What Are the Factors Affecting ERP System Integration?

Observations from a Large Manufacturing Enterprise

Tommi Kähkönen, Andrey Maglyas and Kari Smolander

Software Engineering and Information Management, Lappeenranta University of Technology,

P.O. Box 20, 53851, Lappeenranta, Finland

Keywords: Information Systems, Enterprise Systems, Enterprise Resource Planning, ERP, Integration, ERP

Development Network, Stakeholders, Affecting Factors, Moderating Factors, Grounded Theory.

Abstract: The first wave of Enterprise Resource Planning (ERP) systems integrated the core internal business

processes and provided operational benefits for companies. The second wave of ERPs introduced additional

challenges due to the need for ERPs to interact also with various other systems beyond organizational

boundaries, highlighting integration as a critical activity during the ERP system development. This paper

takes a Grounded Theory approach to investigate ERP system integration. A model of four groups of factors

affecting on ERP system integration was created. Challenged by the domain, organizational landscape, ERP

development network partners and system characteristics, ERP system integration is a continuous and

cooperative effort during the ERP development, conducted by the dynamic ERP development network. It

struggles through forced-marriage relationships, political games and organizational changes and aims at an

integrated business engine that makes the business more competitive. The model creates a base for further

research to investigate how integration issues are solved in ERP development networks.

1 INTRODUCTION

”If you investigate IT and are searching for an easy

integration between systems, there is no such thing.

Or, if there is, I’m very interested in hearing more

about it.” –Enterprise architect, adopting

organization

Companies have adopted ERP systems to

automate and integrate their core business processes

in order to achieve operational benefits and to

improve the business performance (Beheshti, 2006).

Implementing an ERP system is a challenging and

costly project. It is constant balancing between

customization of the package and re-engineering the

business processes to fit the package (Law et al.,

2010). Moreover, ERP projects are complex socio-

technical endeavours that involve both social

interactions between many stakeholders and

technical aspects in development or customization of

the ERP system (Albuquerque and Simon, 2007).

ERP systems tend to change the organizational

culture and way how people do their work (Liang

and Xue, 2004). Despite the fact that ERP vendors

including SAP, Microsoft and Oracle have been

building additional capabilities to their products, we

repeatedly observe the failures of ERP projects (IDG

Consumer and SMB, 2013). The increased body of

knowledge and more advanced products in the

market have not prevented ERP projects from

challenges.

Even though ERP systems are usually adopted to

replace numerous legacy systems, an ERP system

does not eliminate the need of other information

systems (Lehmann and Gallupe, 2005; Xu, 2011).

During the last two decades, the boundaries between

systems have become fuzzier as systems cross the

organizational borders to collaborate with business

partners besides the integration of internal business

functions (Hsu, 2013). Integrating an ERP system

with non-ERP systems is not considered easy (Doedt

and Steffen, 2011; Momoh et al., 2010). Because of

the extended role of an ERP system as the backbone

enterprise business suite that connects with

customers and business partners (Hvolby and

Trienekens, 2010), integration becomes an important

consideration during the ERP system development.

In our previous study, we analysed the existing

literature on ERP system integration and concluded

that there is a lack of studies with systematic

research approaches and ERP-specific integration

5

Kähkönen T., Maglyas A. and Smolander K..

What Are the Factors Affecting ERP System Integration? - Observations from a Large Manufacturing Enterprise.

DOI: 10.5220/0004866000050017

In Proceedings of the 16th International Conference on Enterprise Information Systems (ICEIS-2014), pages 5-17

ISBN: 978-989-758-027-7

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

strategies have not been widely studied, especially

from the perspective of different groups of

organizations involved in the project (Kähkönen and

Smolander, 2013). Furthermore, integration is not

well understood as a concept (Chowanetz et al.,

2012; Gulledge, 2006). Recognizing this we attempt

to fill the gap and contribute to the knowledge on

ERP system integration. We apply a qualitative

method and use the Grounded Theory methodology

(Corbin and Strauss, 1990) to observe and

understand the practice of ERP system integration in

a global manufacturing enterprise. When making the

inquiry into the practice, we concentrated on the

following research question: what are the factors

affecting ERP system integration?

The next section provides the background for

this study by describing the concepts ERP system

integration and ERP development network. In

Section 3, the research approach is presented. A

model of factors affecting ERP system integration is

developed in Section 4. The model is compared with

the existing literature and future research is

discussed in Section 5. Section 6 concludes this

paper.

2 BACKGROUND

2.1 ERP System Integration

Integration is a general term that has various

dimensions and meanings in the domain of

information systems. According to Linthicum

(2004), integration has technical, business process

and strategic perspectives and it includes data

exchange between systems, standardization of

business processes and also cooperation and

coordination between human actors (Linthicum,

2004). Integration can happen inside a single

organization or it can cross organization boundaries,

which can be considered external integration (Barki

and Pinsonneault, 2005). Gulledge (2006) clarified

the concept of integration related to enterprise

systems by dividing integration into “big I”, in

which business processes are integrated by a single

software application such as ERP, and “little I”, in

which enterprise systems are linked together by

different approaches, such as database-to-database

and application server integration (Gulledge, 2006).

When examining integration from the

perspective of an ERP system, it can be concluded

that integration consists of diverse activities.

Integration of business functions is the goal of an

ERP implementation as the ERP system enables data

flow between business processes (Hsu, 2013).

However, numerous other information systems, such

as Decision Support Systems (DSS) and

Manufacturing Execution Systems (MES) are still

needed, and application level integration of ERP

system and these systems is often necessary (Shafiei

et al., 2012; Tao et al., 2004). The functionality of an

ERP is often enhanced by bolt-on applications, such

as CRMs (Customer Resource Management), and

WMSs (Warehouse Management System) (Watts et

al., 2008). Because the purpose of a contemporary

ERP is to provide the backbone for business

collaboration, external integration with business

partners’ systems is unavoidable (Møller, 2005).

Another form of ERP system integration is to

provide interfaces for customers and clients to

access the system on mobile. This type of integration

is called portal-oriented application integration

(POAI) where an interface is built to display the

desired information needed by the intended user

group (Linthicum, 2004). In this paper we

understand ERP system integration as an activity

that builds interfaces and manages interconnections

between the ERP and other internal and external

systems during the ERP development, where the

dimensions of technology, standardization and

business processes must be dealt as a collaborative

effort with proper strategies by the ERP

development network.

2.2 ERP Development Network

Many groups of stakeholders are involved in ERP

projects (Skok and Legge, 2002). Besides the

adopting organization, the ERP vendor can have the

key role in the project by providing support and

tools for development (Somers and Nelson, 2004).

