Copyright Protection for 3D Printing by Embedding Information

Inside Real Fabricated Objects

Masahiro Suzuki

1

, Piyarat Silapasuphakornwong

1

, Kazutake Uehira

1

,

Hiroshi Unno

1

and Youichi Takashima

2

1

Kanagawa Institute of Technology, 1030 Shimo-ogino, Atsugi, Japan

2

Nippon Telegraph & Telephone Corp. Service Evolution Laboratories, 1-1 Hikarinooka, Yokosuka, Japan

Keywords: Digital Fabrication, 3D Printer, Copyright Protection.

Abstract: This paper proposes a technique that can protect the copyrights of digital content for 3D printers. It embeds

the information on copyrights inside real objects fabricated with 3D printers by forming a fine structure

inside the objects as a watermark. Information on copyrights is included in the content before data are input

into the 3D printer. This paper also presents a technique that can non-destructively read out information

from inside real objects by using thermography. We conducted experiments where we structured fine

cavities inside the objects by disposition, which expressed binary code depending on whether or not the

code was at a designated position. The results obtained from the experiments demonstrated that binary code

could be read out successfully when we used micro-cavities with a horizontal size of 2 x 2 mm, and

character information using ASCCI code could be embedded and read out correctly. These results

demonstrated the feasibility of the technique we propose.

1 INTRODUCTION

Digital fabrication technologies are attracting a great

deal of attention because they offer the possibility of

changing the system of manufacturing and logistics

((B. Berman, 2012), (B. Garrett, 2014)). Compact

low-cost 3D printers have recently been produced

and become easier for everyone to obtain. Their use

is expected to become widespread by the general

public. People are expected to have such digital

fabrication equipment at home in the future,

purchase the digital content of objects they want to

produce from Web sites, and then download the

content and manufacture objects at home with 3D

printers instead of purchasing real objects from

shops.

Although the final products are real objects in

such cases, the digital data have value, not the real

objects. Therefore, consumer pay for digital data and

not real objects that are final products because once

consumers obtain digital data, they can produce any

number of final product themselves.

As businesses where consumers purchase digital

data for 3D printers to produce real objects at home

become more widespread, the problem of illegal

copies of digital data will become serious because

digital data are easy to copy. This problem did not

exist when consumers purchased real objects from

stores and it is exclusive to selling digital content for

real objects produced by 3D printers. Copyrights for

digital content and digital watermarking have been

developed ((I. J. Cox et al., 1997), (M. D. Swanson

et al., 1998), (M. Hartung et al., 1999)) as

technologies to protect them. Moreover, digital

watermarking for 3D content has also been

developed ((P. R. Alface and B. Macq , 2007) (Q.S.

Ai, et al., 2009)). However, conventional digital

watermarking technologies cannot be applied to

cases where real objects are produced from digital

content by consumers because digital watermarking

is only read out from digital content and after real

objects are produced, it cannot be read out.

Here, we propose a technique that can protect the

copyrights of digital content for homemade products

using digital fabrication technologies such as those

in 3D printers. It embeds information on copyrights

inside real objects produced by 3D printers by using

fine structures inside the objects that cannot be

180

Suzuki M., Silapasuphakornwong P., Uehira K., Unno H. and Takashima Y..

Copyright Protection for 3D Printing by Embedding Information Inside Real Fabricated Objects.

DOI: 10.5220/0005342401800185

In Proceedings of the 10th International Conference on Computer Vision Theory and Applications (VISAPP-2015), pages 180-185

ISBN: 978-989-758-091-8

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

observed from the outside. We also propose a

technique that can non-destructively read out

information from inside real objects using

thermography. We conducted experiments to

confirm the feasibility of the proposed technique.

This paper also presents the results we obtained

from the experiments.

