A Variable Structure Controller for a Class of Hyper-redundant

Arms

Decebal Popescu

1

, Nirvana Popescu

1

, Mircea Ivanescu

2

and Dorin Popescu

2

1

Department of Computing Science, POLITEHNICA University of Bucharest, Splaiul Independentei, Bucharest, Romania

2

Department of Mechatronics, University of Craiova, A.I. Cuza, Craiova, Romania

Keywords: Hyper-redundant Robot, Continuum Arms, Control.

Abstract: The paper treats the control problem of a class of hyper-redundant robot constituted by a chain of continuum

segments. The technological model basis is a central, long and thin, highly flexible and elastic backbone.

The driving system is a decoupled one. The main parameters of the arm control are determined by the

curvature and curvature gradient. The dynamic model is inferred. A sliding mode control system is used in

order to achieve a desired shape of the arm. The stability of the closed loop control system is proven.

Numerical simulations are also provided to verify the effectiveness of the presented approach.

1 INTRODUCTION

The goal of this paper is to implement a control

system for a class of hyper-redundant robots with

continuum components. The tentacle robots

represent one of the most attractive domains of

robotics during the last decades. The control of these

systems is very complex and several researchers

have tried to offer solutions as it will be further

discussed. In (Chirikjian, 1990), (Robinson, 1999),

(Gravagne, 2000), (Gravagne and Walker, 2000),

(Jones and Walker, 2006) the kinematic models

were analysed, based on a “backbone curve” that

captures the robot’s macroscopic geometric features.

In (Mochiyama, 1999), (Hirose

and Umetani, 1976)

the problem of controlling the shape of a robot with

two-degree-of-freedom joints was also investigated

using spatial curves. A controller for continuum

robots was developed by using neural network feed-

forward components in (Braganza, 2007),. Other

researchers derived a new kinematic model by using

the differential geometry (Walker, 1999), (Kapadia,

Walker and Dawson, 2009), (Hannan, 2005) or

introduced a real-time controller for continuum

robots (Jones, 2006). In (Kapadia, 2009) it was

proposed a sliding controller for extensible robots.

Other papers (La Spina, 2007), (KeJun, 2009),

(Webster and Jones, 2010) have developed several

biomimetic prototypes with undulatory action.

Our paper treats the control problem of a class of

light weight hyper-redundant robots. The

technological model basis is a central, long and thin ,

highly flexible and elastic backbone. The driving

system is a decoupled one. The main parameters of

the arm control are determined by the curvature and

curvature gradient. The dynamic model is inferred.

A sliding mode control system is used in order to

achieve a desired shape of the arm.

The paper is structured as follows: section 2

presents technological structure, section 3 analyses

the dynamic model, section 4 treats the control

algorithm, section 5 verifies the control laws by

computer simulation and section 6 contains the

conclusions.

2 TECHNOLOGICAL ARM

The technological model basis is an arm with a

distributed mass. The 3D model basis from Fig 1

consists of a central, long and thin, highly flexible

and elastic backbone. It is made from homogeneous

materials, the bending represents the main motion

and we neglect the deformations of axial

tension/compression and shear. The arm is divided

in several segments, each segment having its own

driving system. The motion of the arm, the

bending, is determined by antagonistic cables

(tendons) attached to the terminal point of each

segment and a DC motor driving system. These

cables develop the driven torques τ

i

, i=1, 2…

121

Popescu D., Popescu N., Ivanescu M. and Popescu D..

A Variable Structure Controller for a Class of Hyper-redundant Arms.

DOI: 10.5220/0005005901210126

In Proceedings of the 11th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2014), pages 121-126

ISBN: 978-989-758-039-0

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

The cables ensure an independent bending for each

segment so that the segment driving control is a

decoupled one.

