A Learning Model for Intelligent Agents Applied to Poultry Farming

Richardson Ribeiro

1

, Marcelo Teixeira

1

, Andr´e L. Wirth

1

, Andr´e P. Borges

2

and Fabr´ıcio Enembreck

2

1

Department of Informatics, Federal University of Technology-Paran´a, Pato Branco, Brazil

2

Graduate Program in Computer Science, Pontificial Catholical University-Paran´a, Curitiba, Brazil

Keywords:

Intelligent Agents, Broiler Management and Decision Making Problems.

Abstract:

This paper proposes a learning model for taking-decision problems using intelligent agents technologies com-

bined with instance-based machine learning techniques. Our learning model is applied to a real case to support

the daily decisions of a poultry farmer. The agent of the system is used to generate action policies, in order to

control a set of factors in the daily activities, such as food-meat conversion, amount of food to be consumed,

time to rest, weight gain, comfort temperature, water and energy to be consumed, etc. The perception of the

agent is ensured by a set of sensors scattered by the physical structure of the poultry. The principal role of the

agent is to perform a set of actions in a way to consider aspects such as productivity and profitability without

compromising bird welfare. Experimental results have shown that, for the decision-taking process in poultry

farming, our model is sound, advantageous and can substantially improve the agent actions in comparison with

equivalent decision when taken by a human specialist.

1 INTRODUCTION

The use of learning systems based on intelligent

agents (Castelfranchi, 1997; Maes, 1995) is an alter-

native to address a number of computational prob-

lems, such as vehicle control (Au et al., 2014),

games and robotics (Bachrach et al., 2014; Cobo

et al., 2013), vehicular traffic control (Ribeiro et al.,

2012; Jiang et al., 2014), collective decision making

(Ribeiro and Enembreck, 2013; Ribeiro et al., 2013),

etc. In this work, we propose a learning model using

intelligent agents supported by learning techniques

based on instances (Aha et al., 1991). Our approach

has the advantage of providing flexibility to construct

data models and training sets, eliminating the need of

a prior heuristic.

The proposal to be described can be summarized

as follows. We aim to generate action policies from

historical data of broiler management, emerging an

expert system able to assist poultry farmers in the

decision-making process. Usually, predictive systems

require distributed and flexible approaches to become

usable in industrial scale, since they are required to

adapt themselves to dynamic environments. In this

context, agent-based approaches are appropriate for

the construction of open, distributed, heterogeneous

and flexible architectures, that can offer a variety of

services without imposing architectural constraints.

Thus, the incremental development of the agent in the

decision making process based on machine learning

algorithms becomes easier (Enembreck and Barth`es,

2005). The agent developed in this paper takes results

from a machine learning process, including the ex-

traction of knowledge from database of previous pro-

duction systems.

Pragmatically, it has been implemented machine

learning techniques to extract information from his-

torical data of broiler management, providing the

agent with such information and examining its be-

havior in the decision-making process. The decision-

making itself occurs on a set A of activities performed

in broiler management (Ferket and Gernat, 2006).

Activities that define A involve actions occurring

throughout the broiler chicken life cycle, which inter-

fere on factors such as: amount of consumed feed and

water, light, ventilation, humidity, resting time, and

temperature control. These factors directly impacts

on the amount of food that is consumed, with respect

to the amount of meat that is produced. This relation

is called Feed Conversion Ratio (Fontana et al., 1992)

and is crucial to the success of the broiler production

system.

The decision-making process is the result of the

agent’s action policy in the environment (aviary). An

action policy represents the behavior that the action

causes, e.g., increasing, maintaining or decreasing the

495

Ribeiro R., Teixeira M., L. Wirth A., P. Borges A. and Enembreck F..

A Learning Model for Intelligent Agents Applied to Poultry Farming.

DOI: 10.5220/0005373604950503

In Proceedings of the 17th International Conference on Enterprise Information Systems (ICEIS-2015), pages 495-503

ISBN: 978-989-758-096-3

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

temperature, the humidity, the amount of food, etc.

These actions interfere on the productivity indicators.

To define an action policy, the agent receives a set

of resources, such as qualitative characteristics of the

environment or knowledge bases containing actions

from previous managements. A good action policy

is achieved when the productivity is somehow im-

proved, in terms of feed conversion.

In the paper, we evaluate and validate our estima-

tions by comparing them against field tests, conducted

using real data from poultry farming. The behavior

observed from the agent has been confronted against

empirical decisions taken by human experts (farmers)

when handling the process. The same configuration

has been assumed for the scenario. To classify opti-

mized actions, we apply an instance-based algorithm

over historical data.

The manuscript is structurally organized as fol-

lows: Sections 2 and 3 respectively introduce ba-

sic concepts on poultry farming and related machine

learning techniques. Section 4 presents the proposed

model, which is experimentally evaluated in Section

5. Finally, Section 6 presents some conclusions and

perspectives.

2 POULTRY INDUSTRY

Poultry farming is the raising domesticated birds.

Among the birds in poultry stand out the species

G. gallus, subspecies G. g. domesticus with trino-

mial name of Gallus gallus domesticus - or simply

chicken. When it is raised for meat production it is

called broiler poultry (Charles and Stuart, 2011). On a

smaller scale, there are also bred birds such as ducks,

goose, quail, turkeys, ostriches, pheasants etc.

