Engineering Implantable Microfluidic Drug Delivery Device for

Individualized Cancer Chemotherapy

Peiyi Song, Danny Jian Hang Tng, Rui Hu and Ken-Tye Yong

School of Electrical and Electronic Engineering, Nanyang Technological University, Singapore 639798, Singapore

Keywords: Cancer Drug Delivery, Implantable Device, Biocompatibility, in Vitro, in Vivo.

Abstract: Cancer patients nowadays suffer from serious side effects and unpleasant experiences when treated with

anti-cancer drugs. Conventional drug delivery methods including drug pills/capsules, topical drug gels/drops

and drug injections are too simple, incapable of providing controllable and efficient tumour drug delivery in

cancer treatment. Implantable drug delivery devices open a new horizon for drug treatment. Through device

implantation locally onto disease site, high efficiency drug delivery can be achieved. Utilizing techniques

from microfluidics, precise manipulation of drug fluids by these devices offer great advances for treatment.

In our study, an electrochemical actuated microfluidic drug delivery device was fabricated and studied in

vitro and in vivo. Cultured pancreatic cancer cell colonies were successfully inhibited by programmable

Doxorubicin treatments controlled by devices. Further, 12 devices were implanted into 12 Kunming mice

for evaluation of biocompatibility and drug delivery performance. Tissue biopsy and blood sample analyses

indicated all 12 mice remaining healthy after devices implantation. Adrenaline was delivered to the

abdominal cavity of the mice by using the implanted device and compared with conventional injection as a

positive control. Both approaches have shown that they are able to precisely control and manipulate the

increment rate of blood pressure in the small animals.

1 INTRODUCTION

Chemotherapy is an important method in treating

cancer. However, nowadays cancer patients suffer

from serious side effects and unpleasant treatment

experiences during chemotherapy with anti-cancer

drugs, which are usually highly toxic in order to

inhibit the rapid growth of cancer tumors (Song et

al., 2013, Song et al., 2014, Gensler et al., 2010b).

Conventional drug delivery methods including drug

pills/capsules, topical drug gels/drops and drug

injections have either low efficiency, wasting most

of the drug formulation during transportation via

systemic circulation, or invasive; which causes pain

and cellular damage (Li et al., 2010, Li et al., 2009,

Li et al., 2008, Tsai and Sue, 2007). Also only

simple drug profiles can be achieved by

conventional methods (Elman and Upadhyay, 2010).

The application of conventional drug delivery

methods has reached its limit in terms of

controllability and efficiency for chemotherapeutic

treatment of tumours. Recent developments in drug

delivery devices enable drug carrying devices to be

implanted locally at disease sites, providing an

unprecedented efficiency in drug delivery (Gensler

et al., 2012, Meng and Hoang, 2012, Saati et al.,

2010b, Song et al., 2013, Farra et al., 2012).

Leveraging on microfluidic technologies, precise

manipulation of drug fluids by these devices offer

great advances in treatment. These devices present

enormous capabilities; allowing the tailoring of drug

dosages, drug delivery profiles, as well as localized

and targeted delivery of drugs to the disease sites.

Through the optimization of these parameters,

effective treatment fitting the needs of every

individual patient can be realized. This approach

will minimize the side effects of drugs formulation

to the body while maintaining the desired

therapeutic concentration for effective therapy of

illnesses.

Currently, there is one type of implantable drug

delivery devices that has a chip-like structure,

consisting of an array of micro-reservoirs (10 –

200nL capacity). By selectively open those micro-

reservoirs, designed drug formulations will diffuse

to disease site. These devices have been tested in

vitro (Chen et al., 2009, Chung et al., 2009, Elman et

al., 2009, Yang et al., 2011), in vivo (LaVan et al.,

37

Song P., Tng D., Hu R. and Yong K..

Engineering Implantable Microfluidic Drug Delivery Device for Individualized Cancer Chemotherapy.

