Transformer Working Condition Assessment using Laser Raman

Spectroscopy

Toshihiro Somekawa

1

, Makoto Kasaoka

2

, Fumio Kawachi

2

,

Yoshitomo Nagano

2

, Masayuki Fujita

1,3

and Yasukazu Izawa

1,3

1

Institute for Laser Technology, 2-6 Yamadaoka, Suita, Osaka 565-0871, Japan

2

Kanden Engineering Corporation, 3-1-176 Fukuzaki, Minato-ku, Osaka 552-0013, Japan

3

Institute of Laser Engineering, Osaka University, 2-6 Yamadaoka, Suita, Osaka 565-0871, Japan

Keywords: Raman Spectroscopy, Transformer, C

2

H

2

, Furfural.

Abstract: Analyses of dissolved gas and furfural in the insulating oil are a very efficient tool for assessing the working

conditions of transformer. We propose the in-situ transformer health diagnosis without the need for oil

sampling by measuring the Raman signals from C

2

H

2

and furfural concentrations present in transformer oils.

Raman signals in oil at ~1972 cm

-1

and ~1705 cm

-1

originating from C

2

H

2

and furfural, respectively, were

detected. The results show that laser Raman spectroscopy is a useful alternative method to diagnose the

transformer faults.

1 INTRODUCTION

Transformers are important components in any

power system and their condition monitoring is

essential for ensuring reliable operation of the

system. In general, power transformer coils are

insulated with a cellulose paper and immersed in

mineral oil. Under the normal operating conditions,

insulating mineral oils in the transformers include

small amounts of gases, but failure of the

transformer is known to be preceded by significant

evolution of hydrogen(H

2

), carbon monoxide(CO),

carbon dioxide(CO

2

), methane(CH

4

), ethane(C

2

H

6

),

ethylene(C

2

H

4

), and acetylene(C

2

H

2

) gases caused

by corona discharges, overheating, and arcing.

Therefore, a dissolved gas analysis (DGA) of the

insulating oils has become the most widely used

method for investigating incipient faults in

transformers (Duval, 1989). Dissolved gases

extracted from oil aliquots due to pressure reduction

or substitution by inert gases are measured by gas

chromatography. In addition, it is known that

furfural in oil comes only from the decomposition of

insulation paper. So the furfural content in insulation

oil is an important indicator for assessing the

degradation of insulating paper in transformer

(Morais et al., 1999). Furfural concentration in oil

was generally extracted by methanol and measured

by high performance liquid chromatograpy. These

methods usually offer sensitive detection limits at

ppm levels that are suitable for monitoring the

transformer conditions, but require time consuming

preprocessing steps and include risks of sample

contamination during sampling.

We recently reported detections of C

2

H

2

dissolved in the insulation oil using laser Raman

spectroscopy technique (Somekawa et al., 2013).

C

2

H

2

is mainly produced at very high temperatures

that occur in presence of arcing. C

2

H

2

is not detected

in transformers during normal operation, but

concentrations as high as 1% are detected in

presence of huge arcing (Duval and dePablo, 2001).

Therefore, C

2

H

2

is introduced as an effective

indicator. Our approach does not require gas

separation in oils and the gas content in the

insulating oil is directly measured by irradiating

laser. Based on this technique, on-line and in-situ

detection of dissolved gases and byproduct materials

can be adapted for diagnosis of transformer faults.

In this paper, we demonstrate that C

2

H

2

and

furfural in insulating oils can be directly detected by

Raman spectroscopy. We found that Raman signals

of C

2

H

2

(~1972 cm

-1

) and furfural (~1705 cm

-1

) can

be used for monitoring the transformer condition

with no interfering peaks overlapping from the

insulating oil. Hence, Raman spectroscopy could be

a useful technique for in-situ transformer health

diagnosis without the need for oil sampling.

21

Somekawa T., Kasaoka M., Kawachi F., Nagano Y., Fujita M. and Izawa Y..

Transformer Working Condition Assessment using Laser Raman Spectroscopy.