The broiler poultry farming is an economic ac-

tivity increasingly important worldwide. In 2013,

the world chicken meat production accounted 82,178

(1,000 MT), being 16,958 (USA); 13,500 (China);

12,308 (Brazil); 9,750 (EU- 27); 3,420 (India), and

28.242 (others). In Brazil, the production of the

subspecies G. g. domesticus reached 12.30 million

tons in 2013, corresponding to a growth in compar-

ison with 2012, when 12.23 million tons were pro-

duced. With this performance, Brazil is getting close

to China, currently the second largest world producer,

whose production in 2013 summed up 12.550 million

tons, only behind the United States, with 16.648 mil-

lion tons, according to projections from the US De-

partment of Agriculture (USDA)

1

.

1

Brazilian Poultry Association (2014). “Annual Re-

port”, 2013/2014. www.brazilianchicken.com.br.

The growth in 2013 was largely driven by the in-

creased consumption of chicken meat and the 5.1%

expansion in exports, with a total 3.8 million tons of

chicken exported to more than 150 countries. Out of

the total national production of chicken, 69% was in-

tended for domestic consumption, and 31% for ex-

ports.

The growth and economic impact of broiler poul-

try farming shows its importance. Increased pro-

ductivity, reduced costs and environmental aspect

and well-being of animals has forced the industry to

modernize processes, with public and private invest-

ments in genetic improvementresearch (Closter et al.,

2012); immunology, health and disease (Lee et al.,

2011);quality programs and good manufacturing

practices (Northcutt and Jones, 2004); metabolism

and nutrition (Shariatmadari, 2012); physiology, en-

docrinology and reproduction (Bakst et al., 2012);

modernization of industrial processes, e.g. process-

ing, products and food Safety (Tavarez et al., 2011);

and the development of computer-aided solutions.

The development of expert system is the scope of this

work.

(Arowolo et al., 2012) developed an expert system

for diagnosing poultry diseases which could also be

used both by the farmer and the experts to train their

students. The knowledge (elicited from the experts

and literature review) was represented in the system

using a rule-based approach. The Unified Modeling

Language was used to describe the design of the sys-

tem. The expert system was tested using design crite-

rion and knowledge-base expert system for stratified

root.

(Maseleno and Hasan, 2012) built a web map-

ping and Dempster-Shafer theory as an early warning

system of poultry diseases. Dempster-Shafer theory

combines beliefs in certain hypotheses under condi-

tions of uncertainty and ignorance, and allows quan-

titative measurement of the belief and plausibility in

identification result. Web Mapping is also used for

displaying maps on a screen to visualize the result of

the identification process. The result reveal that poul-

try diseases warning system has successfully identi-

fied the existence of poultry diseases and the maps

can be displayed as the visualization.

(Schmisseur and Pankratz, 1989) proposed an

expert/knowledge-based microcomputer program to

the diagnose layer management problems and recom-

mend expert remedial management advice. The pro-

gram also provokes management action by calculat-

ing the economic loss attributed to major management

problems. It analyzes data generated by a commer-

cially marketed layer performance financial micro-

computer program and has demonstrated the ability

ICEIS2015-17thInternationalConferenceonEnterpriseInformationSystems

496

to emulate poultry management experts in the diag-

noses of 80 individual layer management problems.

The program provides scarce expert poultry manage-

ment advice to poultry layer managers regardless of

size and scale of operation.

In spite of the extensive options of poultry farming

technology, few computer systems are specialized in

applying machine learning techniques to automate the

decision-taking process. In the following, we present

some alternatives that have been used for that pur-

pose in industry, highlighting the novelties and ben-

efits brought by this particular paper.

3 AUTOMATIC LEARNING

Techniques based on imperative programming, com-

bined to empirical knowledge and formal methods

(Teixeira et al., 2014) can be applied to coordinate

sequences of operations in factory automation. Such

sequences can then be commanded by conventional

tools and technologies for automation, and performed

without human intervention.

In a number of practical problems, the exploitation

of those pre-programmedsequences may identify bot-

tlenecks that, when properly addressed, could lead to

significant improvements on the production system,

either in terms of process performance or quality of

manufactured items. For that, nevertheless, one has to

consider dealing with dynamic variables that appear

along the process, such as temperature, pressure, flow

and rates of resources to be consumed, etc. Learn-

ing mechanisms are alternatives to be combined to

imperative programming in order to handle it. This

approach allows to analyze industrial problems char-

acterized by sequences of events which are unknown

a priori and depend on the dynamics of the environ-

ment and on the availability of resources.

The ability for a system to learn, so performing

complex tasks better than human specialists, is of

great value for industry. Traditionally, such learn-

ing process has been hand-crafted, capturing from a

human expert intuitions about the process, which re-

quires a tedious and extensive human effort, while the

results are imprecise, mixed and poor, in general.

In contrast, a successful learning machine is able

to learn a given industrial task purely from computa-

tional effort, without the intellectual help of a human

expert (even though he exists). In most cases and

successful domains, such automatic learning tech-

niques have performed significantly better than the

best hand-crafted efforts (Andrieu et al., 2003).