Consultants are often hired to ERP projects to solve

different problems that occur during the

implementation (Metrejean and Stocks, 2011). The

ERP community has been defined as a group

consisting of an ERP vendor, consultant and

implementing organization and it is suggested that

understanding the relationships and interactions

within this group would be a key milestone in the

ERP research (Sammon and Adam, 2002). Koch

(2007) uses the term “ERP network” in his work but

mainly focuses on the complexity of organizational

structures of ERP vendors.

However, it is often the case that this network of

stakeholders involved in ERP development is even

more complex if all the involved organizations are

taken into account. The “flagship” organization,

such as SAP or Microsoft can have a major role in

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

6

the ERP development when a packaged ERP is

adopted. The network also includes supply chain

partners, suppliers of supporting software

(databases, operating systems and tools), as well as

vendors of existing systems that are integrated with

the ERP system. Multiple levels from the key

organizations are involved, including the upper

management, business process owners, mid-level

managers, the IT-department, business

representatives and end-users. Furthermore, the

network is dynamic, which means that it constantly

changes its shape during the ERP development. In

this regard, we define the ERP Development

Network (EDN) as a dynamic group of stakeholders

from different levels of all the involved organizations

that are needed for ERP-related problem solving

during the ERP system development.

3 RESEARCH APPROACH

Qualitative research methods are essential also in

information systems development (ISD) and

software development, because of the central role of

human behaviour in them and due to the fact that

they introduce, besides technological challenges,

also numerous organizational and management

issues (Seaman, 1999). Grounded Theory (GT),

originally developed by Glaser and Straus in 1967,

was chosen as the research method for this study due

the fact that ERP projects are complex and they

include cooperation and collaboration of various

stakeholders. As an inductive research method that

is based on rich real-world research data, GT is

suitable for approaching complex organizational

phenomena (Charmaz, 2006). ERP development is a

socio-technical endeavour making the role of

network of stakeholders and human interactions

evident (Albuquerque and Simon, 2007).

Respectively, ERP system integration is not purely a

technological challenge but includes also

collaboration and knowledge sharing among various

stakeholders (Welker et al., 2008).

Our specific focus on the integration challenges

in ERP development networks required in-depth

knowledge of different stakeholders involved in the

ERP project. Therefore, we needed to approach the

subject with an iterative inquiry into the EDN and

with investigation of the challenges presented from

different viewpoints. Without having a predefined

theoretical model in mind, we investigated the EDN

from the viewpoint of one stakeholder to another,

iteratively collecting and analysing the data, which

GT supported well. This far GT has not been widely

utilised to investigate the integration in ERP

projects. However, we deemed it especially suitable

when investigating broad phenomena, such as ERP

system integration, in depth.

GT is a qualitative research method that allows

to develop theory iteratively based on data that is

systematically collected and analysed (Strauss and

Corbin, 2008). Data is usually collected by

interviewing or observing one or several cases, but

other sources of evidence like written documentation

or other archive material can be used as well

(Urquhart et al., 2010). GT is considered to be useful

for creating context-based and process-oriented

descriptions of organizational phenomena and it

provides, in its Strauss and Corbin version, relatively

clear guidelines for the data analysis (Corbin and

Strauss, 1990). The main benefit of GT is that it

allows a researcher to trace back to the original

sources of data in order to observe how the theory

has been developed and how different instances of

data have emerged into concepts and relationships

between them (Strauss and Corbin, 2008).

The data analysis in Strauss and Corbin’s version

of GT consists of three coding procedures: open,

axial, and selective coding. In open coding, the

transcribed data is first labelled with codes that

capture the meaning of the current piece of data. The

most important procedure in open coding is constant

comparison between the pieces of data in order to

find similarities and differences. In axial coding, the

connections between categories are formed.

Basically, this is the interpretation of codes,

categories, and properties developed in open coding

with the goal of refining the constructs and making

them more abstract and theoretical (Urquhart et al.,

2010). In selective coding, the goal is to choose a

core category and interpret its relationships to other

categories and explain it as a theory.

As data is collected and analysed iteratively, the

main question is when to stop the process. As a

theory emerges, more focus can be needed on some

particular aspects of it. At the same time, categories,

dimensions, and properties become more refined as

more data collected. The situation when a researcher

finds out that any new set of data will not bring

significant new codes, categories and/or

relationships is called theoretical saturation (Strauss

and Corbin, 2008).

3.1 Case Description

The adopting organization (from now on referred as

AO) is a large and global manufacturing enterprise

with an annual turnover over 8 billion euros. AO

WhatAretheFactorsAffectingERPSystemIntegration?-ObservationsfromaLargeManufacturingEnterprise

7

decided to build a fully-customized ERP system for

sales and logistics in order to replace several legacy

systems and also to overcome the year 2000 problem

without having to make the necessary updates to all

the existing systems. The implementation started in

the middle of 1990s and during that time, the

existing ERP packages did not have the desired

functionality to support business processes of the

domain and control the complex supply chain in

AO’s specific business field. The ERP project went

through major challenges, including redesigning the

insufficient system architecture and a merger of

companies. Eventually, the project greatly exceeded

the intended budged. However, the system is

currently in a global use and it was widely

considered as successful in the interviews. It is still

under a constant development in 2014. The supplier

of the system has remained the same from the

beginning and has a long-term relationship with AO.

Major parts of the development have been recently

outsourced to Asia by the supplier to reduce

development costs. Benchmarking against ERP

products in the market is constantly being done, but

for the time being, AO has decided to keep the

system to handle its core business processes.

ERP system integration has been a challenging

endeavour during the early phases of the project,

requiring a vast amount of resources, expertise and

strict processes, and also being the major

consideration of the current development. The ERP

system is integrated with a packaged ERP system

from SAP that is used for administrative processes

such as financial controlling and human resources.

Moreover, according to AO’s global ERP strategy

the system is taken into use in any new facility in

order to achieve synergy benefits. This requires

integrating the system with operative systems in

facilities. In order to let customers and partners to

access the relevant information, a web interface to

the system has been built. Creating an infrastructure

to support mobile use to access the system with

mobile devices has also been under consideration.

Integration with supply chain partners and their

systems, including systems of warehouse and

transportation operators as well as customs systems

has also been made. To ease the supply chain

collaboration, e-business standardization with

competitors and business partners within the same

domain has been considered.

When interviewees were asked about their

thoughts how the challenging project was managed

to be completed, it was pointed out that the timing

was right, there were not much economic pressure

that kept the faith of upper management for the

project. However, the interviewees estimated that if

a similar project would have been carried out few

years later, it had never been completed.