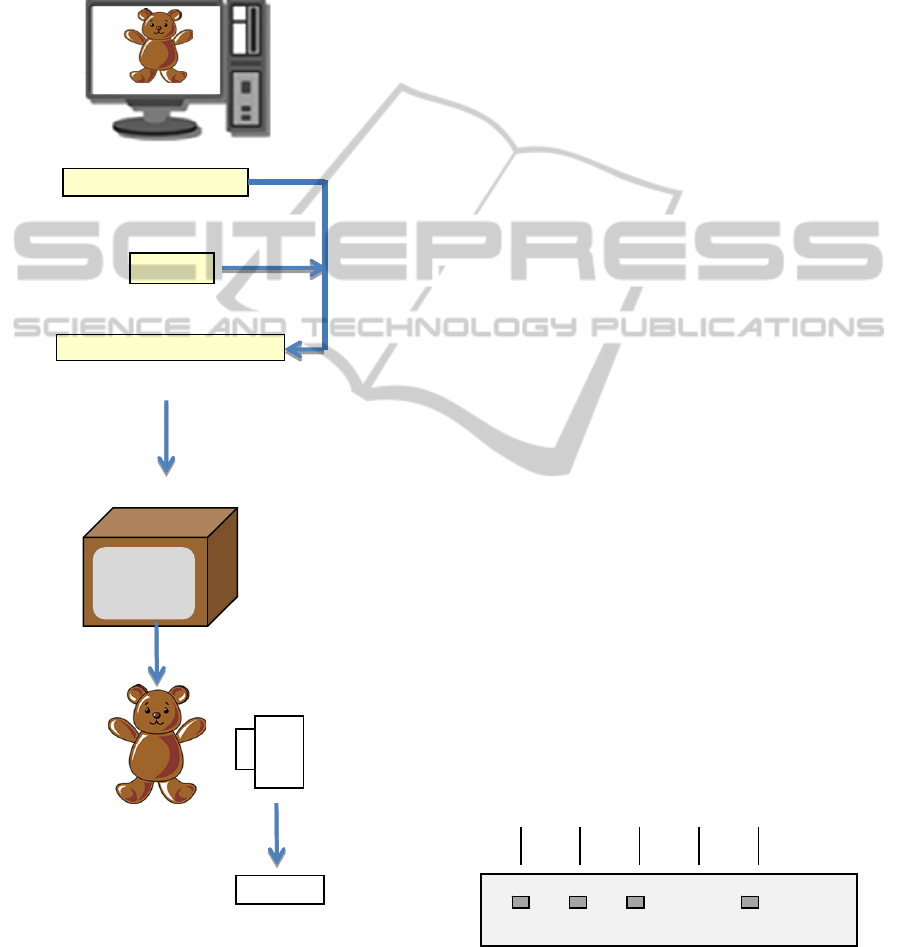

Content data

(Produced by 3D-CAD)

************

3D Printer

Information on copyright

A

BCD

*********************

Integrated data

Fabrication of

real object

ABCD

Download

Information on copyright

is embedded inside real

object

Reading out copyright

information from inside

real object

[Content provider]

[Customer]

Figure 1: Basic concept underlying proposed technique.

2 PROPOSED TECHNIQUE

2.1 Basic Concept

Figure 1 outlines the basic concept underlying the

technique we propose. After content data are

produced using 3D-CAD or 3D-CG tools, the data

for information on copyright are integrated with the

content data by a content provider. A customer

purchases the integrated data by downloading them

and inputs them into a 3D printer to produce an

object. The real object is basically formed using the

content data; however, fine structures are

simultaneously formed inside the real object during

its fabrication. These structures express the

information on copyright. The structures are non-

destructively analyzed from the outside and

information that the structures express is decoded,

i.e., embedded information is read out.

Therefore, if the content provider finds a real

object and is suspicious that it has been illegally

produced, he/she can check this by using the method

mentioned above. This has an effect of restraining

illegal copies or production. The restraining effect

we are expecting is the same as that of conventional

digital watermarking. Here, illegal production means

more products than those permitted for the content

that is purchased, in addition to production using

content that is illegally copied.

2.2 Embedding Information with Fine

Structures inside Objects

The easiest and simplest way of expressing

information is by using fine structures inside objects

to form character shaped structures. However, this is

also easy for people to observe who are trying to

illegally produce objects. Another way is to form

code that is encoded from character information.

