Managing a Retail Perishable Product with RFID-enabled Inventory

Visibility

¨

Ozgen Karaer

Department of Industrial Engineering, Middle East Technical University, 06800 Ankara, Turkey

Keywords:

Inventory, RFID, Perishable, Fashion, Imperfect Read Rate, Retail.

Abstract:

Radio Frequency Identification Technology (RFID) helps reduce or completely eliminate inventory record

inaccuracy at retail stores, and thus facilitates inventory visibility in the system. In this paper, we investigate

the value of RFID-enabled inventory visibility for a retailer that sells perishable/seasonal merchandise, such as

fashion apparel. Because the retailer already commits to a total quantity for the item before the season begins,

we cannot anticipate an increase in sales or a reduction in holding cost. Here, we formulate the value as a

change in total revenue generated from the product. We characterize how this impact changes with respect to

various factors in the model and identify its components.

1 INTRODUCTION

RFID (Radio Frequency Identification) technology

has been described as the “best thing since the bar-

code” (Economist, 2003) since its rise in 2000s.

Through a simple chip embedded in each tag, RFID

technology offers a higher capacity to carry informa-

tion; i.e., Electronic Product Code (EPC) and thus

a unique identification of the labeled product - as

opposed to a generic one provided by the barcode.

Additionally, identification of a tag does not require

line-of-sight and/or scanning; in fact, a sophisticated

RFID reader can promptly identify or communicate

with an RFID tag through radio waves. Thus, RFID

technology offers a superior and a faster way of

object identification compared to the barcode tech-

nology. Through this enhanced “product visibility,”

RFID presents numerous implementation and bene-

fit opportunities across different industries, both pub-

lic and private, in areas such as inventory manage-

ment, logistics and transportation, cold chain manage-

ment, safety, security and counterfeit management,

and sales and promotion management (Pisello 2006,

Swedberg 2013, Collins 2006, Prince 2013). Re-

turn expectations regarding RFID technology are es-

pecially high in supply chain management. In fact,

among others, “such [RFID-enabled] visibility can

save labor cost, improve supply chain coordination,

reduce inventory, and increase product availability”

(Lee and

¨

Ozer 2007).

Inventory record inaccuracy, which is defined as

the discrepancy between the inventory record and the

actual inventory level available, is a serious prob-

lem in retail. Due to factors such as replenishment

errors, transaction errors, employee theft and cus-

tomer shoplifting, damaged or spoiled goods, incor-

rect product identification, and incorrect recording

of sales, the recorded inventory and the actual lev-

els diverge (DeHoratius and Raman 2008, DeHor-

atius, Merserau and Schrage 2008). In fact, Kang and

Gershwin (2005) report that a global retailer, at the

end of the annual physical audit, discovered that in

an average store only about 51% of the SKUs had a

match between its recorded and actual inventory lev-

els. In fact, for only 76% of the SKUs, the record and

the actual inventory levels were in the neighborhood

of ±5 units. Faced with a severe problem like this,

retailers suffer from stock-outs due to under- or over-

replenishment of stores as well as demand forecasting

issues.

RFID technology, by means of fast, efficient, and

inexpensive physical inventory audits, facilitates a re-

tailer to track the two inventory levels and correct its

records weekly, daily, hourly, and even in real-time

if so preferred. Achieving inventory record accuracy

through RFID enables correct and prompt replenish-

ment, which in turn is expected to increase availabil-

ity, and hence sales (Reda 2010). Retail practition-

ers adopt this mainstream approach as well; Macy’s

and Wal-Mart both plan to initiate item-level tagging

for replenishment goods (basics), which are items

with relatively stationary demand and are regularly

179

Karaer Ö..

Managing a Retail Perishable Product with RFID-enabled Inventory Visibility.

DOI: 10.5220/0005253001790184

In Proceedings of the International Conference on Operations Research and Enterprise Systems (ICORES-2015), pages 179-184

ISBN: 978-989-758-075-8

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

stocked and automatically resupplied (Businessweek

2011, Roberti 2010).

