TE Modes in Liquid Crystal Optical Fibers Embedded with

Conducting Tape Helix Structure

Masih Ghasemi and P. K. Choudhury

Institute of Microengineering and Nanoelectronics, Universiti Kebangsaan Malaysia, U.K.M. Bangi, 43600, Malaysia

Keywords: Liquid Crystal Fibers, Complex Optical Microstructures, Electromagnetic Waves.

Abstract: The transverse electric (TE) behaviour of light in a doubly-clad cylindrical optical fiber loaded with radially

anisotropic liquid crystal material at the outermost cladding is investigated. Moreover, this situation is

studied when a conducting tape helix structure is introduced at the boundary of the isotropic dielectric core

and the inner dielectric clad of the fiber. The outer clad is considered to be made of anisotropic nematic

liquid crystal (NLC). Using Maxwell’s electromagnetic field equations, confinement plots are obtained for

the transmitted power in each scenario, under the situation of varying core dimension, and compared.

Results confirm the achievement of better confinement in the liquid crystal layer of the conducting tape

helix loaded fiber, which can even be tailored by using different angle of helix pitch.

1 INTRODUCTION

Nonlinear properties of liquid crystals (LCs) have

been utilized in variety of applications in optics

industries. For instance, the latest research illustrates

the impact of temperature on the optical harmonic

generation in fiber-coupled nematic LCs (Trashkeev

et al., 2014). Other report shows that LC fiber array

would confine transmission of high energy laser

pulses, which can be exploited as protector for

downstream sensors (Khoo et al., 1996). The

literature on LC based waveguides proved potentials

of research concealed behind the dispersion property

of radial anisotropy orientation of LC material

(Ioannidis et al., 1991).

Apart from the aforementioned applications, LCs

are greatly useful for devising various forms of

sensing and field coupling needs that include optical

sensors as well. For example, such materials become

indispensable in fabricating lasers (Dolgaleva et al.,

2009), polarimetric sensors (Wolinski et al., 2001),

dispersion compensators (Akbulut, 2006), imaging

systems (Gebhart et al., 2005), electric field and

temperature sensors (Wolinski et al., 2006),

photonic crystal based guides (Wolinski et al.,

2005), optical filters (Stratis et al., 2001), integrated

optic devices (d’Alessandro, 2004) etc. Within the

context, optical fibers based on liquid crystals can be

given a serious thought, and the sensing applications

of such LC fibers have been investigated before

(Choudhury, 2014). It has been reported earlier that

tapering the fiber cross-section greatly enhances the

optical sensing capability of LC based fibers

(Choudhury et al., 2011).

Amalgamation of material and geometrical

properties could be the possible way to govern the

lightwave propagation in waveguide technologies

(Choudhury et al., 2004; Ghasemi et al., 2014).

Apart from the LC material, perfectly conducting

twisted clad fibers have also been reported as useful

complex mediums wherein the pitch angle of

conducting sheath or tape helices impose great

control over the propagation characteristics of

electromagnetic waves (Ghasemi et al., 2014).

In the present paper, we deal with a three-layer

optical fiber with the outermost region being coated

with radially anisotropic LC material, and the inner

dielectric core-clad interface is loaded with

conducting tape helix structure. It must be

remembered that the thickness of conducting tape

remains infinitesimally small, which makes one to

assume this parameter as almost vanishing. As such,

the perpendicular component of surface current over

the tape may be ignored, as compared to the parallel

one. With the assumption of the availability of the

flow of current over the surface of tape, recent report

emphasized that the LC layer is more prone to

confine the transmission of power for the lowest

zero-order hybrid mode (Ghasemi et al., 2014). In

Ghasemi M. and Choudhury P..

TE Modes in Liquid Crystal Optical Fibers Embedded with Conducting Tape Helix Structure.

DOI: 10.5220/0005319800610066

In Proceedings of the 3rd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2015), pages 61-66

ISBN: 978-989-758-092-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

the present work, we emphasize on the confinement

due to transverse electric (TE) modes under varying

tape helix pitch angle. Results reveal that small

changes in the angle of pitch bring in considerable

shifts in the characteristics of power transmission

properties. The TE

01

mode with lower propagation

constants transmits lower amount of power, and the

fractional power increases with the increase in

propagation constant in LC layer of fiber structure

under consideration. The results are also compared

with the situation when the tape helix structure is

eliminated, in order to investigate the effect of the

presence of conducting tape helical windings.

