Differential Evolution for Multiobjective Optimization of Process

Design Problems

Antonio Ochoa-Robles, Catherine Azzaro-Pantel and Serge Domenech

Université de Toulouse, Laboratoire de Génie Chimique, INP-ENSIACET,

4 Allée Emile Monso, 31432 Toulouse cedex 4, BP 84234, France

Keywords: Differential Evolution, Stopping Criterion, Evaluations, Structural Problems.

Abstract: Optimization is a highly important area in chemical engineering, particularly for process design that is

generally formulated as a mixed and non-linear problem with several competing objectives. A way to tackle

the problem is to couple multiobjective optimization based on evolutionary algorithms with a process

simulator. This situation may yet lead to prohibitive computational time as the number of objectives

increases. In this paper, the potential of multiobjective differential evolution (MODE) is tested with three

different stopping criteria. The performance of MODE is compared with the results obtained with a variant

of NSGA II. The performance metric is based on the number of evaluations used to get the Pareto front. The

results show that the combination of an efficient algorithm and the stopping criterion helps to reduce the

optimization time but its choice may affect the results. As far as multiobjective is concerned, it must be

emphasized that the final solution is the result of compromise that the decision maker must be aware.

1 INTRODUCTION

Process design is a key activity in the chemical

engineering field for implementing new

technologies, creating new facilities, or retrofitting

existing processes. If the traditional design approach

incorporates economic objectives, process systems

design has come to include more performance

measures, such as environment, safety,

controllability, and flexibility. This kind of problems

can be generally modelled as mixed integer

nonlinear programming (MINLP) formulations,

involving continuous and integer variables. This

class of mathematical problems generally involves

non-convexities, which are related to the problem

formulation concerning both the objective

function(s) and/or the set of constraints. The

inherent combinatorial nature of the problem

contributes to its complexity. In that context,

evolutionary algorithms (EAs) have received a lot of

attention for solving nonlinear multimodal problems

(Angira and Babu, 2006). They are also particularly

attractive to capture the multiobjective nature of the

criteria. Among the methods that have reported in

the dedicated literature, multiobjective optimization

(MOO) (Rangaiah, 2009) and particularly

evolutionary algorithms constitute a promising

approach to tackle the problem.

The early design stage implies the evaluation of

the various alternatives that can be used to produce a

chemical product involving several reaction routes

with various types of equipment and their

corresponding operating conditions. The importance

of early design activities has been addressed in

several recent studies. The problem is generally

solved by use of a process simulator for flowsheet

generation such Aspen (“Aspen One® -

AspenTech,” 2013), Hysis (“Aspen HYSYS® -

AspenTech,” 2013), Prosim (“PROSIM,” 2013).

If the computational time required for simulation

is quite acceptable (from several seconds to several

minutes for large size problems), the situation may

be quite different when performing optimization

where the various objectives must be evaluated

many times by successive use of the process

simulator. It must be emphasized that multiobjective

optimization does not lead to a single ideal solution

but to a set of compromise solutions (Jones et al.,

2002) that are generally represented through a Pareto

front as far as the objective functions are considered.

Problems such as the optimization of the process

of hydrodealkylation (HDA) of toluene, to produce

benzene were investigated previously (Ouattara et

226

Ochoa-Robles A., Azzaro-Pantel C. and Domenech S..

Differential Evolution for Multiobjective Optimization of Process Design Problems.

DOI: 10.5220/0004833102260232

In Proceedings of the 3rd International Conference on Operations Research and Enterprise Systems (ICORES-2014), pages 226-232

ISBN: 978-989-758-017-8

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

al., 2012) involving various objective functions

based on economic and ecological criteria evaluated

by coupling two simulators for chemical process and

utility requirement. Every evaluation involves a call

to the support software tools that makes the

optimization task quite long. Another example is the

selection of the synthesis strategy for a chemical

plant described by Grossmann (Papoulias and

Grossmann, 1983). The superstructure considers the

chemical and utility plant as the heat recovery

network. The objectives are to determine the

configuration of the plant, the heat exchanger

network and utility system that allows maximizing

the annual profit. Other examples can be mentioned

such as the supply chain management problem

presented in (Kallrath, 2000) as a multi-site, multi-

product, multi-period production/distribution

network planning system with the objective of

finding the best production schedule satisfying a

given demand.

