Remote Laboratories in the Cloud

A Digital Holographic Microscope

Wolfgang Osten, Giancarlo Pedrini and Marc Wilke

Institute of Technical Optics, University of Stuttgart, Pfaffenwald Ring 9, Stuttgart, Germany

Keywords:

Remote Laboratory, Remote Metrology, Virtual Laboratory, Cloud Computing, Comparative Digital Holog-

raphy, Optical Shape Measurement, Master-Sample-Comparison.

Abstract:

Cloud computing introduces a new paradigm for using IT resources, the often quoted “everything as a service”,

where resources are leased and paid for on a time-limited ad-hoc basis. Related advances in information tech-

nology open up the potential of combining optical systems with net based infrastructures, allowing for remote

inspection and virtual metrology. Coupling the cloud to physically existent laboratories provides universal

access to non-virtual resources. In this paper, we report our recent work on building a remote laboratory for

digital holographic metrology. We describe the architecture and the techniques involved in setting up the re-

mote controlling metrology system. Further consideration will be given to the integration into an advanced

infrastructure for remote experimentation, data storage and publication.

1 INTRODUCTION

Cloud computing can be defined by the following

three aspects: “The illusion of infinite computing re-

sources, available on demand”, “the elimination of

an up-front commitment by the cloud user”, and “the

ability of paying for use of computing resources on

a short term basis as needed” (Amburst et al., 2009).

The goal is to provide virtual computing resources as

a utility over the net. Three basic levels of service can

be distinguished, defined by the types of capabilities

provided (Wang et al., 2008)”:

1. Hardware as a Service (HaaS): Access to com-

plete computer systems, grids or data centers is

provided, the user can install and run his own sys-

tem and software as needed (e.g. Google App En-

gine (Goo, a) or Amazon EC2 - Amazon Elastic

Compute Cloud (Ama, )).

2. Software as a Service (SaaS): Software or appli-

cations are provided, the actual hardware and plat-

form remains completely transparent for user (e.g.

Google Doc (Goo, b)).

3. Data as a Service (DaaS): Access to data for stor-

age and semantic access over the net is provided

(e.g. Google’s Bigtable (Chang et al., 2006))

In our work we are extending this paradigm, or,

more precisely, Software as a Service, to include

non-computational hardware, in our case a physi-

Figure 1: Accessing a remote lab through The Cloud.

cally existent laboratory for optical metrology (see

Figure 1). However, the restrictions of such an im-

plementation are obvious: the access is limited to

computer resources (computing power, software, data

storage, and service). The embedding of external,

non-computational facilities is not addressed in the

above concept. Therefore our approach extends this

paradigm by adding non-computational hardware, in

our case a physically existent laboratory for optical

metrology (see Figure 1).

The idea of remote and virtual metrology has been

reported as early as 2000 (Osten, 2000; Osten et al.,

2001) with a conceptual illustration by use of compar-

ative digital holography (Osten et al., 2002) , aimed at

374

Osten W., Pedrini G. and Wilke M..

Remote Laboratories in the Cloud - A Digital Holographic Microscope.

DOI: 10.5220/0004377103740381

In Proceedings of the 3rd International Conference on Cloud Computing and Services Science (CLOSER-2013), pages 374-381

ISBN: 978-989-8565-52-5

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

the comparison of two nominally identical but physi-

cally different objects, e.g., master and sample, in in-

dustrial inspection processes. In a first step, a digital

hologram of the master is generated and stored, allow-

ing transmission through the Internet. This provides

instant, global access to the complete optical informa-

tion of the master object. For comparison, the mas-

ter hologram is optically reconstructed using a spatial

light modulator (Osten et al., 2002; Baumbach et al.,

2006; Kohler et al., 2008) and projected onto a sample

under inspection, resulting in interferometric patterns

that can be analyzed to retrievethe differencebetween

the master and the test object. However, the concept

of remote and virtual metrology can be extended far

beyond this. For example, it does not only allow for

the transmission of static holograms over the Inter-

net, but also provides an opportunity to communicate

with and eventuallycontrol the physical set-up of a re-

mote metrology system. Furthermore, the metrology

system can be modeled in the environment of a 3D

virtual reality using CAD or similar technology, pro-

viding a more intuitive interface to the physical setup

within the virtual world. An engineer or scientist who

would like to access the remote real world system can

log on to the virtual system, moving and manipulating

the setup through an avatar and take the desired mea-

surements. The real metrology system responds to the

interaction between the avatar and the 3D virtual rep-

resentation, providing a more intuitive interface to the

physical setup within the virtual world. The measure-

ment data is stored and interpreted automatically for

appropriate display within the virtual world, provid-

ing the necessary feedback to the experimenter. Such

a system opens up many novel opportunities in indus-

trial inspection such as virtual remote testing (Osten,

2000) and controlling.