DOI: 10.5220/0005202900370043

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2015), pages 37-43

ISBN: 978-989-758-071-0

Copyright

c

2015 SCITEPRESS (Science and Technology Publications, Lda.)

2003, Prescott et al., 2006) and in human(Farra et al.,

2012). However, these drug delivery microchips are

unsuitable for cancer chemotherapies due to their

limited reservoir volume, necessitating periodic re-

implantations to achieve the long term drug

treatment effects (Santini Jr et al., 2000). New

studies proposed to solve this challenge by

employing an implantable drug delivery device with

a single reservoir system instead of relying on

multiple micro-reservoirs. The device system is

integrated with a MEMS micropump actuator for

driving the fluid out from the large reservoir (Tsai

and Sue, 2007). The localized delivery of drugs is

then achieved by using a cannula connected to the

drug reservoir and thereby allowing the drugs to be

delivered to the targeted tumor site. It is

demonstrated that these devices can be implanted

subcutaneously (Shobo et al., 2011) thereby

allowing one to easily refill the system with drugs

using a specialized port or via a syringe (Po-Ying et

al., 2010, Tng et al., 2013). For cancer treatment, the

significance of refilling serves not only to extend the

drug therapy period, but more importantly, the

capability to amend the formulations used,

especially when drug resistance is encountered

(Song et al., 2013, Gottesman, 2002). Single

reservoir drug delivery devices have been

extensively tested for in vitro (Gensler et al., 2012,

Shobo et al., 2011, Gensler et al., 2010b, Lo et al.,

2009b), ex-vivo(Li et al., 2008) and in vivo (Saati et

al., 2010a, Gensler et al., 2010a, Ambati et al., 2000).

Here, we demonstrate an electrochemically

actuated, single reservoir implantable microfluidic

drug delivery device for cancer treatment studies.

Fabrication was achieved using MEMS

microfabrication techniques with biocompatible

materials. The use of the microfluidic drug delivery

device for cancer chemotherapy in vitro is presented

and the experimental results highlights the drug

delivery device’s capability of customizing specific

drug delivery profiles for treating different types of

pancreatic cancer cell lines. Furthermore, working

towards usage in clinical settings, the impact and

biocompatibility of these devices implanted in the

body were carefully studied in vivo. We carefully

examine the impacts and biocompatibility of the

implantable microfluidic drug delivery device by

subcutaneously implanting them into 12 Kunming

mice for a 28 days observation. In addition, we also

demonstrate the device can be successfully used for

drug delivery therapy under implantation settings

upon comparing its effectiveness with the

conventional intravenous injection method.

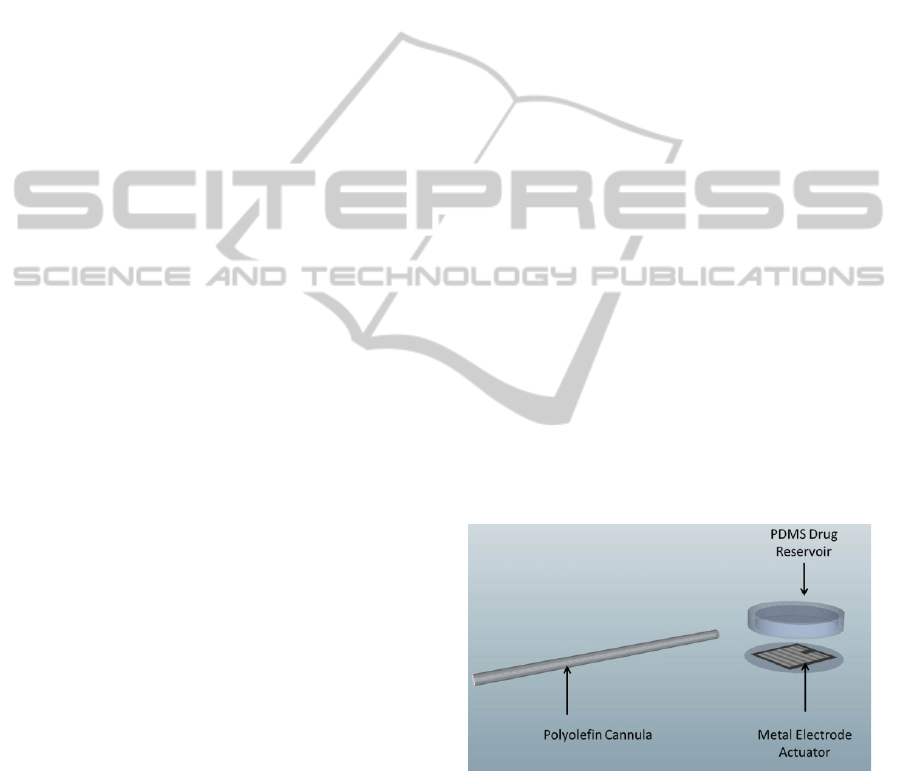

2 DESIGN

The microfluidic drug delivery device is constructed

by three parts: the Polydimethylsiloxane (PDMS)