Among multiobjective evolutionary approaches,

Genetic Algorithms (GAs) constitute a quite popular

method used in engineering field, particularly in the

chemical engineering community (Abbass et al.,

2001). One of the most efficient genetic algorithms

is NSGA II Non-dominated Sorting Genetic

Algorithm (Deb et al., 2002) an upgrade version of

NSGA which estimates the density of solutions

surrounding a particular one, in order to perform a

scanning of the solution space.

The design optimization time obviously depends

on the number of the successive evaluations of the

possible solutions by use of the process simulator.

In that context, the formulation of an effective

criterion is necessary in the case of the

multiobjective optimization problem as judging the

advance of the optimization. If the selection of an

appropriate criterion has been identified as one of

the fundamental topics, it must be highlighted that

this issue has not been solved properly.

The objective of this work is twofold: first, the

potential of Differential Evolution (DE) is

investigated since DE has been successful in the

solution of a variety of continuous single-objective

optimization problems in which it has shown great

robustness and a very fast convergence. Recently,

there have been successful proposals to extend DE

to MOO (Robič and Filipič, 2005). A multi-

objective differential evolution algorithm was thus

implemented. The second objective is to evaluate

different stopping criteria for reducing the number of

evaluations. For this purpose, some benchmark

problems and a chemical engineering problem are

tested.

This paper is divided into 5 sections. Section 2 is

devoted to main concepts of differential evolution.

Section 3 describes the solution strategy. Section 4

discusses the results obtained with test problems.

Section 5 concerns the application to a small-size

structural problem for process design. Finally,

conclusions and perspectives are proposed.

2 DIFFERENTIAL EVOLUTION

(DE)

Differential Evolution (DE) is an evolutionary

algorithm proposed by Price (Price, 1996) using

vectors to perturb the best solution found so far

together with mutation and crossover. It needs three

parameters, i.e., population size , scaling constant

and crossover constant .

The details on DE algorithm, various strategies

of DE and wide range of applications in various

engineering areas are well documented in literature

(Angira and Babu, 2006)(Onwubolu and Babu,

2004). Only the principles are presented here for the

sake of brevity.

The procedure is rather simple. The first step is

to initialize the population for every variable in

the dimension and evaluate the fitness of each

individual within the boundary constraints (upper

and lower bounds and L, respectively), such as:

0,1

,

1,…,;

1,…,

(1)

Each iteration consists in 4 steps. First, three

individuals of the population are randomly selected

(

,

,

); they must be mutually different and also

different of the current vector . Secondly, a trial

vector is created according to equation (2), where

0,1

is a randomly generated number and

is a randomly selected variable.

,

,

,

0,1

⋁

(2)

Step 3 checks the boundary constraints; if a value is

out of the boundary zone, it is calculated again

according to:

∉

,

0,1

.

(3)

Finally, if the trial vector is inferior or equal to the

current one, the trial individual replaces the current

individual.

Some guidelines for the use of DE are proposed

in (Storn, 1996):

At initialization step, the population should be

DifferentialEvolutionforMultiobjectiveOptimizationofProcessDesignProblems

227

spread as much as possible over the objective

function surface.

Most often, the crossover probability CR

(∈

0,1

must be considerably lower than 1. If

no convergence can be achieved, a value of CR

within

0.8,1

is yet recommended

For many applications, a size of the population

corresponding to 10 times the size of the problem

(10) is a good choice. F is usually

chosen within the interval

0.5,1

.

Some differences between DE and GA (Abbass et

al., 2001) can be highlighted:

In GAs, crossover is carried out between two

parents and the child is a recombination of both

of them, while in DE, three parents are selected

and the child is only the perturbation of one of

them.

The new child only replaces a randomly selected

vector of the population when it is better. In GA,

the children replace the parents with some

probability regardless of their fitness.

