A Quick Method to Determine the Impurity Content in Gold

Ornaments by LIBS Technique

A. F. M. Y. Haider, S. Sengupta and K. M. Abedin

Physics Department and Laser Spectroscopy Laboratory, CARS, University of Dhaka, Dhaka, Bangladesh

Keywords: Libs, ED-XRF, Carat Values, Impurities.

Abstract: Laser induced breakdown spectroscopy (LIBS) and low energy dispersive X-ray fluorescence (ED-XRF)

spectrometer, were used to determine the line intensity and concentration ratios of the major impurities (Cu

and Ag) with respect to Au in gold ornaments with different caratage. Calibration curves were drawn with

the data sets, obtained from LIBS and XRF, and from these calibration curves the unknown caratage of gold

ornaments were obtained by using the line intensity of elements determined by LIBS. We have

demonstrated the accuracy of this method by comparing the result with the carat value obtained by typical

XRF method. This is yet another novel application of LIBS as a versatile analytic technique.

1 INTRODUCTION

Fast, reliable and accurate determination of the

elemental composition of gold alloys along with its

carat value has become an important task not only

for its use in worldwide jewelry manufacturing but

also in fields like nano-medicine (Ali et al., 2011)

and microelectronic industries (Goodman, 2002).

Traditional cupellation method or ‘Fire Assay’

(Bugbee, 1950) is one of the most trusted procedures

till date for measuring the caratage of gold and

hallmarking them. However, cupellation method is

destructive, time consuming, operator dependent and

involves the usage of lead and nitric acid which also

produces toxic fume at high temperature. Because of

these complications, X-ray fluorescence

spectrometry (Beckhoff et al., 2006) (wavelength

dispersive, WD-XRF and energy dispersive, ED-

XRF) has been adopted as a convenient and reliable

technique in gold market for testing gold purity as

they offer fast and sample preparation free (unlike

atomic absorption spectroscopy) nondestructive

analysis. In practice, high energy dispersive XRF

can provide fairly accurate result although it is quite

expensive and requires expert analysts; so they are

not commercially feasible for detecting caratage of

gold ornaments. But there exists low energy

dispersive XRF spectrometer specifically designed

and pre-calibrated by international standards for

simultaneous analysis of alloy constituents. Low

energy dispersive XRF offers accuracy of 2-5

0

/

0

.

However, its accuracy deteriorates if the sample is

small, curved or ball-shaped. Furthermore, with

XRF only about 1-2 μm of surface depth can be

examined. So XRF technique is less precise in

detecting forgery like a copper or silver bar

electroplated with a thick layer of pure gold. The

topic of gold jewelry analysis by XRF has been

reviewed by Marucco (Marucco, 2006). Also

Gamma ray transmission technique, proposed in

(Suzuki et al. 2006) provides analysis of gold

samples which are about 1-5 mm thick with 99%

accuracy. But because of radiation hazard due to

strong gamma ray and lack of portability, this

method is also not commercially feasible in

analyzing gold purity. Laser Induced Breakdown

Spectroscopy (LIBS) (for details, see (Miziolek et al,

2006, Singh et al. 2007), on the other hand has no

extra trouble of special sample preparation and

hence posses simplicity along with detection limit of

few ppm and unlike XRF, has larger information

depth of 10 μm or more depending on laser pulse

power which makes it an ideal choice for testing

gold purity within a very short period of time. Using

LIBS, all the elements in the periodic table can be

measured in a single setup of the spectrometer.

Despite all these advantages, LIBS has never

been adopted as an ideal method for impurity

detection in gold. Typically, the signal intensity for

an element present in the plasma depends on laser

parameters: laser energy, irradiance, laser focusing

and pulse duration. Fluctuations in any of these

41

Haider A., Sengupta S. and Abedin K..

A Quick Method to Determine the Impurity Content in Gold Ornaments by LIBS Technique.

DOI: 10.5220/0005249300410046

In Proceedings of the 3rd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2015), pages 41-46

ISBN: 978-989-758-092-5

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

parameters and also sample inhomogeneity and

matrix effects may lead to nonlinearity in the

calibration curves, affecting the analytical precision

and consequently lowering the accuracy of

measurement by LIBS technique.