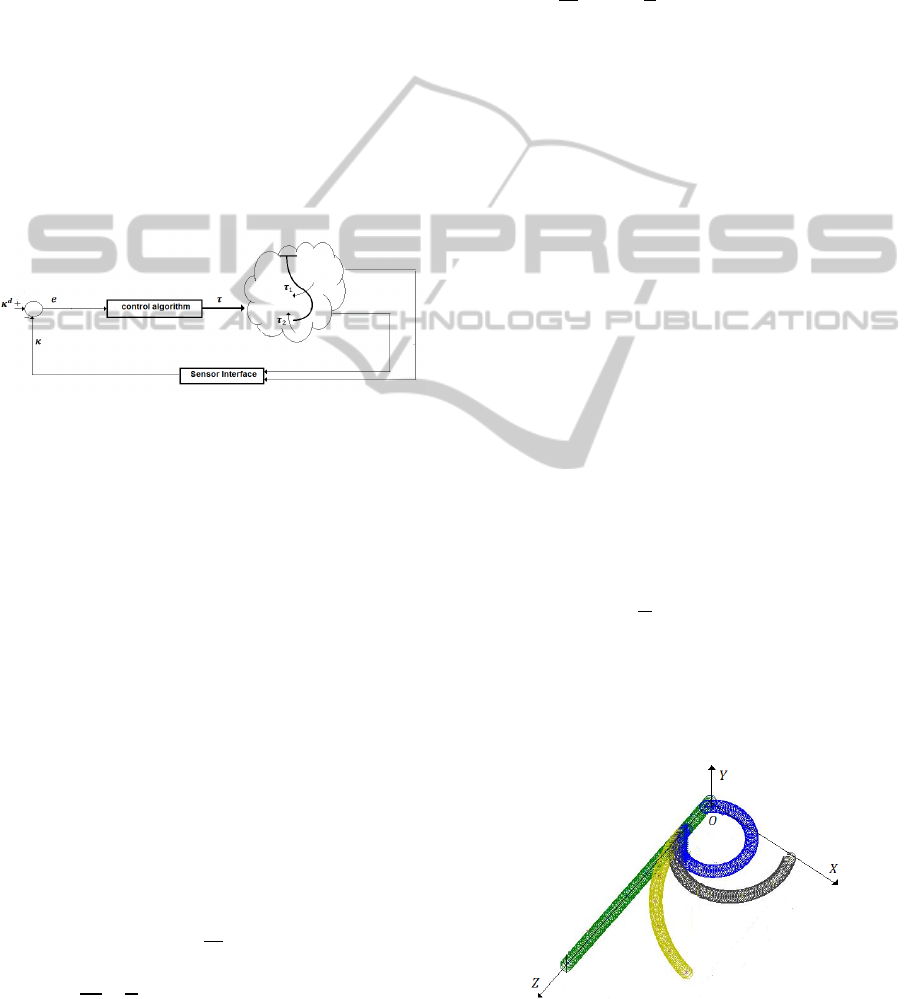

Figure 1: The technological arm.

3 DYNAMIC MODEL

We consider a hyper-redundant arm constituted by a

serial connection of a number of continuum arm

segments, with equal lengths L (Fig 2). For the

segment i, the curvature is defined by

0i

0

=

dω

i

s=0

ds

=

dθ

i

s=0

ds

dq

i

s=0

ds

κ

1i

=

dω

i

s=l

ds

=

dθ

i

s=L

ds

dq

i

s=L

ds

(1)

and we assume that the continuity of the arm

curvature requires the following segment boundary

conditions

Figure 2: The backbone model.

κ

0 i

0

= κ

1 i-1

(L)

(2)

with

κ

0 0

0

= 0

(3)

Using the same procedure as in (Gravagne,

2000), we obtain the partial differential equations

(PDE) of the arm segment,

I

ρ

ω

i

= EI ω

ss

i

- B ω

i

+h

i

(ω

i

)

(4)

where ω

i

=ω

i

t,s

, ω

i

=(θ

i

,q

i

)

T

, s∈Ω,ω

i

=

∂ω

i

∂t

⁄

, ω

s

= ∂ω

i

∂s

⁄

, I

ρ

is the rotational inertial

density matrix, I

ρ

=diag I

ρ

θ

, I

ρ

q

, I

ρ

θ

=I

ρ

q

=I

ρ

, B is

the equivalent damping matrix of the arm,

B=diag

b

θ

,b

q

, b

θ

= b

q

=b and represents the

nonlinear component vector determined by

gravitational components , h

i

= (h

1

i

,h

i

2

)

T

. The initial

and boundary conditions are

ω

i

0,s

=ω

i

0

(s)

(5)

EI ω

s

i

t,l

= τ

i

t

, ω

s

i

t,0

=0

(6)

ω

s

0

t,0

=0

(7)

ω

0

t,0

=0

(8)

where τ

i

is the equivalent moment generated by

the forces F

i

at the end of the arm segment i,

τ

i

t

= F

i

.r ,r is the radix of the moment,

τ

i

=

τ

θi

τ

qi

, F

i

=

F

θi

F

qi

(9)