drug reservoir, the Polyolefin cannula and the metal

electrode actuator (Figure 1). PDMS and Polyolefin

were chosen as construction materials for their

proven bio-compatibility. PDMS has an attractive

resealing feature thus the singular drug reservoir

constructed of PDMS can be filled/refilled using

syringe and needle without damage its structure(Lo

et al., 2009a). The metal electrode actuator contains

a pair of interdigitated Pt/Ti fingers as anode and

cathode. When supplying bias voltage on the

electrodes, Hydrogen (H

2

) and oxygen (O

2

) gases

were generated by water electrolysis. The formation

of the gases quickly increases the pressure within the

drug reservoir, and then pushes drug solution within

the reservoir to be released through the long cannula,

reaching to the disease site. This single reservoir

together with long cannula design negates the

requirement to implant the entire device at the

disease site. This is a major advantage as diseases

are hard to be reached by implantable chips due to

spatial and physiological constraints at the disease

site can now be treated with implantable devices.

For example, Ambati et al. have reported the

subcutaneous implantation of an osmotic pump

between the scapulars with a long cannula delivering

drug into the choroid and retina of rabbit eye, where

it was hard to implant an entire drug delivery chip

(Ambati et al., 2000).

Figure 1: Design of the microfluidic drug delivery device.

In the traditional design of metal electrodes, a 2-

layer electrode design was used (Song et al., 2013,

Li et al., 2008). Titanium served as adhesive layers

for platinum/gold onto substrate, which resists

oxidation in the electrolysis reaction. However,

metal electrode structure delamination was

frequently observed when the actuator was designed

to be miniaturized for implantation into small

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

38

animals. And the delamination would negatively

affect the actuation performance as well as lifetime

(Hang Tng et al., 2014). Facing this challenge, we

invented a nanosandwiched Pt/Ti multi-layer

electrode design. The multilayered design of the

electrode was constructed with several repeating

units of thin Ti/Pt layers instead of one. All unites

are bonded together to withstand forces from water

electrochemical reaction. A relatively thick layer of

Ti at the top of metal structure provides additional

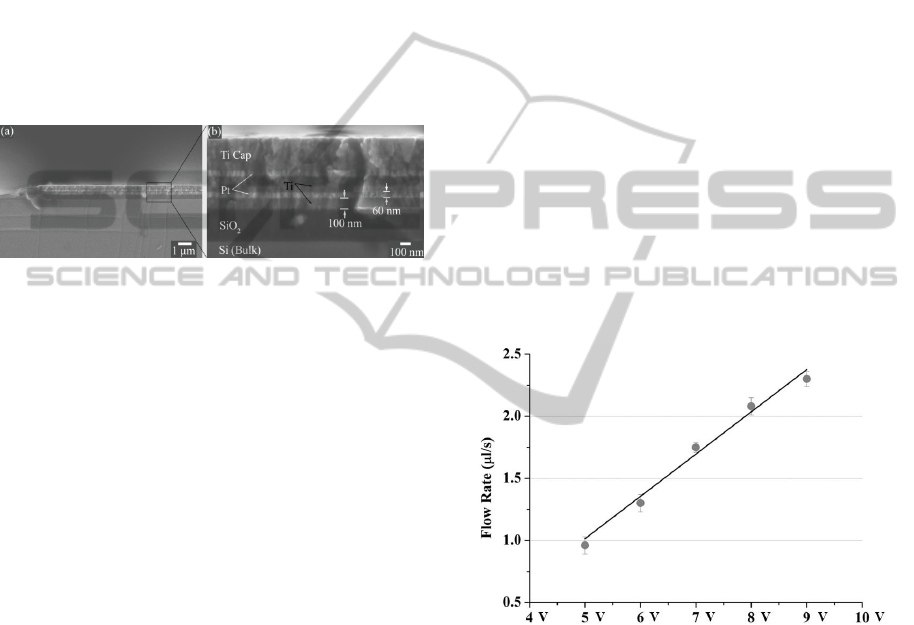

protection for the electrode (Figure 2). In our study,

the new metal electrode actuator design has shown

to enhance the lifetime up to 400% more than

conventional, despite its smaller feature size (<

20μm) than before.