2 THEORY

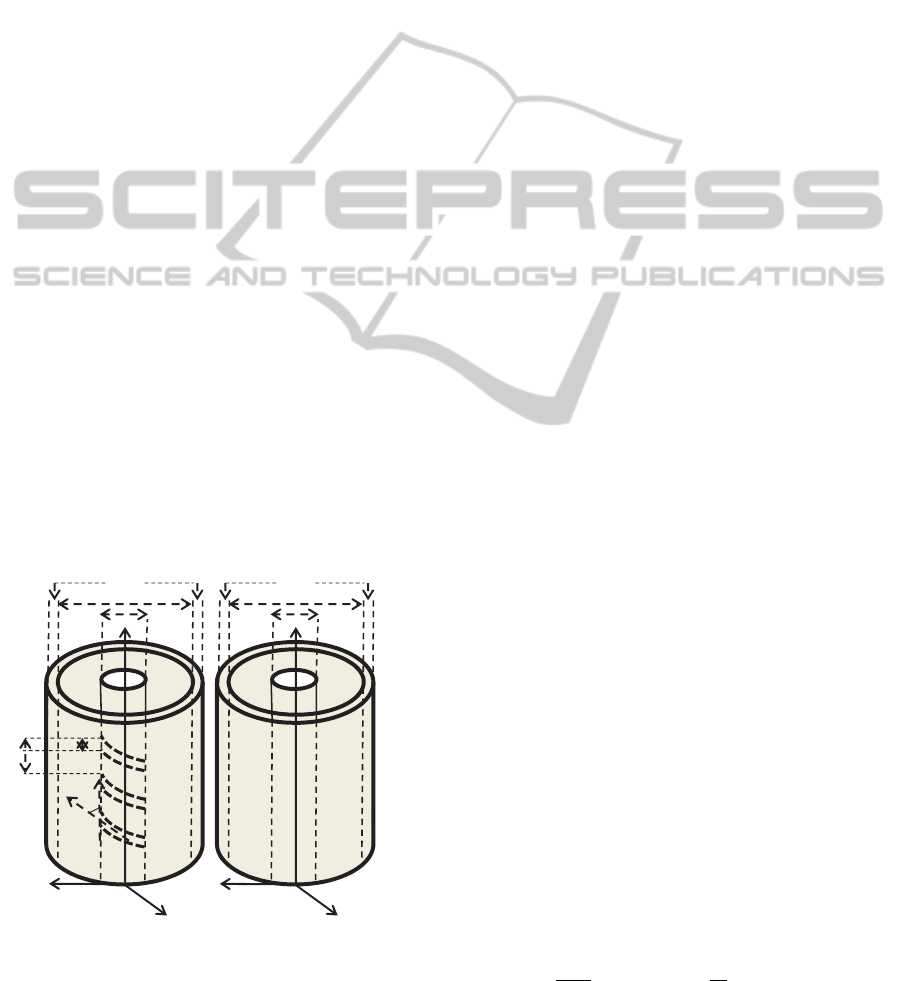

Figures 1a and 1b, respectively, illustrate the

schematics of LC optical fibers with and without

conducting tape helix loadings. In the case of fig. 1a,

represents the helix pitch angle, which may

assume values between 0 and 90. For the sake of

simplicity, the LC layer is considered to be infinitely

extended in the radial direction, whereas the inner

isotropic dielectric core and the clad sections have

the radius values as and , respectively. The

refractive index (RI) of the core and the inner clad

regions are taken to be

and

, respectively.

Owing to the ordinary and the extraordinary

orientations of the outermost LC layer, we consider

and

as the respective RI values belonging to

each orientation. Numerically, the RI distribution

profile may be written as

.

Figure 1: Schematic diagram of the LC fiber embedded

with conducting tape helix (a) and without tape helix (b)

structure.

The cylindrical polar coordinate system ,, is

used for the analysis of fibers with conducting tape

helix loadings. We consider that the time - and axis

-harmonic electromagnetic waves propagate along

the -direction. Considering fig. 1a, the parameters

, and , respectively, represent the pitch angle of

conducting tape helix, width of the conducting tape

and the distance between two successive tape helical

windings. However, it must be noted that and

are related through

arctan/2

(1)

Equation (1) indicates that the helix pitch angle

essentially depends on the fiber core dimension. As

such, in the present investigation, computations are

made for different values of core diameter, which

provide particular values of pitch angle.