With the development of broadband Internet and

software for remote control, we are able to make

progress toward this goal: to build a remote metrol-

ogy system based on digital holography. Our proto-

type, being developed within the framework of the

BW-eLabs project(Jeschke et al., 2011) , does not in-

tend to implement all the functionality stated above

in the current project phase. Instead, we are build-

ing a remote experimental system that can perform

deformation measurement on small objects such as

MEMS under various loads on nanometer scale, and

3D holographic microscopic imaging of (biological)

samples on micron scale (Kemper and von Bally,

2008; Schnekenburger et al., 2007) by providing uni-

versal access through the Internet. Digital hologra-

phy offers several fundamental advantages in the field

of microscopy, ranging from increased contrast in the

phase reconstruction compared to intensity in trans-

parent objects such as biological samples to numerical

focusing in arbitrary reconstruction planes (Langeha-

nenberg et al., 200y; K¨uhn et al., 2009). The phys-

ical hardware is controlled through LabView (lab, )

and will be connected to a 3D virtual reality, based on

the Open Source project Wonderland (Won, ) . Data

storage and retrieval, including a search engine and

meta data generation are handled through the Open

Source project eSciDoc(eSc, ; Razum et al., 2009)

. The system is primarily designed for deployment

in the field of scientific research, in particular for in-

ternational collaboration in joint experiments. Never-

theless, it is equally useful in education. In the field

of chemistry and chemical engineering, such weblabs

have been widely employed for education of various

curriculum at many international leading universities

including MIT in USA and University of Cambridge

in the UK (Selmer et al., 2007) . We will not address

the details of the security aspects implemented in the

infrastructure, instead focusing on the technical as-

pects of the actual experiment, the remote control and

the storage of the results.

2 APPLICATIONS FOR REMOTE

LABORATORIES IN OPTICAL

METROLOGY

In the following we will provide two examples for re-

mote laboratories. The first, an application of com-

parative digital holography demonstrates how two

objects in very distant places can be compared on

a micrometer scale while the second is a proof-of-

principle implementation of a digital holographic mi-

croscope.

2.1 Remote Comparative Digital

Holography

Holographic interferometry offers a method for shape

control with interferometric sensitivity. However, the

need of matching microstructures results in an im-

portant consequence for the conventional procedure:

the limitation to the comparison of an object with it-

self in different states, such as deformation from me-

chanical or thermal loading. Therefore, for the com-

parison of the shapes or the responses to a load of

two nominally identical but physically different ob-

jects (master-sample comparison) it was necessary to

evaluate the resulting interferograms independently

and to compare the resulting data numerically. A

more elegant approach, the so-called Comparative

Holographic Moir Interferometry, was introduced by

RemoteLaboratoriesintheCloud-ADigitalHolographicMicroscope

375

Rastogi(Rastogi, 1984) and Simova et al(Sainov and

Simova, 1989). The method is based on the incoher-

ent superposition of the involved interferograms and

the evaluation of the resulting Moir pattern. The ap-

pearing Moir fringes provide a direct indication of

the difference between the both objects. However,

the sensitivity of this method is limited due to the

poor signal-to-noise ratio in the Moir image. D.B.

Neumann published a completely new holographic

technique in 1980, which enables the direct detec-

tion of the deviations of two objects with different

microstructure. He called it Comparative Hologra-

phy (Neumann, 1980). The innovative aspect of this

method was the coherent illumination of every state

of the sample with the conjugated wave front of the

corresponding state of the master. The wave front

of the master plays the role of a coherent mask for

the adaptive illumination of the sample. Although the

procedure has interferometric sensitivity its practical

relevance is still low because of the complicated ex-

perimental background. A series of valuable contri-

butions with respect to the improvement of this tech-

nique were made by Fzessy and Gyimesi(F¨uzessy and

Gyimesi, 1984) who introduced the application of the

double reference beam technique for the independent

storage and reconstruction of both object states. In the

following we describe the basic principles of Compar-

ative Digital Holography(Ostenet al., 2001) and show

the advantages of this new procedure in examples

dealing with issues of optical shape control. Further-

more the possibility of remote shape control by mak-

ing the coherent masks globally by data transfer via

the Internet is discussed. Comparative Digital Holog-

raphy is a new method for direct holographic compar-

ison of the shape or the deformation of two nominally

identical but physically different objects(Osten et al.,

2002). It is not necessary for both samples to have the

same microstructure or to be simultaneously present

at the same location. Consequently, remote shape

or deformation comparison between a master and a

sample is possible(Baumbach et al., 2006). In con-

trast to the well known incoherent techniques based

on inverse fringe projection this new approach uses

a coherent mask that is imaged on the sample object

having a different microstructure, called holographic

illumination. The coherent mask is created by digital

holography to enable the instant access to the com-

plete optical information of the master object at any

place wanted. The transmission of the digital master

holograms to the relevant locations can be done with

a broadband digital telecommunication network.