Figure 2: Cross section SEM images of nanosandwiched

multilayer electrodes (a) An overview of a metal electrode.

(b) An enlarged electrode marked by measurements.

Images are reprinted with permission from Royal Society

of Chemistry (RSC).

3 FABRICATION

Nanosandwiched Pt/Ti multi-layer electrode actuator

was fabricated through photolithography, electron

beam metal evaporation and lift off processes.

AZ5214 photoresist was spun coated onto the Si

substrate at 4000 rpm for 45 s followed by a pre-

exposure bake (105 ˚C, 2 min). The electrode pattern

was generated by photolithography. Five metal

layers of titanium and platinum were then deposited

respectively (Ti-Pt-Ti-Pt-Ti) by electron beam

evaporation to create the nanosandwich structure.

The wafer was rinsed with acetone to lift-off the

remaining AZ photoresist and release electrodes.

Two thin copper wires were bonded to electrodes

with silver conductive adhesive paint. The Pt/Ti

multilayer electrode actuator measures 5mm long,

5mm wide and 0.5mm thick. The actuator was

integrated as the base of the drug reservoir.

Drug reservoir was fabricated through soft-

lithography processes. SU-8 photoresist was spun

coated onto the Si substrate at 1000 rpm for 60 s

followed by a pre-exposure bake (110 ˚C, 4 hour).

Device mold pattern was generated by exposure

(420 W, 90 s, hard contact). A post exposure bake

(95 ˚C, 1 hour) and developing was performed to

release the SU-8 mold. Polydimethylsiloxane

(PDMS) was poured into the SU-8 mold and then

degassed with in a vacuum oven. The PDMS was

then cured at 120 °C for 20 min and was

subsequently removed from the mold to get drug

reservoir pattern. Electrode actuator and drug

reservoir were assembled using PDMS. The PDMS

drug reservoir measures 10mm long, 10mm wide

and 2mm thick. A polyolefin cannula measuring 30

mm long and 0.5mm inner diameter and 0.8mm

outer diameter was then bonded to drug reservoir

using PDMS. Subsequently, the whole device was

baked at 120 ˚C for curing.

4 RESULT AND DISCUSSION

4.1 Device Characterization

The delivery performance of our electrochemical

actuated microfluidic drug delivery device was

studied. Drug flow rates versus supplied voltages

were measured. Characterization results are shown

in figure 3.

Figure 3: Characterization of drug delivery flow rates at 5,

6, 7, 8 and 9 V (n = 4, mean ± SD).

The result showed that flow rates from 1 μl/s to

2.3 μl/s can be achieved with supplied voltage from

5 V to 9 V. An approximately linear trend was

observed. The controllability of actuator on delivery

drug flow rates offers great advances in treatment,

providing flexible treatment profiles (flow rates,

drug volume and treatment timing) on demands. By

using the reliable nanosanwiched metal electrode

actuator, devices showed great reliability and

consistency during drug delivery as shown by the

relatively small standard deviation. No fluid leakage

occurred during the whole test. It is worth to

mention that long-time operation of electrolysis

actuation with high voltage may lead to temperature

EngineeringImplantableMicrofluidicDrugDeliveryDeviceforIndividualizedCancerChemotherapy

39

rising. In the characterization of our devices, no

significant raise in temperature occurred during a

reasonable operation time.