In general, sample inhomogeneity can be

categorized into two classes: bulk non-uniformity

and non-representative surface composition. The

first can be dealt with by averaging results of

multiple measurements taken over different parts of

the sample. Samples whose outer layers don’t

represent bulk composition can be probed by making

crater with depth ranging from few µm to 10-20 µm

depending on the laser parameters. This will usually

solve the problem of non representative surface

composition. Low ED-XRF, as mentioned before,

can’t probe such depth.

Matrix effect corresponds to the change in the

signal intensity of a specific element with variation

in the concentration of one or more elements

forming the matrix even though the overall

elemental concentration remains constant in the

sample. One approach to correct such effects is to

use internal standard principle i.e. to consider the

ratio of the intensity of analytical spectral line to that

of another component of the sample which has fixed

or known concentration because even if the

measured values change significantly, their ratio

alter a little (Haider et al. 2014). As LIBS offers

immense possibilities for spectroscopic analysis,

significant efforts are given to develop new

calibration methods (for a review, see (Zorov et al.

2010)) to correct LIBS measurements and increase

its ability of quantitative analyses.

Although LIBS is a standalone analytical

method, over the years, it has been combined with

other analytical methods to enhance performance for

selected applications. One such example is LIBS-

LIF (Laser Induced Fluorescence) where free atoms

in the plasma formed by LIBS laser are excited with

second laser beam tuned at specific frequency to

induce some transition in atoms and this method,

though not have multi-elemental detection

capability, has higher sensitivity to detect single

specific element in the sample. This has been

reflected in spectro-chemical analysis of metals in

soil (Hilbk-Kortenbruck et al., 2001).

In this paper, we report a method for determining

the carat values of gold in general, and in particular

of gold ornaments, by combining LIBS with low

energy dispersive XRF. This technique was also

adopted by Pouzar et al., 2011, for quantitative LIBS

analysis of vanadium in samples of hexagonal

mesoporous silica catalysts. One can thus bypass

the limitations, which both the systems suffer

individually, and enhance the detection ability of

impurity content in gold ornaments using calibration

curves obtained by correlating LIBS and XRF data.

It has been shown that improved accuracy of

determination of caratage of gold ornaments of any

size and shape are possible by using these

calibration curves and comparatively more reliable

results can be obtained from the LIBS technique.

2 EXPERIMENTAL

Suisse gold bar (24 carat) obtained from Singapore

Bullion market and gold ornaments: 3 finger rings

with known carat values, as determined by ED-XRF

technique, of 22.024K, 20.912K and 18.507K, a

round solid earring (20.495K), a round flat pendant

(18.807K), a curved ear-top (18.649K) and a stone

studded ring (8.040K) were used as samples. The

thickness of the targets was different for different

samples depending upon the type of ornaments.