DOI: 10.5220/0004710800210025

In Proceedings of 2nd International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS-2014), pages 21-25

ISBN: 978-989-758-008-6

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

2 EXPERIMENTAL

2.1 Raman Spectroscopy

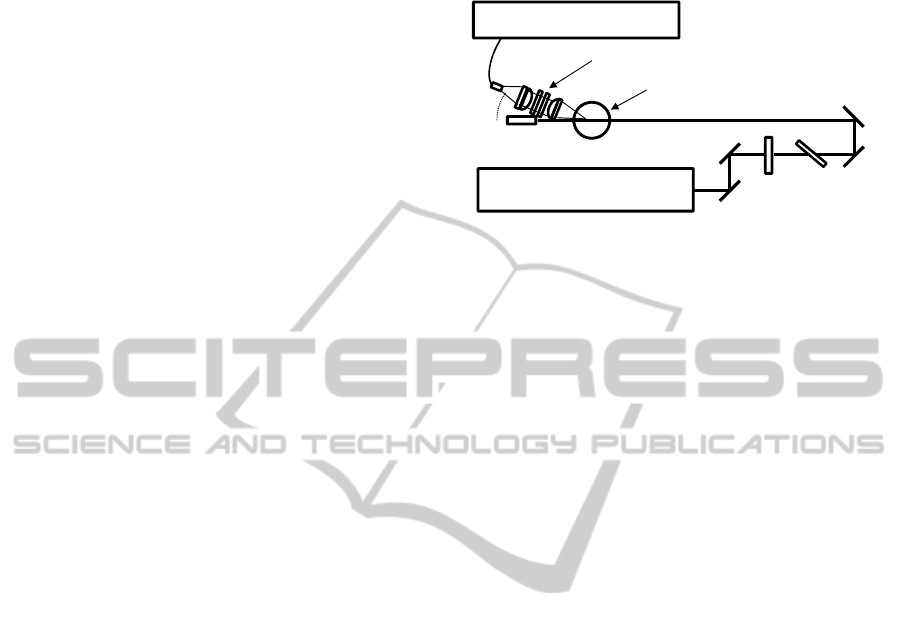

Figure 1 shows the schematic diagram of Raman

spectroscopy. The laser was a standard Q-switched

Nd:YAG laser (Continuum, Surelite: 10 ns pulse-

width with 100 mJ pulse energy at 10 Hz repetition

rate) operating at its second harmonic wavelength of

532 nm. A non-focused laser beam having about 8

mm diameter was used to avoid laser induced

damage of oil sample. The Raman signals from

samples are collected using an achromatic lens at an

angle of 25° from the forward direction of the laser

beam. This design provides a longer optical path

length than a conventional detection geometry at

90°, offering an order of magnitude increase in

Raman scattering intensity. After passing through

the edge and notch filters at 532 nm, the Raman

signal is coupled into an optical fiber bundle by

using an achromatic lens. The collected Raman

signal is dispersed by a spectrometer (Acton,

SpectraPro-2300i) with an entrance slit width set to

15 μm and detected with a liquid nitrogen-cooled

charge-coupled device (CCD) camera (Princeton

Instruments, SPEC-10). The exposure time was 90

ms. Accumulation numbers of C

2

H

2

and furfural

measurements were 3000 and 500, respectively.

Higher accumulation number in the C

2

H

2

detection

was required to reduce the random noise in Raman

spectra and improve the S/N ratio. The spectral

resolution of this system was estimated to be about 5

cm

-1

.

2.2 Sample Preparation

The insulating oil used in this work was a mixture of

naphthenic(41.6%), paraffinic(50.0%), and

aromatic(8.4%) oils. The used insulating oil

samples were optically clear in visible region. The

insulating oils were stored in glass bottles with

diameters of 3 cm. We confirmed that the glass

bottles had no effect on Raman spectra. After

complete degassing in vacuum for 4 hours, high-

purity C

2

H

2

gas (more than 99%) was introduced via

a gastight syringe. The C

2

H

2

concentrations of the

samples under the investigation were measured by

the gas chromatography and had 1.9%, 5.7%, and

10% concentrations, respectively.

Furfural is only slightly soluble in this oil.

Therefore, toluene solvent is added to oil. The

concentration of toluene in oil was constant at

approximately 9% for quantitative analysis. Furfural

used in this experiment becomes yellow on exposure

to air and light, but the spectrum obtained using 532

nm excitation is not dominated by fluorescence.

Edge+notchfilters

Surelite

(532nm,1W,10Hz)

Spectrometer+CCD

Oil,Furfural,To luene

25°

Polarizer

Half‐waveplate

M

M

M

M

Figure 1: Schematic diagram of the experimental setup.