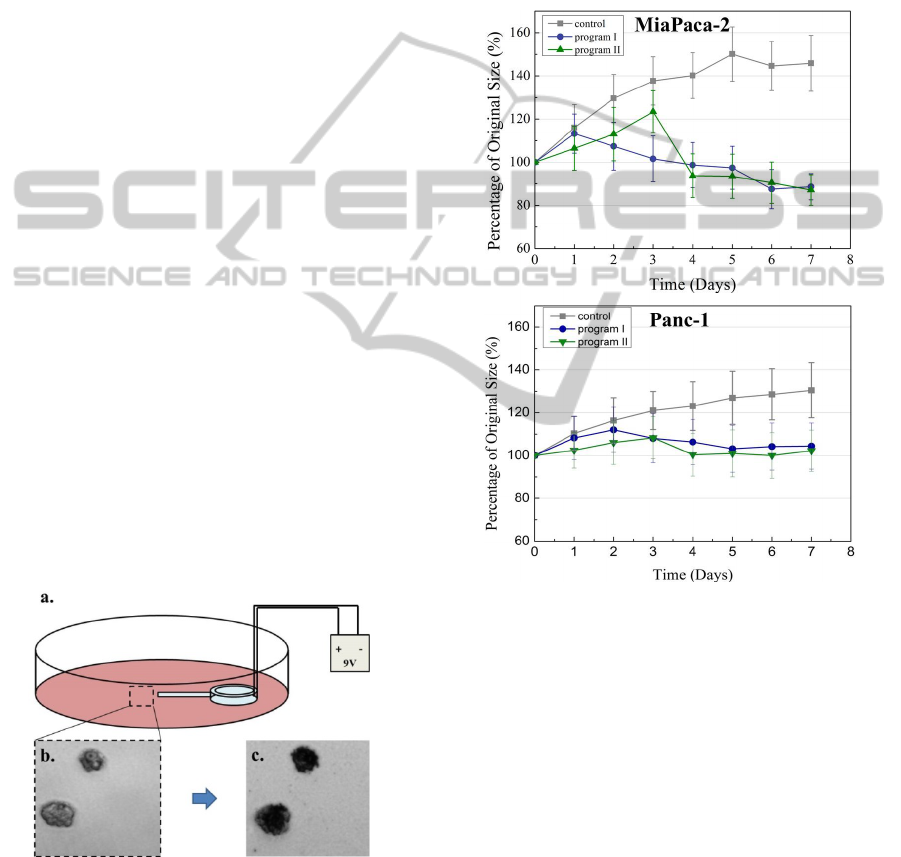

4.2 Individualized Cancer Treatment

Study in Vitro

Experiment setting is shown in figure 4a. Two types

of pancreatic cancer cell (MiaPaCa-2 and Panc-1)

were cultured in petri dish for 10 days until they

have grown into colonies (Figure 4b). Cancer

chemotherapy drug doxorubicin (Dox) was delivered

to cultured cancer cell colonies using our

microfluidic drug delivery device automatically for

8 days. Gaining from the device’s controllability on

drug delivery profiles, two customized drug dose

profiles (program I: 6μg of doxorubicin delivery in

day 0, day 1 and day 2, program II: 9μg of

doxorubicin delivery in day 0 and day 3) were

conducted onto the two types of pancreatic cancer

cells. The cancer cell colonies size changes were

monitored during the 8 days treatment. Our results

have shown that cancer colonies lost their viability

after chemotherapy (Figure 4c) and the growth of

cancer cell colonies was successfully inhibited as

compared with control group (Figure 5). It is

important to notice that, the MiaPaCa-2 group and

Panc-1 group have demonstrated different response

under each customized treatment profile. Under the

treatment profile “program II”, the treatment effects

occurred at DAY 3 when the drug concentration

reached 18μg for both MiaPaCa-2 and Panc-1.

However, under the treatment profile “program I”,

the timing when inhibition of growth occurred was

different in each group (DAY 1 and DAY 2), which

Figure 4: Pancreatic cancer chemotherapy using

microfluidic drug delivery device in vitro: a. Drug

delivery device is placed in cell culture dish powered with

a 9 volt battery. b. Microscopy image of pancreatic cancer

cell colonies after 10 days culturing. c. Cancer cell

colonies after chemotherapy.

means 12μg of DOX delivery would be sufficient to

inhibit MiaPaCa-2 pancreatic cancer. Thus treatment

profile “program II” may not be suitable for treating

MiaPaCa-2 cancer for possibly overdosing the drug

amount. Therefore, using the implantable device for

an controlled drug delivery treatment, it is possible

for designing and conducting individualized

treatment profiles to treat and cure cancers towards

each patient’s needs, in the meanwhile to avoid side

effects of chemotherapies.

Figure 5: Pancreatic cancer cell colonies size changes

under programmed treatment profiles. Pictures are

reprinted with permission from Royal Society of

Chemistry. Images are reprinted with permission from

Royal Society of Chemistry (RSC).