Item-level RFID adoption decision is mainly

driven by the sales increase or inventory holding cost

decrease expectations in retail. Thus, implementa-

tion discussion mostly stays limited to “replenishment

items (basics),” both in academia and in practice. This

trend gives rise to the presumption that there is no

value if sales cannot increase or inventory holding

cost cannot be reduced. What happens if the prod-

uct has a short lifecycle (i.e., it is not a “basic”) or

when the total stock of the product is already fixed at

the beginning of the season is not clear at all. In this

paper, we address this issue. We study the value of in-

ventory visibility, enabled by a technology like RFID,

in managing a retail perishable product.

We characterize the revenue generated by a re-

tailer from a perishable product with and without in-

ventory visibility in his chain. By a perishable prod-

uct, we mean an item with a short lifecycle (e.g., a

fashion product). A retailer typically has to commit

to a total buy quantity of the perishable product way

before the selling season starts. All inventory left at

the end of the regular season, if any, is cleared through

markdowns. This estimated change in revenue could

guide practitioners in item-level RFID adoption deci-

sions regarding a perishable product. In addition to

characterizing the magnitude of the value of visibil-

ity, we also investigate how it changes with respect to

the various factors in the retail environment.

Our results show that though value of visibility is

statistically significant and robust, but not entirely en-

couraging for some retailers. Inventory visibility has

a two-fold benefit: diminished lost sales in the regular

season and better yield management in the markdown

period. The extent of the visibility impact depends

on some characteristics such as including inventory

record inaccuracy, the retailer’s competence in fore-

casting and planning, product lifecycle, product per-

ishability, and store service level targets.

The remainder of the paper is organized as fol-

lows. In §2 we review the relevant literature and in

§3 we introduce the model details. We present our

findings in §4. In §5 we highlight our insights and

conclude the paper.

2 LITERATURE REVIEW

Our work is mainly related with two bodies of re-

search. One focuses on the inventory record inac-

curacy and analytical inventory management models

that account for it in a retail environment. The second

stream focuses on quantifying the benefit of RFID

technology in various settings.

Inventory Record Inaccuracy: Within the op-

erations management literature, there is an extensive

body of work which studies the inventory record in-

accuracy issue in retail and develops sophisticated

models to avert it. DeHoratius and Raman (2008)

demonstrate the severity of the inventory discrep-

ancy through an empirical analysis and character-

ize the factors that mitigate or exacerbate the issue.

DeHoratius, Merserau, and Schrage (2008) develop

a Bayesian Update methodology to keep track of

the actual inventory level in the presence of inven-

tory record inaccuracy. Merserau (2013) studies an

information-sensitive inventory management system

for a retailer with inventory discrepancy issues. K

¨

ok

and Shang (2007) characterize the optimal inspec-

tion policy that balances the risks and costs associ-

ated with inventory discrepancy due to transaction er-

rors with inspections costs. As in all these papers, we

study a retailer’s performance in the presence of in-

ventory discrepancy but we focus on quantifying the

value of inventory visibility under a given inventory

management framework.

RFID Uses and Benefits: A substantial stream of

research studies the implementation of a RFID tech-

nology and its impact on business (i.e., value) due

to increased inventory visibility or eliminated inven-

tory record inaccuracy. Kang and Gershwin (2005)

demonstrate how inventory shrinkage could “freeze”

store inventory by preventing replenishment due to a

high inventory record when the product is in fact out

of stock. The authors propose RFID technology as a

solution to eliminate or alleviate this issue. Similarly,

Fleisch and Telkamp (2005) study the RFID impact

regarding the elimination of inventory discrepancy in

a multi-echelon retail supply chain. Lee and

¨

Ozer

(2007), Karaer and Lee (2007), Gaukler et al. (2008),

deKok et al. (2008), Sahin et al. (2008), Rekik et al.

(2009), C¸ akici et al. (2011) study the impact of RFID

technology under various settings and they all share

a cost-savings perspective. Rekik et al. (2007, 2008)

mostly focus on the profit impact of RFID through a

Newsvendor-like setting. Our work and all these ar-

ticles, though in different settings, share the common

goal of assessing the value of inventory visibility, en-

abled by a technology like RFID. We refer the inter-

ested reader to Sarac¸ et al. (2010) for an extensive

review of the research on RFID and its value.