3 RESULTS AND DISCUSSION

3.1 Raman Spectrum of Oil

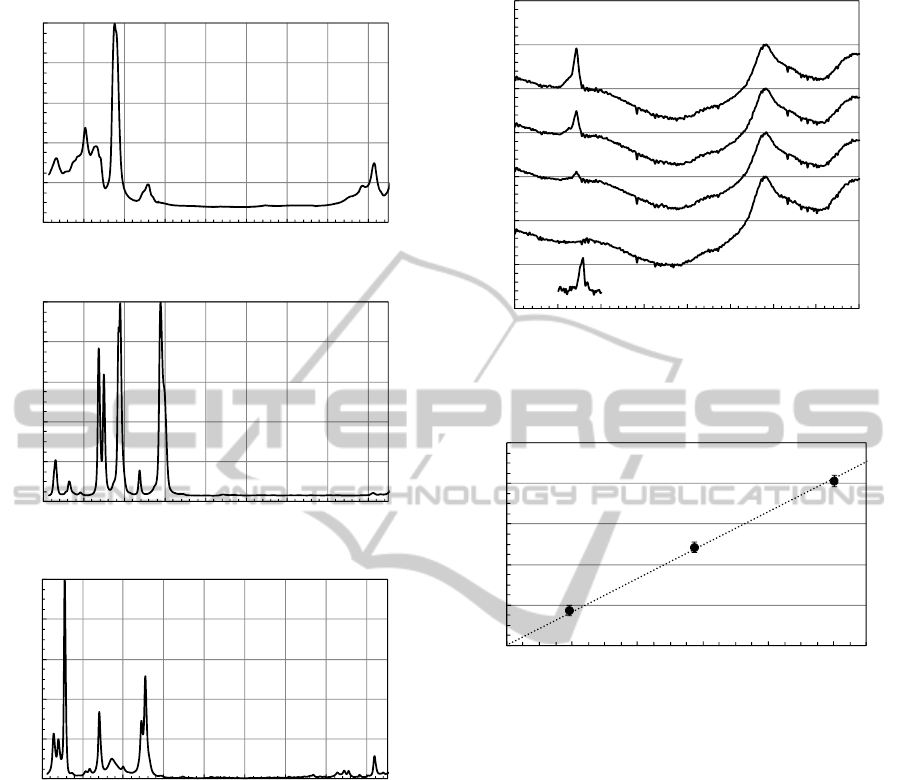

Figure 2(a) shows the Raman spectra of oil. In short

and long edges of the spectrum, it exhibits numerous

features that are specific to complex oil structures

(Somekawa et al., 2013), however, it has no large

Raman spectral features and relatively low

background baseline between 1700 to 2500 cm

-1

range. The large peak centered at 1450 cm

-1

corresponds to CH

3

-CH

2

bending mode, and the set

of peaks at 1302 and 1350 cm

-1

corresponds to

paraffin C-H twisting modes. The peak at 1610 cm

-1

is due to an aromatic C=C stretching mode. The

band at 2725 cm

-1

can be assigned to the C-H

stretching mode. In higher wavenumber side not

shown here, the Raman spectrum of oil shows only

C-H stretching mode around 3000 cm

-1

, but no

signals in the region between 3100 and 4200 cm

-1

.

Figures 2(b) and 2(c) show the Raman spectra of

furfural and toluene, respectively, as discussed

below.

3.2 Raman Spectrum of C

2

H

2

Dissolved

in Oil

Figure 3 shows the spectra of C

2

H

2

gas at different

concentrations dissolved in the insulation oil. These

Raman spectra were normalized at ~2191 cm

-1

Raman signal intensity peaks. Weak Raman signals

were detected at 2191 cm

-1

, which were assigned to

the oil-derived Raman signal since its Raman peak

intensity remained almost unchanged as the C

2

H

2

concentration increased in the oil. On the other hand,

Raman peak intensity of relatively sharp line at

~1972 cm

-1

increased linearly versus increasing

C

2

H

2

concentration. We assign the peak around 1972

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

22

(a)Oil

0

0.2

0.4

0.6

0.8

1

1100 1300 1500 1700 1900 2100 2300 2500 2700

Intensity(count arb.unit)

Wavelength(nm)

(b)Furfural

0

0.2

0.4

0.6

0.8

1

1100 1300 1500 1700 1900 2100 2300 2500 2700

Intensity(count arb.unit)

Wavelength(nm)

0

0.2

0.4

0.6

0.8

1

1100 1300 1500 1700 1900 2100 2300 2500 2700

Intensity(count arb.unit)

Ramanshift(Δcm

‐1

)

(c)Tol u e n e

Figure 2: Raman spectra of (a) oil, (b) furfural and (c)

toluene.

cm

-1

to the C≡C stretching mode of C

2

H

2

(Fast and

Welsh, 1972). We conclude from Fig. 3 that the

Raman band of C

2

H

2

located at ~1972 cm

-1

can be

used for monitoring the C

2

H

2

dissolved in the

insulation oils. In Fig. 3, Raman spectrum of 10%

C

2

H

2

and 90% N

2

gas mixture is also presented.

