High Density Cell Electrofusion on Chip using an Array of

Non-connected Metallic Pads

Feriel Hamdi

1,3

, Wei Wang

1

, Frederic Subra

2

, Elisabeth Dufour-Gergam

3

, Olivier Francais

1

and Bruno Le Pioufle

1

1

Ecole Normale Supérieure de Cachan, CNRS, SATIE, UMR 8029, Cachan, France

2

Ecole Normale Supérieure de Cachan, CNRS, LBPA, UMR 8113, Cachan, France

3

Univ Paris-Sud, CNRS, Institut d’Electronique Fondamentale, UMR 8622, Orsay, France

Keywords: Electrofusion, Dielectrophoresis, High Density, Microfluidics.

Abstract: Cell fusion consists on creating a hybridoma cell containing the genetic properties of the progenitor cells. It

can be performed chemically or electrically. The latter method, called Electrofusion, is a more efficient way

to create hybrid cells investigated for antibody production or cancer immunotherapy. To envision this

application, a high amount of hybrid cells is needed. This work presents an original design for high density

electrofusion on chip. The structure consists of an array of non-connected electroplated gold pads patterned

between two connected electrodes. While applying a Voltage on the connected electrodes, the Electric field

is disturbed around the gold pads inducing a Dielectrophoretic Force on cells used to trap and pair them.

When cells are paired, Electric pulses are applied to induce electrofusion. The absence of wire connections

on the pads permits the high density trapping and electrofusion. Successful alignment and electrofusion of

murine melanoma cells with this structure are demonstrated.

1 INTRODUCTION

Cell fusion is a method to generate a hybrid cell

which combines specific properties of its progenitor

cells. While cell fusion has been developed for

antibody production (Köhler and Milstein, 1975), it

is now also investigated for cancer immunotherapy

(Sukhorukov et al., 2006) and reprogramming of

somatic cells (Tada et al., 2001). There are different

methods for cell fusion, such as biological (Okada,

1958), chemical (Pontecorvo, 1975) and electric

pulse mediations (electrofusion). For electrofusion,

the operation is simple and the system is free of

chemical or genetic contaminations. Combined to

the high fusion efficiency (Skelley et al., 2009)), this

makes the method widely used. Therefore, the most

used method for electrofusion consists on using an

electroporation cuvette composed of two facing

electrodes with 1 to 4 mm distance or ellipsoidal

ones with 200µm inter-electrodes distance

(Eppendorf). In these cuvettes, there is no possible

placing of cells and the yield of one-to-one fusion

cells is very low (20% fusion rate including multiple

cell fusion (Zimmermann et al., 2006)). The use of

small biodevices is investigated since 1989 (Masuda

et al., 1989) to solve this problem by a primary step

of placing cells. Different strategies for cell trapping

and pairing were presented such as fluidic (Skelley

et al., 2009) or electric using a Dielectrophoretic

force (Masuda et al. 1989); (Techaumnat et al.,

2008); (Kirschbaum et al., 2012).

Another issue in the development of biodevices

for electrofusion is the yield. Indeed, a large amount

of hybridomas is needed to make an injection, but in

the classic microfabricated structures, the density is

limited because of the electric connections.

In this work, we present a novel structure

dedicated to electrofusion on chip with high density

capability. The structure involves an array of non-

connected micro-size electroplated gold pads,

positioned between two electrodes, which induce a

specific electric field topology. The absence of

wiring, and connections, as gold structures are not

powered, permits the high density arraying which is

necessary when the high throughput is envisioned

for the electrofusion. The successful self-alignment

of cells in this array, thanks to DiElectroPhoretic

(DEP) forces, followed by the application of

electrofusion pulses is demonstrated.

In this paper, we first introduce the structure

design with an FEM simulation of the electric field.

68

Hamdi F., Wang W., Subra F., Dufour-Gergam E., Français O. and Le Pioufle B..

High Density Cell Electrofusion on Chip using an Array of Non-connected Metallic Pads.