3 MODEL DETAILS

We model a multiple-store (N) chain of a retailer who

maximizes the total revenue generated from the sales

ICORES2015-InternationalConferenceonOperationsResearchandEnterpriseSystems

180

of a perishable/fashion product. The retailer manages

all his stores through a single distribution center (DC)

in the presence of inventory record inaccuracy at the

stores. After the regular season is over, the prod-

uct is marked down so that all leftover inventory is

cleared. No transshipment is possible among stores.

We adopt a periodic-review inventory environment in

our model.

We use a linear function to model the periodic

demand at store i. It comprises of a deterministic

and an uncertain part; i.e., d

it

= K

it

− ap

it

+ ε

it

, t =

1, ..., T + 1 where ε

i

is iid across stores and periods,

and has zero mean. Here, a represents the price sensi-

tivity of consumer demand. Over the regular season,

the product is sold at a previously-set regular price p

across the chain. In the markdown period the price is

discounted so that at each store the leftover inventory

is cleared. A store’s demand potential over the regular

season is stationary whereas it is possibly lower in the

markdown period; i.e., K

i,T +1

≤ K

i1

= ... = K

iT

. The

notation we use in the model is available in Table 1

below.

Table 1: Notation .

d

it

Demand at store i, at period t, i = 1, .., N, t = 1, ..., T

y

it

The order-up-to level for store i, for the beg. of period t

x

it

The actual inventory level at store i at the beg. of period t

z

it

The replenishment sent to store i at the beg. of period t

ˆx

it

The inventory on record at store i at the beg. of period t

ε

it

The random shock on demand at store i at period t

θ

it

The inaccuracy shock at store i at period t

K

it

The demand potential at store i at period t

a Price sensitivity parameter

p The chain-wide regular season product price

p

im

The realized markdown price at store i

The sequence of events in a regular season period for a

retailer without full visibility are summarized below:

(1) The retailer checks the inventory record ˆx

it

at store

i and creates an allocation order based on the

order-up-to level y

it

at each store. The orders are

shipped if there is enough inventory at the DC to

satisfy all allocation orders. If not, the retailer

determines the shipment quantities to balance out

the store service levels as much as possible

1

. The

stores are instantly replenished based on the de-

termined shipment quantities (referred to as z

it

) .

(2) The demand at store i (d

it

) is realized, and sales

s

it

= min(d

it

, x

it

+ z

it

) are recorded. In addition

1

At the beginning of period T , which is the last period in the

regular season, the retailer ignores the pre-set y

it

and determines

allocation orders to clear away all the inventory at the DC and bal-

ance out the expected service level at each store.

to demand, there is also a random inaccuracy

shock θ

it

on the actual inventory level at the store;

i.e., x

i,t+1

= x

it

+ z

it

− s

it

− θ

it

. The inaccuracy

shock being positive translates into shrinkage due

to theft, shoplifting, misshipment, damages, and

etc. The net inaccuracy shock being negative

translates into emerging misplacements, misship-

ments, misidentifications, and etc. Whenever θ

it

is positive and x

it

+ z

it

< d

it

+ θ

it

, we assume the

available inventory is split proportionally between

customer demand and shrinkage. Note that, we

assume θ

it

is iid across stores and periods, and fol-

lows a distribution with mean µ

θ

> 0 and standard

deviation σ

θ

> 0; i.e., inaccuracy shock may be

positive or negative but is more likely to be pos-

itive than negative. Based on the sales observed,

the inventory record to start the next period is cal-

culated as ˆx

i,t+1

= ˆx

it

+ z

it

− s

it

.

The retailer has to sell off all units as the regular

season ends. Therefore, in the markdown period, he

offers price discounts to generate enough demand to

clear away the leftover inventory. Thus, after ε

i,T +1

is

realized, the clearance price p

im

(p

i,T +1

) is observed

so that K

i,T +1

− ap

im

+ ε

i,T +1

equals the available in-

ventory at store i at the beginning of the markdown

period. Markdown price cannot be greater than the

regular season price and has to be nonnegative.

4 ANALYSIS

To evaluate the value of inventory visibility in man-

aging a perishable/fashion product, we compare two

types of retailers:

(1) Uninformed Retailer (U): This retailer relies on

the current information system, and hence can-

not observe the actual inventory levels at the

stores. He makes allocation/replenishment deci-

sions based on the inventory on record.