2.1 Stopping Criterion

As mentioned in the motivation of this work, the

stopping criterion is of major importance to

guarantee that the solution (or the set of solutions)

obtained so far is of acceptable quality regarding the

numerical effort. Various scenarios can be used

among others (Martí et al., 2007):

the solution yielded so far is satisfactory;

the method is able to produce a solution : it is yet

not satisfactory but a better one will not be

produced;

the method is unable to “converge” to any

solution;

there is no progress in the search of a new

solution.

3 SOLUTION STRATEGY

3.1 Principles

The algorithm used is the one suggested by Price

(Price, 1996) that was adapted for considering mixed

variables and a multiobjective formulation. By lack

of place, a major attention is only paid to the

stopping criterion in what follows.

The binary variables are taken into account using

the strategy of Angira (Angira and Babu, 2006), that

means that the variable is handled as a continuous

one, within the interval (Feoktistov, 2006) with a

rounded value (Feoktistov, 2006). Every variable

that is modified during the optimization process

must be within its definition domain; otherwise, it is

initialized again.

The violation of constraints is calculated and

used in the adaptation comparison procedure

according to Deb’s criterion, that means that a vector

A dominates B if one of the next conditions is

achieved (Deb et al., 2002):

A is feasible and B not;

A and B are not feasible but the violation of the

constraints is lower in A than in B;

A and B are feasible but A dominates B.

3.2 MGMB

The MGMB criterion (from the initials of the

authors (Martí et al., 2007)) is based on the

comparison of the set of non-dominated solutions of

two iterations. A progress indicator (

) is to be

calculated indicating or not an evolution of the

population. For example, a value of

equal to 1

means that the last population is better than the

previous one. A value of

equal to 0, means that

there is no progress and a value of

equal to -1 is

the sign of deterioration of the population. A

correction step

is considered to take into account

the influence of the changes.

3.3 Consolidation Ratio (CoR)

This is a convergence metric that can be used as a

stopping criterion. The consolidation ratio is the

fraction of the population at the generation ∆

(∆represents a kind of observation step) that has

evolved up to the current generation .

This is calculated as the ratio of the number of

non-dominated individuals () in the generation

∆ present in the generation and the non-

dominated of the last generation (), expressed as:

∆

(4)

In the early stages of the algorithm, a large fraction

of non-dominated will not remain in the last

population that will result in a low value for CoR,

while the quantity of non-dominated individuals

after several generations that will remain in the

population will be higher, leading to a CoR ratio

close to 1 (no changes of non-dominated vectors).

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

228

3.4 Improvement Ratio (IR)

This ratio represents the proportion of the population

∆ dominated by the population of size

, as

expressed by:

∆

(5)

The initial value of this ratio is equal to unity, which

means that every solution is dominated by the latest

population, while when convergence is achieved this

value is equal to zero.

3.5 Final Selection with TOPSIS

The final selection process is made using a

multicriteria decision-making process that takes into

account the optimal alternatives found in the Pareto

front. These alternatives are found to be non-

dominated solutions near optimal value, and

although the decision maker may use judgment to

make the final selection from the alternatives, a

formal method based on TOPSIS (Technique for

Order of Preference by Similarity to Ideal Solution)

was adopted (Lai et al., 1994); (Ren et al., 2010).

This method is based on the idea of choosing the

best alternative solution from a set by analyzing the

shortest geometric distance from the positive ideal

solution and the longest distance from the negative

ideal solution. It also requires weights to be assigned

per criterion and normalizes the information, so that

the various alternatives are ranked. Although other

ranking and classification methods exist, TOPSIS

has proven its efficiency in the final alternative

selection process obtained through GA (Gomez et

al., 2010) and is used here after MODE process. The

same weight was allocated to each criterion in the

experimental study. The approach for each stopping

criterion will be tested based on the solution that

obtained the top rank by TOPSIS.

4 VALIDATION

The test problems selected to evaluate the

performance of the algorithm are the classical SRN

and TNK problems used in previous works (Deb et

al., 2002). The formulation of the two problems is

presented in Table 2 as well as the Pareto fronts of

SRN and TNK. First, to validate the algorithm, the

classical DE algorithm was used without any

specific stopping criterion (the algorithm stops when

the maximum number of generation is reached) and

the results were compared with the solutions

obtained by previous researchers with other

algorithms. The parameters used were CR=0.6,

F=0.8, NP=200 and 100 generations They can be

visualized in Fig. 1 and 2 and are in agreement with

the results obtained with deterministic methods.