It must be remembered that, while investigating

the TE

01

mode in the fiber structure, the only

available fundamental electric fields component is

, which is independent of the coordinate ; the

other components of field vanish. As such, we

consider

/0, and the solutions of the

coupled differential equations contain Bessel and the

modified Bessel functions (Snyder et al., 1983).

,

1,0:

0

2:

0,

1,

3:

∞

(2)

Equation (2) is written in symbolic form where the

number of layer that corresponds to each region of

fiber and represents subpart of the combined

Bessel function within each layer. More explicitly,

,

is Bessel function of the first kind in the first

layer,

,

and

,

are the modified Bessel

functions in the second layer, and

,

is Hankel

function of the second kind in the third layer of the

LC fiber. Furthermore, the quantities , and

related to the core, the inner clad and the outer clad

parameters, respectively, are defined as

√

(3)

√

(4)

√

(5)

Upon substituting the above eq. (2) in Maxwell’s

equations, we finally obtain the following axial,

radial and azimuthal components of electromagnetic

field in the different fiber sections:

,

,

(6)

2

2

(a)

2

2

(b)

,

,

2

,

,

,

,

(7)

,

(8)

,

,

,

,

(9)

,

,

2

,

,

,

,

,

,

2

,

,

,

,

(10)

,

,

(11)

,

,

(12)

,

,

2

,

,

,

,

(13)

,

(14)

In the above equations, , , and are the

(unknown) arbitrary constants, which are to be

determined by the use of suitable boundary

conditions (Ghasemi et al., 2014). The relevant

analytical treatment ultimately yields the values of

these constants as

ϱ

(15)

ϱ

(16)

Cϱ

(17)

Dϱ

(18)

where ϱ

is the total current density over surface of

tape helix, as obtained by using the tangential

components of magnetic field in the core and the

inner clad regions of fiber. Corresponding to the

situation of TE

01

mode, ϱ

would assume the form

ϱ

(19)

Further, the other symbols used in eqs. (15)(18)

have meanings as follows:

(20)

(21)

(22)

(23)

(24)

(25)

with

,

(26)

,

,

(27)

,

(28)

,

(29)

,

,

(30)

,

,

(31)

,

(32)

,

(33)

,

,

(34)

,

,

(35)

,

(36)

,

,

(37)

In the case of fiber with the loading of

conducting tape helix (fig. 1a), we consider that the

flow of current takes place over the surface of tape.

However, in the case of fig. 1b, fields remain

continuous at each boundary, and power

confinements are derived from the continuity

conditions. The elimination of conducting tape will

essentially cause the expressions of electric and

magnetic components to have different set unknown

constants, viz.

,

,

and

. Thus, we can have

the field components in this case as

,

,

(38)

,

,

2

,

,

,

,

(39)

,

(40)

,

,

,

,

(41)

,

,

2

,

,

,

,

,

,

2

,

,

,

,

(42)

,

,

(43)

,

,

(44)

,

,

2

,

,

,

,

(45)

,

(46)

Equations (38)(46) can be exploited to

implement the continuity conditions of fields

corresponding to the non-helix kind of LC fiber.

Further, eqs. (26)(37) can be utilized in order to

extract the expressions for the unknown constants

corresponding to the TE

01

mode excitation. Finally,

the unknown constants

and

will assume the

forms, in terms of

, as follows:

(47)

(48)

(49)

with

(50)

(51)

Finally, in order to compute the propagation of

power through the LC fiber structures of fig. 1, we

use eqs. (15)(18) corresponding to the case of

conducting tape helix based fiber (fig. 1a), whereas

eqs. (47)(49) for the fiber without the existence of

tape helix structure (fig. 1b). Furthermore, by the use

of electromagnetic field equations corresponding to

the case of particular fiber, the expressions for the

confinement of power in the different fiber regions

for the respective LC fiber structure can be deduced.

3 RESULTS AND DISCUSSION

We now make attempts to evaluate the confinement

of power in the fiber structures of fig. 1 due to the

transmission of the TE

01

mode. At this point, this

must be remembered that, as stated above, the entire

mathematical treatment is not incorporated into the

text, in order to avoid the length of the manuscript.