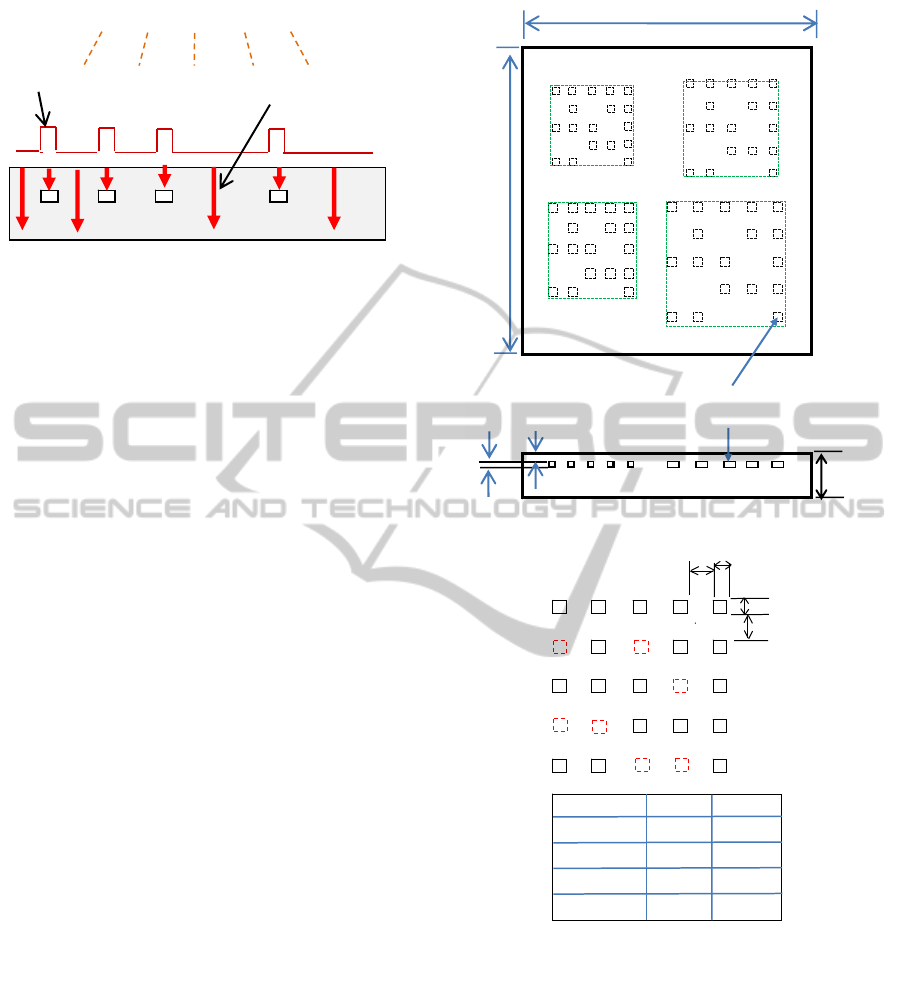

Figure 2 has a simple example of this method. An

object produced by a 3D printer contains fine

1 1 1 0 1

Figure 2: Example representation of binary code by using

fine structure inside real object. Hatched areas are fine

domains whose physical characteristics differ from other

areas.

CopyrightProtectionfor3DPrintingbyEmbeddingInformationInsideRealFabricatedObjects

181

Heat flow

Tem

p

erature

p

rofile

Surface heatin

g

b

y

li

g

htin

g

Figure 3: Example representation of binary code by

structuring fine domain inside real object.

domains whose physical characteristics such as

optical, acoustic, or heat conduction differ from the

body of the object. The disposition of the fine

domain expresses this information. Although there

are various ways of expressing information due to

the disposition of the fine domain, one example is

where binary data, “1” or “0”, are expressed due to

the existence or non-existence of the fine domain in

a designated position, as shown in Fig. 2. Therefore,

we can expect to read out these embedded binary

data using X-rays or ultrasonic waves if we know

the disposition of the fine domain from the outside

of the real object by utilizing the difference in

physical characteristics between the fine domain and

the body material of the object.

We formed small cavities as fine domains in this

study to structure the inside of a real object and

embed information on copyright in it. Since there

was no material in the cavities, their physical

characteristics were different from those of other

areas where material was filling up.