3.2 Data Collection and Analysis

The data was collected by theme-based interviews

that were conducted during February and May 2013.

Instead of determining a large number of fixed

questions addressing specific areas of interest, the

questions for the interviews were open-ended,

focusing on the interviewee’s experiences in the

ERP project. The more detailed questions were

asked based on responses of interviewees. For

example, major challenges and successes

experienced in ERP development were asked. This

way, we were able to get a rich set of data for further

investigation.

The data collection started with discussions with

our key contact person from the upper management

in AO. The goals of the research project were briefly

presented to him in order to identify the right

persons to interview. In general, the snowballing

technique (Strauss and Corbin, 2008) in which the

next interviewee is a referral from the previous one

was used for selecting the interviewees. Rather than

interviewing random persons, we navigated through

the ERP development network from one interviewee

to another in order to get different viewpoints to the

same issues.

In total we interviewed 17 industrial experts

representing different roles in the EDN. The

interviewees had different positions, ranging from

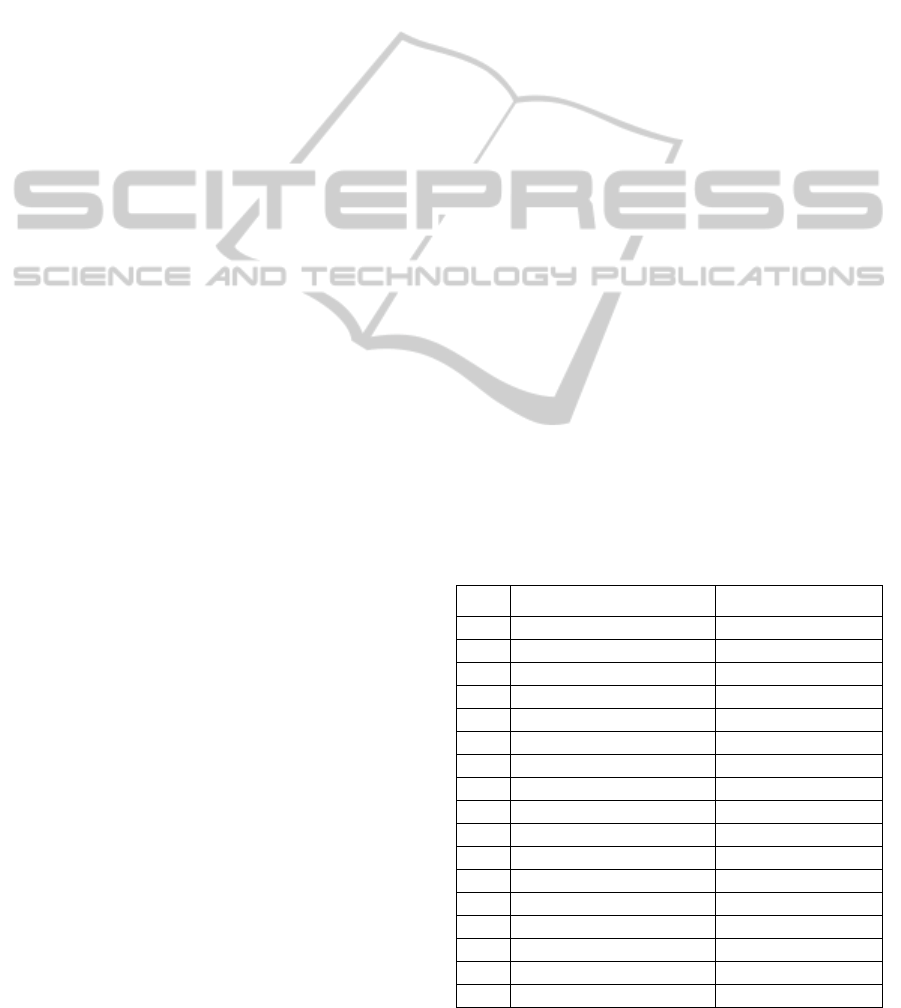

Table 1: Roles and organizations of the interviewees.

Role Organization

AO1 Business-IT negotiator Adopting organization

AO2 IT manager of business area Adopting organization

AO3 Programme manager Adopting organization

AO4 Enterprise architect Adopting organization

AO5 Representative of sales Adopting organization

AO6 IT support manager Adopting organization

AO7 Representative of logistics Adopting organization

AO8 Project manager Adopting organization

S1 Software manager Supplier

S2 Service owner Supplier

S3 Continuous service manager Supplier

S4 Infrastructure manager Supplier

S5 Project manager Supplier

S6 Lean software developer Supplier

S7 Service manager Supplier

C1 Middleware manager Consulting company

C2 Technical consultant Consulting company

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

8

upper management to mid-level management and

developers, and included people from AO, the

supplier of the ERP system and a consulting

company. Due to the long duration of the ERP

system development, the roles and responsibilities of

the interviewees have been constantly changing.

Some of the interviewees have been intensively

involved during the early implementation of the

system whereas others are currently working with

the system.

The duration of interviews ranged from 26 to 73

minutes, the average being 45 minutes. The list of

interviewees’ roles and their organizations are listed

in Table 1.

3.2.1 Open Coding

After conducting the interviews, they were

transcribed to text format and analysed by using

ATLAS.ti as the coding tool. The first step in GT is

to open code the data by conceptually labelling the

data based on its interpreted meaning. Customer-

supplier relationship, packaged ERP suitability and

evaluating the system architecture are examples of

open codes. The total number of different codes

created was 192. We classified the open codes into

categories. A category gives the context for the code

and provides the data with more concrete meaning.

For example evolution if appearing without the

category, is ambiguous but providing the code with a

category ERP development network will clarify the

meaning. The code ERP development network:

evolution associates the evolution to the EDN. This

means that when identifying the name of the code,

the context for the corresponding piece of data is

also identified. The total of 10 categories were

created in open coding. These categories and their

relations are further described in the next section.

3.2.2 Axial Coding

In axial coding, the relationships between categories

are identified and new categories may be formed

based on them. Open and axial coding are not

necessarily sequential steps in the analysis process,

but are often done concurrently.

The category ERP development network (EDN)

includes all the organizations related to ERP system

development, including Adopting organization (the

company that takes the ERP system into use),

Supplier (takes care of the actual implementation of

the system) and Consultants (external experts

involved in development). Besides these three

groups of organizations, the EDN consists of supply

chain partners, database and infrastructure vendors

among other organizations. In addition,

relationships, conflicts, cooperation, cultural issues

and knowledge transfer were put into this category.