DOI: 10.5220/0004246100680072

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2013), pages 68-72

ISBN: 978-989-8565-34-1

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

Secondly, the fabrication process of the biochip and

the preparation of cells are presented. Finally,

experiments for cell trapping and electrofusion are

described in the last sections.

2 MATERIALS AND METHODS

In this work, electrofusion on chip is based on the

use of non connected high conductive materials

(gold) to modify the electric field topology between

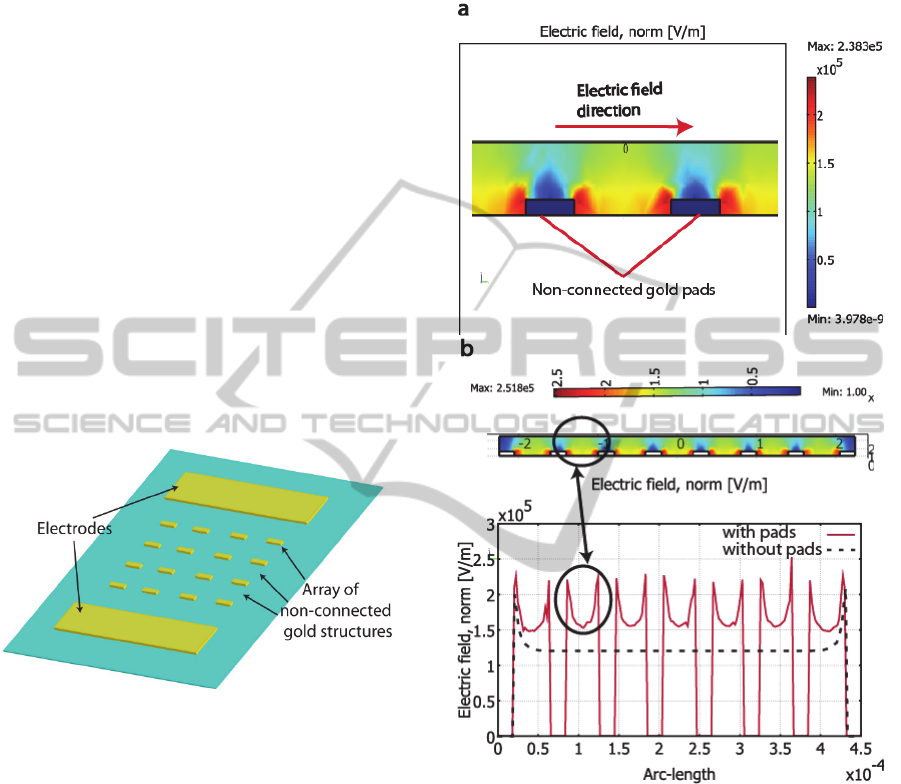

two electrodes (Figure 1). This enables cells

alignment and pairing between arrayed gold

structures with assistance of DEP force, which is

necessary before initiating the cell electrofusion

protocol. To create the new design, a 3D simulation

of the Electric Field and DEP in the structure had

been achieved using a finite element method

(AC/DC module of COMSOL Multiphysics ©). The

result (figures 2 and 3) shows that with the

appropriate conditions, cells are attracted to the area

between the facing pads.

Figure 1: Schematic view of the chip developed showing

electrodes generating electric field and gold structures for

DEP effect.

2.1 Structure Modeling

Using the AC/DC module of COMSOL

Multiphysics, we simulated a structure composed of

an array of 6x4 non-connected metallic pads (10 µm

x 40 µm size separated by 50 µm distance) between

two electrodes (410 µm distance). The metal is 5.5

µm thick gold. The structure was immersed in 25

µm height low conductivity medium (0.03 S/m) and

we applied 50 V on the connected electrodes.