The availability of the complete optical informa-

tion of the master object in the form of a digital holo-

gram offers two ways of comparing its shape and/or

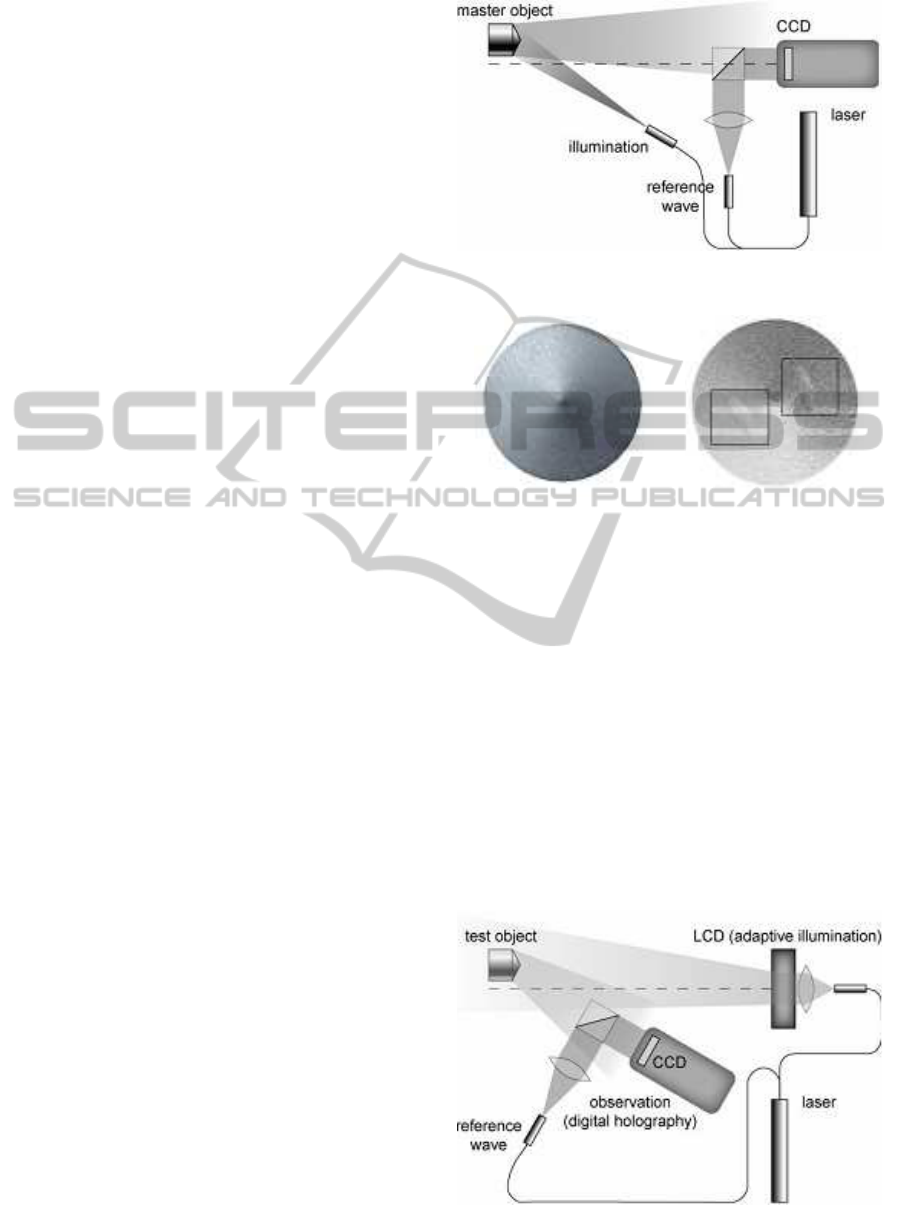

Figure 2: Recording of the coherent mask with the master

object.

(a) Master object (diameter 10

mm)

(b) Sample object with marked

dents

Figure 3: Master and Dented Sample Object.

deformation with those of a sample object having a

different microstructure:

• numerical comparison of the respective phase dis-

tributions of the relevant digital holograms or

• optical comparison of both interferograms by

Digital Comparative Holography.

In the case of a numerical comparison the differ-

ence phases of the master object and the sample object

are subtracted directly in the computer. This results in

the elimination of the basic shape of the object and the

enhancement of differences between the two objects.

In case of the optical technique the digital interfer-

ogram of the master object has to be reconstructed

Figure 4: Coherent illumination of the sample by the con-

jugated wavefront of the master.

CLOSER2013-3rdInternationalConferenceonCloudComputingandServicesScience

376

(a) Result of the coherent illumina-

tion with the conjugated wavefront

of the master

(b) Result of conventional two-

wavelength contouring

Figure 5: Shape comparison between a master and a sample

object by comparative digital holography.