The dynamic model of the arm can be expressed

in terms of the curvature κ

1 i

t,L

as

I

ρ

L

2

A κ

(t) = -b

L

2

Aκ(t) -

EI

L

Cκ(t)+

1

L

τ(t)+h(κ)

(10)

κ

0

=

κ

0

(11)

where

κ = (κ

11

, κ

12

, ... κ

1n

)

T

(12)

with

κ

i

t

=

κ

1 i

(t, L)

(13)

represents the new state vector, κ∈ R

n

, τ denotes

the general input of the arm,

τ= (τ

1

,τ

2

,…..,τ

n

)

T

(14)

the linear components are defined by the (n x n )

matrices

A =

1 0 0 0 . . . .0

2 1 0 0 . . . 0

2 2 1 0 . . 0

……………

2 2 2 2 2 1

, C=

0 0 0 . . . 0

1 0 0 . . 0

0 1 0 . .0

. . . . . . .

0 0 0 . .1 0

(15)

and the nonlinear component is determined by

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

122

h=(h

,h

,….,h

)

T

(16)

where h

= h

i

(κ

i

) and satisfices the inequality

(Popesu,2014)

‖

h

ω

‖

≤M

‖

κ

‖

(17)

4 CONTROL ALGORITHM

We consider a desired state κ

d

,κ

d

∈ R

n

, that satisfies

(10) with initial condition (11) and we define by

e

t

=κ

d

-κ(t)

(18)

the error variable, e ∈R

n

.

The control problem consists of finding the

control law τ(t), on the boundary s=L of each

segment such that the error converges to zero.

Figure 3: The control system.

The main idea of the control system is based on

the variable structure control associated with the

special properties of the physical system. We

propose a controller with a boundary torque variable

structure control. Let us define by S (t) the sliding

surface, associated with the model (10) and the error

(18)

S

t

=e

t

+σ e(t)

(19)

where

S=

S

1

, S

2

… S

n

T

, σ=diag (σ

1

, σ

2

… σ

n

), σ

i

are

positive constants.

Theorem 1. For the system described by (10)

with the initial conditions (11), if the variable

structure controller is given by

∆τ= -K

1

sgn

S

-K

2

Ce sgnS

T

K

2

Ce

-K

3

AI

ρ

σ

-1

-bIesgnS

T

AI

ρ

σ

-1

-bIe

(20)

K

1

>0

(21)

K

2

C-MI-

EI

L

C>0

(22)

K

3

L

-

L

2

II

ρ

Aσ

-1

- b I > 0

(23)

where K

j

=diagk

j1

, k

j2

,..,k

jn

,j=1,2,3 represent

the control coefficients, then the motion of the

system will reach the sliding line S=0 and then keep

it there , where ∆τ is defined by

τ = τ

d

- ∆τ

(24)

and τ

d

represents the torque vector on the desired

position κ

d

that satisfies the equations,

-

EI

L

C

d

+

1

L

τ

d

+hκ

d

=0

(25)

Proof. See Appendix

5 NUMERICAL SIMULATIONS

Consider a dynamic model of a vertical hyper-

redundant arm, with two arm segments, with the

length of the segment L=1 m, the rotational inertial

density I

ρ

= 0.001 kg m

2

, the bending stiffness

EI=0.1Nm

3

, the viscous coefficient

b

θ

=0.06 Nms/rad. These constants are scaled to

realistic ratios for a long thin arm. The initial and

boundary conditions are: θ

0

s

= 0 , θ

s

t, 0

=0,

EIθ

s

(t,L) =τ, where is the torque applied at the top

of the arm segment. We consider that the uncertain

term h

θ

is defined by the gravitational

components. For the characteristic values of the arm

parameters,

0.8

⁄

, 10

⁄

,

4.10

, associated with this thin long arm, the

inequality (17) is satisfied for M = 10. The arm is

simulated by a chain of vertebrae.

We simulated two motions. The first motion is a

XOZ plan motion, the arm (the both segments) is

moving toward the desired position defined in term

of curvature, κ

θd

=-

π

14

. A control law (20) with the

controller gains, k

1θ

i

= 20, k

2θ

i

= 8, k

3θ

i

= 3 is used,

where k

1θ

i

, k

2θ

i

, k

3θ

i

, i=1, 2…., verifies the conditions

(21) - (23). The motion of the arm, several

intermediary positions and final positions are

illustrated in Figure 4.