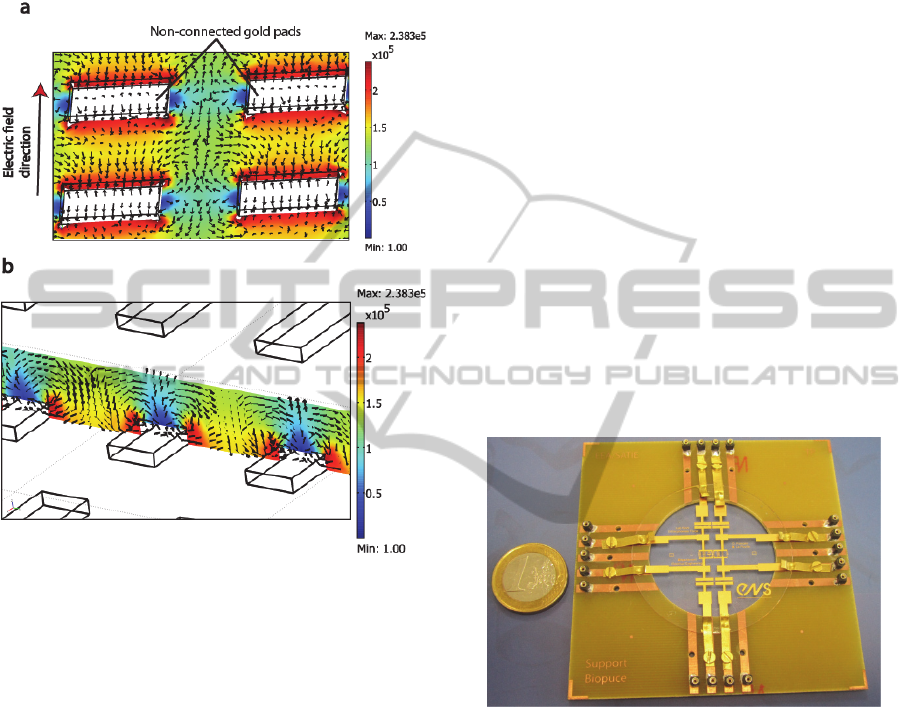

As shown in figure 2a and 2b, the maximum

electric field (E) values are between the gold pads

(parallel to E) close to the edges, while the minima

are above the pads, in the middle and on the edges

perpendicular to the electric field (Figure 3a).

The electric field gradient obtained is used to

trap cells. The gap between pads will then constitute

the fusion zone. Thus, this gap is calculated to be

equivalent to the size of two cells.

Figure 2: a.) Cut view of the 3D simulated structure

showing electric field topology (color) b.) Electric field

distribution along a raw of pads (continuous curve) and

without pads (discontinuous curve)

Figure 2b shows that without the presence of the

non-connected pads, the area between the electrodes

presents a very homogeneous E but lowered to 1.2

kV/cm. If we apply the same voltage with the

presence of the pads, the electric field in the fusion

zone is increased to 1.5 kV/cm.

Due to the non-homogeneity of the electric field

induced by the presence of the pads, insulating

particles (as cells) would experience

Dielectrophoresis in this structure. If we want to trap

cells in the fusion zones, we can apply a sinusoidal

HighDensityCellElectrofusiononChipusinganArrayofNon-connectedMetallicPads

69

wave at a frequency inducing positive

Dielectrophoresis (particles attracted by high E

areas). Indeed, as shown by arrows in figure 3, if

cells are in low E field areas, they will be pushed to

the fusion zone (high E).

Figure 3: 3D simulated structure showing electric field

topology (color) and DEP direction (arrow, case positive).

Therefore, the non-connected pads contribute to:

- increase the electric field in the fusion area

- create a topography of the electric field to induce

cell trapping

In the next section we will present the device

fabrication before introducing the experimental

results obtained with biological cells.

2.2 Biodevice Fabrication

All the materials used for the fabrication of the

device are biocompatible. The chip is fabricated on a

quartz wafer pre-coated with a thin layer of Cr (15

nm Chromium to insure adhesion of Gold) and 150

nm Au as a primer for electroplating. Gold layer

thickness is increased up to 5.5 µm in an electrolytic

bath based on Potassium Aurocyanure KAu[CN]

2

(Dalmay et al., 2011) in order to enhance the electric

field amplitude at the non-connected conductive

pads. A photolithography step (using S1805

pohotresist) followed by a wet etching process (with

KI/I

2

for Gold followed by Cr etchant

MicroChemicals for Chromium) defined the

electrodes (electric field generation) and the non-

connected gold structures (cell positioning). The

photoresist was then removed by acetone.