In spite of the apparent advantages, few ap-

proaches have applied machine learning techniques

to develop agent-based architectures to support the

decision-making process in industry. The main rea-

son why this approach does not reach industrial scale

is that the choice for the appropriate learning method

to be used depends on the application itself, and this

decision may not be straightforward. What it is ob-

served is that applying machine learning on large and

complex problems implies to handle a large and intri-

cate combination of variables and instances. There-

fore it may not be trivial to extend the theory to prac-

tical problems (e.g., poultry farming), due to the in-

herent computational cost.

4 PROPOSED MODEL

An alternative to make machine learning practically

feasible is to combine the approach to Case-Based

Reasoning (CBR) models (Amores, 2013; Leake and

McSherry, 2005). A case can be seen as a tuple of

attributes of an instance, i.e. the records that com-

pose an instance of the problem. The basic idea of the

CBR method is to solve new instances of the prob-

lem according to solutions of previous ones (Aamodt

and Plaza, 1994; Abdel-Aziz et al., 2014; McSherry,

2014; Jaidee et al., 2013), which had been stored in

a knowledge database, in this paper denoted by train-

ing set (T S). The update of T S is a 3-steps process,

namely: (i) extract knowledge from previous situa-

tions; (ii) identify relevant characteristics on previous

cases construct better solutions; and (iii) store solved

problems as new learned cases (elements t

i

∈ T S).

The quality of a CBR solution basically depends

on the number of instances that define T S. For

each new instance to be solved, a comparison is con-

ducted against instances in T S, attempting to define

whether or not it improves the solution for the prob-

lem (Aamodt and Plaza, 1994). This procedure is

called classification. To classify new instances, we

adopt in this paper a learning algorithm called k-nn (k-

nearest neighbor)(Aha et al., 1991), which is appro-

priate to be used in conjunction to the CBR method.

The classification itself consists of finding a class

for any new (candidate) instance t

c

that arrives to be

evaluated. Following the k-nn algorithm, t

c

is firstly

loaded to memory and it is compared to everyt

i

∈ T S.

The element in T S that provides the shortest “dis-

tance” to t

c

determines the class it actually belongs.

In this paper, instances are represented by data tu-

ples and, so, we provide a model (see (1)) to imple-

ment the k-nn idea to classify them. We basically

compare the j

th

attribute of t

c

to the j

th

attribute of

every t

i

∈ T S. New instances are then derived based

on the distance similarity between T S and t

c

.

ALearningModelforIntelligentAgentsAppliedtoPoultryFarming

497

n

∑

i=1

∑

m

j=1

(t

j

i

·t

j

c

)

q

(

∑

m

j=1

(t

j

i

)

2

) · (

∑

m

j=1

(t

j

c

)

2

)

(1)

The idea behind the model in (1) is as follows.

Assume a training set T S such that each element

t

i

∈ T S, for i = 1, ··· , n, is a m-tuple hι

i

, τ

i

, µ

i

, ν

i

, γ

i

,

···m

i

i, indexed by j

i

, for j = 1, ··· , m. We also as-

sume that t

c

= hι

c

, τ

c

, µ

c

, ν

c

, γ

c

, ··· m

i

i is a singe can-

didate tuple, which is expected to be estimate, from

the training data, which class it belongs to. Thus, we

associate and normalize the tuples from T S and t

c

,

obtaining as a result their similarity degree.

4.1 Example

Consider that T S and t

c

are given as in Table 1.

Table 1: Parameters for the illustrative example.

T S ι

i

τ

i

µ

i

ν

i

γ

i

t

1

2 22 53 33 23

t

2

3 33 60 100 45

t

3

1 24 62 44 15

t

c

ι

c

τ

c

µ

c

ν

c

γ

c

3 28 65 17 22

By applying (1) to the example, we obtain a sim-

ilarity degree SD for t

c

with respect to i = 1, 2, 3 re-

spectively on the order of:

SD

1

= 0, 96 SD

2

= 0, 76 SD

3

= 0, 94

Therefore, for this particular example, SD

1

and

SD

3

clearly define the class t

c

belongs to.

5 EXPERIMENTAL RESULTS

Now, we use a more realistic example to illustrates

our approach. The broilers management process aims

to improve the performance of a breeding (flock) in

terms of feed conversion. Broiler production (broiler

is a type of chicken raised specifically for meat pro-

duction) is a sequential process where the ultimate

performance is dependent on the successful comple-

tion of a set of steps. Each step must be toughly as-

sessed and improvements are required for the max-

imum performance to be obtained. However, those

steps are all interdependent, in such a way that if one

of them is sub-optimal, then whole process perfor-

mance suffers. The success of the poultry is directly

related to environmental and feed control.

Data from the broilers management process can

be formally described by 5-tuples hι, τ, µ, ν, γi where:

• ι = 1, 2, 3 is the light density;

• τ, for t ≥ 18 ≤ 33, is the temperature value (C);

• µ, for u ≥ 50 ≤ 70, is the humidity value (%);

• ν ∈ N is the spent time ventilating the structure;

• γ ∈ N is the amount of consumed nutrients (feed).