2.3 Reading out Information

We propose a method of thermography to read out

embedded information. Figure 3 outlines the

principles behind reading out binary code using

thermography. First, the temperature of the surface

of the object rises by heating. This results in heat

conduction from the surface to the inside of the

object. However, heat conduction is blocked by

small cavities because their heat conductivity is very

low. This causes the temperature of the surface area

under the cavities to increase and such areas become

slightly higher than the other areas, as shown in Fig.

3. Therefore, if we obtain the temperature profile of

the surface of the object using thermography, we

expect to know the disposition of the fine domain,

i.e., it enables us to read out the binary data

embedded in the real object.

(b) Cross-section

50 mm

1 mm

(a) Top view

A

B

C

D

s

w

w

s

(mm)

D

2

2

GroupA

B

C

s

w

1

2

1

1

2

1

Micro-domain

(Micro-cavity)

50 mm

1 mm

10 mm

(c) Possible positions of cavity and size

parameters. Dashed lines indicate positions

where there are no cavities

Figure 4: Sample used in experiment (Sample 1).

3 EXPERIMENTS

We evaluated the feasibility of this method that used

thermography to analyze the distribution of fine

cavities and read out character information by

decoding binary code. Figure 4 has an example of

the sample (Sample 1) we used in an experiment.

VISAPP2015-InternationalConferenceonComputerVisionTheoryandApplications

182

00110100 -K

00110001 -A

00110000 -I

00110010 -T

01010100 -2

01001001 -0

01000001 -1

01001011 -4

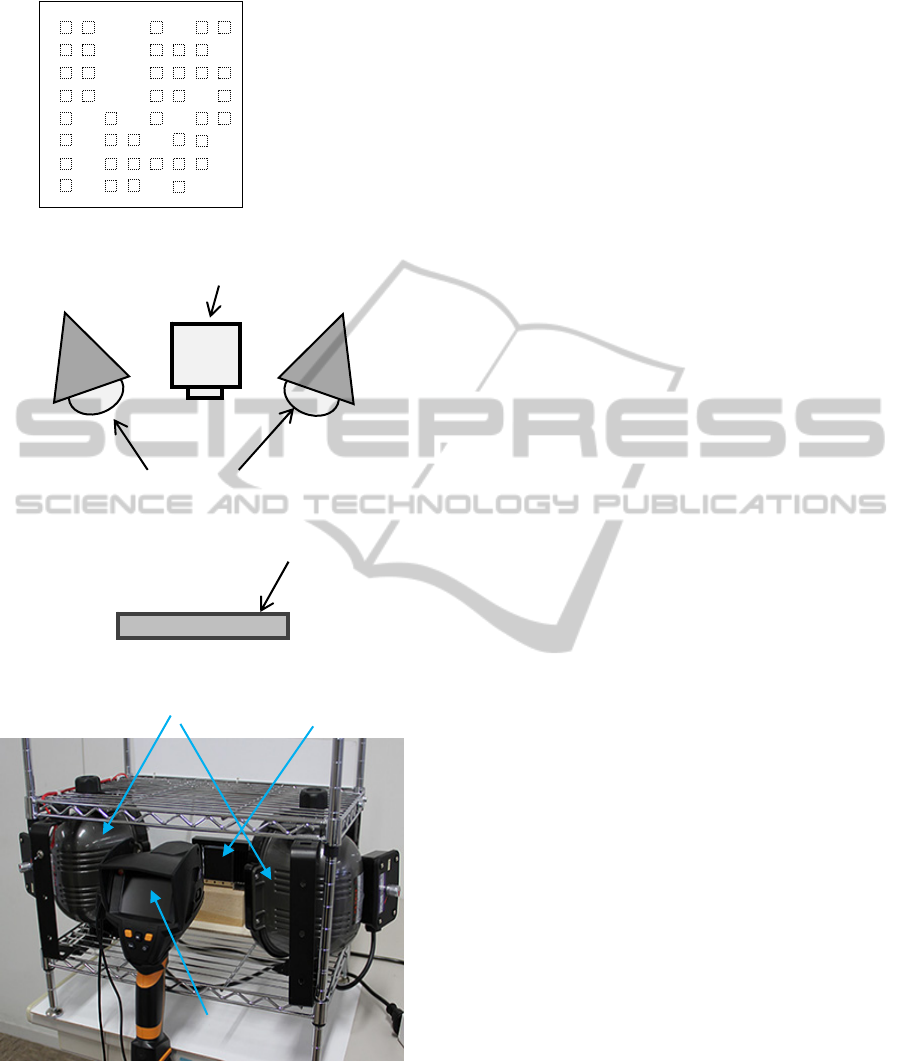

Figure 5: Sample used in experiment (Sample 2).