by a suitable spatial light modulator such as a liquid

crystal SLM or a digital micro mirror device. Fig. 2

shows the setups for recording the master-hologram,

Fig. 4, and for investigating the sample/test object by

the comparative technology, Fig. 3(b). For that pur-

pose the sample object is coherently illuminated by

the conjugated wavefront of the master object. To re-

construct the conjugated wavefront of the master the

master-hologram is written to the SLM and the SLM

is illuminated by the conjugated reference wave that

was used for making the master-hologram. This 2step

procedure leads to an interferogram of the sample that

indicates only the difference in shape or deformation

between master and sample, Fig. 3 and Fig.5 . In our

example the objects to be compared are two macro-

scopically identical aluminum cylinders with a cone

at their upper end, Fig. 3(a). One of the cylinders

has 2 small dents of some micrometers in the cone,

Fig. 3(b). For the experiment a synthetic wavelength

of = 0,326 mm was adjusted by the two single ex-

posures with 1=579,41 nm and 2=580,44 nm. Due

to the holographic illumination of the sample with

the conjugated wavefront of the master the indicated

difference phase (P) corresponds directly to the dif-

ference of the height deflections between master and

sample in every object point. Consequently, the reg-

istered phase distribution indicates only the deviation

between master and sample, Fig. 5(a). The size of

the detected deviations depends as well on the reso-

lution of the used SLM and CCD, and the size of the

synthetic wavelength. In the described experiment we

detected height deviations of several 10 microns. Us-

ing the SLM, misalignment between the master and

the sample can be compensated by a corresponding

phase shift of the reconstructed master wavefront. A

comparison of Fig. 5(a) with Fig. 5(b), the result of

conventional holographic contouring, shows the ad-

vantage of Comparative Digital Holography for shape

comparison: only the difference in shape of two nom-

inally identical objects with various microstructure is

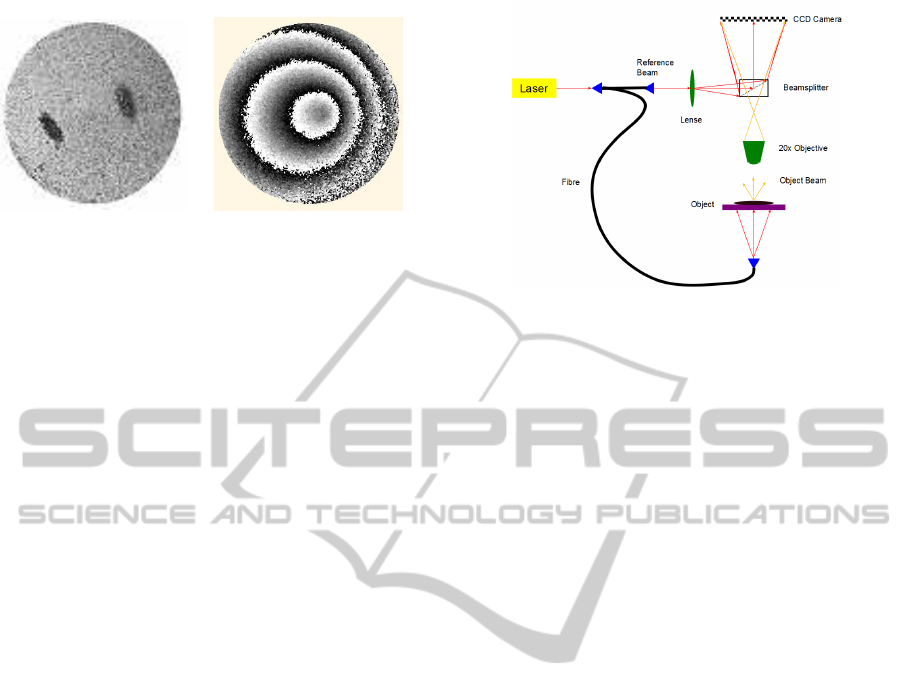

Figure 6: Experimental setup of the digital holographic mi-

croscopic system.

displayed. The high level of noise is justified by the

relatively large pixel size of the used LCD-modulator

compared to the available CCD-sensor (CCD 9m,

LCD 18m).

2.2 Digital Holographic Microscopic

System

In this section we describe the functional implementa-

tion of the architecture, focusing mainly on the setup

of the holographic system and the configuration of the

remote control (i.e. the components in the box on the

right in Fig. 7). The experimental setup of the digital

holographic microscopic system is shown in Fig. 6. A

laser beam of is first coupled into a fiber and subse-

quently divides into a reference arm and object arm.

The object arm fiber can be switched for different il-

lumination modes, i.e., transmission mode or reflec-

tion mode, depending on the property of the object

to be investigated. The object is imaged through a

20x/0.5 microscopic objective. The reference beam is

coupled into the system using a beam splitter, to in-

terfere with the object wave. The sample is mounted

on an electric-driven 3D positioner (Physical Instru-

ment), allowing the user to shift the field of view at

sub-micron precision. A CCD camera (SVS16000)

records the hologram and transfers the data to the

computer for sbsequent processing. The camera has a

large sensing area of 43.3 mm diagonally with 16 M

(4896× 3280) pixels of 7.4× 7.4 microns in size. The

provides a transmitting rate of as high as 1 gigabit per

second, with effective frame rates of 3f ps. It is con-

nected to the host computer through a PCI(e) network

interface card with 82541 chip set (for example, In-

tel Pro/1000 GT PCI card in our case) using an RJ45

network cable.

Reconstruction of the object wave is performed

numerically. The intensity pattern f(ξ, η) recorded

is first filtered in the spatial Fourier-Domain(M. et al.,

RemoteLaboratoriesintheCloud-ADigitalHolographicMicroscope

377

1982) , removing the DC component and the conju-

gate twin image in the reconstruction. The filtered

signal is inverse Fourier transformed and then propa-

gated and focused in the object plane (x, y) at distance

z using the Fresnel transformation T (z) (approxima-

tion of the wave propagation for distances z ≫ λ)

g(x, y, z) :=

exp(ikz)

iλz

Z

∞

−∞

Z

∞

−∞

f(ξ, η) ·

· exp(

ik

2z

((x− ξ)

2

+ (y− η)

2

))dξdη

= T (z)( f(ξ, η))

The whole reconstruction process can thus be ex-

pressed as

g(x, y, z) := T (z)(F

−1

(h(F ( f(ξ, η)))))

where F denotes the Fourier-Transform and h the

spatial filtering in the Fourier-Domain.