Temperature and humidity are collected from sen-

sors. Ventilation time and light density can be ob-

tained from poultry environmental controller. In order

to measure the amount of consumed feed, we con-

struct an automatic scale (see Fig. 1) able to register

the total weight consumed per day.

weighing

box

feed

release

distribution

box

Figure 1: Mechanism for weighing feed.

We automate the supply and transportation equip-

ment, which has allowed us to measure flocks of feed

arriving to be consumed. For the experiments, the

scale has been adjusted to measure flocks of 50 kg,

starting to operate whenever the supplier engine ac-

tuates. By reaching 50 kg, the supplier engine is

switched off and the distribution engine starts to fill

the feeders. When this step is over, the scale resets

and the process restarts.

The weighing mechanism has been integrated to

our learning model by the electrical device in Fig.

2 (a), which detects when the feed amount reaches

the setting value (50 kg) and communicates this to a

server (voltage levels of 0 and 5 volts (Fig. 2 (b)))

through a parallel port. A monitoring software then

records the action.

(a)

(b)

Feed weigher

220v

50 kg

Voltage

reduction

device

Computer

5v

Figure 2: Device for voltage reduction.

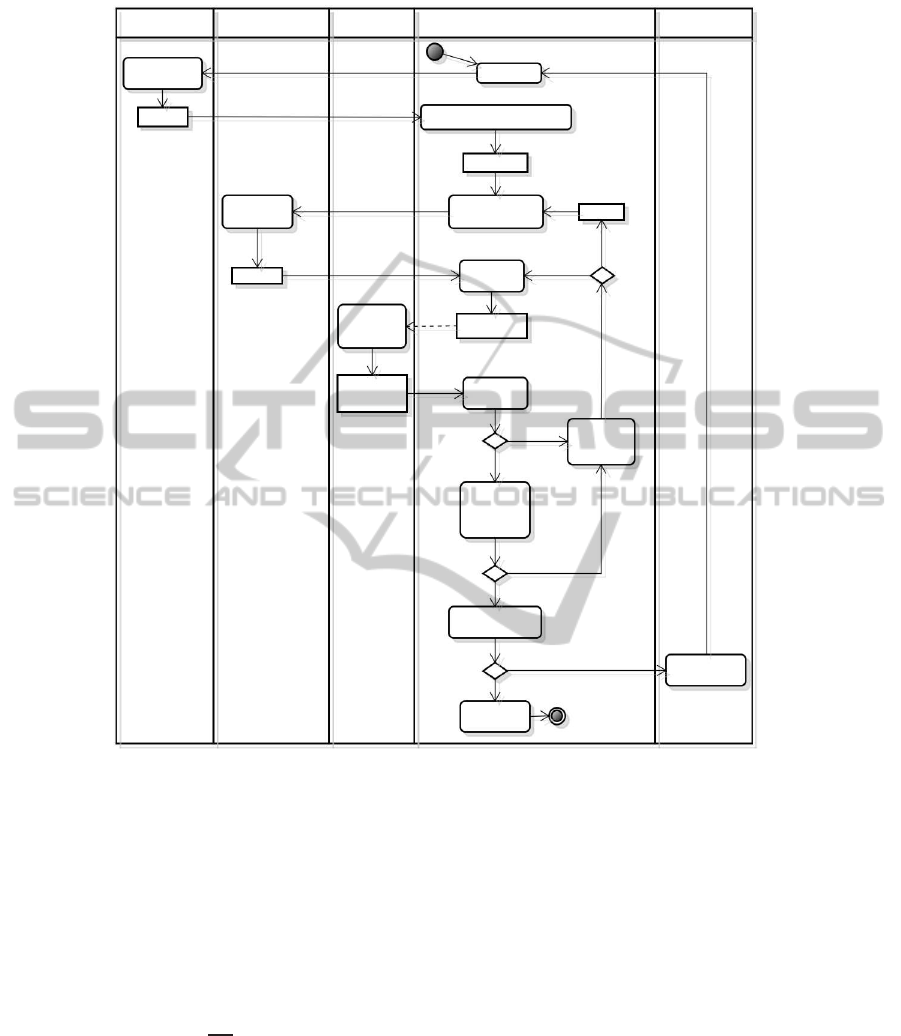

For our experiment to be suitable for analysis by

our learning model, the followingmodules are also in-

tegrated to the weighing mechanism, in order to prop-

erly compose instances: sensor, classifier, calculator,

decision and actuator, whose interaction is depicted in

Fig. 3.

ICEIS2015-17thInternationalConferenceonEnterpriseInformationSystems

498

Sensor

Classifier

Calculator

Decision-maker

Actuator

Read

perception

p: [ok]

Read data

Convert p in a vector

v: [ok]

v: [ok]

v: [ok]

Classify

c: [ok]

Submit v to

k-nn

Process

result

[Change management]

[c changed]

Calculate

conversion

x: [ok]

Refine

action

action

[Possible]

[Impossible]

Change

Validate

with human

expert

[valid]

[invalid]

Update base

Same week

Weekend

Relearn

Generate

Figure 3: Learning model interaction.