Later an ornament of unknown carat value was used

for verification of the proposed method. It was

evident from XRF analysis that goldsmiths mostly

use copper and silver, as impurity to gold alloys for

obtaining desired color, shine and solidity of the

ornaments. The percentage content of impurity

elements (Cu and Ag) in the samples were

ascertained by low energy dispersive XRF. Other

elements which were present in trace amount were

Ni, Cd and Zn. That’s why in our work we have

mainly focused on establishing two separate

calibration curves; one for copper and another for

silver as the inclusion of other base metals were

negligible. These calibration curves were used to

estimate the impurity content of the gold ornament

of unknown caratage to verify the applicability of

this technique. The concentrations of constituent

elements in the gold samples were obtained by

desktop energy dispersive XRF spectrometer (EDX

3600B) which is equipped with Tungsten anode X-

ray tube operated at 40 KeV and 80 µA and electro-

cooling UHRD detector which leads to good energy

linearity, energy resolution, spectral property and

high peak-background ratio

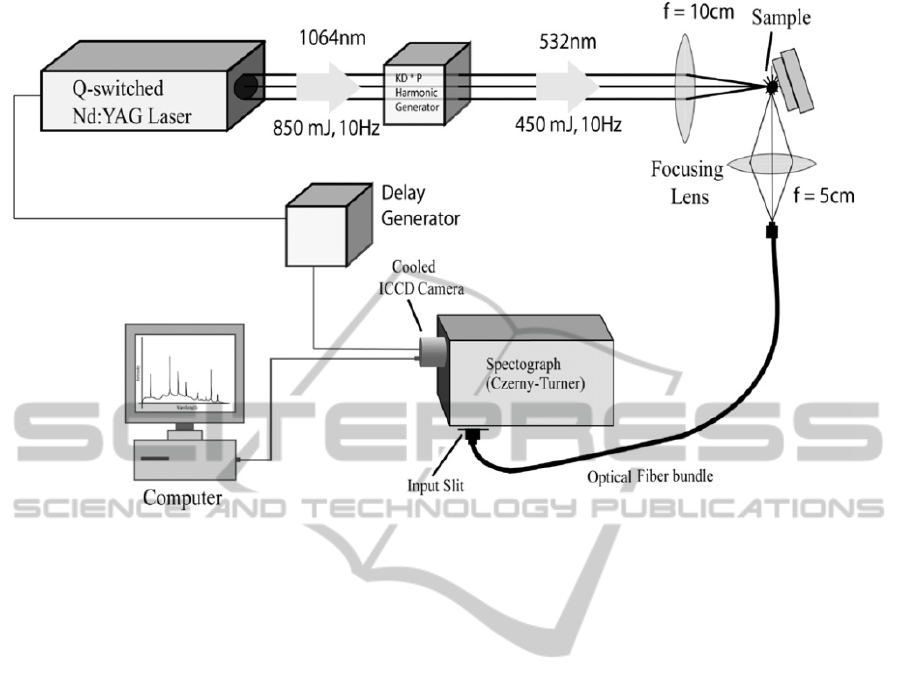

(http://www.skyrayxrf.com/ edx3600b). The LIBS

spectrometer used in the present work is shown

figure 1 (Haider et al., 2014). It has a pulsed Q-

switched Nd:YAG laser operating at 1064 nm with

pulse duration of 8ns and repetition rate of 10 Hz.

But we have used harmonic generator that has a

nonlinear Potassium Dihydrophosphate (KDP)

crystal to obtain the 2

nd

harmonic at 532 nm with

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

42

Figure 1 A Schematic diagram of LIBS set-up.

ablation energy varying from 40 mJ to 150 mJ for

our analysis. The spectrometer, SpectraPro 2758

(http://www.princetoninstruments.com/products/

spec/actonseries), used is a Czerny Turner

spectrograph with focal length of 750 mm and a

triple grating turret. With the focusing geometry

used in the experiment [see figure 1] the beam waist

at the focus of the lens is 10 micro-meters. The

spectrograph is equipped with three ruled gratings in

the turret, viz., 300 grooves/ mm blazed at 300 nm ,

600 grooves/mm blazed at 500 nm, and 2400

grooves/mm blazed at 240 nm, which are

interchangeable under computer control. The

selection of the gratings determines the resolution of

the instrument. If the 600 grooves/mm grating is

used, as was the case in the present experiment, a

spectrum of about 38 nm of spectral width can be

captured without moving the grating. The output end

of the spectrograph is coupled with an intensified

and gated CCD camera (Princeton PI-MAX with

Unigen II coating and programmable delay

generator). The ICCD camera has 1024 x 1024

pixels and was cooled to –20

0

C by a Peltier cooler

to reduce noise (http://www.princeton

instruments.com/products/imcam/pixis). The camera

was electrically triggered by the Nd: YAG Q-switch

pulses after a software-controlled, adjustable time

delay. With a suitable time delay, the intense

background initially created by the high-temperature

plasma can be largely eliminated, and the atomic

emission lines of theelements were more clearly

observed. In most of our experiments, a time delay

of about 1.0 micro-second was selected. Usually,

spectra from a number of laser shots (about 40-80)

were acquired and averaged to increase the signal-

to-noise ratio. The ICCD was interfaced with the

spectrometer and data acquisitionand spectral

analysis were carried out by theintegrated software

WinSpec/32, provided by the manufacturer.

