Micro Sensors for Real-time Monitoring of Mold Spores and Pollen

Kei Tsuruzoe and Kazuhiro Hara

Department of Electrical and Electronics Engineering, School of Engineering, Tokyo Denki University

5 Senjyu-Asahicho, Adachiku, Tokyo 120-8551, Japan

Keywords: Mold Spore, Pollen, Real–time Monitoring, Micro Sensor, Semiconductor Thin Film, Metal Oxide.

Abstract: Organic airborne particles such as mold spores and pollen cause a variety of diseases. Two types of micro

sensors for real-time monitoring of such organic airborne particles have been developed using

semiconductor thin-film. A basic type thin-film sensor has a simple configuration with a double-layered

sensing film deposited on an alumina substrate. A MEMS type sensor is composed of two parts: a sensing

element and a micro heater. Both parts are fabricated by using thin film technology, IC fabrication process

and micromachining technique. The double-layered sensing film is deposited on a diaphragm formed on a

Si substrate. A thin film heater is placed in parallel at a distance of about 50 μm. The resistance of both

sensors steeply decreases and then recovers to the initial value when a mold spore or a grain of pollen

adheres to the surface of the sensing film and burns on it. The resistance change and the recovery time

depend on the size of the organic airborne particles. Thus it is possible to identify the species of the particle

by the developed sensors. The sensors offer simple and inexpensive method to monitor organic airborne

materials.

1 INTRODUCTION

Many people fall in pneumonia by inhalation of

mold spores such as aspergillus fumigatus. At the

same time, the number of people who are allergic to

organic airborne particles such as pollen and house

dust has been increasing. Although human noses are

sensitive to some toxic gases and odors such as burnt

odor and bad smell, human noses cannot detect

organic airborne particles. Therefore, it is required to

develop sensors for these airborne particles.

Some methods have been developed to monitor

airborne

materials so far. Various types of samplers

are usually used to count the number of airborne

mold spores (Hoisington et al., 2014; Whyte et al.,

2007). However, they are disadvantageous in that it

takes several days to culture them on agar. The

gravitational method by a Durham’s sampler is a

common one to obtain the number of pollen

(Konishi et al., 2014). It also takes a lot of time to

get the number because they are observed by the

human eye through an optical microscope. These

two methods are not fit for real-time monitoring of

airborne materials. Particle counters with laser optics

are sometimes used (Weber et al., 2012). However,

they cannot distinguish organic airborne particles

from inorganic particles such as ashes and sands. In

addition, they are complex and expensive in general.

This paper describes novel, inexpensive micro

sensors that are capable of detecting organic

airborne particles such as mold spores and pollen.

Two types of micro sensors have been developed: a

basic type sensor and a MEMS type sensor. The

former has a simple structure with a relatively large

sensing area that is suitable for detection of larger

airborne particles. The latter has a smaller sensing

area that is better suited for detection of smaller

airborne particles.

Both sensors have configurations which are

similar to thin-film gas sensors (Brunet et al., 2012;

Sharma et al., 2011). In addition, similar sensing

materials based on semiconductor metal oxides such

as SnO

2

and Fe

2

O

3

were used for the developed

sensors. In general, these metal oxides are stable at

elevated temperatures and their resistance changes

by the redox reaction on the surface when a reducing

gas or an oxidizing gas is introduced. In ordinary gas

sensors, greater sensing area is better because it

increases the sensitivity to these gases. In this study,

however, the sensing area was reduced to fit for

detection of fine airborne particles.

174

Tsuruzoe K. and Hara K..

Micro Sensors for Real-time Monitoring of Mold Spores and Pollen.