The sensor captures different parameters from a

flock, such as light density, temperature and humidity

values, time ventilating, consumed feed supply. The

actuator regulates (maintain, increases or decreases)

the values of model parameters. The calculator mod-

ule derives the value of the feed conversion (F

c

), tak-

ing into account the quantity of consumed food (Q

f

)

and the weight of the broilers (W

b

), according to the

Equation (2).

F

c

=

Q

f

W

b

(2)

The decision module is responsible for the agent

behavior. It receives data from sensors and generates

a perception p. The values of p are then structured as

a vector v in such a way that each position represents

the i

th

position of the 5-tuple that models an instance

of the problem to be solved. The vector v (instance)

is then submitted to the classifier, which returns an

action c. Based on the value of c it has to be computed

the values for the expected F

c

and remaining elements

in the tuple.

If the estimated value for the F

c

is less than the

reference value (from historical data), the state is

recorded in a log file and estimated actions effected

by the actuator. Otherwise, the amount of resources

is increased. This happens until the F

c

is smaller than

the conversion generated from managements of pre-

vious flocks.

If it is not possible to increase the amount of re-

sources of v, the previous management is maintained

and the F

c

is interactively recomputed until it finds a

value of F

c

able to optimize resources. The log gen-

eration allows to promote the process of re-learning,

although this is considered beyond this paper.

The knowledge obtained from the application of

machine learning can be represented by a set of rules,

as illustrated next.

ALearningModelforIntelligentAgentsAppliedtoPoultryFarming

499

R

1

: (F

c

< EXPECTED)∧

(FEED CONSUMPTION > EXPECTED)

=> ad just ι;

R

2

: (WEIGHT < EXPECTED) ∧

(FEED CONSUMPTION < EXPECTED) ∧

(LIGHT LEVEL ≥ 2)

=> increase τ;

···

R

1

is read as follows: “IF a feed conversion is less

than expected and feed intake is smaller than assumed

then adjust the light level”. The values for the ex-

pected and estimated parameters are suggested by a

human expert.

The rules presented above as well as the sequence

diagram in Fig. 3 are used in conjunction to the model

presented in Equation (1). An experiment is proposed

to further validate the proposed learning model.

5.1 Practical Example

In the following experiments, the actions suggested

by the proposed model are compared to the original

management, empirically carried out by a human ex-

pert. Table 2 shows the structure and the configuration

values for the experiments to be conducted.

Table 2: Structure and scenario configuration.

Parameters considered in our experiments

Amount of broilers 25.000

Amount of flocks (historical bases)

30

Number of weeks per flock

6

Dimension of the environment (poultry)

2.100 m

2

Silo for feed

27.000

Box of water

10.000 liters

Automatic feeders

780 dishes

Automatic waterers

3.000 nozzles

Ventilation system

24 fans

Nebulization system

300 nozzles

Temperature control panel

1

Heating furnace

1

The agent behavior has been evaluated under two

situations: i) based on the average weight of the broil-

ers; and ii) on the weekly feed conversion. Both cases

are discussed next.