AO operates in Domain, which determines the

business processes to be automated by the ERP

system. External changes and incidents such as the

year 2000 problem or the economic crisis can take

place on the domain. ERP system development

includes all the activities of development, including

specifying the system, testing, change management

and roll-out. Integration contains all the activities

related to integration, for example, providing

interfaces, master data management, integration

with internal systems and integration with the supply

chain. Integration is realized during the ERP system

development. ERP system is the ultimate artifact that

results from the development process. It has a

certain scope and architecture and it evolves through

technological changes. Additional categories were

created for Challenges and Success factors and

codes of these categories can relate to any of the

aforementioned categories.

We interpreted that there were indications of

theoretical saturation in the analysis of last

interviews. The data did not produce new codes and

already observed phenomena and patterns repeated.

Supplier:

Involvement

Expertise

...

Adoptingorganizatio n:

Enterprise

architecture

Costcutting

Structuralchange

...

ERPdevelopment

net work:

Customer‐supplier

relationship

Evolution

Actor–SCpartner

Actor–

Stan dardi zation

organizatio ns

...

Integration:

Internalsystems

Customerinterfaces

Supplychain

Mobileaccess

...

Consult ants:

Involvement

Expertise

...

ERPsys tem :

Scope

Flexibility

Unclear

boundaries

...

Domain:

PackagedERP

suitability

Businessproc esses

Economicsituation

...

ERPsys tem development:

Deployment/rollout

Road‐mapping

Developingpractices

andprocesses

...

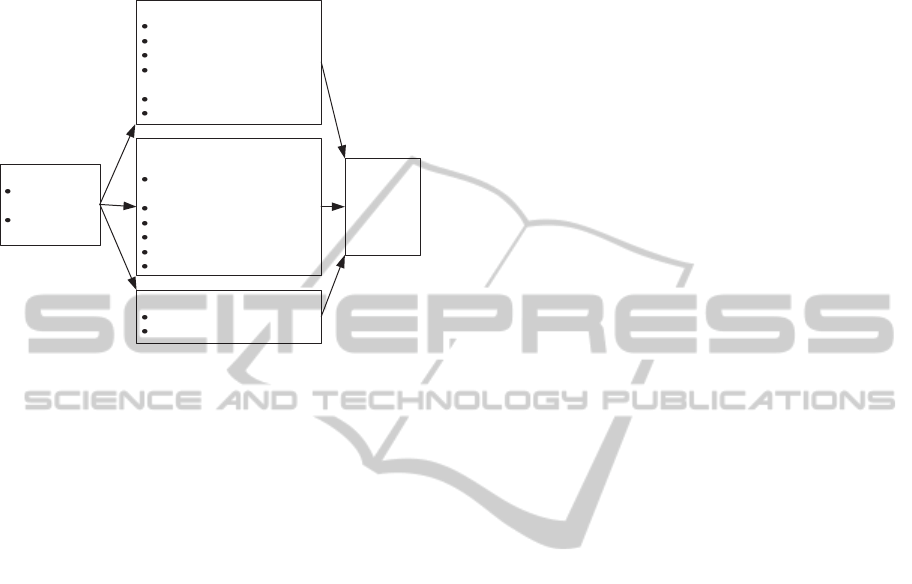

Figure 1: Categories with some of their codes after

selective coding.

3.2.3 Selective Coding

Finally, in selective coding, the core category is

selected and the whole data is then looked from the

perspective of this category. Other categories

support the core category in explaining the emerging

theory. We chose Integration as the core category,

because it emerged from the data as an important

matter, having been a major challenge during the

project phase of the ERP system development as

well as being one of the current challenges. Figure 1

WhatAretheFactorsAffectingERPSystemIntegration?-ObservationsfromaLargeManufacturingEnterprise

9

shows the main category and related categories (two

of the categories, Challenges and Success factors

have been excluded from this figure) and some of

the codes of these categories.

From the categories, four classes of factors that

affect ERP system integration were identified. These

levels are Organizational landscape (renaming the

category Adopting organization), EDN partners

(combining categories EDN, Supplier and

Consultants), ERP system and Domain (using the

categories with the same same). The individual

codes from these categories that were identified as

factors affecting ERP system integration are

presented in the next section.

4 FACTORS AFFECTING ERP

SYSTEM INTEGRATION

4.1 Organizational Landscape

The EDN forms around AO, which adopts the ERP

system. Organizational landscape, consisting of

Enterprise architecture (EA), ERP strategy,

Supporting practices and Integrative systems’

characteristics form the base for ERP system

integration. Structural change and Political agendas

can introduce additional integration challenges. The

following chapters describe these factors in more

detail.

Enterprise Architecture: Because of the global

organization and demanding supply chain, the EA of

AO is rather complex. By having a single and

integrated system used by different business units

with different needs, specifying new functionality

for the system is challenging. In order to manage the

EA, as new features are introduced into the ERP

system, an internal architecture check is done first to

see if there is a duplicate feature in the IT

architecture and if the new functionality could be

achieved through integration.

ERP Strategy: AO has a global ERP strategy, in

which they aim to reach synergy benefits by

implementing the system globally in every new

facility. AO is constantly road-mapping the ERP

system to develop the strategy. A representative of

AO commented the challenges of road-mapping:

”You never reach the ideal world, you end up in

having lots of stuff [different systems] here and

there, maybe all the possible ERP vendors in some

way. Then you have this company-level roadmap

and it constantly evolves.” –AO1

It was also pointed out that the current ERP

strategy needs often to be explained to new

managers:

“Our manager has changed a couple times over

the past years, and every time at the three-month

mark the new manager wonders why we have two

ERPs instead of one.” –AO5

Furthermore, it appeared that the ERP strategy

has been changing, which has caused a need for

additional integrations:

“The scope has changed somewhat, as far as

logistics goes we've moved away from the system

and we've replaced it with external ERP systems,

and integrated those with the system.” –AO3

Supporting Practices: Developed through trial

and error, AO has created well-established practices

and processes to support ERP development. These

practices appeared to have a significant role in roll-

outs, when integrating the ERP system with facility

systems:

”I think that ERP and its network are not just the

system, but also the supporting processes and

service processes that we have been building.” –

AO6

“Auditors haven't produced any findings for

years regarding our process control. […] We've

been told by our auditor that they have never seen

processes controlled this well anywhere.” –AO5

Deployments of the system to facilities have

been challenging projects that have required active

participation of different members of EDN,

including the supplier, managers, facility managers,

end-users and business representatives. Moreover,

decent practices and processes for integration have

been necessary. The first roll-out did not succeed

because of serious performance issues due to the

lack of systematic testing practices and because the

initial testing environment did not match the real

environment. Integration testing was seen as one

area where strict processes are necessary:

“Then we arranged a pretty massive testing. We

tested with the facilities’ real business cases that

[the system] works the way it’s supposed to and is

compatible with the system of the facility and other

integrated systems, because [the system] had to be

integrated with each facility system.“ –AO2

“And the more successful the testing sessions are

between the facility system and the ERP, the better

everything will start off. In that sense the testing of

the facility integration is absolutely the key”–AO5

Integrative Systems’ Characteristics: Because

the system replaced several existing legacy systems,

the parallel run of the ERP system and a legacy

system could take from several months to one year

of time. Because of the heterogeneity of the facility

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

10

systems, the system integration approach is different

in each location due to varying functionality of the

facility system in question. Different templates for

roll-outs have been made to deploy the system. The

interviewees commented on the deployments:

“It was a big thing to first integrate it to each

facility system, and in [the system’s] case we even

had to modify it a little bit in each facility because of

their differences, and then all that testing and

launching and such, it required a lot of work.” –

AO2

“In many cases it will require big changes to

[the system], depending on the facility. Some

facilities don't require many changes […] The ease

of the roll-out may vary greatly between facilities.”

–S2

“We have big differences between facilities,

depending on how well the integration was carried

out, and how well the interface is managed.” –AO5

Structural Change: The organizational structure

of AO appeared to be constantly changing during the

development of the ERP system. A big merger of

two companies took place when the system was not

yet taken into use. The merger did not only

introduce competing systems but also changed the

power structures inside AO:

”But then came the merger into the picture and

then started the fight whose systems to be utilized in

where. And unfortunately, the upper management

gave too much freedom for the units to determine,

which systems to use. This caused at least one year

of uncertainty of how to move forward.” –AO7

Political Agendas: Because of the structural

changes in AO, different functional areas became

under a changed leadership. This led to decisions to

take some of the functionality away from the ERP

system to be implemented in other systems, which

required additional integrations with the ERP

system. As a result, the original scope of the system

changed. This was mentioned as one of the major

challenges in the current state of the system and it

has also increased the costs:

“So the strategy has been changed allowing

units to have more decision power on which

direction to take […] I would have maybe... thought

harder on detaching our logistics systems from it.

Because one of the strengths of the ERP system was

that it was so comprehensive, everything was

included. All the logistical functions could be done

within it. So to then go and detach them from the

system.” –AO3

“They [logistics] started making separate

islands, they wanted to “freeze” the system to a

certain point and started to include all kinds of

additional systems there. It has been ongoing for ten

years now and we have ended up to serious

problems and the costs have increased in that area.

[Consultants] have evaluated the systems and made

this great finding that it’s a spaghetti and a new

transportation management system needs to be built

there…” –AO1

One interviewee also criticized the replacing the

functionality of the ERP system with additional

integrations:

“Now and then you underestimate things like the

demands of system integration. […] The relevant

data produced by logistics systems should also be

imported to the ERP system. That is the area where

we probably have the biggest gaps at the moment.

We do not have sufficient transparency in the sales

and supply chain system, this being the ERP system,

with regard to logistical processes.” –AO5

4.2 EDN Partners

ERP development is a cooperative effort of the EDN

in which AO forms relationships with other

members of the EDN. These relationships appear to

change during the ERP development. For example,

AO ended up in a conflict with a database vendor,

which eventually led to the change of the provider of

ERP database. Customer-supplier relationship,

Supplier’s expertise, Software vendors, Consultants’

involvement, Supply chain (SC) partners and

Standardization partners appeared to have an impact

on ERP system integration.

Customer-supplier Relationship: AO has had a

long-term relationship with the supplier of the

system. Both AO and the supplier had a positive

viewpoint on their relationship:

“I have to give credit to the supplier as well, they

had worked with us before. And they knew our

business. They understood our needs, and they knew

how to look for the right solutions.” –AO3

“We've had the benefit of very skilled

representatives from the supplier side, with a long

history with [the system] and system integration.

This is worth its weight in gold, and more.” –AO5

“I think [the relationship] is some kind of a

partnership. We are in a close cooperation daily, we

are making things together. It is not a traditional

customer-supplier…” –S6

However, it was pointed out that neither of the

partners has always been satisfied with this

relationship. AO has even considered of buying the

source code of the system from the supplier, but

according to interviewee “it did not turn out to be a

realistic option”. One interviewee comments the

WhatAretheFactorsAffectingERPSystemIntegration?-ObservationsfromaLargeManufacturingEnterprise

11

relationship:

“We have understood for a long time that we are

in a kind of a forced marriage” –A05

The customer-supplier relationship appeared to

have a major importance in ERP system integration.

Deploying the system to new facilities has been

carried out by close cooperation between AO and

supplier. However, it seems that AO is locked to the

supplier, because it may not be possible to replace

the well-established cooperation and knowledge

base built during many years of collaboration.

Supplier’s Expertise: It turned out that the

supplier has had the key role in ERP system

integration. Because of the long-term relationship,

the supplier has built many of the current systems

used facilities and has the required knowledge on

these systems when integrating systems.

Furthermore, the supplier’s knowledge on AO’s

business has proven to be a major facilitator in

cooperation.

Software Vendors: It appeared that database

vendors affected the decisions on integration

technologies in the early phases of the ERP project.

The supplier was relying on the solution of a large

database vendor as the main technology for the ERP

system. AO was also relying on the supplier’s

expertise in this matter and the project ended up in

difficulties because of a non-scalable system

architecture. Consultants from a small middleware

company were not able to convince AO to choose

their technology until later when the architectural

problems occurred.

Consultants’ Involvement: Consultants were

involved in the beginning of the system

implementation to redesign the system architecture

by replacing the original 2-tier architecture with a

middleware solution based on transaction processing

monitors. This made the system architecture more

scalable for a broader user base and enabled the

integration of business functions. Consultants’

relationship with the supplier appeared to be crucial

when redesigning the system architecture:

“Practically, they [the supplier] didn’t have a

clue of how to make it work, and when we looked at

it, it seemed that the way of implementing the system

and the use of object model was completely wrong.”

–C2

A middleware consultant also mentioned that the

cooperation with the supplier was challenging in the

beginning, but after the initial challenges, an

improved system architecture was realized.