(2) Retailer with Full Visibility (F): This retailer,

through a technology like RFID, has visibility

over the actual inventory levels at the stores. At

the beginning of each period, he conducts a phys-

ical audit at the stores and updates his system

with the actual inventory levels observed. He

uses these values in allocation/replenishment de-

cisions.

We compare the two retailers in total revenue gener-

ated from the product. Specifically, we seek to assess

the % difference in total revenue (∆) as our primary

metric for the value of inventory visibility:

∆

F−U

=

Π

F

− Π

U

Π

U

∗ 100 (1)

ManagingaRetailPerishableProductwithRFID-enabledInventoryVisibility

181

where Π stands for revenue. .

We adopt simulation as our analysis methodology.

This allows us to avoid simplifications that would oth-

erwise be essential to generate analytical results, and

at the same time characterize its magnitude and the

impact of various factors on it. For a given set of pa-

rameters, we run 250 replications. For each realiza-

tion/instance, we calculate the revenue generated by

the uninformed and full visibility retailers, and calcu-

late the % gap (∆

F−U

). We calculate the 95% confi-

dence intervals for this gap. When we need to present

a single value for ∆

F−U

, we refer to the mean values

when the gap is statistically significant.

Note that we assume the retailer works with 1 pe-

riod between reviews and instant replenishment; i.e.,

zero lead time. Thus, when he sets the order-up-to

levels at the stores, he uses a type-1 service level tar-

get to cover the exposure demand of 1 period. We

also assume there is no discounting due to time value

of money across periods.

4.1 Value of Full Inventory Visibility

In our simulation studies, we use discretized Normal

distribution to model periodic demand uncertainty

(ε ∼ N(0, 6.5)) and inaccuracy shock (θ ∼ N(1, 2)).

We use the regular season price p = 50, price sensitiv-

ity parameter a = 0.7, regular season market potential

(K

r

= K

it

∀i, ∀t ≤ T ) 100, and markdown period mar-

ket potential (K

m

= K

i,T +1

∀i) 60. Thus, the expected

inaccuracy shock in a period is about 1.54% of the

expected demand. We conducted experiments with

number of periods 4 through 10; number of stores 5,

14, 20, and 40; store service levels 95%, 97%, 99%;

and a wide-range of total buy quantity Q. Below we

present our main insights regarding the value of visi-

bility and its change with respect to the various factors

in our model.

Result #1: Value of inventory visibility is high,

and thus investment in a technology like RFID is more

worthwhile if the retailer’s gross margin percentage is

low and if the product price is high.

In our studies, value of inventory visibility is

about 1 − 5%. Although it is highly sensitive and

can increase considerably with some product/retailer

characteristics (e.g. product life, inaccuracy rate,

etc.), the current numbers show that inventory visibil-

ity has limited returns for a perishable/fashion product

retailer. Thus, inventory visibility by itself may or may

not justify investment into a new technology like RFID

for some retailers. For a major retailer that generates

revenue in the order of billion dollars, however, this

“limited return” is still quite substantial.

Inventory visibility enables the retailer to sell at a

higher average price and thus increases total revenue.

The increase in sales will directly be reflected in the

total gross margin. Then for the total gross margin,

we should expect a higher impact percentage with the

same magnitude of increase in the numerator but a

lower value (than revenue) in the denominator; i.e.,

gross margin impact can easily pass the 10% mark.

Thus, the lower a retailer’s gross margin percentage

in an average product, the more valuable inventory

visibility is.

A 1 − 5% revenue impact also helps characterize

the cost-return tradeoff for RFID investment. In ad-

dition to the fixed implementation cost regarding in-

frastructure, RFID investment implies a tag cost to be

incurred for each labeled product, and thus practically

increases the retailer’s unit product cost. Based on our

current estimations, tag cost will not be deterring if

the product price is high enough. If we take a passive

RFID tag cost as 5 − 6 cents (Ashton 2011), a product

price of $5 − 6 easily justifies the technology invest-

ment.

Result #2: Value of inventory visibility has two

components: increase in regular season sales and in-

crease in margin in markdown sales.

Result #3: Value of inventory visibility is highest

when the retailer is a competent planner but slightly

“buys into markdown.”