Then, the three stopping criteria are considered

for DE i.e., the so-called MGMB (Martí et al.,

2007), consolidation ratio (Goel and Stander, 2010)

and improvement ratio (Goel and Stander, 2010) in

combination with the maximum number of

generations.

The DE procedure is compared with a variant of

NSGA II developed for mixed problems and

implemented in the Multigen environment (Gomez

et al., 2010). The stopping criterion proposed in

Multigen (in addition to the maximum number of

generations) consists in comparing the Pareto fronts

associated with non-dominated solutions for

populations and , where the period ∈

10,20,30,40,50 for example. If the union of the

two fronts provides a single non dominated front, the

procedure stops; else the iterations continue.

Table 1: Problem formulation for the test functions.

SRN TKN

2

1

2

9

1

225

3

10

∈

20,20

1

0.1cos

16tan

⁄

0

0.5

0.5

0.5

∈

0,

Figure 1: Pareto front of

the test problem SRN.

Figure 2: Pareto front of

the test problem TNK.

Three scenarios for DE and one for NSGA-II are

tested as shown in Table 2. The period represents the

time of observation and application of the stopping

criterion. Every problem is analyzed relative to the

number of evaluations performed for each stopping

criterion and procedure. The solutions obtained after

TOPSIS application are also analyzed which can be

viewed as another validation. The solutions concern

DifferentialEvolutionforMultiobjectiveOptimizationofProcessDesignProblems

229

both the values of the objective functions and the

associated variables.

Table 2: Scenarios for DE and NSGA-II.

DE

Test 1

DE

Test 2

DE

Test 3

NSGA II

Individuals 100 100 100 100

Maximum number

of generations

200 200 200 200

CR 1 0.6 0.4 0.9

F 0.8 0.8 0.8

0.5

(mutation)

Period 10 10 5 -

By lack of place, the Pareto front obtained for

each problem is not presented here. All the fronts

exhibit similar behaviors as previously seen in Fig. 1

and 2. It must be said that the curves are overlaid in

the domain with common intersection each other.