Thermography

Sample

Halogen lamp

Figure 6: Configuration for experiment.

Halogen lamp

Thermography

Sample

Figure 7: Photograph of experimental system.

We produced it with a stereolithographic 3D printer

and polylactide (PLA) resin was used as the material

for the sample, which was 5 x 5 x 1 cm. The sizes of

the cavities and spaces between them were changed

as experimental parameters, as listed in Fig. 4 (c).

They were formed at positions at a depth of 1 mm

from the surface.

We also prepared a sample in which the

character information was embedded by disposition

of the cavities which expressed the American

Standard Code for Information Interchange (ASCII)

code for the characters (Sample 2). Figure 5 has an

example of Sample 2. The size parameters were the

same as those for Group D of Sample 1. Although

Figure 5 only shows the top view, the vertical sizes

of the sample and the cavities are also the same as

those of Sample 1. We assigned “0” to positions

where there were cavities and “1” where there were

no cavities. The disposition of these cavities

expressed ASCCI code for eight characters –

KAIT2014.

Figure 6 illustrates the experimental system. We

used two 500-W halogen lamps to heat the object

surface. The lamps were placed at a distance of 10

cm from the sample. Thermography that had a

resolution of 160 x120 pixels was used to capture a

thermal image on the surface of an object. The

temperature resolution of thermography was 0.1

degree. Figure 7 has a photograph of the

experimental system.

We read out the arrangement of cavities as

follows. Since we knew the possible positions of

cavities in advance, we checked whether there were

cavities or not at all possible positions by comparing

the temperature of the surface area above possible

positions and that of peripheral areas where there

were no cavities, i.e., we determined this depending

on if the difference in temperature was larger than a

threshold value or not.

4 RESULTS AND DISCUSSION

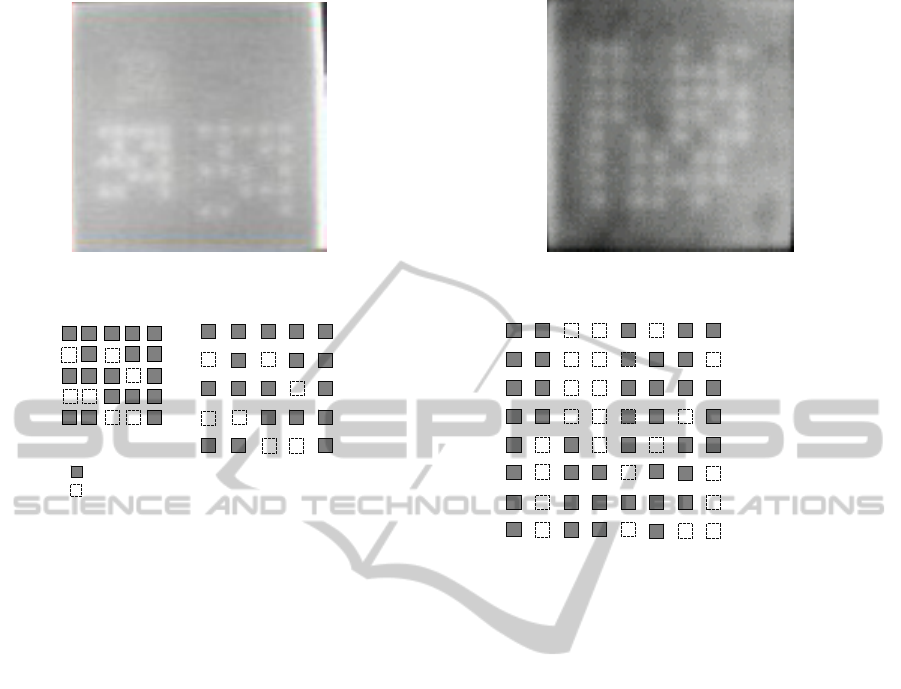

Figure 8 has an image captured with thermography

for Sample 1. This image was one captured 10 s

after heating started. It can be seen from Fig. 8 that

the temperature of the surface area above the

cavities is higher than that of the other areas

regardless of the space length between adjacent

cavities. Figure 9 has the results for determining the

existence of cavities at possible positions for the 2 x

2 mm cavities. It can be seen that it is possible to

correctly determine cavities for all the positions.