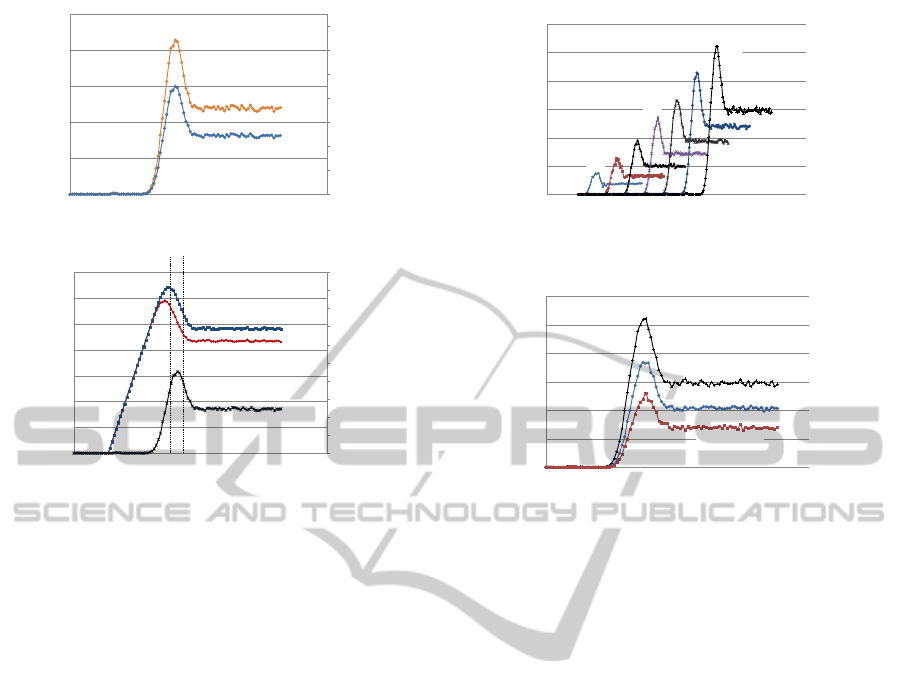

Figure 1 depicts the value of inventory visibility

with respect to the total buy quantity in a 14-store

retail chain. In Figure 1(a), we see that ∆

F−U

be-

comes significant only when the buy quantity Q is

high enough, reaches a peak as Q increases, and then

stabilizes to a certain level as Q increases further. If

the retailer does not buy enough units to meet the de-

mand, inventory visibility does not have any return

for the retailer. The retailer will sell all units at full

price regardless of whether he has inventory visibil-

ity or not. If the retailer bought too many units com-

pared to the demand, he will have to offer significant

discounts at markdown (practically give the product

away for free) in either case. The stabilized level

of ∆

F−U

for high Q values here represents the value

saved from regular season lost sales with better re-

plenishment performance.

Value of inventory visibility is highest when the

total quantity bought roughly matches the demand;

i.e., if the retailer is competent at forecasting to match

the demand. Figure 1(b) shows that inventory visibil-

ity brings the highest return when the retailer slightly

overbuys compared to the optimal supply required.

This practice can also be characterized as “buying into

markdown”; i.e., the retailer also plans for the demand

over the markdown period or slightly overestimates

ICORES2015-InternationalConferenceonOperationsResearchandEnterpriseSystems

182

0

2000

4000

6000

8000

10000

12000

14000

0.00%

0.50%

1.00%

1.50%

2.00%

2.50%

6500 7500 8500 9500 10500 11500 12500

Total Buy Quantity Q

(a) ∆

F−U

(primary axis) vs. Π

F

−Π

U

(secondary axis)

0

2000

4000

6000

8000

10000

12000

14000

16000

18000

20000

360000

370000

380000

390000

400000

410000

420000

430000

6500 7500 8500 9500 10500 11500 12500

Total Buy Quantity Q

Π

𝐹

− Π

𝑈

Π

𝑈

Π

𝐹

(b) Π

F

, Π

U

(primary axis) vs. Π

F

− Π

U

(secondary

axis)

Figure 1: Value of Inventory Visibility WRT Total Buy

Quantity Q in a 14-Store Chain.