For SRN problem(see Table 1), the solutions

obtained by DE-TOPSIS exhibit a similar behavior

both for criteria and variables. The order of

magnitude of criteria and variables is quite different

with NSGA-II. It must be emphasized that for

NSGA II, the algorithm ends because the maximum

number of generations is reached. Regarding the

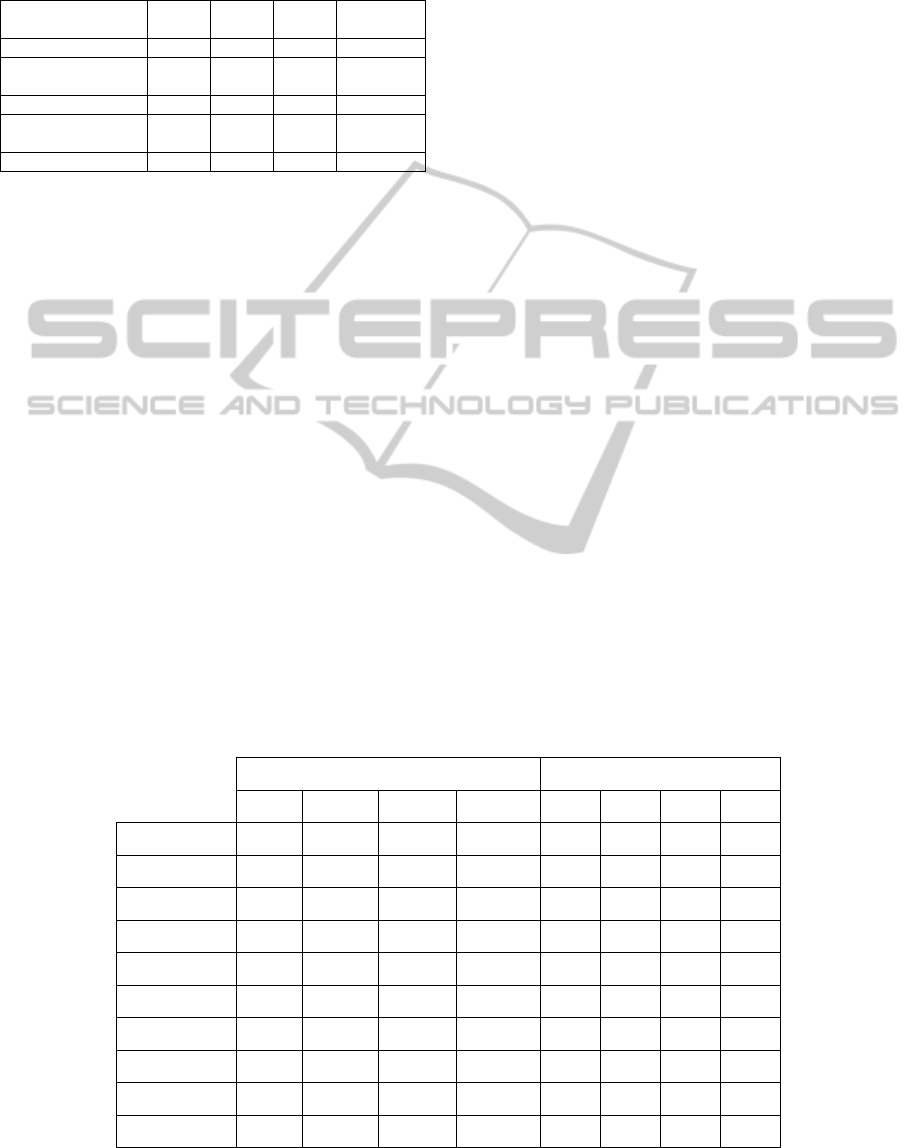

objective functions, the stopping criteria IR and CoR

require yet a higher number of evaluations (Figure

3) than MGMB.

For TNK problem (see Table 1), the order of

magnitude of the objective functions is quite similar,

in fact all the selected solutions are non-dominated

between them. Considering the number of

evaluations, it is interesting to see that the MGMB

requires around 9 times lower evaluations than the

other criteria, which can be of practical importance

in solving real problems (Figure 4). Considering the

homogeneity of the selected solutions obtained after

DE-TOPSIS, IR shows almost no difference, while

CoR and MGMB have a larger deviation. This can

be attributed to scattered points in the Pareto front

obtained for each test, thus giving different ranking

after application of TOPSIS method.

5 APPLICATION TO A

STRUCTURAL DESIGN

PROBLEM

This problem is a bicriteria one proposed by

Papalexandri and Dimkou (Papalexandri and

Dimkou, 1998). It consists of 3 continuous variables,

3 binary variables and two objective functions. The

formulation can be expressed as follows:

,

3

2

(6)

,

2

3

2

2

(7)

,

3

2

0

(8)

,

4

2

40

7

0

(9)

,

2

3

7

0

(10)

,

1012

0

(11)

,

102

0

(12)

Table 3: Selected solutions for SRN and TNK problem using DE-TOPSIS.

SRN TNK

NSGA-II

0,0282 18,4389 310,003 -303,861 0,043 1,039 0,043 1,039

IR Test 1

-2,418 -11,666 181,939 -182,183 1,029 0,063 1,029 0,063

IR Test 2

-2,539 -12,499 204,821 -205,07 1,006 0,088 1,006 0,088

IR Test 3

-2,924 14,1161 198,274 -198,344 1,022 0,072 1,022 0,072

CoR Test 1

-2,288 -8,6635 113,773 -113,978 1,006 0,088 1,006 0,088

CoR Test 2

-2,165 -12,371 198,117 -198,254 0,957 0,138 0,957 0,138

CoR Test 3

-2,351 -12,292 197,614 -197,842 0,089 1,004 0,089 1,004

MGMB Test 1

-2,066 13,1749 166,762 -166,824 0,108 1,011 0,108 1,011

MGMB Test 2

-2,287 14,1367 192,948 -193,152 0,068 1,026 0,068 1,026

MGMB Test 3

-3,176 -12,307 205,862 -205,656 0,066 1,042 0,066 1,042

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

230

Figure 3: Number of

evaluations for SRN

problem.