4.3 Device Implantation in Vivo Study

with Kunming Mice

In Vivo study has been conducted for evaluating the

biocompatibility and overall performance of our

microfluidic drug delivery device. In total 12

devices were implanted subcutaneously in 12

Kunming mice where the long cannula was inserted

into the animal abdominal cavity for drug delivery

purpose. The microfluidic drug delivery device can

be easily implanted through minimally invasive

surgery procedures by creating 2 separate small

incisions in the small animal (Figure 6a, b). All 12

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

40

mice remained alive and healthy after surgery

throughout the 28 days experiment. 9 mice carrying

devices were involved into biocompatibility test and

other 3 mice were in implanted drug delivery study.

Figure 6c shows the representation of a device

implanted in a mouse. From the basic observations,

we concluded that the device implantation did not

cause major adverse impacts to the implanted mice.

Furthermore we carefully examined the

biocompatibility of our device by blood analysis and

tissue histology. At DAY 2, DAY 4 and DAY 28, 3

mice were sacrificed and their 1 ml blood samples as

well as tissues samples surrounding implanted

devices were acquired. Blood markers including

haemoglobin (Hb), total bilirubin (TBILI), direct

bilirubin (DBILI), red blood cell (RBC) count,

neutrophils (NE), monocytes (MO), lymphocytes

(LY), and white blood cell (WBC) showed no

abnormal variance indicating no severe infection and

adverse immune response generated from the

implantation for 28 days. Alanine aminotransferase

(ALT), alkaline phosphatase (ALP), creatinine

(CRE), and uric acid (UA) level indicated the

healthy liver and kidney functions of tested mice.

Figure 6: Device implanting into Kunming mice: a. Before

implantation. b. After implantation. c. Photography of

Kunming mouse 10 days after device implantation.

Surrounding tissue samples showed a normal

wound healing process on tested mice from DAY 2

to DAY 28 (Figure 7a, b). Implanted devices were

fully encapsulated by fibrous tissues at DAY 28

(Figure 7b). Further we have done microscopy of

haematoxylin-eosin (H&E) stained paraffin-

embedded fixed tissue sections. The observations

showed that, in DAY 4 (Figure 7c), a slight

inflammation and edema occurred at device

implantation area, but in DAY 28 (Figure 7d)

surrounding tissues returned to normal with newly

capillaries and fibrous cells formed. The results

strongly suggested that there is no rejection of the

implanted devices showing in tested animals. Our

microfluidic drug delivery device presented great

biocompatibility during the implantation with

Kunming mice.

Figure 7: Biocompatibility studies of microfluidic drug

delivery device implantation: a. Photography of device 2

days after implantation surgery. b. Photography of device

28 days after implantation surgery. c. Microscope photos

of subcutaneous tissue surrounding implanted device,

haematoxylin-eosin (H&E) stain, day4 with 10X

magnification. d. H&E stained tissue sample, photo taken

at Day28 with 10X magnification.

4.4 Implanted Drug Delivery

3 microfluidic drug delivery devices carrying 50 μl

of adrenaline were implanted into 3 Kunming Mice.

After implantation, devices were switched on for 25

seconds to deliver the adrenaline formulation into

abdominal cavities of mice. The changes of systolic

blood pressure (SBP) and diastolic blood pressure

(DBP) were measured before/5-minute after

adrenaline delivery. As comparison, 50 μl adrenaline

formulations were intraperitoneal injected to 3

Kunming mice without implant as control group.

The result showed that the SBP and DBP of both

control and experimental groups increased as the

same trend after drug delivery (Figure 8a, b). We

concluded that the microfluidic drug delivery device

is functioning properly under the implantation

setting. As the adrenaline formulation worked

similarly in both groups, we assume that in the

application of microfluidic drug delivery device for

cancer treatment, chemotherapy drug activity would

not be affected by the new delivery method.

EngineeringImplantableMicrofluidicDrugDeliveryDeviceforIndividualizedCancerChemotherapy

41

Figure 8: Blood pressure measurement data: a. Drug

delivery by syringe injection. b. Drug delivery by devices.

Both SBP and DBP were measured for every mouse.