For the computational purpose, we assume the RI

values of the core and the inner clad sections as

1.462 and

1.458, respectively, while in

the LC layer we take the nematic liquid crystal as

BDH mixture 14616 having the respective ordinary

and the extra ordinary RI values as

1.457 and

1.5037. The wavelength of operation is taken

as 633 nm. Further, it must be remembered that, in

the evaluation of power, the distance between two

consecutive tape helix windings is governed by the

following expression:

/2

/

(52)

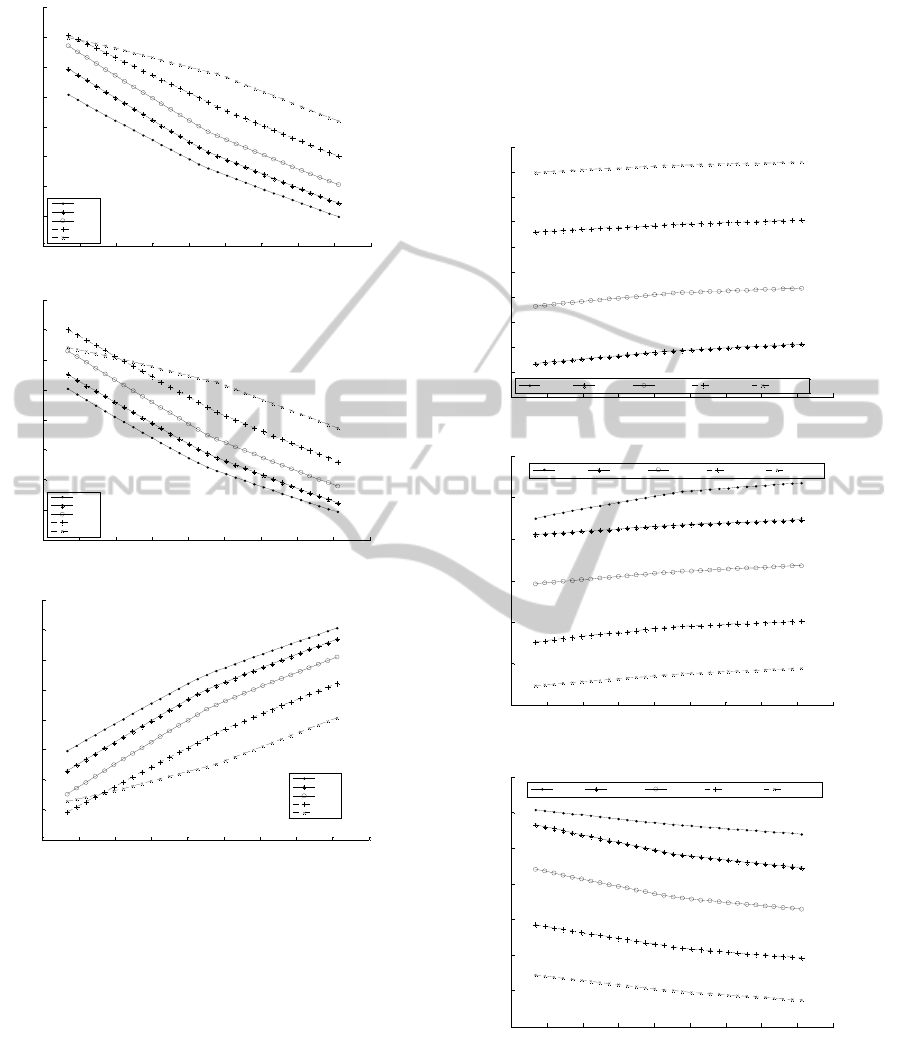

Figures 2a, 2b and 2c illustrate the plots of the

propagation of power in the core, the inner clad and

the outer clad sections, respectively, under the

situation when the LC fiber is assumed to have a

loading of conducting tape helix with specific

orientation. For this purpose, we consider five

different values of fiber core dimension through

setting the value of as 5 µm, 15 µm, 30 µm, 50 µm

and 70 µm. Also, the inner clad size is taken to be

fixed with as 150 µm, while the outermost LC clad

is extended to infinity. Furthermore, we consider

that , the width of the tape, is 10 times smaller than

the pitch formed due to the gap between two

successive windings of conducting tape helix. Since

the pitch of helix has inverse relationship with the

core size, the lowest value of pitch corresponds to

the largest core size. The aforementioned values of

give the respective values of helix pitch angles as

0.79, 0.26, 0.13, 0.08 and 0.06. In figs. 2, plots

of confinements are illustrated corresponding to

these specific values of that essentially represent

varying orientation of conducting tape helix.