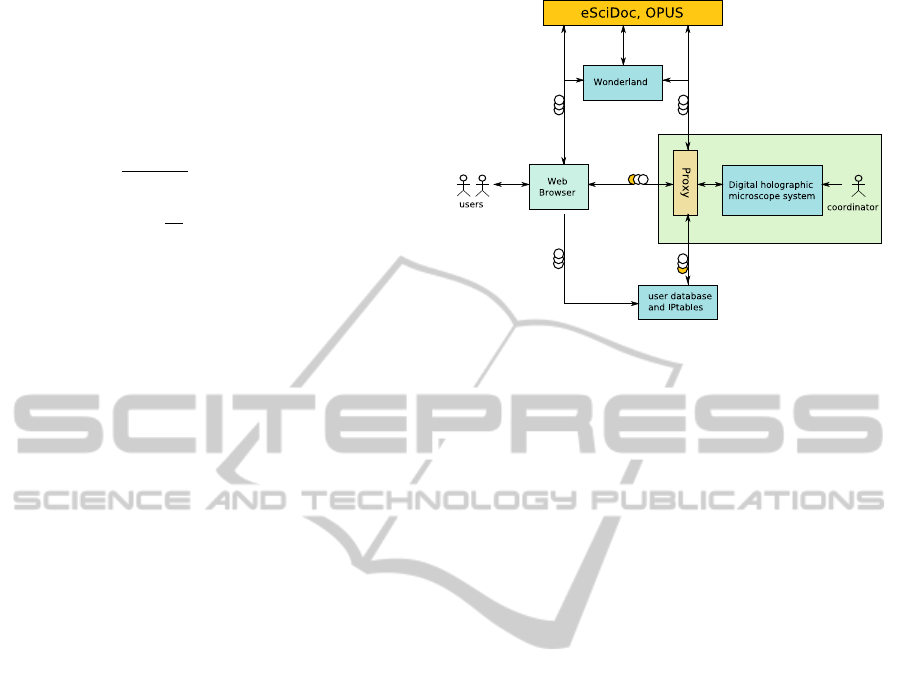

3 SYSTEM ARCHITECTURE FOR

THE HOLOGRAPHIC

MICROSCOPy

The system architecture for the remote lab is schemat-

ically shown in Fig. 7. At the heart of the archi-

tecture is the digital holographic microscopic system,

which is hidden behind a proxy server and can be ac-

cessed directly only by an operator at our institute.

The computer running the software necessary for con-

trolling the physical experiment is invisible from the

outside. All outside contact is handled by the proxy

server, using an SSH tunnel for encrypted, secure data

exchange. Users access the experiment through the

BW-eLabs portal, which authenticates against an eS-

ciDoc user data base. On successful authentication,

an SSH tunnel is opened to the SSH server running

on the proxy, with authentication passed on using

PAM (“pluggable authentication modules”). eSciDoc

also provides storage and access to experimental data,

passing data for automatic configuration of the exper-

iment, and access to the publication infrastructure of

OPUS(Opu, ) . From the user’s perspective, the func-

tionality of eSciDoc is mostly transparent, working

automatically in the background. The coordinator has

to provide a script defining the data, format and meta-

data to be stored. The actual storage process and the

corresponding retrieval process is fully symmetrical,

allowing not only access to raw data for analysis, but

also to restore the complete state of the experimen-

tal setup (e.g. in our case, the position of the ob-

ject under investigation, the focusing of the micro-

scope, the parameters requires in the reconstruction

Figure 7: Schematic architecture for the remote experimen-

tal system.

of the hologram). eSciDoc is accessible by generic

users, providing search functionality based on meta-

data generated during the experiment. The roles and

rights of users in eSciDoc are rather complex and can

be set individually for each experimental set-up and

each set of data (if desired), protecting against unde-

sired third party access while enabling collaboration

between privileged partners.

3.1 Setup of the Remote Controlling

System

Many techniques can be used for remote controlling.

The choice for our project, Virtual Network Com-

puting (VNC) used by MIT (Selmer et al., 2007) al-

lows in principle for complete control of a host com-

puter by a remote client. While somewhat slower and

very open compared to alternatives like “LabVIEW

Remote Panel” (lab, ) (LRP) developed by National

Instruments Inc, it offered some fundamental advan-

tages within the framework of the project as a whole.

VNC can connect through a proxy using an SSH tun-

nel, adding standard authentication through PAM and

encryption for security, based on existing software

such as Java-Portlets running on the BW-eLabs Portal

server and Python modules on the proxy server. As

a result, authentication is left very flexible and does

not require local accounts, any number of different

authentication methods are possible (e.g. the whole

system, including eSciDoc, could authenticate against

a trusted identity provider using Shibboleth (Shi, ) or

similar). The second argument for VNC was the easy

integration of proprietary software for remote control,

an aspect vital in future expansions of the project.