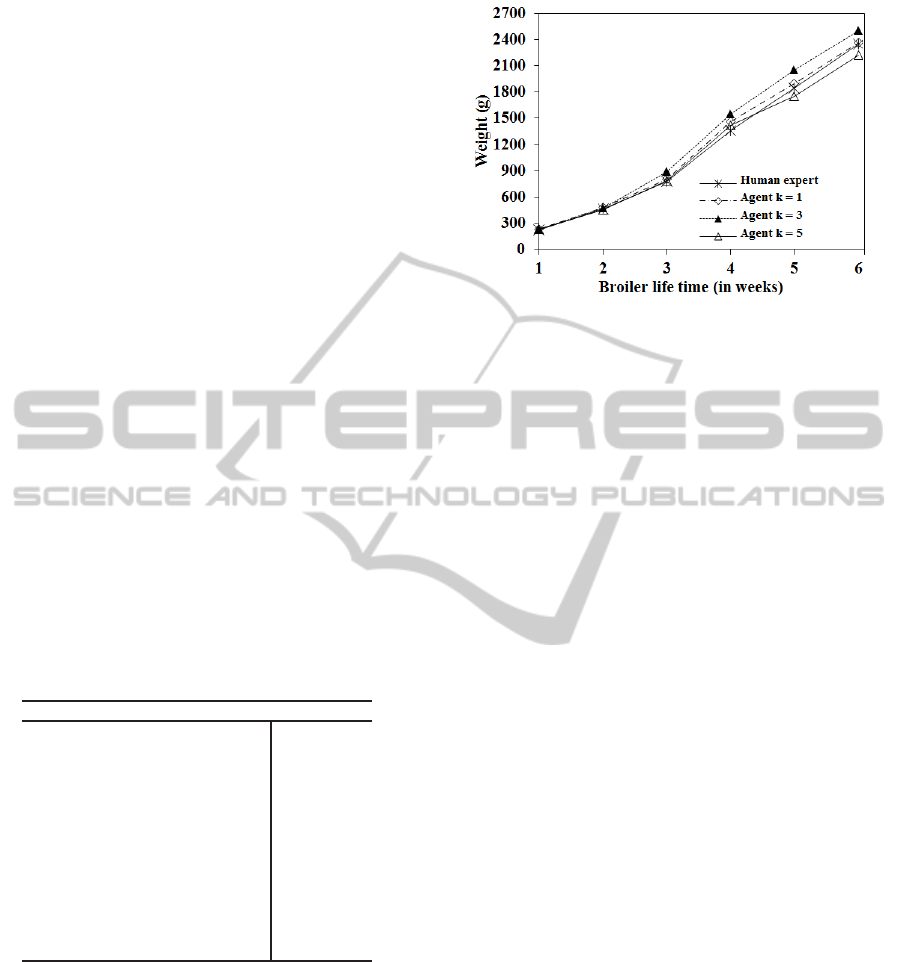

5.1.1 Broilers Weight

An action policy is satisfactory when management

employee increases the weight of the broilers and im-

proves the feed conversion. Fig. 4 shows the aver-

age weight of broilers along six weeks (period of one

flock).

Figure 4: Broilers average weight: Agent × Human expert.

Is possible to observe that the broilers average

weight is similar in the initial weeks. This occurs be-

cause during this period the growth process of broil-

ers is influenced by the dose of certain supplements.

From the third week is possible to notice that the man-

agement suggested by the agent obtains in general

better efficiency in the average weight of the broilers.

The best results were achieved with the agent using

k = 3, which led to a classification with a higher de-

gree of accuracy.

Remark also that the management suggested by

the agent can increase or maintain the average weight

of the broilers, because it uses historic data to gener-

ate combinatorial rules, a task that would be impracti-

cable by human expert, given the their potential com-

plexity. This complexity arises, for example, from the

amount of management features and related combina-

torial possibilities.

It is natural for the human expert to empirically

select and apply resources, without considering fac-

tors such as temperature, humidity, light, broilers rest-

ing time, etc., nor the combination of these factors.

In fact, the human expert merely observes and acts

according to his perception and knowledge, having

no mechanisms to improve the accuracy of such acts

on the process. On the other hand, techniques using

agents provide for the system a decision-making with

minimal human intervention, in order to anticipate en-

vironmental changes and act accordingly. This occurs

because during the learning procedure, an appropriate

number of samples are created and, at each manage-

ment, the agent seeks to specialize itself.

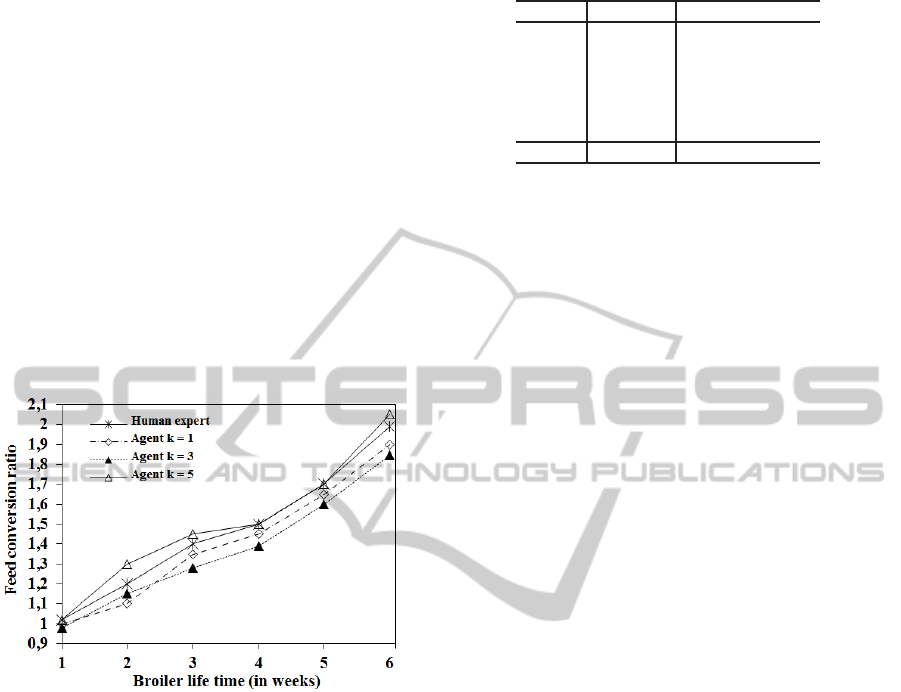

5.1.2 Feed Conversion

When a particular management is applied, feed con-

version is modified by a number of factors, such as

the environmental and structural conditions and daily

activities. To be efficient in the management, the

ICEIS2015-17thInternationalConferenceonEnterpriseInformationSystems

500

amount of feed should be constant and close enough

to the maximum capacity of the reservoir, thus opti-

mizing the time spent managing.

Usually, this is not trivial to be precisely estab-

lished, though. The feed × time relationship, seeking

for an efficient and profitable management, under dif-

ferent scenarios, can be complex even for a human

expert. In this sense, an agent always attempts to

maintain the amount of feed as close as possible to

the maximum level. In Fig. 5, it can be noted that the

feed conversion with the agent is more efficient when

compared to equivalent procedure conducted by a hu-

man expert. This occurs because the agent tends to

simultaneously increase the level of light, relative air

humidity and temperature. On the other hand, the hu-

man expert tends to maintain such features below the

expected value, attempting to achievefood conversion

using few resources.