Figure 4: A XOZ plan motion.

AVariableStructureControllerforaClassofHyper-redundantArms

123

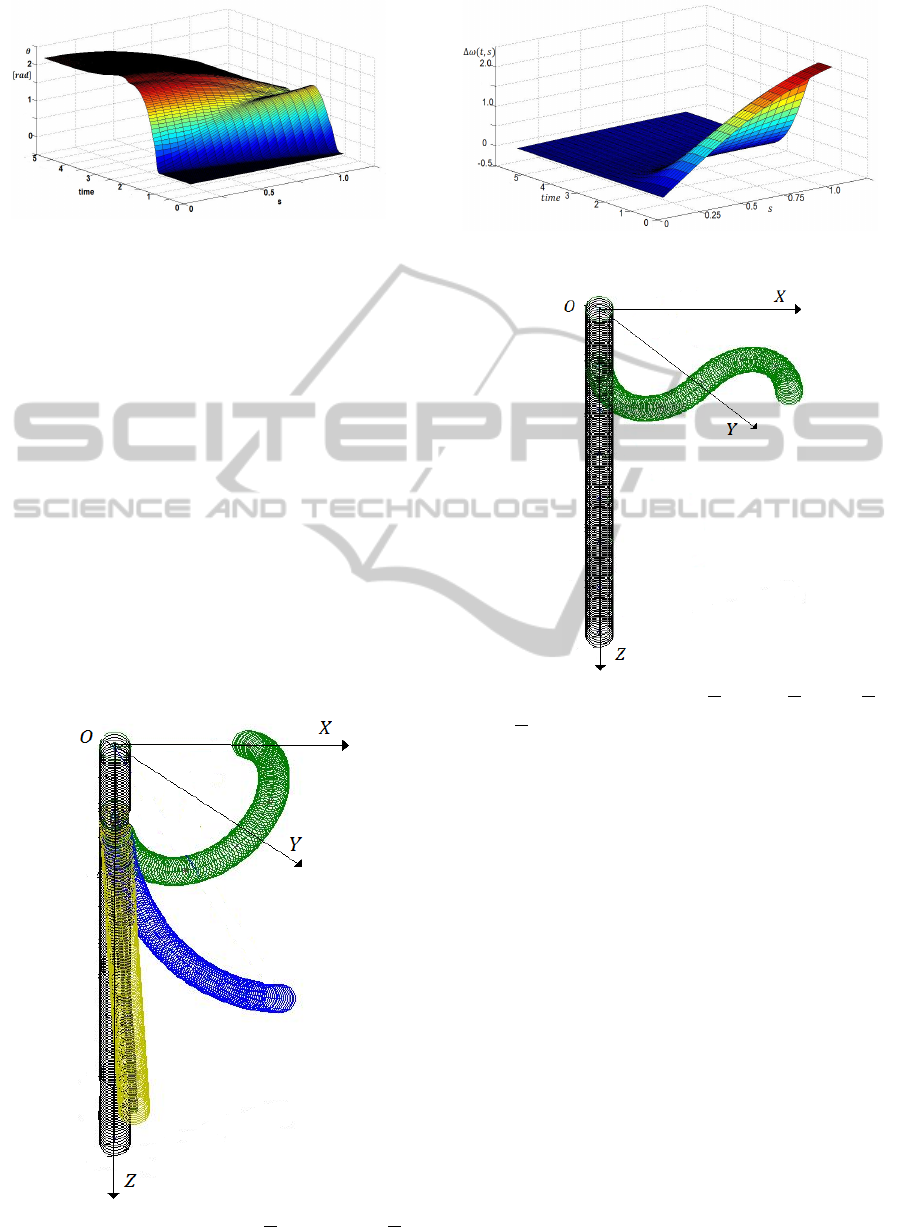

Figure 5: The state evolution for the plan motion.

The time evolution can be analysed if we use the

distributed parameter dynamic model described by

PDE (4) with boundary conditions defined by the

control law of torque (20).The state variable

evolution is presented in Fig 5.

A 3D motion of a 2-segment arm is presented in

Figure 6.The desired position is defined by

1θd

= κ

2θd

= -π/14, κ

1qd

= κ

2qd

= -π/24. The control

parameters were selected as

k

1θ

i

=k

1q

i

= 20 ,k

2θ

i

=k

2q

i

=8,k

3θ

i

=k

3q

i

=3, i=1,2…

The both segments bend with the same curvature.