We can only see slight differences in temperature

for the surface area above cavities that are 1 x 1mm.

These differences were too small to enable the

embedded information to be read out correctly. The

reason we could not see the difference in

temperature for 1 x 1 mm cavities was because heat

CopyrightProtectionfor3DPrintingbyEmbeddingInformationInsideRealFabricatedObjects

183

Figure 8: Image captured with thermography for Sample 1.

Positions where no cavities

Positions where cavities exists

Figure 9: Results for existence of fine cavities for Sample 1.

not only diffused straight down, but diffused in all

directions depending on the temperature gradient.

However, we still have the possibility of detecting

cavities to enhance the resolution of the temperature

of the thermal image of the object surface.

Figure 10 has an image captured with

thermography for Sample 2. Figure 11 has the

results to determine the existence of cavities at

possible positions and it also reveals the characters

decoded from the ASCCI code. It can be seen from

Figs. 10 and 11 that embedded character information

(KAIT2014) can be read out correctly. These results

demonstrate the feasibility of our proposed

technique.

5 CONCLUSIONS

We proposed a technique that could protect the

copyright of digital content for digital fabrication

technologies such as 3D printers. It embeds

information on copyrights inside real objects

produced by 3D printers by using fine structures

inside objects. We also proposed a technique that

can non-destructively read out information from

inside real objects using thermography. We

conducted experiments where we used fine cavities

to express binary information depending on whether

it existed or not at designated positions. The results

Figure 10: Image captured with thermography for Sample 2.

00110100 -K

00110001 -A

00110000 -I

00110010 -T

01010100 -2

01001001 -0

01000001 -1

01001011 -4

Figure 11: Results for existence of fine cavities for Sample 1.

from the experiments demonstrated that binary code

could be read out successfully when we used fine

cavities with a horizontal size of 2 x 2 mm and

character information using ASCCI code could be

embedded and read out correctly. These results

demonstrate the feasibility of the technique we

propose.

We intend to test materials other than PLA resin

in future work; especially material that has high heat

conductivity. We will also try to make embedded

information more invisible both as digital content

data and in real objects.

REFERENCES

B. Berman, 2012. 3-D printing: The new industrial

revolution. Business Horizons, 55 (2): 155–162.

B. Garrett, 2014. 3D Printing: New Economic Paradigms

and Strategic Shifts. Global Policy, 5(1): 70–75.

I. J. Cox, J. Kilian, F. T. Leighton, and T. Shamoon, 1997.

Secure spread spectrum watermarking for multimedia,

IEEE Trans. Image Process., 6 (12): 1673–1687.

M. D. Swanson, M. D. Swanson, M. Kobayashi, and A.H.

Tewfik, 1998. Multimedia data-embedding and

watermarking technologies, Proc. IEEE, 86 (6): 1064–

1087.

VISAPP2015-InternationalConferenceonComputerVisionTheoryandApplications

184

M. Hartung and M. Kutter, 1999. Multimedia

watermarking techniques, Proc. IEEE, 87 (7): 1079–

1107.

P. R. Alface and B. Macq , 2007. From 3D Mesh Data

Hiding to 3D Shape Blind and Robust Watermarking:

A Survey, Transactions on Data Hiding and

Multimedia Security II: Lecture Notes in Computer

Science, 4499: 91–115.

Q.S. Ai, Q. Liu, Z.D. Zhou, L. Yang, and S.Q. Xie, 2009.

A new digital watermarking scheme for 3D triangular

mesh models, Signal Processing, 89 (11): 2159–2170.

CopyrightProtectionfor3DPrintingbyEmbeddingInformationInsideRealFabricatedObjects

185