Figure 4: Number of

evaluations for TNK

problem.

,

20

0

(13)

,

40

0

(14)

,

17

0

(15)

,

25

0

(16)

∈

100,100

(17)

∈

0,1

(18)

For the three stopping criteria, the previous

conditions were applied (see Table 2). A similar

analysis as the one previously adopted for SRN and

TNK is carried out.

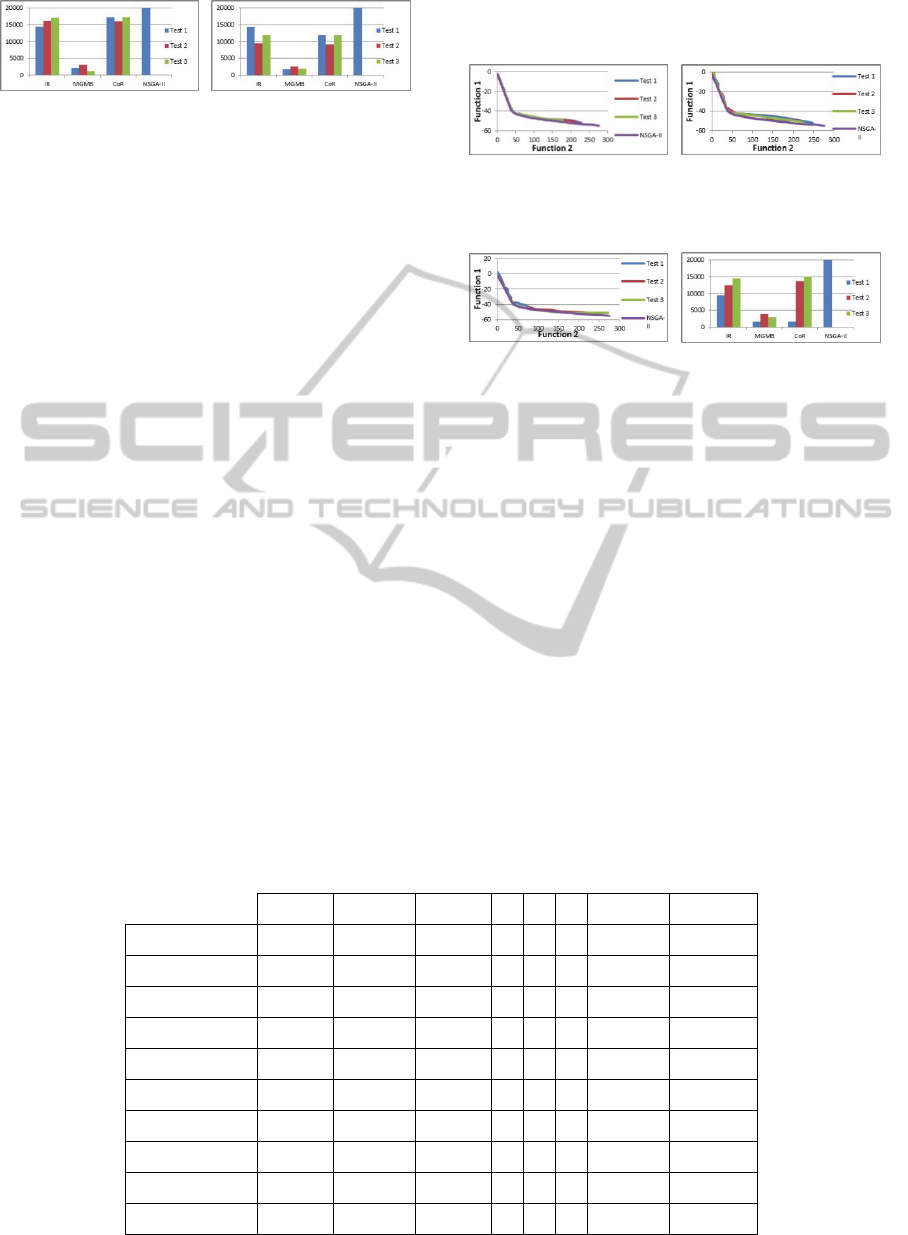

For the Improvement Ratio (Fig. 13) all the runs

exhibit similar results and the slight discrepancy that

is observed can be attributed to the different choice

in parameter settings.