The LIBS spectrum, taken in ambient air, was

analyzed by using the 600 grooves/mm grating. The

resolution of the spectrometer for the 600

grooves/mm grating is about 0.02 nm (Haider et al.,

2014) and the repeatability and accuracy of the

computer-controlled system is ±0.05 nm and ±0.1

nm respectively (manufacturer supplied data).

The plasma was checked for optical transparency

(optical thinness) following the method described in

one of our earlier paper (Haider et al., 2014).

3 RESULT AND DISCUSSION

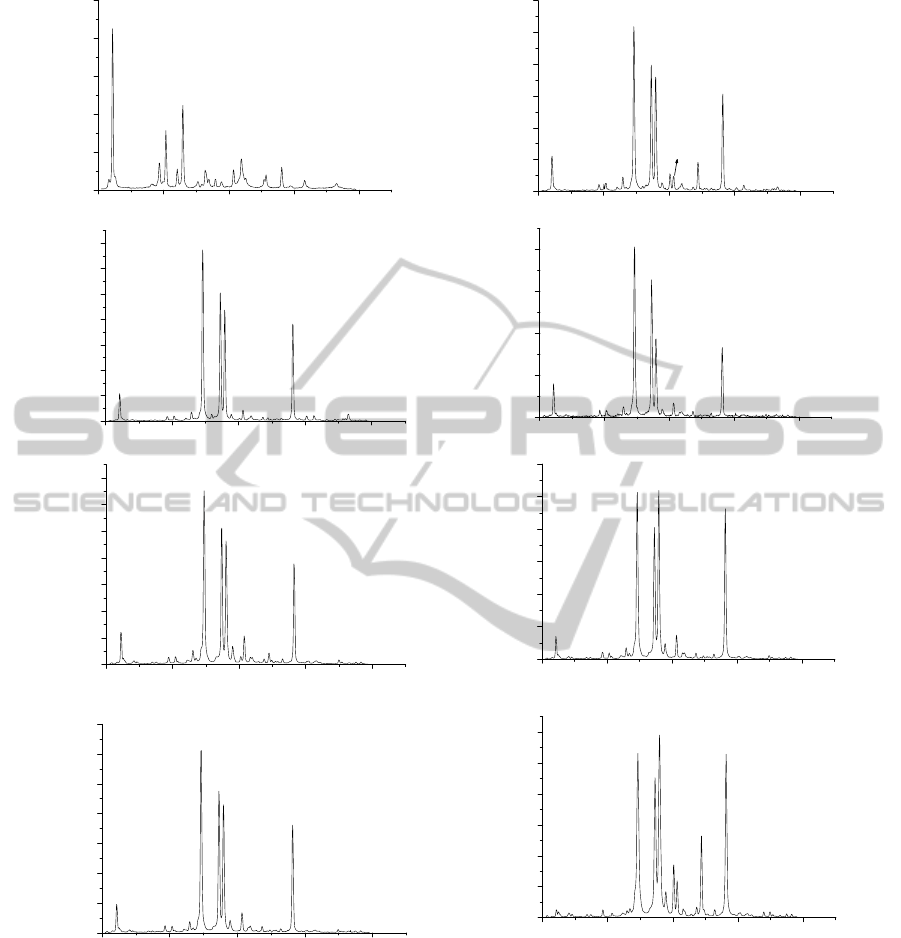

The LIBS spectra of samples with different carat

values are shown in figure 2. The spectral lines were

identified using the online NIST (US National

Institute of Standards and Technology) Atomic

Spectra Database and the presence of Au and two

other alloying elements (Cu and Ag) was confirmed

AQuickMethodtoDeterminetheImpurityContentinGoldOrnamentsbyLIBSTechnique

43

310 320 330 340 350

0

5000

10000

15000

20000

25000

Ag I

Cu I

Au I

Au I

Au I

Au I

Au I

Au I

Au I

intensity

wavelength

(a)

310 320 330 340 350

0

5000

10000

15000

20000

25000

30000

Ag I

Au I

Ag I

Cu I

Cu I

Au I

Au I

intensity

wavelength

(b)

310 320 330 340 350

0

5000

10000

15000

20000

25000

30000

35000

Au I

Ag I

Ag I

Cu I

Cu I

Au I

Au I

intensity

wavelength

(c)