When C

2

H

2

is dissolved in oil, the gas phase band

position at ~1979 cm

-1

is shifted to ~1972 cm

-1

in

oil. This shift could be attributed to the variation of

vibration modes in oils (Somekawa et al., 2013).

Quantitative analysis in Raman spectroscopy was

performed with a band intensity ratio. This is

because the Raman scattering intensity is a weak

signal and the reproducibility of a Raman spectrum

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

1900 1950 2000 2050 2100 2150 2200 2250 2300

Intensity(arb.unit)

Ramanshift(Δcm

‐1

)

10%

0%

1.9%

5.7%

10%C

2

H

2

/90%N

2

gasmixture

Figure 3: Raman spectra of C

2

H

2

gas at different

concentrations dissolved in the insulation oil.

0

0.2

0.4

0.6

0.8

1

0246810

Ramanpeakintensityratio

C

2

H

2

concentration(%)

Figure 4: Raman peak intensity ratio (I

1972cm-1

/I

2191cm-1

) as

a function of dissolved C

2

H

2

concentration in oil.

is degraded due to the variation in the excitation

laser intensity and changes in the sample matrix. The

oil-derived Raman signals at ~2191 cm

-1

were used

for these analyses. Figure 4 shows Raman peak

intensity ratios, I

1972cm-1

/I

2191cm-1

, as a function of

C

2

H

2

concentration. The error bars were evaluated

using the standard deviation of 10 consecutive

spectra. The slope of the linear fit is 0.0825.

Therefore, the C

2

H

2

concentration is determined by

this slop and the Raman peak intensity ratio. Also,

we estimated the detection limit of the present

system to be 3σ

C2H2

~0.37%, where σ

C2H2

is the

standard deviation of the Raman spectra from C

2

H

2

free oil sample (0%) in 1952-1977 cm

-1

spectral

range. Thus, the high C

2

H

2

concentrations (~1%)

observed in actual insulating oils are detectable with

current Raman system. On the other hand, the

detection limits could be improved by using longer

path length oil sample, higher average power CW

laser, and more sensitive CCD detector.

TransformerWorkingConditionAssessmentusingLaserRamanSpectroscopy

23

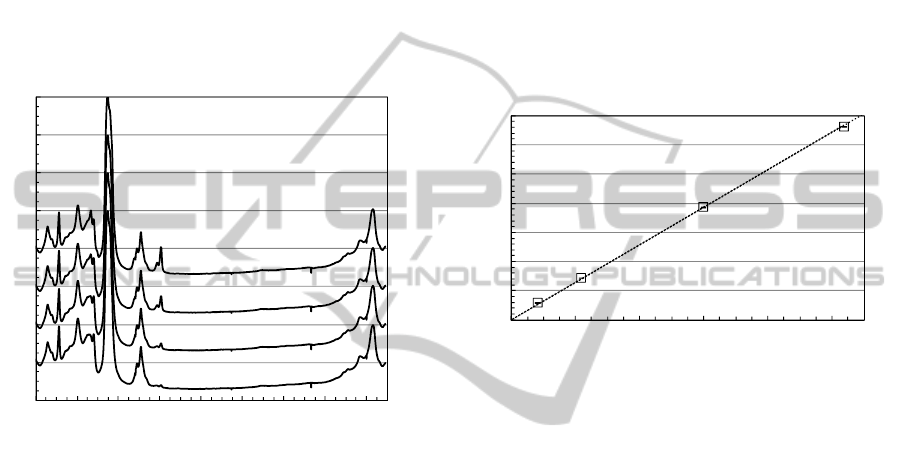

3.3 Raman Spectrum of Furfural in Oil

Figure 2 shows the Raman spectra of (b) furfural and

(c) toluene. The furfural Raman spectrum shows a

H-C-C/O bending mode at 1372 cm

-1

, C-C

stretching mode at 1398 cm

-1

, C=C stretching modes

at 1478 and 1573 cm

-1

, C=O stretching modes at

1675-1705 cm

-1

(Kim et al., 2011). As shown in Fig.

2(c), the measured Raman spectrum of toluene

includes no spectral interferences caused by Raman

band overlap over ~1600 cm

-1

. Detailed toluene

mode assignments can be found elsewhere (Hameka

and Jensen, 1996).

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1100 1300 1500 1700 1900 2100 2300 2500 2700

Intensity(count arb.unit)

Ramanshift(Δcm

‐1

)

0.08%

0.22%

0.60%

1.04%

Figure 5: Raman spectra of furfural at different

concentrations in oil in the presence of toluene (~9%) as a

solvent.

The furfural spectrum clearly shows an

additional C=O stretching mode at 1675-1705 cm

-1

,

which is not found in oil. Thus, we can easily

distinguish furfural from oil using this Raman band.