DOI: 10.5220/0005279301740179

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2015), pages 174-179

ISBN: 978-989-758-071-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

2 EXPERIMENTAL

2.1 Sensor Configuration

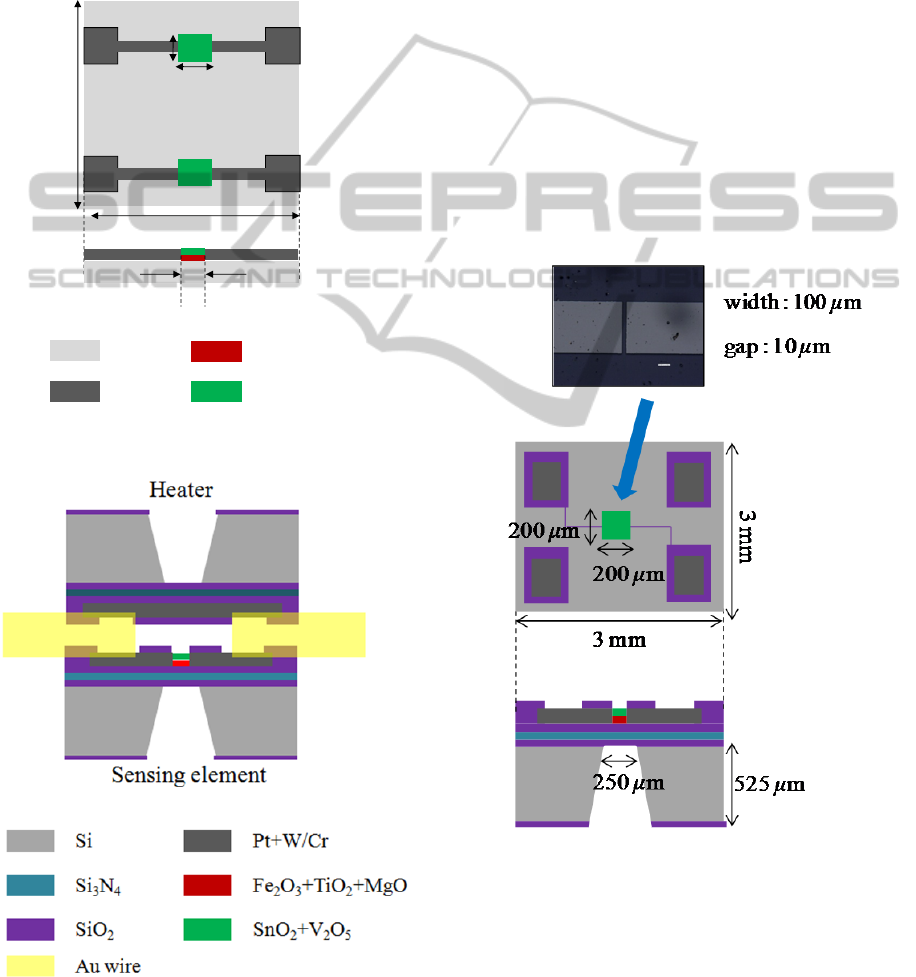

A schematic top and cross-sectional view of a basic

type micro sensor is shown in Figure 1. A sensing

film was deposited on an Al

2

O

3

substrate. The

sensing film had a double-layered structure. The first

layer was Fe

2

O

3

+TiO

2

(5 mol%) + MgO (4 mol%)

Figure 1: Schematic top and cross-sectional view of a

basic type sensor.

Figure 2: Schematic cross-sectional view of a MEMS type

sensor.

and the second layer was SnO

2

+ V

2

O

5

(4 mol%). Its

sensitivity and stability have been improved by

adopting a double-layered structure (Hiwatari and

Hara, 1998). The thickness of the first and the

second layers was 100nm and 100nm, respectively.

The length and the width of the sensing film

between the electrodes were 15 μm and 100 μm,

respectively. The sensor was heated by a

commercially available Pt heater covered by

alumina ceramics when the sensor response was

tested.

A schematic cross-sectional view of a MEMS

type micro sensor is shown in Figure 2. The sensor

is composed of two parts: a sensing element and a

micro heater. A sensing film was deposited on a

SiO

2

/Si

3

N

4

/SiO

2

diaphragm formed on a Si

substrate. A thin film heater was also made on a

similar diaphragm formed on another Si substrate.

The sensing element and the micro heater were

placed in parallel at a distance of about 50 μm by

inserting gold wires.

Figure 3: Schematic top and cross-sectional view of the

sensing element.

The sensing film was heated by the heater

through the air that existed between the two parts

when the response was examined (Hara, 2013). The

sensing film had a double-layered structure; the

material of the sensing film is the same as that of the

Pt+W

Fe

2

O

3

+TiO

2

+MgO

SnO

2

+V

2

O

5

Al

2

O

3

10 mm

10mm

15 μm

500 μm

300 μm

MicroSensorsforReal-timeMonitoringofMoldSporesandPollen

175

basic type sensor. The thickness of the first and the

second layers was 100 nm and 100 nm, respectively.