310 320 330 340 350

0

1000

2000

3000

4000

Ag I

Au I

Ag I

Cu I

Cu I

Au I

intensity

wavelength

(d)

310 320 330 340 350

0

20000

40000

60000

80000

100000

120000

140000

Au I

Cu I

Ag I

Cu I

Ag I

Cu I

Au I

intensity

wavelength

(e)

310 320 330 340 350

0

10000

20000

30000

40000

50000

60000

Au I

Ag I

Ag I

Cu I

Cu I

Au I

Au I

intensity

wavelength

(f)

310 320 330 340 350

0

20000

40000

60000

80000

100000

120000

Au I

Ag I

Ag I

Cu I

Cu I

Au I

intensity

wavelength

(h)

310 320 330 340 350

0

5000

10000

15000

20000

25000

30000

35000

Au I

Ag I

Ag I

Cu I

Cu I

Au I

Au I

intensity

wavelength

(g)

Figure 2: Typical LIBS spectra with identified lines for samples with different carat value (a) 99.99%, (b) 91.76%, (c)

87.13%, (d) 85.390%, (e) 78.36%, (f) 77.7%, (g) 77.10%, (h) 33.5%.

other alloying elements (Cu and Ag) was confirmed

in the samples. The intensity of the emission line

was measured by multiplying the peak intensity with

FWHM of the line. The line intensity ratio of

impurity to gold ( I

Cu

/ I

Au

and I

Ag

/ I

Au

) by LIBS and

the ratio of concentration of impurity to gold (Cu

/Au and Ag/ Au) as determined by XRF were

recorded for different samples.

The intensity ratios obtained from LIBS

measurement, as well as the ratios of concentration

of Cu and Ag, to Au, determined from XRF analysis

represent an estimate of how much impurities

(mainly Cu and Ag) are present in samples. The

LIBS spectral emission lines for Au, Cu and Ag

used in the intensity ratio calculations were at

312.278±0.15 nm, 324.754±0.15 nm

and338.207±0.15 nm respectively.