Note: The following values were used to generate Figure 1, (T=9, N=14,

p = 50, Store service level=95%, K

it

= 100 (∀i, ∀t ≤ T ), K

i,10

= 60 (∀i),

ε

it

∼ N(0, 6.5) (discretized) (∀i, ∀t ≤ T + 1), θ

it

∼ N(1, 2) (discretized) (∀i,

∀t ≤ T ) )

the total demand. In this range, in addition to a better

regular season performance, the retailer with full visi-

bility can now make a difference in the markdown pe-

riod and achieve better yield management. Thus, we

see both components of the value of visibility when

the buy quantity is at reasonable levels but is slightly

more than the optimal level required.

Result #4: Value of inventory visibility increases

as the product lasts longer; i.e., as replenishment op-

portunities increase.

Result #5: Value of inventory visibility diminishes

as the retailer’s store service level increases.

Figure 2(a) characterizes the change in the value

of inventory visibility with respect to the product life;

the number of regular season periods. Every period

an inaccuracy shock occurs, and the retailer with full

visibility seizes an opportunity to correct his records

whereas the uninformed retailer faces with accumula-

tion of the errors over the season. Thus, as the product

life extends, value of inventory visibility increases.

Figure 2(b) shows that as the retailer’s store ser-

vice levels increase, value of visibility decreases.

When the retailer operates with a high service level

like 99%, even an uninformed retailer successfully

0.00%

0.50%

1.00%

1.50%

2.00%

2.50%

3.00%

2000 4000 6000 8000 10000 12000 14000

Total Buy Quantity (Q)

T=6

T=10

T=9

T=8

T=7

T=5

T=4

(a) ∆

F−U

WRT Total Product Life (Number of Periods

in a Season)

0.00%

0.50%

1.00%

1.50%

2.00%

2.50%

3.00%

8000 8500 9000 9500 10000 10500 11000 11500 12000 12500 13000

Total Buy Quantity (Q)

95% Service Level

97% Service Level

99% Service Level

(b) ∆

F−U

WRT Service Level

Figure 2: Value of Inventory Visibility WRT Product Life

and Service Level.

Note: The following values were used to generate Figure 2, (T=10, N=14,

p = 50, K

it

= 100 (∀i, ∀t ≤ T ), K

i,11

= 60 (∀i), ε

it

∼ N(0, 6.5) (discretized)

(∀i, ∀t ≤ T + 1) )

prevents the regular season lost sales. Addition-

ally, since a high-service retailer has more inven-

tory leftover for markdown, even a balanced inven-

tory across stores -enabled by visibility- cannot sus-

tain high markdown gross margins. Thus, value of in-

ventory visibility is not as high if the retailer already

operates with high store service level targets. In fact,

the value of visibility (both ∆

F−U

and Π

F

−Π

U

) more

than doubles between 99% and 95% service levels.

5 CONCLUSIONS

To our knowledge, this is the first study that focuses

on RFID-enabled inventory visibility in managing a

retail perishable product. We find that value of visi-

bility has two components: growth in regular season

sales and improved yield management in the mark-

down period. Through extensive numerical simula-

tions, we show that value of inventory visibility is ro-

bust across retailers, but potentially not impressive for

some retailers. Thus, return-on-investment in an en-

abler technology like RFID needs to be carefully eval-

uated by each individual retailer. We also find that re-

ManagingaRetailPerishableProductwithRFID-enabledInventoryVisibility

183

tailers that sell products with prices above the $5 − 6

mark, that carry products with relatively long life-

cycles, that operate with relatively low service levels,

and that plan his sales well or even “buy into mark-

down” should expect higher returns from inventory

visibility.

Our findings suggest further extensions, especially

regarding the retailer’s planning methodology and the

chain structure. One wonders how value of visibility

would change if the retailer adopted a dynamic ap-

proach and updated his forecast and inventory targets

based on observed sales, or if the stores in the chain

were not identical. One would also wonder the in-

teraction of inventory visibility with price promotion

decisions for a retailer. These settings could further

help characterize the value of inventory visibility in a

perishable/fashion retail environment.

REFERENCES

Ashton, K. (2011). Whither the Five-Cent Tag?

www.rfidjournal.com (retrieved: August 1, 2014).

C¸ akıcı, O. E., Groenevelt, H., and Seidmann, A. (2011).

Using RFID for the Management of Pharmaceutical

Inventory - System Optimization and Shrinkage Con-

trol. Decision Support Systems, 51.