The length and the width of the sensing film

between the electrodes were 10 μm and 100 μm,

respectively. The dimension of the Si substrates and

the diaphragms was 3 mm×3 mm×0.5 mm and

250 μm ×250 μm ×7 μm, respectively, for both

elements.

The detailed configuration of the sensing element

and the micro heater is shown in Figure 3 and Figure

4, respectively.

Figure 4: Schematic top and cross-sectional view of the

micro heater.

2.2 Sensor Fabrication

The fabrication process of a basic type micro sensor

is as follows. A Pt+W (5 mol%) film was deposited

on an Al

2

O

3

substrate for use as an electrode and

defined by photolithography. Next, a layer made of

Fe

2

O

3

+TiO

2

(5mol%) + MgO (4 mol%) and another

layer made of SnO

2

+ V

2

O

5

(4 mol%) were

successively deposited to form a sensing film.

Finally, the sensing film was patterned by lift-off

technique. All these thin films were deposited by r.f.

sputtering technique.

The fabrication process of a MEMS type sensor

is described below. A multi-layered SiO

2

/Si

3

N

4

/SiO

2

film was successively deposited on a Si substrate.

The thickness of the SiO

2

, Si

3

N

4

, and SiO

2

films was

4 μm, 2 μm and 1 μm, respectively. Next, a part of

Si was removed by wet etching to make a diaphragm

structure. A triple-layered Cr/Pt + W (5 mol%)/Cr

film was deposited as a sensor electrode and

patterned by photolithography and subsequent

sputter etching. The thickness of Cr, Pt + W and Cr

films was 35 nm, 200 nm and 35 nm, respectively.

Finally, a sensing film was deposited and patterned

by lift-off technique. This process yielded a sensing

element as shown in Figure 3.

A triple-layered thin film heater (Cr/Pt + W (5

mol%)/Cr) was made on a diaphragm formed on

another Si substrate with a similar process. The

heater had a meander pattern, whose total length and

width were 500 μm and 10 μm, respectively. This

process yielded a micro heater as shown in Figure 4.

All these thin films were deposited by r.f. sputtering

technique to fabricate a MEMS type sensor.

The sensing element and the micro heater were

placed in parallel at a distance of about 50 μm by

inserting gold wires between the sensing element

and the micro heater as shown in Figure 2.

2.3 Experimental Setup

The sensor was set in a closed test box made of

acrylic. The inner volume was 5.4 L. The responses

to organic airborne particles such as mold spores and

pollen were examined; the change of the sensor

resistance was measured by using a digital

multimeter.

Both sensing films need to be heated for

operation. The temperature of the basic type sensor

was measured to be 425 Ԩ. The estimated sensor

temperature of the MEMS type sensor ranged from

330 Ԩ to 360 Ԩ , while the estimated heater

operating temperature ranged from 550 Ԩ to 600 Ԩ,

corresponding to the consumed power that ranged

from 125 mW to 140 mW.

2.4 Samples for Detection

Figure 5: Photographs of (a) mold spores, (b) pine pollen,

and (c) cedar pollen.

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

176

Mold spores, pine pollen and cedar pollen were used

as test samples. The photographs of these particles

are shown in Figure 5(a), 5(b) and 5(c), respectively.

The typical diameter was 10 μm, 50 μm and 35 μm,

respectively.