Figure 5: Feed conversion: Agent × Human expert.

Clearly, the human expert faces difficulties to pre-

dict the exact effect of actions, thus making com-

plex the management planning throughout the broil-

ers life cycle, indicating a feed conversion lower than

expected. It has been observed that a proper (and

complex) combination of different resources is more

likely to lead to a higher average weight of broilers,

contrasted with a lower feed intake. From the val-

ues of average broiler weight and feed conversion ob-

tained from the use of the proposed learning model,

we have noticed a substantial improvement on the

broiler management process. Table 3 exemplifies the

increase we have obtained on the average of weight

and on the quality improvement of feed conversion,

per week, on the simulated flock.

It can be observed that when previous experiences

are recovered by the k-nn algorithm, the results are

satisfactory, because the system can classify values

from previous solutions, finding better results when

compared to the human expert. Another advantage of

the proposed model is that new processed cases lead

Table 3: Best agent compared to the human expert.

Week Weight (%) Feed Conversion (%)

1 4.25 2.04

2

1.05 4.34

3

11.96 9.28

4

9.28 7.99

5

12.38 6.25

6

6.00 7.85

Average 7.48 6.29

to new solutions, which allows the agent learn and

adapt its behaviors toward new situations.

6 CONCLUSIONS AND

PERSPECTIVES

Broiler managementis a complex task for humans due

to the number of factors influencing on the develop-

ment of broilers. In this paper, a learning model using

intelligent agents has been introduced to support the

automatic management of poultry farming. A learn-

ing agent controls the amount of feed, level of light,

ventilation, temperature and relative humidity using

the knowledge learned from previous cases (historical

databases). An algorithm has been applied to classify

patterns that improve feed conversion from previous

data managements.

It has been shown that the proposed model sub-

stantially improves the poultry farming process. For

the evaluated case, feed conversion improvements

have been on the order of 6%, while the gain with

broilers weight has increased in 7%. Despite promis-

ing preliminary results, additional research is yet re-

quired to complement the model and hopefullyabsorb

the diversity of scenarios in which the human expert

may be immersed.

Future research includes: i) evaluating the perfor-

mance of the agent when handling specific manage-

ment situations; (ii) checking the performance of the

algorithm to process variations of scenario; iii) chang-

ing the set of attributes used to generate the rules,

which can make them less susceptible to influence;

iv) verifying the learning algorithm with other met-

rics distance. Such statements are objects of study for

future research.

ACKNOWLEDGMENTS

We thank anonymous reviewers for their comments.

This research is supported by the Program for

Research Support of UTFPR, Directorate of Re-

search and Post-Graduation (DIRPPG) - campus

ALearningModelforIntelligentAgentsAppliedtoPoultryFarming

501

Pato Branco), Araucaria Foundation of Parana State

(Fundac¸˜ao Arauc´aria) and National Council for Sci-

entific and Technological Development (CNPq).

REFERENCES

Aamodt, A. and Plaza, E. (1994). Case-based reasoning:

Foundational issues, methodological variations, and

system approaches. Artificial Intelligence Communi-

cations, 7(1):39–59.

Abdel-Aziz, A., Strickert, M., and H¨ullermeier, E. (2014).

Learning solution similarity in preference-based cbr.

In Case-Based Reasoning Research and Develop-

ment: 22nd International Conference, ICCBR 2014,

ICCBR ’14, pages 17–31.

Aha, D. W., Kibler, D., and Albert, M. K. A. (1991).

Instance-based learning algorithms. Machine Learn-

ing, 6(1):37–66.

Amores, J. (2013). Multiple instance classification: Re-

view, taxonomy and comparative study. Artificial In-

telligence, 201:81–105.

Andrieu, C., de Freitas, N., Doucet, A., and Jordan, M. I.

(2003). An introduction to mcmc for machine learn-

ing. Machine learning, 50(1):5–43.

Arowolo, H., Weaver, W. D. Jr. and Amosa, B., and Faleye,

E. (2012). An expert system for management of poul-

try diseases. International Proceedings of Computer

Science & Information Tech., 47:113–117.

Au, T.-C., Zhang, S., and Stone, P. (2014). Semi-

autonomous intersection management. In Proceed-

ings of the 2014 International Conference on Au-

tonomous Agents and Multi-agent Systems, AAMAS

’14, pages 1451–1452.

Bachrach, Y., Savani, R., and Shah, N. (2014). Cooper-

ative max games and agent failures. In Proceedings

of the 2014 International Conference on Autonomous

Agents and Multi-agent Systems, AAMAS ’14, pages

29–36.

Bakst, M. R., Akuffo, V., Nicholson, D., and French, N.

(2012). Comparison of blastoderm traits from 2 lines

of broilers before and after egg storage and incubation.

Poultry Science, 91(10):2645–2648.