The error evolution is presented in Figure 7. In

Figure 8 is presented a new motion of this arm, with

a different desired position of each arm

segment:

κ

1θd

=-π/14,κ

1qd

=-π/24, κ

2θd

=π/14,κ

2qd

=-π/24

The good performances of the proposed control

algorithm are concluded from the graphics.

Figure 6: A 3D motion:

1θd

= κ

2θd

= -

π

14

, κ

1qd

= κ

2qd

= -

π

64

.

Figure 7: The error evolution for the 3D motion.

Figure 8: A 3D motion

1θd

= -

π

14

, κ

1qd

= -

π

64

, κ

2θd

=

π

14

,

κ

2qd

= -

π

64

.

6 CONCLUSIONS

The paper presents the control problem of a class of

hyper-redundant robot constituted by a chain of

continuum segments. The technological model basis

is a central, long and thin, highly flexible and elastic

backbone. The driving system is a decoupled one.

The main parameters of the arm control are

determined by the curvature and curvature gradient.

The dynamic model is inferred in terms of the

curvature. A sliding mode control system is used in

order to achieve a desired shape of the arm. The

stability of the closed loop control system is proven.

Numerical simulations are also provided to verify

the effectiveness of the presented approach.

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

124

ACKNOWLEDGEMENTS

This work has been supported by PPCA 150/2012

grant of the Romanian Executive Agency for Higher

Education, Research, Development and Innovation

Funding (UEFISCDI).

REFERENCES

Robinson ,G. , Davies, G. B. C., 1999 “Continuum Robots

– a State of the Art”, Proc. IEEE Int. Conf. on

Robotics and Automation, Detroit, May 1999, Pp.

2849 – 2854.

Gravagne, Ian A., Walker, Ian D., 2000, on the Kinematics

of Remotely - Actuated Continuum Robots, Proc.

2000 IEEE Int. Conf. on Robotics and Automation,

San Francisco, April 2000, Pp. 2544-2550.

Gravagne, Ian A., Walker, 2000 Ian D., Kinematic

Transformations for Remotely-Actuated Planar

Continuum Robots, Proc. 2000 IEEE Int. Conf. on

Rob. and Aut., San Francisco, April 2000, Pp. 19-26.

Chirikjian, G. S., Burdick, J. W.,1990, an Obstacle

Avoidance Algorithm for Hyper-Redundant

Manipulators, Proc. IEEE Int. Conf. on Robotics and

Automation, Cincinnati, Ohio, May 1990, Pp. 625 –

631.

Mochiyama , H., Kobayashi, H.1999, the Shape Jacobian

of a Manipulator with Hyper Degrees of Freedom,

Proc. 1999 IEEE Int. Conf. on Robotics and

Automation, Detroit, May 1999, Pp. 2837- 2842.

Braganza, D., D.M. Dawson, Walker, N. Nath, N., 2007,

“A Neural Network Controller for Continuum

Robots”, IEEE Transaction Robotics, Vol. 23, Issue 6,

Dec. 2007, Pp. 1270 – 1277.

Walker, I., M. Hannan, M., 1999, “A Novel Elephant’s

Trunk Robot”, AIM ’99, Pp. 410 – 415.

Jones, B., I. D. Walker, 2006, “Practical Kinematics for

Real-Time Implementation of Continuum Robots”,

IEEE Trans. Robotics, Vol. 22, No. 6, Dec. 2006, Pp.

1087 – 1099.

Kapadia, I. Walker, D. Dawson,2009 “a Model – based

Sliding Mode Controller for Extensible Continuum

Robots”, Recent Advances in Signal Processing,

Robotics and Automation, ISPRA Conf., 2009, Pp.

103 – 120.

Popescu, N., Popescu, D., Ivanescu, M., Nitulescu, M.,

2014, the Curvature Control of a Hyper-Redundant

Robot Proc. of Int. Symp of Robotics, Munich, June,

2014 ,Pp 251-257.

G. La Spina, M. Sfakiotakis, D. Tsakiris, a. Memciassi, P.

Dario, 2007, Polychaete-like Undulatory Robotic

Locomotion in Unstructured Substrates, IEEE Trans

on Robotics, Vol 23,No 6,Febr 2007, Pp1200-1212.