3 SENSING PERFORMANCE

3.1 Response to Mold Spores

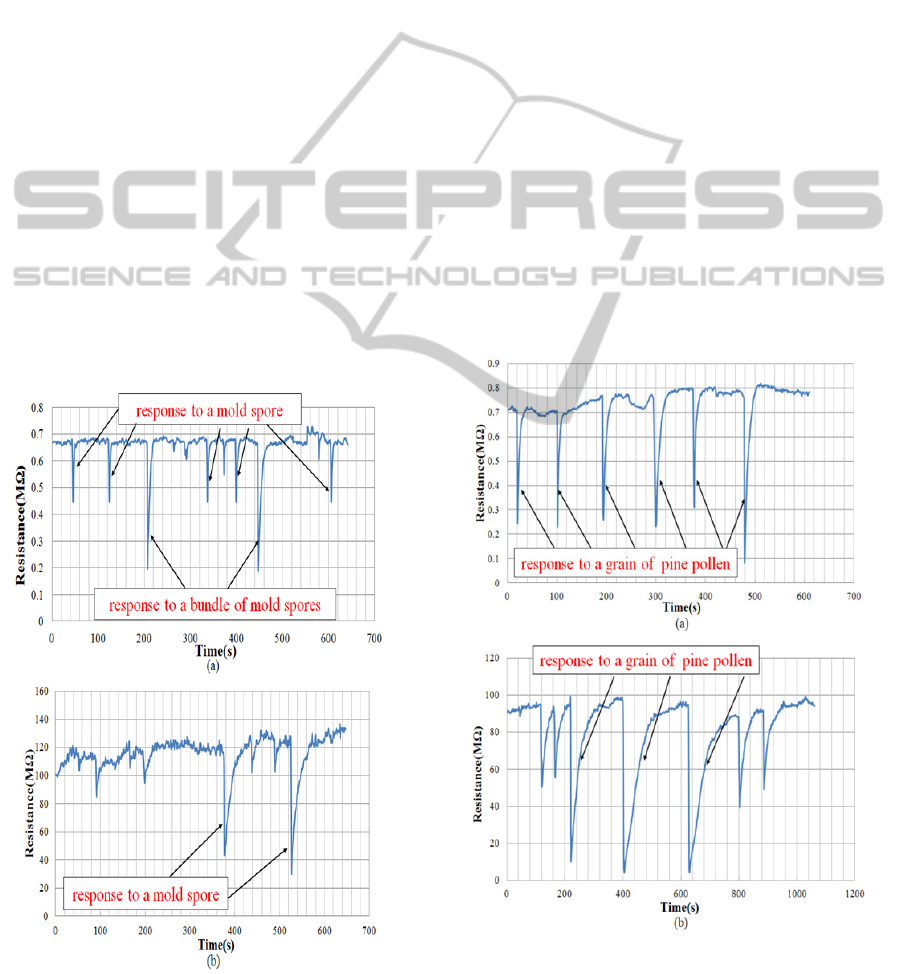

The response to mold spores of the basic type sensor

and the MEMS type sensor is shown in Figure 6(a)

and 6(b), respectively. The operating temperature of

the sensing films was about 425 Ԩ and 330 Ԩ ,

respectively. The sensor resistance steeply decreased

after adhesion of mold spores and then gradually

recovered to the initial value as the mold spores

combusted on the sensor surface for both sensors.

For the basic type sensor, the relative resistance

decrease was 34.2 % when a mold spore adhered to

the surface and it was about 70 % when a bundle of

mold spores adhered. The recovery time was 3.2 s

when a mold spore adhered to the surface and it was

about 12 s when a bundle of mold spores adhered.

The repeatability of the response was satisfactory.

Figure 6: Response to mold spores: (a) basic type sensor

and (b) MEMS type sensor.

For the MEMS type sensor, the relative resistance

decrease was 69.3 % when a mold spore adhered to

the surface. The recovery time was 29.5 s. The

response was larger and the recovery time was

slower compared to those for the basic type sensor.

3.2 Response to Pine Pollen

The response to a grain of pine pollen of the basic

type sensor and the MEMS type sensor is shown in

Figure 7(a) and 7(b), respectively. The temperature

of the sensing film was about 425 Ԩ and 330 Ԩ,

respectively. The sensor resistance steeply decreased

after adhesion of a grain of pine pollen and then

gradually recovered to the initial value as a grain of

pine pollen combusted on the sensor surface for both

sensors.

For the basic type sensor, the relative resistance

decrease was 65.9 % when a grain of pine pollen

adhered to the surface. The recovery time was 9.5 s.

For the MEMS type sensor, the relative

resistance decrease was 95.1 %. The recovery time

was 99 s. The response was larger and the recovery

time was slower compared to those for the basic type

sensor.

Figure 7: Response to pine pollen: (a) basic type sensor

and (b) MEMS type sensor.