Any existing remote control can be easily integrated

into BW-eLabs through VNC, shifting the focus of

development to the interaction with eSciDoc for auto-

CLOSER2013-3rdInternationalConferenceonCloudComputingandServicesScience

378

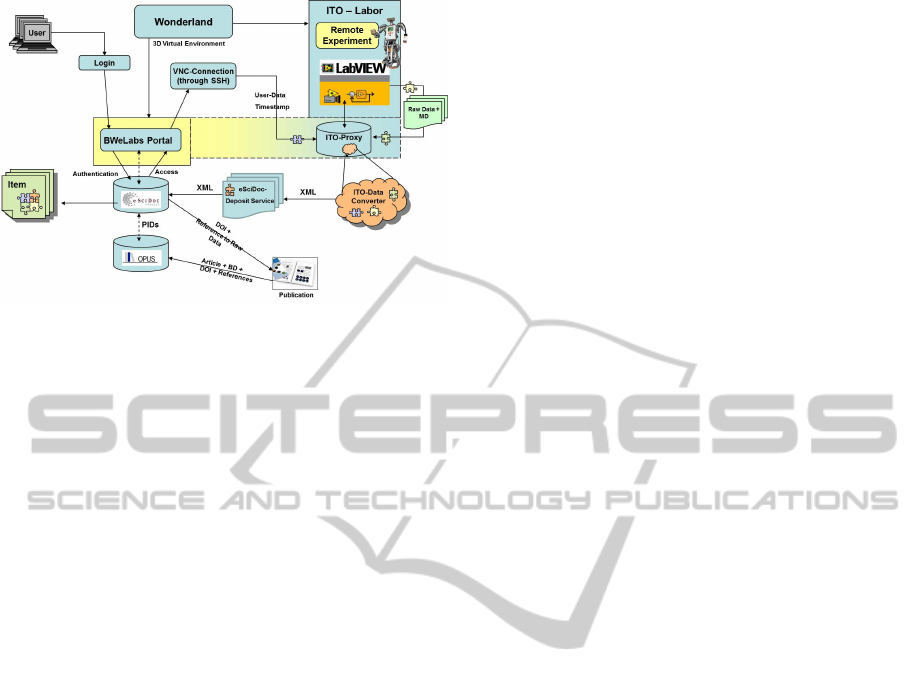

Figure 8: Architecture and Components for the Remote

Laboratory.

matic storage and access to experimental data.

The major advantage of this setup lies in the min-

imal effort demanded from the provider of the ex-

periment. User authentication, secure connection,

user management, scheduling of experiments, stor-

age, publication and retrieval of data are all provided

by the infrastructure and can be located anywhere, ei-

ther on specific systems or within the cloud (although

the publication process does require long-term acces-

sibility to the stored data, though not necessarily on

the same, permanent location).

3.2 Data Flow and Integration into the

Infrastructure

Fig. 8 shows a schematic representation of the data

flow within BW-eLabs, with the remote controlled ex-

periment described above being represented in the up-

per right corner and the connection through the BW-

eLabs portal using VNC in the center. This section

will be concerned with the integration into the infras-

tructure, mainly, the connection to the eSciDoc repos-

itory.

The data transfer between the experiment and eS-

ciDoc is very generic. A daemon (a small program

running continuously in the background) called eS-

ciDoc Deposit Service is installed on the controlling

computer and adapted to watch a specific directory. If

a file is written to this directory, it will be automati-

cally copied and send to a specified eSciDoc instance.

In the transfer process the data is extended with cer-

tain metadata, including, but not limited to:

• Description of the experiment and the object un-

der investigation (maunally created by the experi-

menting scientist)

• Parameters describing the physical state of the set-

up, including positioning of the object, focusing

of the microscope, a blind measurement needed

to compensate for the curvature of the reference

wave in the phase reconstruction (generated auto-

matically by the controlling LabView program)

• Parameters needed in the analysis and interpreta-

tion of the raw data, in our case a description of

the laser (type, wavelength), optical path length

for the Fresnel reconstruction, filter parameters

used in the Fourier domain, algorithms used etc

(generated automatically by the controlling Lab-

View program)

• Administrative metadata, specifying institution,

project, investigation, measurement series and

similar (usable in billing, parts created automat-

ically in eSciDoc).

• Time stamp and user id (created automatically in

eSciDoc).

This metadata serves in support of semantical search

as well as in restoring a specific, physical state of

the experimental setup or in the numerical analysis

and interpretation of raw data (in our case, the re-

construction of the hologram and the measured defor-

mation of the object). The first three types of meta-

data are laboratory-specific and have to be defined in

a Python/Perl/shell script (see below). The last two

generated automatically by eSciDoc.

The data itself can be anything, ranging from raw,

binary data to complex structured data. Transfer to

eSciDoc is performed using HTTP. On the eSciDoc

server, the data is passed on to an eSciDoc depository

service that in turn calls a pre-defined script (Ito Data

Converter) to build an eSciDoc item, consisting of

raw data and XML metadata. These items are stored

in eSciDoc, with the metadata being used for index-

ing search functionalities. Loading an item is again

performed using HTTP, with the returned data being

identical to that originally saved. The whole process

is completely symmetrical and transparent for the user

performing the experiment.

eSciDoc provides a multitude of functionalities to

handle experimental data, ranging from hierarchical

organization of datasets into projects, versioning and

even “publication” through the assignment of a per-

sistent identifier like a DOI. Upon publication, the

DOI marked data set can be published on the OPUS

document server utilized by several German public

and university libraries.