Supply Chain (SC) Partners: Due to a need to

collaborate with the supply chain, SC partners have

been introducing external systems to be integrated

with the ERP system. It was pointed out that a

sudden need to integrate a system can occur:

”And later came – it was not originally specified

as a requirement of the system – this transportation

cost management system came there.” –AO7

Connecting the system with SC partners’ systems

was occasionally seen challenging:

“ERP has connections to various logistics

providers, since the system also handles logistical

functions. So third party companies are involved,

freight forwarders, harbor operators, warehousing

and such. But they are not giving us any sort of

definitions, the system simply has connections to

these third parties. This has sometimes been

challenging.” –S2

Standardization Partners: AO has participated

in e-business standardization efforts within the

domain in order to develop standardization with

other companies. Standardization partners appear to

be another EDN group that has an impact on ERP

system integration: – AO develops standards in

cooperation with these partners to ease the business

integration in SC.

4.3 ERP System Characteristics

At the system level, the Amount of customization

and System architecture were identified as important

factors affecting ERP system integration.

Amount of Customization: The interviewees

commented the benefits of the customized system by

highlighting the control of development, being free

of licensing costs and the advanced functionality

provided through customization:

“[The system] is a tailored system for us and the

input for development comes 100% from us” –AO4

“With SAP or another such solution, there's

always other parties driving development, you don't

have to come up with everything you need, ideas

from other sources get productized as well. That's

something we're completely missing.” –AO5

“They couldn’t have had a better system what

they got when they made a glove to a hand […] I

have never seen such advanced functionality

anywhere, you can just drag a shipping container

and drop it to a ship” –S4

However, development of an extremely

customized system introduced some of the specific

challenges, such as the performance issues due to

non-scalable system architecture. Moreover, the

benefits of a customized ERP do not come for

granted. The development is expensive and there are

no other parties driving the development as it is the

case with packaged ERP systems:

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

12

“We have a big burden in driving development.

We need to come up with everything that we want in

the system. There is no baseline of a ready-made

package.”–AO5

In the interviews, the discussion often ended up

comparing the amount of customization and

business process change in ERP development. The

interviewees generally saw that having a fully

customized system is not very common due the fact

that ERP systems are usually implemented with

packaged products, either by using a single vendor

strategy or a best-of-breed approach by combining

software packages from multiple vendors. By having

a customized ERP system, AO can have a total

control over the system and its integration

capabilities. AO is not affected, for example, by the

version updates made by the ERP flagship

organization, such as SAP. A middleware consultant

commented on updating a packaged ERP in another

organization:

“Based to all that how difficult it was to make

version updates in SAP, from the spectator’s

perspective I can only estimate that there is a hell of

a lot of home-made ABAP-code [in the system].” –

C2

Also, the supplier commented the situation, in

which additional layers for integration had to be

made whereas as in AO the integration logic could

be built directly to the system itself:

“We made for [the competitor] these integration

portions where they integrate existing ERP systems,

but because their functionality was not sufficient, we

made additional layers which had intelligence for

processing the supplied goods, it was processed into

a form that the ERP systems could handle it. At

[AO] we didn’t have to make these additional layers

because we could build the intelligence into the

actual resource planning system.” –S1

System Architecture: The system architecture

had to be flexible enough to allow the integration

with external systems. One interviewee saw that

integrating ERP with external systems has been

relatively painless:

“One benefit of the system is that is a has many

things that allows the external partners to operate in

it” –AO7

However, it also appeared that replacing certain

functionality in the system has not always been

straightforward, because of the architectural design

of the system.

“It would have been better to create the system

in such a way from the start that different aspects

had been more like separate modules. So that you

could have taken them and combined them more.” –

AO3

4.4 Domain

Domain was identified to have an indirect impact on

integration by defining the suitability of packaged

ERPs, defining the environment where AO operates,

including Business processes and Economic

situation.

Business Processes: During the time when AO

made the decisions about the system, business

process support of available ERP products in the

market was not comprehensive. This was seen as the

major driver that led to the decision to make a fully

customized ERP. The business processes were said

to be “challenging” and “difficult to change to fit

the packaged ERP”. The business processes affected

the amount of customization of the system which in

turn have been affecting ERP system integration.

Economic Situation: Economic situation was

pointed out to be another issue affecting ERP system

integration by constantly introducing changes to the

organizational structure of AO. These changes have

sometimes altered the business processes that the

ERP system must support and further caused

rearrangements to the system:

“[The system] has enabled many things that we

have been doing over the years to increase our

competitiveness and supported the organizational

changes. We have been able to rearrange the

services by fluently combining different machine

lines and production pipelines according to how we

want to arrange our business.” –AO6

Recently, AO has been constantly cutting the

development costs, which has postponed the

development of lower-priority features, such as the

mobile access to the system. A representative of the

supplier pointed out that “selling” new features, like

the mobile access to the system has been challenging

because of the cost cutting of AO.

4.5 Summary of Results

Figure 2 presents a model of factors affecting ERP

system integration. ERP system integration is a

collaborative effort of AO and EDN partners. ERP

strategy and enterprise architecture manage the ERP

system integration by determining when to integrate

the ERP system with other systems. Supporting

practices and involvement of all the relevant

stakeholders need to be present when integrating the

ERP system internally. Different integration

approaches must be created based on the

WhatAretheFactorsAffectingERPSystemIntegration?-ObservationsfromaLargeManufacturingEnterprise

13

characteristics of integrative systems. Additional

challenges can be caused by structural changes in

AO and political agendas of managers that may

introduce competitive systems to be integrated with.

Figure 2: Factors affecting ERP system integration.

Supplier is the most important EDN partner in

solving ERP system integration issues. Supplier’s

expertise and relationship to AO create a base for

successful ERP system integration. Other EDN

partners that can have impact on integration are

software vendors (that affect the decisions on

integration technologies), consultants (that can enter

the project to solve integration problems), supply

chain partners (that can suddenly introduce

additional systems to be integrated with) and

standardization partners (who are involved in

development of standards to facilitate the supply

chain collaboration).

ERP system characteristics at the system level,

including the amount of customization and system

architecture can either facilitate or hinder the

integration. It seems that by having a full control on

the system characteristics, modifying the system is

possible and integration can be less troublesome.

However, the system architecture may introduce

challenges when parts of the ERP system

functionality are replaced with other external

integrative systems.

Domain on which AO operates has indirect

impact on integration by determining the business

processes and economic situation of AO. It also

determines the standardization environment and

business environment including the business

partners to be collaborated with. The amount of

customization of the ERP system is determined by

the extent to which business processes of AO are

supported by the ERP products on the market.

5 DISCUSSION

Our findings contribute to the field of ERP and IS

integration by highlighting the socio-technical nature

of ERP system integration and especially the role of

different organizations affecting it. In our literature

review (Kähkönen and Smolander, 2013) we pointed

out that ERP system integration is often studied with

non-systematic research methods, and integration

between ERP and a specific target system is usually

considered by means of technical solutions. The role

of EDN is not often emphasized in the studies of

ERP system integration. We believe that considering

EDN becomes especially relevant when managing

the complex architecture consisting of ERP and

multitude of other systems and their integration.