5 CONCLUSIONS

Implantable microfluidic drug delivery devices have

been shown to have great potentials in futuristic

cancer treatment. Their controllability and ability to

leverage on the strengths of anti-cancer drugs has

made them an attractive option for overcoming the

present challenges faced in medicine. Demonstrated

with the in vitro pancreatic cancer model, we

concluded that through the programing of these

devices, chemotherapy could potentially be

individualized for every individual to gain better

treatment effects. The biocompatibility and drug

delivery performance of the device were

demonstrated with Kunming mice model in vivo.

Future researches on the microfluidic drug delivery

device will be focused on treatment effects of

different cancer tumor models on small animals, and

further clinical trials.

REFERENCES

Ambati, J., Gragoudas, E. S., Miller, J. W., You, T. T.,

Miyamoto, K., Delori, F. C. & Adamis, A. P. 2000.

Transscleral Delivery Of Bioactive Protein To The

Choroid And Retina. Investigative Ophthalmology &

Visual Science, 41, 1186-1191.

Chen, J., Chu, M., Koulajian, K., Wu, X. Y., Giacca, A. &

Sun, Y. 2009. A Monolithic Polymeric Microdevice

For Ph-Responsive Drug Delivery. Biomedical

Microdevices, 11, 1251-1257.

Chung, A. J., Huh, Y. S. & Erickson, D. 2009. A Robust,

Electrochemically Driven Microwell Drug Delivery

System For Controlled Vasopressin Release.

Biomedical Microdevices, 11, 861-867.

Elman, N. M., Ho Duc, H. L. & Cima, M. J. 2009. An

Implantable Mems Drug Delivery Device For Rapid

Delivery In Ambulatory Emergency Care. Biomedical

Microdevices, 11, 625-631.

Elman, N. M. & Upadhyay, U. M. 2010. Medical

Applications Of Implantable Drug Delivery

Microdevices Based On Mems (Micro-Electro-

Mechanical-Systems). Current Pharmaceutical

Biotechnology, 11, 398-403.

Farra, R., Sheppard, N. F., Mccabe, L., Neer, R. M.,

Anderson, J. M., Santini, J. T., Cima, M. J. & Langer,

R. 2012. First-In-Human Testing Of A Wirelessly

Controlled Drug Delivery Microchip. Science

Translational Medicine, 4, 122ra21.

Gensler, H., Sheybani, R., Li, P.-Y., Lo, R., Zhu, S., Yong,

K.-T., Roy, I., Prasad, P. N., Masood, R. & Sinha, U.

K. Implantable Mems Drug Delivery Device For

Cancer Radiation Reduction. Micro Electro

Mechanical Systems (Mems), 2010 Ieee 23rd

International Conference On, 2010a. Ieee, 23-26.

Gensler, H., Sheybani, R., Li, P. Y., Lo Mann, R. & Meng,

E. 2012. An Implantable Mems Micropump System

For Drug Delivery In Small Animals. Biomedical

Microdevices, 14, 483-496.

Gensler, H., Sheybani, R., Li, P. Y., Lo, R., Zhu, S. T.,

Yong, K. T., Roy, I., Prasad, P. N., Masood, R., Sinha,

U. K., Meng, E. & Ieee 2010b. Implantable Mems

Drug Delivery Device For Cancer Radiation

Reduction. Mems 2010: 23rd Ieee International

Conference On Micro Electro Mechanical Systems,

Technical Digest.

Gottesman, M. M. 2002. Mechanisms Of Cancer Drug

Resistance. Annual Review Of Medicine, 53, 615-627.

Hang Tng, D. J., Song, P., Hu, R., Yang, C. & Yong, K.-T.

2014. High Reliability Nanosandwiched Pt/Ti

Multilayer Electrode Actuators For On-Chip

Biomedical Applications. Analyst, 139, 407-415.

Lavan, D. A., Mcguire, T. & Langer, R. 2003. Small-Scale

Systems For In Vivo Drug Delivery. Nature

Biotechnology, 21, 1184-1191.

Li, P. Y., Sheybani, R., Gutierrez, C. A., Kuo, J. T. W. &

Meng, E. 2010. A Parylene Bellows Electrochemical

Actuator. Journal Of Microelectromechanical Systems,

19, 215-228.

Li, P. Y., Sheybani, R., Kuo, J. T. W. & Meng, E. A

Parylene Bellows Electrochemical Actuator For

Intraocular Drug Delivery. Solid-State Sensors,

Actuators And Microsystems Conference, 2009.