Collins, J. (2006). RFID Goes Underground in London.

www.rfidjournal.com (retrieved: August 1, 2014).

de Kok, A. G., Donselaar, K. H. V., and Woensel, T. V.

(2008). A Break-even Analysis of RFID Technology

for Inventory Sensitive to Shrinkage. International

Journal of Production Economics, 112.

DeHoratius, N., Merserau, A. J., and Schrage, L. (2008).

Retail Inventory Management When Records are In-

accurate. Manufacturing & Service Operations Man-

agement, 10(2):257–277.

DeHoratius, N. and Raman, A. (2008). Inventory Record

Inaccuracy: An Empirical Analysis. Management Sci-

ence, 54.

Fleisch, E. and Tellkamp, C. (2005). Inventory Inaccuracy

and Supply Chain Performance: A Simulation Study

of a Retail Supply Chain. International Journal of

Production Economics, 95.

Gaukler, G. M.,

¨

Ozer, O., and Hausman, W. H. (2008). Or-

der Progress Information: Improved Dynamic Emer-

gency Ordering Policies. Production and Operations

Management, 17(6):599–613.

Kang, Y. and Gershwin, S. B. (2005). Information Inaccu-

racy in Inventory Systems: Stock Loss and Stockout.

IIE Transactions, 37.

Karaer, O. and Lee, H. L. (2007). Managing the Reverse

Channel with RFID-Enabled Negative Demand In-

formation. Production and Operations Management,

16(5):625–645.

K

¨

ok, A. G. and Shang, K. H. (2007). Inspection and

Replenishment Policies for Systems with Inventory

Record Inaccuracy. Manufacturing & Service Oper-

ations Management, 9(2):185–205.

Lee, H. L. and

¨

Ozer, O. (2007). Unlocking the Value

of RFID. Production and Operations Management,

16(1):40–64.

Merserau, A. J. (2013). Information-Sensitive Replenish-

ment when Inventory Records are Inaccurate. Pro-

duction and Operations Management, 22(4).

Pisello, T. (2006). The ROI of RFID in the Supply Chain.

www.rfidjournal.com (retrieved: August 1, 2014).

Prince, P. (2013). Hospitals in Japan, China Seek to Save

Lives via Pocketsize Reader. www.rfidjournal.com

(retrieved: August 1, 2014).

Reda, S. (2010). Ready (Finally) For Item Level Deploy-

ment. Stores.org (retrieved: August 1, 2014).

Rekik, Y., Jemai, Z., Sahin, E., and Dallery, Y. (2007). Im-

proving the Performance of Retail Stores Subject to

Execution Errors: Coordination versus RFID Tech-

nology. OR Spektrum, 29.

Rekik, Y., Sahin, E., and Dallery, Y. (2008). Analysis of

the Impact of RFID Technology on Reducing Product

Misplacement Errors at Retail Stores. International

Journal of Production Economics, 112.

Rekik, Y., Sahin, E., and Dallery, Y. (2009). Inventory In-

accuracy in Retail Stores due to Theft: An Analysis of

the Benefits of RFID. International Journal of Pro-

duction Economics, 118.

Roberti, M. (2010). Wal-Mart Relaunches EPC RFID

Effort, Starting With Men’s Jeans and Basics.

www.rfidjournal.com (retrieved: August 1, 2014).

Sahin, E., Buzacott, J., and Dallery, Y. (2008). Analysis

of a Newsvendor Which Has Errors in Inventory Data

Records. European Journal of Operational Research,

188.

Sarac¸, A., Absi, N., and Dauzere-Peres, S. (2010). A Liter-

ature Review on the Impact of RFID Technologies on

Supply Chain Management. International Journal of

Production Economics, 128.

Staff (2003). The best thing since the bar-code.

www.economist.com (retrieved: August 1, 2014).

Staff (2011). Macy’s pushing to get RFID technology into

stores. www.businessweek.com (retrieved: August 1,

2014).

Swedberg, C. (2013). Russian Tag Company Reaches for

a Worldwide Audience. www.rfidjournal.com (re-

trieved: August 1, 2014).

ICORES2015-InternationalConferenceonOperationsResearchandEnterpriseSystems

184