Finally, microfluidic channels were made of

thick SU8-2025. That epoxy photoresist was spin-

coated (500 rpm/100 rpm.s

-1

/5 s then 3000 rpm/500

rpm.s

-1

/ 30 s), soft baked (3 min at 65°C, 15 min at

95°C and 3 min at 65°C), insulated (160 mJ), post

exposure baked (same 3 steps than the soft bake) and

developed to form 25 µm high channels. To get a

good adhesion of the photoresist, the device was

hard baked during 2 hours at 175°C.

The device is packaged thanks to a simple

microscope glass slide put on the top of the

microchannel. A printed circuit board holder had

been fabricated to ensure the electrical access to the

micro-electrodes used for electric field generation

(cell positioning (DEP) and electrofusion). A view

of the final device electrically connected to the

power supply through a PCB plate is shown in figure

4.

Figure 4: Global view of the fabricated chip on its PCB

holder.

2.3 Biological Experiments

For biological experiments, mouse melanoma cells

B16F10 had been used. They were suspended in a

low conductivity hypotonic fusion buffer (0.1M

Sorbitol, 0.7 mM MgCl

2

, 0.1 mM Calcium Acetate

and 1 mg/ml BSA) and injected in the fluidic

channel. The diameter of B16F10 cells in this buffer

is around 20 µm.

The experiments were led in static conditions.

An array of 10µm*40µm gold structures separated

by 50 µm has been used in order to be compatible

with the size of paired cells.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

70

2.3.1 Cell Preparation

B16F10 murine melanoma cells are cultured in

Minimum Essential Medium supplemented with

10% Fetal Bovine Serum and 1% PS antibiotics

(Penicilin-Streptomycin). Cultures were maintained

in a 5% CO

2

incubator at 37°C. Before the

experiment, cells were detached with Trypsin and

suspended in the hypotonic fusion buffer (0.1M

Sorbitol, 0.7 mM MgCl

2

, 0.1 mM Calcium Acetate

and 1 mg/ml BSA). The measured conductivity of

the medium is 272 µS/m.

Low conductivity ensures

stronger pDEP and reduces Joule heating. A

preparation of 1 million cells per ml was used for the

experiments. The diameter of B16F10 cells in this

buffer is around 20 µm.

2.3.2 Cell Trapping

With the presence of non-connected conductive

pads, the application of a voltage between the

electrodes produces a non-uniform electric field

(figure 3). When biological cells are exposed to this

field, they experience a dielectrophoretic force

(Fricke, 1924):

F

DEP

2

R

Cell

3

m

e

K

CM

E

2

(1)

where R

Cell

is cell’s radius, E the electric field, K

CM

the Clausius-Mossotti (CM) factor,

e

[K

CM

] its real

part and ε

m

the extracellular medium permittivity.

K

CM

depends on the applied frequency and the

electric parameters of the cell and the medium.

When K

CM

is positive, cells are attracted to

maximum electric field areas, it is positive DEP

(pDEP).

The DEP signal consists of a sine wave. This

force is convenient to move polarisable particles. It

was investigated for carbon nanotubes or other

particles (Krupke et al., 2004), cell sorting and

trapping (Salmanzadeh et al., 2012) or, as in our

case, cell pairing.