Transducers 2009. International, 21-25 June 2009

2009. 1461-1464.

Li, P. Y., Shih, J., Lo, R., Saati, S., Agrawal, R., Humayun,

M. S., Tai, Y. C. & Meng, E. 2008. An

Electrochemical Intraocular Drug Delivery Device.

Sensors And Actuators A-Physical, 143, 41-48.

Lo, R., Li, P.-Y., Saati, S., Agrawal, R., Humayun, M. &

Meng, E. 2009a. A Passive Mems Drug Delivery

Pump For Treatment Of Ocular Diseases. Biomedical

Microdevices, 11, 959-970.

Lo, R., Li, P. Y., Saati, S., Agrawal, R. N., Humayun, M.

S. & Meng, E. 2009b. A Passive Mems Drug Delivery

Pump For Treatment Of Ocular Diseases. Biomedical

Microdevices, 11, 959-970.

Meng, E. & Hoang, T. 2012. Mems-Enabled Implantable

Drug Infusion Pumps For Laboratory Animal

Research, Preclinical, And Clinical Applications.

Advanced Drug Delivery Reviews, 64, 1628-1638.

BIODEVICES2015-InternationalConferenceonBiomedicalElectronicsandDevices

42

Po-Ying, L., Sheybani, R., Gutierrez, C. A., Kuo, J. T. W.

& Meng, E. 2010. A Parylene Bellows

Electrochemical Actuator. Microelectromechanical

Systems, Journal Of, 19, 215-228.

Prescott, J. H., Lipka, S., Baldwin, S., Sheppard, N. F.,

Maloney, J. M., Coppeta, J., Yomtov, B., Staples, M.

A. & Santini, J. T. 2006. Chronic, Programmed

Polypeptide Delivery From An Implanted,

Multireservoir Microchip Device. Nature

Biotechnology, 24, 437-438.

Saati, S., Lo, R., Li, P.-Y., Meng, E., Varma, R. &

Humayun, M. S. 2010a. Mini Drug Pump For

Ophthalmic Use. Current Eye Research, 35, 192-201.

Saati, S., Lo, R., Li, P. Y., Meng, E., Varma, R. &

Humayun, M. S. 2010b. Mini Drug Pump For

Ophthalmic Use. Current Eye Research, 35, 192-201.

Santini Jr, J. T., Richards, A. C., Scheidt, R., Cima, M. J.

& Langer, R. 2000. Microchips As Controlled Drug-

Delivery Devices. Angewandte Chemie International

Edition, 39, 2396-2407.

Shobo, M., Yamada, H., Koakutsu, A., Hamada, N., Fujii,

M., Harada, K., Ni, K. & Matsuoka, N. 2011. Chronic

Treatment With Olanzapine Via A Novel Infusion

Pump Induces Adiposity In Male Rats. Life Sciences,

88, 761-765.

Song, P., Hu, R., Tng, D. J. H. & Yong, K.-T. 2014.

Moving Towards Individualized Medicine With

Microfluidics Technology. Rsc Advances, 4, 11499-

11511.

Song, P., Tng, D. J. H., Hu, R., Lin, G., Meng, E. & Yong,

K.-T. 2013. An Electrochemically Actuated Mems

Device For Individualized Drug Delivery: An In Vitro

Study. Advanced Healthcare Materials, 2, 1170-1178.

Tng, D. J. H., Song, P., Hu, R., Lin, G. & Yong, K.-T. A

Sustainable Approach To Individualized Disease

Treatment: The Engineering Of A Multiple Use Mems

Drug Delivery Device. Nanoelectronics Conference

(Inec), 2013 Ieee 5th International, 2-4 Jan. 2013 2013.

153-156.

Tsai, N.-C. & Sue, C.-Y. 2007. Review Of Mems-Based

Drug Delivery And Dosing Systems. Sensors And

Actuators A: Physical, 134, 555-564.

Yang, X. Q., Moosa, B. A., Deng, L., Zhao, L. & Khashab,

N. M. 2011. Ph-Triggered Micellar Membrane For

Controlled Release Microchips. Polymer Chemistry, 2,

2543-2547.

EngineeringImplantableMicrofluidicDrugDeliveryDeviceforIndividualizedCancerChemotherapy

43