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

44

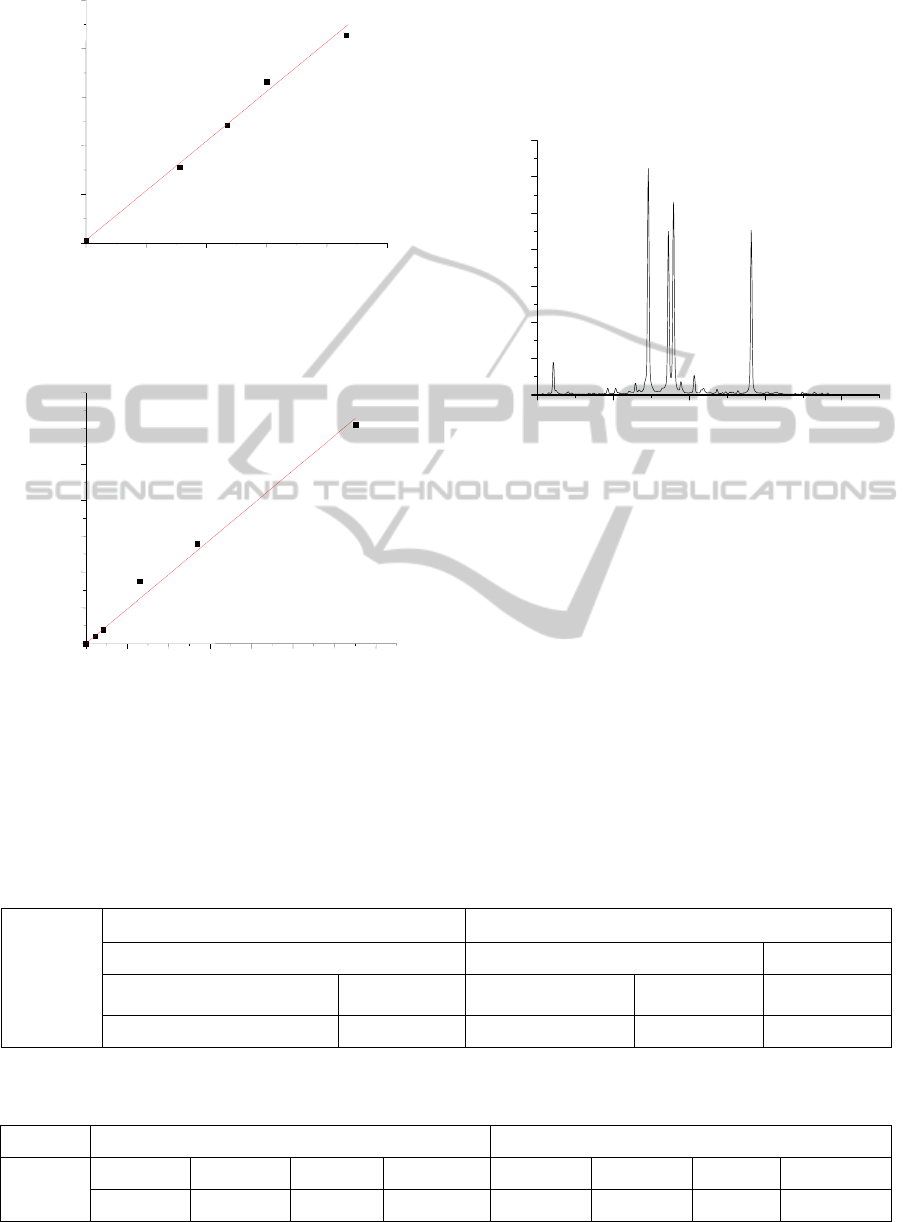

Figure 3: (a) Calibration curves for estimation of Cu

impurities in gold ornament.

Figure 3: (b) Calibration curves for estimation of Ag

impurities in gold ornament.

Therefore, by plotting the intensity ratio (from

LIBS) against the elemental concentration ratios

(from XRF), one can draw calibration curves for Cu

and Ag impurities as shown in Figures 3(a) and 3(b).

From these calibration curves, by knowing the line

intensity ratio by LIBS for an unknown sample, one

can immediately obtain the elemental concentration

ratio in that sample.

310 320 330 340 350

0

10000

20000

30000

40000

50000

60000

70000

Ag I

Ag I

Cu I

AU I

Cu I

Cu I

AU I

intensity

wavelength

Figure 4: LIBS spectrum for the sample of unknown

caratage.

For the verification of this method, LIBS spectra

(Fig 4) for an unknown sample was taken and from

the recorded spectra, line intensity ratios of impurity

(Cu and Ag) to gold i.e. I

Cu

/ I

Au

and

I

Ag

/ I

Au

were

determined. Then the elemental concentration ratios

of impurities to gold (Cu/Au and Ag/Au) were

measured for the corresponding line intensity ratios

from the calibration curves (Fig 3). Now, one can

easily calculate the % of impurity content in the

unknown sample using the Cu: Au: Ag ratio as

shown in Table 1. We have also analyzed the same

unknown sample by XRF technique. Table 2 shows

a comparison between the results obtained by XRF

method and the LIBS technique.

Table 1: Determination of ratio of impurity to gold from calibration curves (figures 3(a) and (b)) for gold sample of

unknown carat value.

Sample

By LIBS From calibration curve

Line intensity ratio of impurity to gold Ratio of impurity to gold

ICu/IAu IAg/IAu Cu/Au Ag/Au Cu:Au:Ag

17.702 12.190 0.173 0.065 17.3:100: 6.5

Table 2: Comparison of results obtained by XRF and that of LIBS technique in the present study for gold sample of

unknown carat value.