Figure 5 shows Raman spectra of furfural at

different concentrations in oil, in the presence of

toluene (~9%) as a solvent. Raman peak intensity at

~1705 cm

-1

increased linearly versus increasing

furfural concentration. The spectral shape

differences between Fig. 2(b) and Fig. 5 can be

observed at 1675-1705 cm

-1

, which may be due to

strong solvent interference (Allen and Bernstein,

1955).

Figure 6 shows Raman peak intensity ratios,

I

1705cm-1

/I

1608cm-1

, as a function of furfural

concentration. The Raman ratio at 1705 cm

-1

shows

a linear dependence on the furfural concentration in

contrast to the non-linear relationship between the

Raman ratio at 1687 cm

-1

and furfural concentration.

In this study, as a furfural-concentration-invariant

signal, we choose the Raman peak of oil and toluene

mixture at 1608 cm

-1

. The error bars were evaluated

using the standard deviation of 5 consecutive spectra

and were hidden in the plot symbols. These ratios

can be reasonably well fitted by a line with a slope

of 0.643. We estimated also the detection limit of the

present system to be 3σ

F

~65 ppm, where σ

F

is the

standard deviation of the Raman spectra from 0.08%

furfural sample between 1720 to 1750 cm

-1

range.

However, the permissible concentrations of furfural

in oil are 1.5 and 15 ppm at caution and danger

levels, respectively (Okabe et al., 2013). Therefore,

further development of the measurement system is

needed to improve sensitivity.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0 0.2 0.4 0.6 0.8 1

Ramanpeakintensityratio

Furfuralconcentration(%)

Figure 6: Raman peak intensity ratio (I

1705cm-1

/I

1608cm-1

) as

a function of furfural concentration in oil.

4 CONCLUSIONS

We demonstrated in-situ application of Raman

spectroscopy for detection of C

2

H

2

and furfural in

the insulating oil to diagnose the transformer health.

Our method also has the advantage of simplicity,

time savings and non-requirement of sample

preprocessing. In addition, the Raman spectroscopy

could simultaneously monitor multi-trace gases and

byproduct materials to get relevant information

about the transformer condition.

In future research, sensitivity improvements of

our Raman spectroscopy system will be performed.

We believe it can be generally applied for assessing

the transformer conditions.

REFERENCES

Allen, G., Bernstein, H. J., 1955. Internal Rotation VII.

The infrared and Raman spectra of furfural. In Can. J.

Chem., 33, 1055-1061.

PHOTOPTICS2014-InternationalConferenceonPhotonics,OpticsandLaserTechnology

24

Duval, M., 1989. Dissolved Gas Analysis: It Can Save

Your Transformer. In IEEE Electr. Insul. Mag., 5, 22-

27.

Duval, M., dePable, A., 2001. Interpretation of Gas-In-Oil

Analysis Using New IEC Publication 60599 and IEC

TC 10 Databases. In IEEE Electr. Insul. Mag., 17, 31-

41.

Fast, H., Welsh, H. L., 1972. High-Resolution Raman

Spectra of Acetylene, Acetylene-d1, and Acetylene-d2.

In J. Mol. Spectrosc., 41, 203-221.

Hameka, H. F., Jensen, J. O., 1996. Theoretical studies of

the methyl rotational barrier in toluene. In J. Mol.

Struct. (Theochem), 362, 325-330.

Kim, T., Assary, R. S., Curtiss, L. A., Marshall, C. L.,

Stair, P. C., 2011. Vibrational properties of levulinic

acid and furan derivatives: Raman spectroscopy and

theoretical calculations. In J. Raman Spectrosc., 42,

2069-2076.

Morais, R. M., Mannheimer, W. A., Carballeira, M.,

Noualhaguet, J. C., 1999. Furfural Analysis for

Assessing Degradation of Thermally Upgraded Papers

in Transformer Insulation. In IEEE Trans. Dielectr.

Electr. Insul., 6, 159-163.

Okabe, S., Ueta, G., Tsuboi, T., 2013. Investigation of

Aging Degradation Status of Insulating Elements in

Oil-immersed Transformer and its Diagnostic Method

Based on Field Measurement Data. In IEEE Trans.

Dielectr. Insul., 20, 346-355.

Somekawa, T., Kasaoka, M., Kawachi, F., Nagano, Y.,

Fujita, M., Izawa Y., 2013. Analysis of dissolved

C2H2 in transformer oils using laser Raman

spectroscopy. In Opt. Lett., 38, 1086-1088.

TransformerWorkingConditionAssessmentusingLaserRamanSpectroscopy

25