MicroSensorsforReal-timeMonitoringofMoldSporesandPollen

177

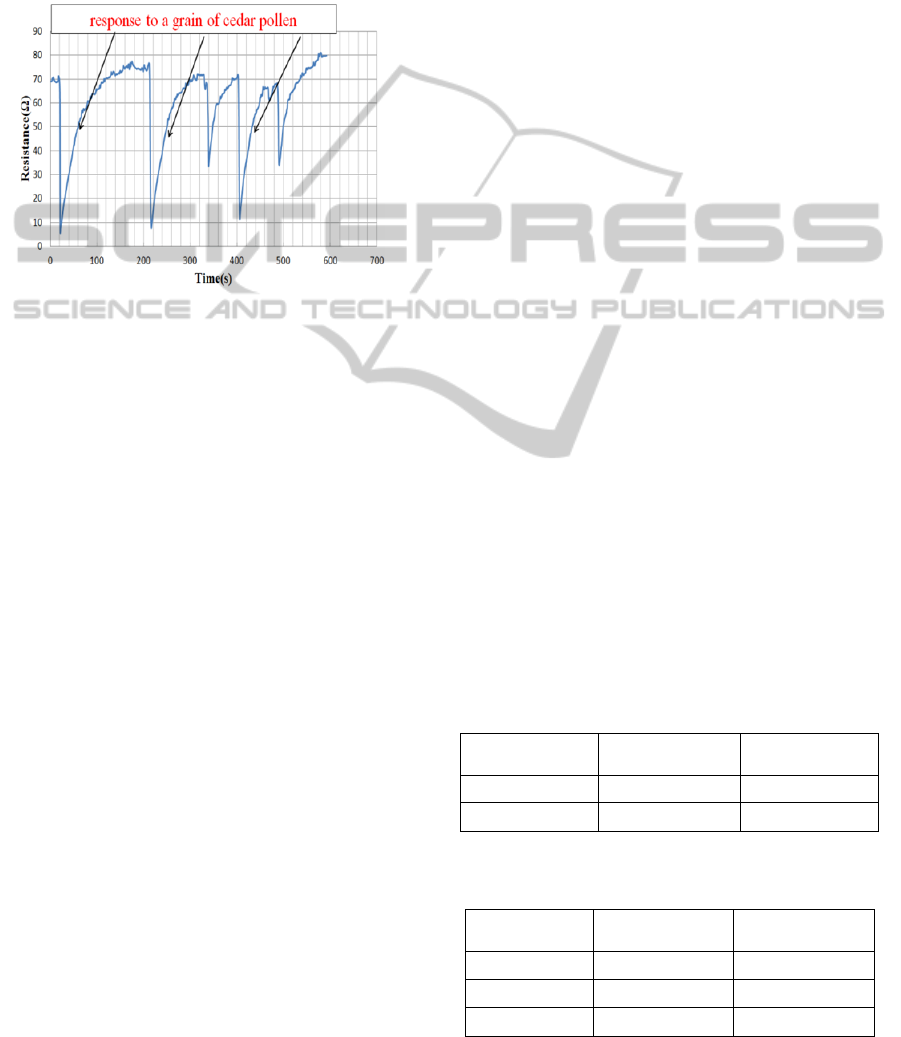

3.3 Response to Cedar Pollen

The response to cedar pollen is shown in Figure 8

for the MEMS type sensor. The temperature of the

sensing film was about 330 Ԩ. The sensor resistance

steeply decreased and then gradually recovered to

the initial value. The relative resistance decrease was

88.9 %. The recovery time was 67 s.

Figure 8: Response to cedar pollen for the MEMS type

sensor.

4 DISCUSSION

4.1 Sensing Principle

The sensing principle for organic airborne particles

is similar to that for reducing gases (Heiland and

Kohl, 1988); hydrogen and carbon atoms in the mold

spores or pollen react with chemisorbed and/or

lattice oxygen on the surface of the metal oxide film,

emitting electrons into the conduction band of the

film. Thus the sensor resistance decreases after

adhesion of organic particles. The resistance value

gradually recovers to the initial one as the particle

burns out on the surface of the sensing film.

The sensor is not selective to a mold spore or a

grain of pollen but sensitive to all organic particles.

However, both the resistance change and the

recovery time are dependent on the size of the

particle.

The observation by the naked eye revealed that

cedar pollen got burned black soon after they

adhered to the sensing surface and then gradually

disappeared. The TDS (Thermal Desorption

Spectroscopy) data on cedar pollen placed on the

surface of the sensing film showed that a peak by

H

2

O appeared at around 150 Ԩ, which was likely to

be derived from the absorbed water in the pollen.

Another peak by H

2

O appeared at around 300 Ԩ,

which was likely to be one of the combusted gases.

Two peaks by CO and CO

2

appeared at around 300

Ԩ and 320 Ԩ, respectively. Both were supposed to

be combusted gases. These results indicate that the

pollen burned on the surface of the sensing film.