Kejun Ning, F.Worgotter, 2009, a Novel Concept for

Building a Hyper-Redundant Chain Robot, IEEE

Trans on Robotics, Vol 25,No 6,Dec 2009, Pp 1237-

1248.

Rucker, D. C., B. A. Jones, R. J. Webster III,2010, a

Geometrically Exact Model for Externally Loaded

Concentric-Tube Continuum Robots, IEEE Trans on

Robotics, Vol 26,No 5,Oct 2010, Pp769-780.

Bailly, Y., Y. Amirat, G. Fried, Modeling and Control of a

Continuum Style Microrobot for Endovascular

Surgery, IEEE Trans on Robotics, Vol 27,No 5,Oct

201, Pp 1024-1030.

Bajo, A., N. Simaan, 2012, Kinematics-based Detection

and Localization of Contacts along Multisegment

Continuum Robots, IEEE Trans on Robotics, Vol

28,No 2,April 2012, Pp 291-302.

B. A. Jones, I. D. Walker, „Kinematics for Multisection

Continuum Robots”, IEEE Transactions on Robotics,

VOL. 22, NO. 1, Febr. 2006, 43- 51.

R. Fareh, M. Saad, M. Saad, „Workspace Tracking

Trajectory for 7-DOF ANAT Robot using a

Hierarchical Control Strategy”, 2012 20

th

mediterranean Conference on Control & Automation

(MED), Barcelona, Spain, July 3-6,2012 122-128.

H. Shang, J. F. Forbes, and M. Guay. “Feedback Control

of Hyperbolic Distributed Parameter Systems”,

Chemical Engineering Science, 60:969 – 980, 2005.

F. Fahimi, H. Ashrafiuon, and C. Nataraj, (2002) “an

Improved Inverse Kinematic and Velocity Solution for

Spatial Hyper-Redundant Robots,” IEEE Trans. on

Robotics and Automation, Vol. 18, No. 1, Feb. 2002,

Pp. 103–107.

S. Hirose, Umetani,Y,(1976), Kinematic Control of

Active Cord Mechanism with Tactile Sensors, Proc of

2nd Int CISM-IFT Symp. on Theory and Practice of

Robots and Manipulators, Pp 241-252,1976.

A. Kapadia, I. Walker, D. Dawson, (2009), “a Model –

based Sliding Mode Controller for Extensible

Continuum Robots”, Recent Advances in Signal

Processing, Robotics and Automation, ISPRA Conf.,

2009, Pp. 103 – 120.

R. J. Webster, B. A. Jones, “Design and Kinematic

Modelling of Constant Curvature Continuum Robots:a

Review”, the International Journal of Robotics

Research, 29 (13), 2010, Pp. 1661-1683,

M. W. Hannan, “Real-Time Estimation for Continuum

Robots using Vision”, Robotica, Vol 23 /Issue 05,

Sept. 2005, Pp 645-661.

APPENDIX

From (10) - (11), the error dynamics will be

described by

I

ρ

L

2

A e

(t) = -b

L

2

Ae(t) -

EI

L

Ce(t)+

1

L

Δτ(t)

+ Δh(κ

d

)

(A.1)

e(0) = e

0

(A.2)

∆h = h - h

κ

d

(A.3)

Let us consider the Liapunov function

AVariableStructureControllerforaClassofHyper-redundantArms

125

V

t

=

1

4

l S

T

t

I

ρ

Aσ

-1

S(t)

(A.4)

The time derivative of is given by

V

=

l

2

S

T

I

ρ

Aσ

-1

S

(A.5)

where in order to simplify the notation, the

variable t is omitted.

V

=

l

2

S

T

I

ρ

Aσ

-1

(e + σe

)

(A.6)

By evaluating (A.6) along with the solutions of

(A.1), it turns out that

V

=

L

2

S

T

I

ρ

Aσ

-1

-Abe-

EI

L

S

T

Ce+S

T

Δh

+

1

L

S

T

Δτ

(A.7)

Now, substituting the control ∆τ from (20), after

simple additional manipulations, we obtain

V

≤ -

1

L

K

1

‖

S

‖

-S

T

K

2

C-MI-

EI

L

C

‖

e

-S

T

(

K

3

L

-

L

2

I)(I

ρ

Aσ

-1

-b I)

‖

e

‖

(A.8)

Using the conditions (21) - (23), this inequality

can be rewritten as

1

‖‖

(A.8)

ICINCO2014-11thInternationalConferenceonInformaticsinControl,AutomationandRobotics

126