Moreover, it has been suggested that methods for

enterprise systems integration have not been aligned

with the advances on integration technologies (Xu,

2011). A literature review on IS integration research

pointed out that we do not know much about

moderating factors on IS integration (Chowanetz et

al., 2012). Our study addresses this gap in this field.

Studies addressing affecting factors on ERP

implementation and studies on ERP success factors

are partly related to our findings. For instance, a

socio-technical model for ERP implementation has

been proposed (Somers et al., 2000). In this model,

ERP implementation process is affected by the

external environment and the organization itself.

This model does not discuss about EDN, which may

be explained by the early publication time of the

study. ERP success factors have been studied

comprehensively (e.g. Momoh et al., 2010; Ngai et

al., 2008). Even though critical success factors are

often organizational, they generally lack the EDN

perspective. Our findings suggest that EDN

relationships, such as customer-supplier and also

supplier-consultant relationship, have a key role

when solving integration issues during ERP

development. The relationship between the client

and the vendor has been identified as a success

factor in ERP implementation (Ngai et al., 2008).

Our study pointed out its relevance also to ERP

system integration.

Lam (2005) studied enterprise application

integration (EAI) success factors and concluded that

they are partly similar to general ERP success

factors – successful EAI needs to consider the

factors on the levels of business, organization,

technology and project. Chowanetz et al. (2012)

extended this list with environmental factors

surrounding the organization. Hoverer, neither of

these classifications is addressing the role of EDN.

Domain

Business

processes

Economic

situation

Systemcharacteristics

Amountofcustomization

Systemarchitecture

ERPdevelopmentnetwork

partners

Customer‐supplier

relationship

Supplier’sexpertise

Softwarevendors

Consultants’involvement

Supplychainpartners

Standardizationpartners

Organizationallandscape

ERPstrategy

Enterprisearchitecture

Supportingpractices

Integrativesystems’

characteristics

Structuralchange

Politicalagendas

ERPsystem

integration

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

14

Besides the role of supplier, our evidence suggests

the important roles of consultants and business

partners in ERP system integration.

As the integration requirements of ERPs have

increased and ERP has been extended towards SCM,

the relationship between ERP and e-business have

been increasingly studied. Thus, factors affecting e-

business adoption can be partly related to our

findings. For instance, there is quantitative evidence

on organizational factors, such as company’s scope

and skills affecting e-business adoption from the

adopting organization point-of-view (Nurmilaakso,

2008). Smolander and Rossi (2008) observed that

political and organizational forces affect the

development process of cross-organizational e-

business initiatives. Xue et al. (2005) and Chen

(2003) discuss the affecting factors on e-business

standardization and identified stakeholders, such as

IT product vendors and systems integrators, and also

organizational factors, including company size,

industry type and IT-infrastructure as factors

affecting the adoption of e-business standards. Our

study highlighted the relationship between ERP and

e-business and is aligned with these findings, but we

see standardization as one (but just one!) important

part of ERP system integration.

5.1 Future Research

By identifying the factors affecting ERP system

integration, our study creates a baseline for future

research on strategies and approaches to effectively

solve the integration issues in different EDNs.

Because they are not widely studied, EDNs need to

be investigated further, especially from the

integration point-of-view. A comparison between

the EDNs of packaged and customized ERPs and

their integration strategies could be an interesting

topic to study further. The EDN of a company

utilizing a packaged ERP is most likely very

different due to a number of external consultants and

the presence of a flagship ERP company, such as

SAP. Moreover, it would be interesting to

investigate how the amount of customization affects

integration. Quantitative studies are also needed to

investigate the factors affecting ERP system

integration in a larger scope.

5.2 Limitations of the Study

This study has some limitations. As in all qualitative

studies, the findings of this study cannot be easily

generalized. The findings are related only to the

specific case and all generalizations are theoretical

(Lee and Baskerville, 2003), i.e. they generalize

specific observations to theoretical concepts. With

these concepts we can explain the events in the

studied organization and we also strongly believe

that these affecting factors on ERP system

integration are similar in other contexts as well.

Understanding the factors can help managers to pay

more attention to integration and interoperability of

ERP systems and evaluate the flexibility of ERP

packages and to further develop approaches to solve

integration issues in ERP projects.

6 CONCLUSIONS

We have proposed an empirically grounded model

of factors that had an effect on ERP system

integration in a large manufacturing enterprise. We

found four classes of factors affecting ERP system

integration: Domain, Organizational landscape,

ERP development network partners, and ERP system

characteristics.

The Domain has an indirect impact on

integration through economic situation and business

processes by affecting all the other classes of factors.

In the Organizational landscape, ERP strategy and

enterprise architecture have a role in managing the

integration of the ERP system with other systems.

Structural changes can introduce political agendas

within the organization by making the ERP system

integration more challenging. ERP system

characteristics can determine the ease of technical

integration. With a fully customized ERP system,

the company has a total control over the interfaces of

the system, which seems to make the integration less

painful, bypassing some general integration

challenges of packaged ERPs.

What has not been discussed earlier in detail is

that ERP system integration is affected by many

stakeholders including software vendors and

suppliers, consultants, supply chain partners and

standardization organizations – ERP development

network partners. We found that the relationships in

the ERP development network can be tightly

coupled and this can have a significant effect on

ERP system integration. In order to be realized, ERP

system integration demands cooperative practices. A

long term customer-supplier relationship and

supplier’s expertise as well as collaboration between

supplier and consultants turned out to be key

enablers of integration.

The developed model of factors affecting ERP

system integration reflects the nature of ERP

development as socio-technical endeavour. The

WhatAretheFactorsAffectingERPSystemIntegration?-ObservationsfromaLargeManufacturingEnterprise

15

current literature often ignores the role of the EDN

by focusing on the adopting organization only. This

study established a base for further research on ERP

system integration to investigate strategies and

approaches to effectively solve the integration issues

in different EDNs.

ACKNOWLEDGEMENTS

This study was funded by Academy of Finland grant

#259454.

REFERENCES

Barki, H., Pinsonneault, A., 2005. A Model of

Organizational Integration, Implementation Effort, and

Performance. Organization Science 16, 165–179.

Beheshti, H.M., 2006. What managers should know about

ERP/ERP II. Management Research News 29, 184–

193.

Charmaz, K., 2006. Constructing grounded theory. Sage

Publications, London ; Thousand Oaks, Calif.

Chen, M., 2003. Factors affecting the adoption and

diffusion of XML and Web services standards for E-

business systems. International Journal of Human-

Computer Studies 58, 259–279.