We observe from fig. 2a that the confinement

due to the TE

01

mode remains very small in the core

section, particularly for the higher values of

propagation constant. Corresponding to all the

values of fiber core dimension, it gradually

decreases with the increase in -values. In the inner

Figure 2: TE

01

mode power confinement patterns in the

fiber (a) core, (b) inner clad, and (c) LC outer clad in the

case of conducting tape helix loaded LC fiber.

clad section too, the behaviour of power distribution

remains almost similar (fig. 2b). Figure 2c illustrates

that, for higher -values, the confinement is

markedly increased, and remains the maximum

corresponding to the maximum value of helix pitch

angle. For 0.79°, we find from fig. 2c that the

confinement varies between 20%65% over the

allowed values of propagation constant.

In order to have a comparative look,

investigations are made of the LC fiber without the

loading of the conducting tape helix windings, and

the corresponding plots are shown in fig. 3. In this

set of figures, we observe that, in every section of

fiber structure, confinement due to the TE

01

mode

becomes smaller, as compared to the situation of

fiber with tape helix (fig. 2).

Figure 3: TE

01

mode power confinement patterns in the

fiber (a) core, (b) inner clad, and (c) LC outer clad in the

case of LC fiber.

Our prime interest remains on the way to

increase the confinement of power in the outermost

section of fiber. We, therefore, observe that the fiber

1.447 1.4475 1.448 1.4485 1.449 1.4495 1.45 1.4505 1.451 1.4515

x 10

7

0.2

0.25

0.3

0.35

0.4

0.45

0.5

0.55

(m

-1

)

Pco

P = 0.43356

m

b = 150

m

= 0.1 P

=0.7 9

=0.2 6

=0.1 3

=0.0 8

=0.0 6

1.447 1.4475 1.448 1.4485 1.449 1.4495 1.45 1.4505 1.451 1.4515

x 10

7

0.2

0.25

0.3

0.35

0.4

0.45

0.5

0.55

(m

-1

)

Pic

P = 0.43356

m

b = 150

m

= 0.1 P

=0.7 9

=0.2 6

=0.1 3

=0.0 8

=0.0 6

1.447 1.4475 1.448 1.4485 1.449 1.4495 1.45 1.4505 1.451 1.4515

x 10

7

-0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

(m

-1

)

Poc

P = 0.43356

m

b = 150

m

= 0.1 P

=0.7 9

=0.2 6

=0.1 3

=0.0 8

=0.0 6

1.447 1.4475 1.448 1.4485 1.449 1.4495 1.45 1.4505 1.4 51 1.4515

x 10

7

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

0.2

(m

-1

)

Pco

a=5

m a=15

m a=30

m a=50

m a=70

m

1.447 1.4475 1.448 1.4485 1.449 1.4 495 1.45 1.4505 1.451 1.4515

x 10

7

0.38

0.4

0.42

0.44

0.46

0.48

0.5

(m

-1

)

Pic

a=5

m a=15

m a=30

m a=50

m a=70

m

1.447 1.4475 1.448 1.4485 1.449 1.4495 1.45 1.4505 1.4 51 1.4515

x 10

7

0.4

0.42

0.44

0.46

0.48

0.5

0.52

0.54

(m

-1

)

Poc

a=5

m a=15

m a=30

m a=50

m a=70

m

(a)

(b)

(c)

(a)

(b)

(c)

embedded with conducting tape helix structure

remains capable to sustain more amount of power in

the outermost liquid crystal section. This essentially

makes the structure possibly more efficient for its

usages like the integrated optic devices for field

coupling and/or in the area of optical sensing.

4 CONCLUSIONS

From the foregoing analyses, it can be inferred that

the LC fiber structure loaded with conducting tape

helix windings would be more useful for

applications in optics industry. This is primarily due

to the reason that the outermost liquid crystal region

becomes more prone to confine higher amount of

power to be used particularly for the evanescent

field based optical applications (e.g. sensing or

coupling of electromagnetic fields). These

conclusive remarks are drawn based on comparing

the results obtained for ordinary LC clad fibers with

radially anisotropic liquid crystal materials.