Liquid components usually evaporate from the

sensing surface because it is maintained above 330Ԩ.

4.2 Identification of Species

A larger organic particle contains more hydrogen

and carbon atoms and consumes more oxygen atoms

on the surface of the sensing film, emitting more

electrons into the semiconductor film. The resultant

relative resistance decrease is greater for a larger

particle. In addition, it takes a longer time to

combust a larger particle. So the recovery time is

slower for a larger particle.

The relative resistance decreases and the

recovery times are summarized in Table 1 and 2 for

the basic type sensor and the MEMS type sensor,

respectively. The smallest relative resistance change

and the fastest recovery time were observed for a

mold spore with a diameter of 10 μm that was the

smallest particle in the experiment, while the largest

relative resistance change and the slowest recovery

time were observed for a grain of pine pollen with a

diameter of 50 μm that was the largest particle. The

medium relative resistance change and the recovery

time were observed for a grain of cedar pollen with a

diameter of 35 μm. Thus it is possible to estimate the

particle size from the resistance decrease and the

recovery time so as to identify the species of the

particles. For example, a grain of cedar pollen that

may cause allergy can be distinguished from a grain

of pine pollen that may not cause allergy based on

the resistance change and the recovery time.

Table 1: Average decrease of resistance and average

recovery time for the basic type sensor.

Measured

substance

Decrease of

resistance (%)

Recovery time

(s)

Mold spore 34.2 3.2

Pine pollen 65.9 9.5

Table 2: Average decrease of resistance and average

recovery time for the MEMS type sensor.

Measured

substance

Decrease of

resistance (%)

Recovery time

(s)

Mold spore 69.3 29.5

Pine pollen 95.1 99

Cedar pollen 88.9 67

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

178

4.3 Features of Two Types of Micro

Sensors

The basic type sensor has a larger sensing area. So it

is suitable for detection of a larger particle such as

pollen. On the other hand, the MEMS type sensor

has a smaller sensing area. So it is better suited for

detection of a smaller particle such as mold spores.

The experimental results reveal that the MEMS type

sensor exhibits larger relative resistance change to a

mold spore compared to the basic type sensor. Thus

it is essential to minimize the sensing area for

detection of a small particle.

The recovery time of the MEMS type sensor was

much slower than that of the basic type sensor for

both mold spores and pollen. This characteristic

feature results from the lower operating temperature

of the MEMS type sensor. Some other experiments

show that both the resistance decrease and the

recovery time strongly depend on the temperature of

the sensing film. So it is necessary to optimize the

temperature of the sensing film for specific particles

to be detected.

The consumed power of the MEMS type sensor

was reduced to about 125 mW by adopting heat-

insulated structure with use of diaphragm. It is small

enough for a portable or wearable detector of

airborne particles.

5 CONCLUSIONS

Two types of micro sensors for real-time monitoring

of organic airborne particles have been developed

using semiconductor thin-film: a basic type thin-film

sensor a MEMS type sensor. Both sensors

successfully detected a mold spore or a grain of

pollen. Based on the resistance change and the

recovery time, it is possible to identify the species of

the particle by the developed sensors. The

repeatability of the sensor response was satisfactory.

The MEMS type sensor was better suited for

detection of smaller particles. Both sensors offer

simple and inexpensive method to monitor organic

airborne materials. Since the consumed power of the

MEMS type sensor is about 125 mW, it can be used

as a portable or wearable detector.

REFERENCES

Hoisington A. J. et al., 2014. Building and Environment,

80.

Whyte W. et al., 2007. Aerosol Science, 38.

Konishi S. et al., 2014. Science of the Total Environment,

499.

Weber K. et al., 2012. Atmospheric Environment, 48.

Brunet E. et al, 2012. Sensors and Actuators B, 165.

Sharma A. et al., 2011. Sensors and Actuators B, 156.

Hiwatari, T., Hara K., 1998. Trans. IEE of Japan, 118-E.

Hara K., 2013. Biochemical Sensors-Mimicking Gustatory

and Olfactory Senses ed. by Toko K., Pan Stanford

Publishing Pte. Ltd., Singapore.

Heiland G., Kohl D., 1988. Chemical Sensor Technology

ed. by Seiyama T., Elsevier, Amsterdam.

MicroSensorsforReal-timeMonitoringofMoldSporesandPollen

179