of solids under

femtosecond laser pulses, Phys. Rev. Lett. 89, 255504.

Shafer C., Urbassek H. M., Zhigilei L. V., 2002, Metal

ablation by picosecond laser pulses: A hybrid

simulation, Phys. Rev. B 66, 115404.

lvanov D. S., Zhigilei L. V., 2003, Effect of Pressure

Relaxation on the Mechanisms of Short-Pulse Laser

Melting, Phys. Rev. Lett. 91, 105701.

Perez D., Lewis L. J., 2003, Molecular dynamics study of

ablation of solids under femtosecond laser pulses,

Phys. Rev. B 67, 184102.

Dowden J. M., 2009, The Theory of Laser Materials

Processing: Heat and Mass Transfer in Modern

Technology, Springer.

Tan B., Dalili A., Venkatakrishnan K.,2009, High

repetition rate femtosecond laser nano-machining of

thin films, Appl. Phys. A: Materials Science &

Processing, 95, 2.

MicromachiningofMaterialsusingFemtosecondLaserPulses-AParametricStudy

9