Sample By LIBS technique in the present study By XRF

Unknown

% of Au % of Cu % of Ag Carat value % of Au % of Cu % of Ag Carat value

80.78 13.97 5.25

19.39

78.610 14.829 6.252

18.87

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35

0

10

20

30

40

50

60

70

(b)

I

Ag

/I

Au

0.00 0.05 0.10 0.15 0.20 0.25

0

5

10

15

20

25

(a)

I

Cu

/I

Au

A

g / Au

Cu/Au

AQuickMethodtoDeterminetheImpurityContentinGoldOrnamentsbyLIBSTechnique

45

4 CONCLUSIONS

We have shown that the LIBS technique can be used

as an effective and quick method for the

determination of carat value of gold ornaments. The

present method using LIBS enjoys a number of

advantages over other methods e.g. the XRF method

as discussed in the introduction. It only requires the

accumulation of the LIBS spectra in a single spectral

window (310nm to 348nm), if one uses the 600

grooves/mm grating and takes time of less than 1

second. One can also use the same LIBS set up for

detection of trace elements which aren’t detected by

XRF. The method of determining the caratage of

gold ornament by LIBS technique is particularly

preferable over the conventional ED-XRF technique

where forgery, by simple gold electroplating of

ornaments made of other metal, e.g. copper, silver or

bronze, is expected.

REFERENCES

Ali. J., Baizer. E., Jafarpur. M., Montazeri. M., Majdi. A.,

Aminifard. S., Zafari. M., Akberi. N. R. and Rad. H.,

2011. Nanotoxicity and Nanoparticle Safety in

Biomedical Designs. International Journal of

Nanomedicine, 6, 1117.

Beckhoff..B., Langhoff. N., Kanngiesser. B., Wedell.

R.and Wolff H. (eds.), 2006. Handbook of Practical

X-Ray Fluorescence Analysis, Springer.

Bugbee. E. E., 1950. A textbook of Fire Assaying, John

Weily and Sons.

For technical specifications: http://www.skyrayxrf.com/

edx3600.

Goodman. P.,2002. Current and Future Uses of Gold in

Electronics, Gold Bulletin, 35, 21.

Haider. A.F.M.Y., HedayetUllah. M., Khan. Z.H., Kabir

F. and Abedin. K.M., 2014. Detection of Trace

Amount of Arsenic in Groundwater by Laser-Induced

Breakdown Spectroscopy and Adsorption, Optics &

Laser Technology, 56, 299–303.

Haider. A. F. M. Y., Ira. M. K., Khan. Z. H. and Abedin.

K.M., 2014. Radiative lifetime measurement of excited

neutral nitrogen atom by Time Resolved Laser-

induced breakdown spectroscopy. J. Anal. At.

Spectrom., 29 (8), 1385-1392.

Hilbk-Kortenbruck. F. H., Noll. R., Wintjens. P., Falk. H

and Becker. C., 2001. Analysis of Heavy Metals in

Soils using Laser Induced Breakdown Spectroscopy

Combined with Laser Induced Fluorescence,

Spectrochimica Acta Part B, 56, 933.

http://www.princetoninstruments.com/products/

spec/actonseries.

http://www.princetoninstruments.com/products/imcam/pix

is.

Marucco. A., 2006. Low Energy ED-XRF Spectroscopy

Applications in Gold Assaying, Nuclear Instruments

and Methods in Physics Research B, 213, 486.

Miziolek. A. W., Palleschi. V. and Schechter. I., (eds.),

2006. Laser Induced Breakdown Spectroscopy:

Fundamentals and Applications, Cambridge

University Press.

Pouzar. M., Kratochvil. T., Capek. L., Smolakova. L.,

Cernohorsky. T., Krejcova. A.and Hromadko. L.,

2011. Quantitative LIBS Analysis of Vanadium in

Samples of Hexagonal Mesoporous Silica Catalysts,

Talanta, 83, 1659.

Singh. J. P. and Thakur S. N. (eds.), 2007. Laser Induced

Breakdown Spectroscopy, Elsevier Science.

Suzuki. T., Kitsutaka. R., Muto. T.and Morisaki. S., 2006.

Determination of the Purity of Gold Alloys Using

Gamma-Ray Transmission Techniques, Japan Journal

of Applied Physics, 37, 624.

Zorov. N. B., Gorbatenko. A. A., Labutin. T. A. and

Popov. A.M., 2010. A Review of Normalization

Techniques in Analytical Atomic Spectrometry with

Laser Sampling: From Single to Multivariate

Correction, Spectrochimica Acta Part B, 65, 642.

PHOTOPTICS2015-InternationalConferenceonPhotonics,OpticsandLaserTechnology

46