For the MGMB criterion (Fig. 14) the behavior is

quite similar for all tests, the best performance being

obtained by test 3.

For the Consolidation Ratio (Fig. 15) the

performance of the three tests is quite similar,

meaning that this criterion leads to quasi-identical

results whatever the intrinsic parameters of the

procedure.

Regarding the number of evaluations of the

objective functions (Fig. 16), the stopping criterion

MGMB leads to the best performance once more. A

slight difference is observed between IR and CoR,

with a lower number of evaluations than NSGA-II.

Figure 5: Pareto front

with Improvement Ratio

as stopping criterion.

Figure 6: Pareto front

with MGMB as stopping

criterion.

Figure 7: Front de Pareto

using Consolidation Ratio

as stopping criterion.

Figure 8: Number of

evaluations for every

stopping criterion.

Table 4) shows that significant differences in

solutions are observed. For IR, CoR and MGMB

Test 1 and 2, the results for function f_1 are better

that those proposed by NSGA-II. Such a situation

never occurs for f_2 since they are out-performed by

the NSGA-II. Test 2 provides consistent results for

all criteria, so the configuration CR=0.6 and F=0.8,

with a period of 10 generations seems the more

appropriate for this problem. As far as the number of

evaluations is concerned, MGMB is more

performing. Yet, if the evaluation functions lead to

similar performances, the corresponding set of

TOPSIS analysis variables is not the same. The final

choice of the decision maker may also consider the

difficulty of implementation of a solution over

another one as an effective lever.

Table 4: Selected solutions for SRN and TNK problem using DE-TOPSIS for the small-design problem.

NSGA-II

0,0919 39,9759 -1,7991 0 0 0 42,9538 -41,7666

IR Test 1

0,1980 36,4077 -0,6076 0 0 1 34,2613 -35,9761

IR Test 2

0,1969 37,6330 -0,0376 0 0 1 35,1213 -36,6318

IR Test 3

0,4251 35,4294 -0,9154 0 0 0 35,3535 -36,1641

CoR Test 1

-0,0011 40,1225 -1,2869 0 0 1 39,7819 -40,4093

CoR Test 2

0,1405 36,7248 -0,3565 0 0 1 34,4699 -36,0615

CoR Test 3

0,2955 36,8305 -0,4736 0 0 1 34,3429 -36,2167

MGMB Test 1

0,2727 39,4125 -1,3556 0 0 1 38,5809 -39,6938

MGMB Test 2

0,9297 35,2025 -2,7510 0 0 0 35,3495 -36,0356

MGMB Test 3

-0,4732 10,8265 -0,8724 0 0 1 49,3434 -41,3825

DifferentialEvolutionforMultiobjectiveOptimizationofProcessDesignProblems

231

6 CONCLUSIONS AND

PERSPECTIVES

A differential evolution algorithm with several

stopping criteria was developed. Its performance

was compared with the results obtained by a variant

of NSGA II implemented in previous works. Results

show that, every proposed stopping criterion

obtained similar results as done by NSGA-II. But,

the use of the MGMB criterion implies a lower

number of evaluations as compared with IR and

CoR. Nevertheless, no stopping criterion is the

panacea. Its choice must be a compromise between

the required gain and the computational effort. This

study will now be applied to a large size chemical

engineering design problem which involves the

evaluation of every proposed solution with a

simulator. Even if MGMB appears to be a good

candidate, its robustness must be now investigated

as far as multiple variable-mapping is concerned.

REFERENCES

Abbass, H. A., Sarker, R., Newton, C., 2001. PDE: A

pareto-frontier differential evolution approach for

multi-objective optimization problems, in:

Evolutionary Computation, 2001. Proceedings of the

2001 Congress On. pp. 971–978.

Angira, R., Babu, B. V., 2006. Optimization of process

synthesis and design problems: A modified differential

evolution approach. Chem. Eng. Sci. 61, 4707–4721.