4 CURRENT RESULTS AND

FUTURE WORK

Figure 9 shows the frontpanel of the LabView VI

RemoteLaboratoriesintheCloud-ADigitalHolographicMicroscope

379

Figure 9: The current Labview front panel, showing a sam-

ple of onion cells.

(“Virtual Instrument”, the LabView term for a pro-

gram) with the image of a webcam showing the phys-

ical setup on the top left, with the numerically recon-

structed hologram, in this case, a biological sample,

onion cells, on the far right. The hologram was fil-

tered in the spatial Fourier-Domain previous to re-

construction (M. et al., 1982) , removing the DC

component and the twin image in the reconstruction

to improve the utilization of the spatial bandwidth

of the camera. The other two display below show

the phase retrieved from the hologram and the phase

difference between the currently investigated holo-

gram and a reloaded, previously recorded hologram

for comparativemetrology. Phase unwrapping (Hunt-

ley, 2001; Ghiglia and Romero, 1994; Ghiglia and

Romero, 1996) provides a 3D reconstruction of the

deformation of the object, displayed on the bottom

left.

The dials control the set-up, move the stepper mo-

tors of the 3D positioner and select a region of inter-

est for the numerical reconstruction of the hologram.

One useful feature and used to demonstrate the inter-

action with eSciDoc is the “save current position” and

the “restore saved position” buttons. The position of

the positioner is stored in an XML file and restored,

positioning the system in the original configuration.

This function is very useful in bringing a given region

of a sample back into focus, an otherwise slow and

tedious process, since the full reconstruction of the

hologram takes a couple of seconds.

The current implementation includes the actual

experiment, the controlling LabView software, the

VNC connection and the login through the BW-eLabs

server. The next steps in the ongoing work of this

project will consist of the connection to the eSciDoc

system, saving and loading data into the repository

and in the integration of the system into a virtual 3D

world, first as a simple solution displaying the VNC

interface within the 3D environment, then in a more

direct manner, controlling the LabView VI directly

from and displaying the recorded holograms directly

within virtual world.

While some provisions have been made towards

access to the laboratory from the cloud, additional

work is required. Authentication and access to the set-

up are flexible enough to accommodate access from

the cloud, as long as they are connected to a specific

eSciDoc instance. eSciDoc itself is quite flexible in

the location of its data, so could be adapted to use

a DaaS paradigm, as long as long-term access to the

data is guaranteed for the DOIs. Analysis of the data

can be either performed remotely on the lab computer,

or, given an installation of the proper LabView VI,

within the cloud under the SaaS paradigm, retrieving

the data from the eSciDoc storage.

5 CONCLUSIONS

We have shown a possible extension of the cloud

computing concept by adding real-world facilities to

the cloud. The facilities are embedded in a remote

laboratory that provides the complete infrastructure

for the remote access and data exchange. Such a

system opens up many novel opportunities in indus-

trial inspection such as the remote master-sample-

comparison and the virtual assembling of parts that

are fabricated at different locations. Moreover, a mul-

titude of new techniques can be envisaged, among

them advanced approaches to documenting, efficient

methods for metadata storage, the possibility for re-

mote reviewing of experimental results, the adding

of real experiments to publications by providing re-

mote access to the metadata and to the experimental

setup via Internet by simply quoting the uniform re-

source locator in the reference list, the presentation of

complex experiments in classrooms and lecture halls,

the sharing of expensive and complex infrastructure

within international collaborations, the implementa-

tion of new ways for the remote test of new devices,

for their maintenance and service, and many more.

However, there are still several problems that have to

be solved before the full potential of the remote labo-

ratory approach can be realized. Among these is the

need for the clarification of a series of legal questions

such as IP rights, the definition and agreement of stan-

dards (protocols, 3D-user interfaces, data structures,

data archiving, ...), and last but not least the conven-

tion and implementation of safety standards for the

remote access to the infrastructure (the continuous

availability, the facility and personal protection, the

access rights and authentication).

CLOSER2013-3rdInternationalConferenceonCloudComputingandServicesScience

380

ACKNOWLEDGEMENTS

This work was funded by the Ministerium f¨ur Wis-

senschaft, Forschung und Kunst Baden-W¨urttemberg

under the project BW-eLabs.

REFERENCES

http://code.google.com/intl/de-DE/appengine/.

http://aws.amazon.com/de/ec2/.

http://docs.google.com/.

http://zone.ni.com/devzone/cda/tut/p/id/4791.

http://openwonderland.org/.

https://www.escidoc.org/.

http://www.opus-repository.org/index.html.

http://shibboleth.internet2.edu/.

Amburst, M., Fox, A., Griffith, R., Joseph, A. D., Katz,

R. H., Konwinski, A., Lee, G., Patterson, D. A.,

Rabkin, A., Stoica, I., and Zaharia, M. (2009). Above

the clouds: A berkeley view of cloud computing.

Technical Report No. UCB/EECS-2009-28, Electri-

cal Engineering and Computer Sciences, University of

California at Berkeley.