Castelfranchi, C. (1997). To be or not to be an agent. In

Proceedings of the Workshop on Intelligent Agents III,

Agent Theories, Architectures, and Languages, ECAI

’96, pages 37–39.

Charles, T. B. and Stuart, H. O. (2011). Commercial poultry

farming. Biotech Books, 6 th edition.

Closter, A. M., Van As, P., Elferink, M. G., Crooijmanns,

R. P. M. A., Groenen, M. A. M., Vereijken, A.

L. J., Van Arendonk, J. A. M., and Bovenhuis, H.

(2012). Genetic correlation between heart ratio and

body weight as a function of ascites frequency in

broilers split up into sex and health status. Southern

journal of agricultural economics, 91(3):556–564.

Cobo, L. C., Isbell, C. L., and Thomaz, A. L. (2013). Object

focused q-learning for autonomous agents. In Pro-

ceedings of the 2013 International Conference on Au-

tonomous Agents and Multi-agent Systems, AAMAS

’13, pages 1061–1068.

Enembreck, F. and Barth`es, J.-P. (2005). Ela – a new ap-

proach for learning agents. Autonomous Agents and

Multi-Agent Systems, 10(3):215–248.

Ferket, P. R. and Gernat, A. G. (2006). Factors that affect

feed intake of meat birds: A review. International

Journal of Poultry, 10(5):905–911.

Fontana, E. A., Weaver, W. D. J., Watkins, B. A., and Den-

bow, D. M. (1992). Effect of early feed restriction

on growth, feed conversion, and mortality in broiler

chickens. Poultry Science, 71(8):1296–1305.

Jaidee, U., Mu˜noz-Avila, H., and Aha, D. W. (2013). Case-

based goal-driven coordination of multiple learning

agents. In International Conference on Case-Based

Reasoning, ICCBR ’13, pages 164–178.

Jiang, S., Zhang, J., and Ong, Y.-S. (2014). A pheromone-

based traffic management model for vehicle re-routing

and traffic light control. In Proceedings of the 2014

International Conference on Autonomous Agents and

Multi-agent Systems, AAMAS ’14, pages 1479–1480.

Leake, D. and McSherry, D. (2005). Introduction to the

special issue on explanation in case-based reasoning.

Artificial Intelligence Review, 24(2):103–108.

Lee, D., Lyu, S., Wang, R., Weng, C., and Chen, B.

(2011). Exhibit differential functions of various an-

tibiotic growth promoters in broiler growth, immune

response and gastrointestinal physiology. Interna-

tional Journal of Poultry Science, 10(3):216–220.

Maes, P. (1995). Artificial life meets entertainment: Life-

like autonomous agents. Communications of the ACM,

38(11):108–114.

Maseleno, A. and Hasan, M. M. (2012). Poultry dis-

eases expert system using dempster-shafer theory and

web mapping. International Journal of Advanced Re-

search in Artificial Intelligence, 1(3):44–48.

McSherry, D. (2014). An algorithm for conversational case-

based reasoning in classification tasks. In Case-Based

Reasoning Research and Development: 22nd Interna-

tional Conference, ICCBR 2014, ICCBR ’14, pages

289–304.

Northcutt, J. K. and Jones, D. R. (2004). A survey of wa-

ter use and common industry practices in commercial

broiler processing facilities. Jounal Applied Poultry

Research, 13(1):48–54.

Ribeiro, R. and Enembreck, F. (2013). A sociologically in-

spired heuristic for optimization algorithms: A case

study on ant systems. Expert Systems With Applica-

tions, 40(5):1814–1826.

Ribeiro, R., Favarim, F., Barbosa, M. A. C., Borges, A. P.,

Dordal, O. B., Koerich, A. L., and Enembreck, F.

(2012). Unified algorithm to improve reinforcement

learning in dynamic environments - an instance-based

approach. In International Conference on Enterprise

Information Systems, ICEIS ’12, pages 229–238.

Ribeiro, R., Ronszcka, A. F., Barbosa, M. A. C., Favarim,

F., and Enembreck, F. (2013). Updating strategies

of policies for coordinating agent swarm in dynamic

environments. In International Conference on Enter-

prise Information Systems, ICEIS ’13, pages 345–356.

ICEIS2015-17thInternationalConferenceonEnterpriseInformationSystems

502

Schmisseur, E. and Pankratz, J. (1989). Xlayer: an expert

system providing management advice to commercial

layer managers. Southern journal of agricultural eco-

nomics, 2(21):183–193.

Shariatmadari, F. (2012). Plans of feeding broiler chickens.

World’s Poultry Science Journal, 68(1):21–30.

Tavarez, M. A., Boler, D. D., Bess, K. N., Zhao, J., Yan,

F., Dilger, A. C., McKeith, F. K., and Killefer, J.

(2011). Effect of antioxidant inclusion and oil quality

on broiler performance, meat quality, and lipid oxida-

tion. Poultry Science, 90(4):922–930.

Teixeira, M., Malik, R., Cury, J., and de Queiroz, M. (2014).

Supervisory control of des with extended finite-state

machines and variable abstraction. Automatic Control,

IEEE Transactions on, 60(1):118–129.

ALearningModelforIntelligentAgentsAppliedtoPoultryFarming

503