Aspen HYSYS® - AspenTech [WWW Document], 2013.

URL http://www.aspentech.com/hysys/ (accessed

6.11.13).

Aspen One® - AspenTech [WWW Document], 2013.

URL http://www.aspentech.com/products/v8-release/

(accessed 6.11.13).

Deb, K., Pratap, A., Agarwal, S., Meyarivan, T., 2002. A

fast and elitist multiobjective genetic algorithm:

NSGA-II. Evol. Comput. IEEE Trans. 6, 182–197.

Feoktistov, V., 2006. Differential evolution: in search of

solutions. Springer.

Gen, M., Cheng, R., Gen, M., Cheng, R., 1999. Genetic

Algorithms and Engineering Optimization. John Wiley

& Sons, Inc., Hoboken, NJ, USA.

Goel, T., Stander, N., 2010. A non-dominance-based

online stopping criterion for multi-objective

evolutionary algorithms. Int. J. Numer. Methods Eng.

84, 661–684.

Gomez, A., Pibouleau, L., Azzaro-Pantel, C., Domenech,

S., Latgé, C., Haubensack, D., 2010. Multiobjective

genetic algorithm strategies for electricity production

from generation IV nuclear technology. Energy

Convers. Manag. 51, 859–871.

Jones, D. F., Mirrazavi, S. K., Tamiz, M., 2002. Multi-

objective meta-heuristics: An overview of the current

state-of-the-art. Eur. J. Oper. Res. 137, 1–9.

Kallrath, J., 2000. Mixed integer optimization in the

chemical process industry: Experience, potential and

future perspectives. Chem. Eng. Res. Des. 78, 809–

822.

Lai, Y.-J., Liu, T.-Y., Hwang, C.-L., 1994. TOPSIS for

MODM. Eur. J. Oper. Res. 76, 486–500.

Martí, L., García, J., Berlanga, A., Molina, J. M., 2007. A

cumulative evidential stopping criterion for

multiobjective optimization evolutionary algorithms,

in: Proceedings of the 2007 GECCO Conference

Companion on Genetic and Evolutionary

Computation. pp. 2835–2842.

Onwubolu, G. C., Babu, B. V., 2004. New optimization

techniques in engineering. Springer.

Ouattara, A., Pibouleau, L., Azzaro-Pantel, C., Domenech,

S., Baudet, P., Yao, B., 2012. Economic and

environmental strategies for process design. Comput.

Chem. Eng. 36, 174–188.

Papalexandri, K. P., Dimkou, T. I., 1998. A Parametric

Mixed-Integer Optimization Algorithm for

Multiobjective Engineering Problems Involving

Discrete Decisions. Ind. Eng. Chem. Res. 37, 1866–

1882.

Papoulias, S. A., Grossmann, I. E., 1983. A structural

optimization approach in process synthesis—III: total

processing systems.

Comput. Chem. Eng. 7, 723–734.

Price, K. V., 1996. Differential evolution: a fast and

simple numerical optimizer, in: Fuzzy Information

Processing Society, 1996. NAFIPS. 1996 Biennial

Conference of the North American. pp. 524–527.

PROSIM [WWW Document], 2013. URL

http://www.prosim.net/fr/index.php (accessed

6.11.13).

Rangaiah, G. P., 2009. Multi-Objective Optimization:

Techniques and Applications in Chemical

Engineering. World Scientific.

Ren, L., Zhang, Y., Wang, Y., Sun, Z., 2010. Comparative

Analysis of a Novel M-TOPSIS Method and TOPSIS.

Appl. Math. Res. EXpress.

Robič, T., Filipič, B., 2005. DEMO: Differential evolution

for multiobjective optimization, in: Evolutionary

Multi-Criterion Optimization. Springer, pp. 520–533.

Storn, R., 1996. On the usage of differential evolution for

function optimization, in: Fuzzy Information

Processing Society, 1996. NAFIPS. 1996 Biennial

Conference of the North American. pp. 519–523.

ICORES2014-InternationalConferenceonOperationsResearchandEnterpriseSystems

232