Baumbach, T., Osten, W., von Kopylow, C., and J¨uptner,

W. (2006). Remote metrology by comparative digital

holography. Appl. Opt., 45:925–934.

Chang, F., Dean, J., Ghemawat, S., Hsieh, W. C., Wallach,

D. A., Burrows, M., Chandra, T., Fikes, A., and Gru-

ber, R. E. (2006). Bigtable: A distributed storage sys-

tem for structured data. In Proceedings of the 7th con-

ference on usenix, Symposium on operating system de-

sign and implementation, volume 7, pages 205–218.

F¨uzessy, Z. and Gyimesi, F. (1984). Difference holographic

interferometry: Displacement measurement. Optical

Engineering, 23(6):236780–236780.

Ghiglia, D. C. and Romero, L. A. (1994). Robust two-

dimensional weighted and unweighted phase unwrap-

ping that uses fast transforms and iterative methods. J.

Opt. Soc. Am. A, 11(1).

Ghiglia, D. C. and Romero, L. A. (1996). Minimum lp-

norm two-dimensional phase unwrapping. J. Opt. Soc.

Am. A, 13(10).

Huntley, J. (2001). Digital Speckle Pattern Interferometry

and Related Techniqus, chapter Automated Analysis

of Speckle Interferograms, pages 108–121. John Wi-

ley & Sons, LTD.

Jeschke, S., Hauck, E., Kr¨uger, M., Osten, W., Pfeiffer, O.,

and Richter, T. (2011). Networking resources for re-

search and scientific education in bw-elabs. In Au-

tomation, Communication and Cybernetics in Science

and Engineering 2009/2010, volume Part 2, pages

241–258.

Kemper, B. and von Bally, G. (2008). Digital holographic

microscopy for live cell applications and technical in-

spection. Applied Optics, 47(4).

Kohler, C., Schwab, X., and Osten, W. (2008). Optimally

tuned spatial light modulators for digital holography.

Appl. Opt., 45:960–967.

K¨uhn, J., Montfort, F., Colomb, T., Rappaz, B., Moratal,

C., Pavillon, N., Marquet, P., , and Depeursinge1, C.

(2009). Submicrometer tomography of cells by mul-

tiplewavelength digital holographic microscopy in re-

flection. OPTICS LETTERS, 34(5).

Langehanenberg, P., Kemper, B., and von Bally, G.

(200y). Autofocus algorithms for digital-holographic

microscopy. In Popp, J. and von Bally, G., editors,

Biophotonics 2007: Optics in Life Science, Proc. of

SPIE-OSA Biomedical Optics, volume 6633. SPIE-

OSA.

M., T., Hideki., and S., K. (1982). Fourier-transform

method of fringe pattern analysis for computer-based

topography and interferometry. J. Opt. Soc. Am., 72.

Neumann, D. (1980). Comparative holography. In Tech.

Digest, Topical Meeting on Hologram Interferometry

and Speckle Metrology. Opt. Soc. Am.

Osten, W. (2000). Holography and virtual 3d-testing. In

Osten, W. and J¨uptner, W., editors, Proceedings of the

International Berlin Workshop HoloMet 2000, vol-

ume 14, pages 14–17, Bremen, Germany. Bremen In-

stitute of Applied Beam Technology.

Osten, W., Baumbach, T., and J¨uptner, W. ((2001)). A new

sensor for remote interferometry. In SPIE, volume

4596, pages 158–168.

Osten, W., Baumbach, T., and J¨uptner, W. (2002). Compar-

ative digital holography. Opt. Lett., 27:1764–1766.

Rastogi, P. K. (1984). Comparative holographic moire in-

terferometry in real time. Appl. Opt., 23(6):924–927.

Razum, M., Schwichtenberg, F., Wagner, S., and Hoppe,

M. (2009). escidoc infrastructure: A fedora-based e-

research framework. In et al., M. A., editor, ECDL,

volume 5 2009, LNCS 5714, pages 227–238.

Sainov, V. and Simova, E. (1989). Comparative holographic

moire interferometry: Separation of moire fringes

from the carrier interference pattern. Optical Engi-

neering, 28(5):285550–285550–.

Schnekenburger, J., Bredebusch, I., Langehanenberg, P.,

Domschke, W., von Bally, G., and Kemper, B. (2007).

Dynamic in vivo analysis of drug induced actin cy-

toskeleton degradation by digital holographic mi-

croscopy. In Popp, J. and von Bally, G., editors, Bio-

photonics 2007: Optics in Life Science, Proc. of SPIE-

OSA Biomedical Optics, volume 6633. SPIE-OSA.

Selmer, A., Kraft, M., Moros, R., and Colton, C. K. (2007).

Weblabs in chemical engineering education. Trans.

IChemE Part D, 2.

Wang, L., Tao, J., Kunze, M., Castellanos, A. C., Kramer,

D., and Karl, W. (2008). Scientific cloud computing:

Early definitions and experience. In 10th IEEE Inter-

national Conference on High Performance Computing

and Communications, 2008. HPCC ’08., pages 825–

830.

RemoteLaboratoriesintheCloud-ADigitalHolographicMicroscope

381