ACKNOWLEDGEMENTS

The authors are thankful to the Ministry of Higher

Education (Malaysia) for granting the financial

support to the work Also, they are thankful to

Professors B.Y. Majlis and S. Shaari for constant

encouragement and help.

REFERENCES

Trashkeev, S. I., Nyushkov, B. N., 2014. Thermal

enhancement of optical harmonic generation in a fiber-

coupled nematic liquid crystal. Laser Optics 2014 –

IEEE International Conference, pp. 11.

Khoo, I. C., Wood, M., Guenther, B. D., 1996. Nonlinear

liquid crystal optical fiber array for all-optical

switching/limiting. In LEOS 96 – IEEE Lasers and

Electro-Optics Society Annual Meeting, vol. 2, pp.

211212.

Ioannidis, Z. K., Giles, I. P., Bowry, C., 1991. All-fiber

optic intensity modulators using liquid crystals, Appl.

Opt., vol. 30, pp. 328333.

Dolgaleva, K., Wei, S. K. H., Lukishova, S. G., Chen,

S.H., Schwertz, K., Boyd, R.W., 2009. Enhanced laser

performance of cholesteric liquid crystals doped with

oligofluorene dye. J. Opt. Soc. Am. B, vol. 25, pp.

1496–1504.

Wolinski, T. R., Szymanska, A., 2001. Polarimetric

optical fibres with elliptical liquid-crystal core. Meas.

Sci. Technol., vol. 12, pp. 948−951.

Akbulut, M., 2006. Broadband all-order polarization mode

dispersion compensation using liquid-crystal

modulator arrays. J. Lightwave Technol., vol. 24, pp.

251−261.

Gebhart, S. C., Stokes, D. L., Vo-Dinh, T., Mahadevan-

Jansen, A., 2005. Instrumentation considerations in

spectral imaging for tissue demarcation: comparing

three methods of spectral resolution. Proc. SPIE, vol.

5694, pp. 41−52.

Wolinski, T. R., Szaniawska, K., Ertman, S., Lesiak, P.,

Domanski, A.W., Dabrowski, R., Nowinowski-

Kruszelnicki, E., Wojcik, J., 2006. Influence of

temperature and electrical fields on propagation

properties of photonic liquid-crystal fibres. Meas. Sci.

Technol., vol. 17, pp. 985–991.

Wolinski, T. R., Szaniawska, K., Bondarczuk, K., Lesiak,

P., Domanski, A. W., Dabrowski, R., Nowinowski-

Kruszelnicki, E., Wojcik, J., 2005. Propagation

properties of photonic crystal fibers filled with

nematic liquid crystals. Opto-Electron. Rev., vol. 13,

pp. 59–64.

Stratis, D. N., Eland, K. L., Carter, J. C., Tomlinson, S. J.,

Angel, S.M., 2001. Comparison of acousto-optic and

liquid crystal tunable filters for laser-induced

breakdown spectroscopy. Appl. Spectroscop., vol. 55,

pp. 999−1004.

d’Alessandro, A., Asquini, R., Gizzi, C., Bellini, B.,

Beccherelli, R., 2004. Integrated optic devices using

liquid crystals: design and fabrication issues. Proc.

SPIE, vol. 5518, pp. 123−135.

Choudhury, P. K., 2013. Liquid crystal optical fibers for

sensing applications. Proc. SPIE, vol. 8818, pp.

88180E-1–88180E-10.

Choudhury, P. K., Soon, W. K., 2011. On the transmission

by liquid crystal tapered optical fibers. Optik, vol. 122,

pp. 10611068 (2011).

Choudhury, P. K., Yoshino, T., 2004. TE and TM modes

power transmission through liquid crystal optical

fibers. Optik, vol. 115, pp. 4956.

Ghasemi, M., Choudhury, P. K., 2014. Propagation

through complex structured liquid crystal optical

fibers. J. Nanophoton., vol. 8, pp. 083997-1083997-

13.

Ghasemi, M., Choudhury, P. K., 2014. Waves in tape

helix loaded liquid crystal optical fiber. Proc. SPIE,

vol. 9172, pp. 91720G-1–91720G-8.

Snyder, A. W., Rühl, F., 1983. Single-mode, single-

polarization fibers made of birefringent material. J.

Opt. Soc. Am., vol. 73, pp. 11651174.