Chowanetz, M., Legner, C., Thiesse, F., 2012. Integration:

An Omitted Variable in Information Systems

Research, in: ECIS 2012 Proceedings. Presented at the

European Conference on Information Systems (ECIS).

Corbin, J., Strauss, A., 1990. Grounded Theory Research:

Procedures, Canons, and Evaluative Criteria.

Qualitative Sociology 13, 3–21.

Doedt, M., Steffen, B., 2011. Requirement-Driven

Evaluation of Remote ERP-System Solutions: A

Service-oriented Perspective. IEEE, pp. 57–66.

Gulledge, T., 2006. What is integration? Industrial

Management & Data Systems 106, 5–20.

Hsu, P.-F., 2013. Integrating ERP and e-business:

Resource complementarity in business value creation.

Decision Support Systems 56, 334–347.

Hvolby, H.-H., Trienekens, J.H., 2010. Challenges in

business systems integration. Computers in Industry

61, 808–812.

IDG Consumer & SMB, 2013. 10 Biggest ERP Software

Failures of 2011 | PCWorld [WWW Document]. URL

http://www.pcworld.com/article/246647/10_biggest_e

rp_software_failures_of_2011.html (accessed

3.21.13).

J. de Albuquerque, E. Simon, 2007. Dealing with Socio-

Technical Complexity:Torwads a Trandisciplinary

Approach to IS Research, in: Proceedings of the

European Conference on Information Systems (ECIS).

pp. 1458–1468.

Kähkönen, T., Smolander, K., 2013. ERP integration - A

Systematic Mapping Study. Presented at the 15th

International Conference on Enterprise Information

Systems (ICEIS 2013).

Lam, W., 2005. Investigating success factors in enterprise

application integration: a case-driven analysis.

European Journal of Information Systems 14, 175–

187.

Law, C.C.H., Chen, C.C., Wu, B.J.P., 2010. Managing the

full ERP life-cycle: Considerations of maintenance

and support requirements and IT governance practice

as integral elements of the formula for successful ERP

adoption. Computers in Industry 61, 297–308.

Lee, A.S., Baskerville, R.L., 2003. Generalizing

Generalizability in Information Systems Research.

Information Systems Research 14, 221–243.

Lehmann, H., Gallupe, B., 2005. Information systems for

multinational enterprises-some factors at work in their

design and implementation. Journal of International

Management 11, 163–186.

Liang, H., Xue, Y., 2004. Coping with ERP-related

contextual issues in SMEs: a vendor’s perspective.

The Journal of Strategic Information Systems 13, 399–

415.

Linthicum, D.S., 2004. Next generation application

integration: from simple information to Web services,

Addison-Wesley information technology series.

Addison-Wesley, Boston.

Metrejean, E., Stocks, M.H., 2011. The Role of

Consultants in the Implementation of Enterprise

Resource Planning Systems. Academy of Information

and Management Sciences Journal 14, 1–25.

Møller, C., 2005. ERP II: a conceptual framework for

next-generation enterprise systems? Journal of

Enterprise Information Management 18, 483–497.

Momoh, A., Roy, R., Shehab, E., 2010. Challenges in

enterprise resource planning implementation: state-of-

the-art. Business Process Management Journal 16,

537–565.

Ngai, E.W.T., Law, C.C.H., Wat, F.K.T., 2008.

Examining the critical success factors in the adoption

of enterprise resource planning. Computers in Industry

59, 548–564.

Nurmilaakso, J.-M., 2008. Adoption of e-business

functions and migration from EDI-based to XML-

based e-business frameworks in supply chain

integration. International Journal of Production

Economics 113, 721–733.

Sammon, D., Adam, F., 2002. Decision Making in the

ERP Community, in: ECIS 2002 Proceedings.

Seaman, C.B., 1999. Qualitative methods in empirical

studies of software engineering. IEEE Transactions on

Software Engineering 25, 557–572.

Shafiei, F., Sundaram, D., Piramuthu, S., 2012. Multi-

enterprise collaborative decision support system.

Expert Systems with Applications 39, 7637–7651.

Shehab, E.M., Sharp, M.W., Supramaniam, L., Spedding,

T.A., 2004. Enterprise resource planning: An

integrative review. Business Process Management

Journal 10, 359–386.

Skok, W., Legge, M., 2002. Evaluating enterprise resource

planning (ERP) systems using an interpretive

ICEIS2014-16thInternationalConferenceonEnterpriseInformationSystems

16

approach. Knowledge and Process Management 9, 72–

82.

Smolander, K., Rossi, M., 2008. Conflicts, Compromises

and Political Decisions: Methodological Challenges of

Enterprise-Wide E-Business Architecture. Journal of

Database Management 19, 19–40.

Somers, T., Nelson, K., Ragowsky, A., 2000. Enterprise

Resource Planning (ERP) for the Next Millennium:

Development of an Integrative Framework and

Implications for Research, in: AMCIS Proceedings

2000. Presented at the Americas Conference on

Information Systems.

Somers, T.M., Nelson, K.G., 2004. A taxonomy of players

and activities across the ERP project life cycle.

Information & Management 41, 257–278.

Strauss, A., Corbin, J., 2008. Basics of Qualitative

Research: Techniques and Procedures for Developing

Grounded Theory, 3rd ed. SAGE Publications.

Tao, Y.-H., Hong, T.-P., Sun, S.-I., 2004. An XML

implementation process model for enterprise

applications. Computers in Industry 55, 181–196.

Urquhart, C., Lehmann, H., Myers, M.D., 2010. Putting

the “Theory” Back into Grounded Theory: Guidelines

for Grounded Theory Studies in Information Systems.

Information Systems Journal 20, 357–381.

Watts, C.A., Mabert, V.A., Hartman, N., 2008. Supply

chain bolt-ons: investment and usage by

manufacturers. International Journal of Operations &

Production Management 28, 1219–1243.

Welker, G.A., van der Vaart, T., Pieter van Donk, D.,

2008. The influence of business conditions on supply

chain information-sharing mechanisms: A study

among supply chain links of SMEs. International

Journal of Production Economics 113, 706–720.

Xu, L.D., 2011. Enterprise Systems: State-of-the-Art and

Future Trends. IEEE Transactions on Industrial

Informatics 7, 630–640.

Xue, Y., Liang, H., Boulton, W.R., Snyder, C.A., 2005.

ERP implementation failures in China: Case studies

with implications for ERP vendors. International

Journal of Production Economics 97, 279–295.

WhatAretheFactorsAffectingERPSystemIntegration?-ObservationsfromaLargeManufacturingEnterprise

17