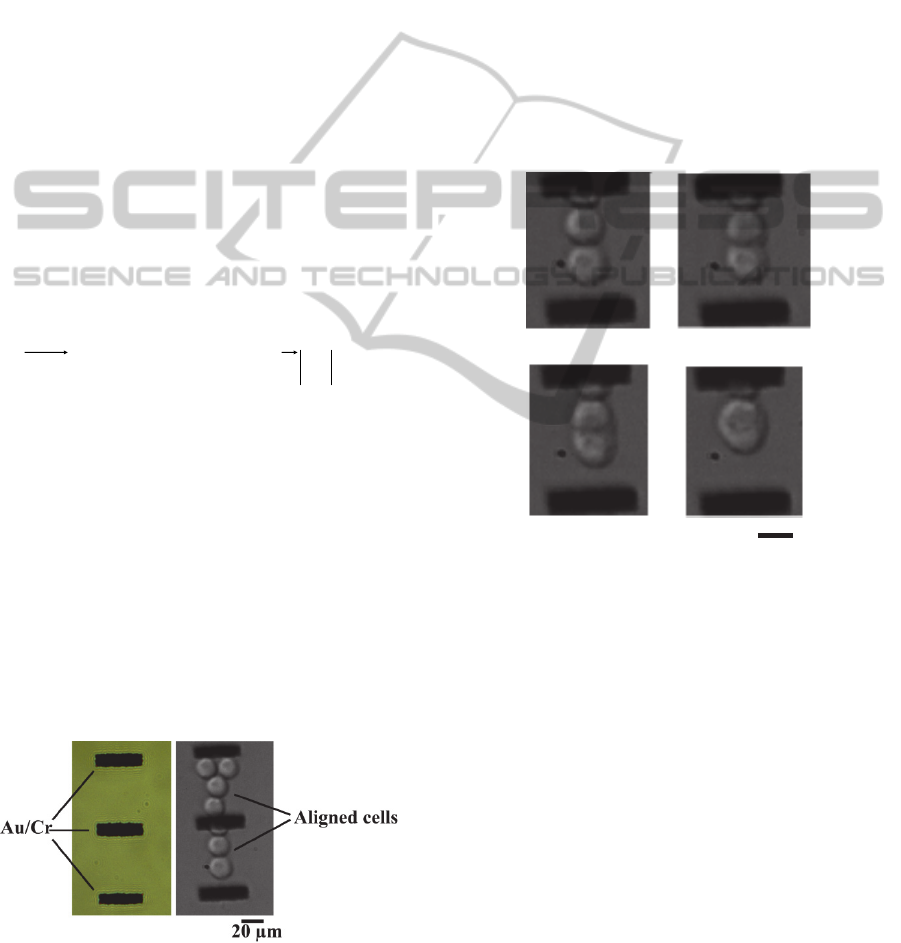

Figure 5: Top view of the non-connected gold pads

arrayed within the microfluidic structure (left) and aligned

cells due to positive DEP force (right).

Experiments describing cell trapping and pairing

are presented in figure 5. A sine wave of 15 Vpp and

400 kHz was used during the experiment to induce

DEP force.

We can see in figure 5 that cells align between

the non-connected pads according to the pDEP

arrows predicted by the simulation shown in figure

3.

2.3.3 Electrofusion

When the cells were paired, electrofusion pulses

were added to DEP signal (10 square pulses of 100

µs duration, equivalent electric field = 1.21 kV/cm).

Successful fusion had been obtained from cells in

the positioning area, between two non connected

gold pads (Figure 6).

Figure 6: Dynamics of cell fusion induced by electric

pulses.

After 12 seconds, the membranes of cells start to

merge to form a hybridoma which regained a

spherical shape 74 seconds after the first pulse.

3 CONCLUSIONS

In this paper we presented a novel structure using

non-connected electroplated gold pads for high

density cell pairing and fusion. The simulation of the

electric field shows the effect of the conductive pads

on the field distribution. Indeed, the presence of the

pads increases the electric field in the fusion areas

without increasing the applied voltage. On the other

hand, due to the non-homogeneity of the electric

field, these pads permit the use of Dielectrophoresis

t=0s t=12.9s

t=18s

t=74.4s

20µm

pads

HighDensityCellElectrofusiononChipusinganArrayofNon-connectedMetallicPads

71

to trap cells prior to electrofusion. We demonstrated

the successful pairing and electrofusion between the

non-connected pads with biological cells. Thanks to

the absence of wiring, this method is a promising

technique for high density cell electrofusion on chip.

ACKNOWLEDGEMENTS

This work was performed thanks to the financial

support of PRES Universud, CNANO’Ile de France,

the ANR PNANO Nanopulsbiochip and the Labex

LASIPS, IMPcell project

REFERENCES

Köhler G. and Milstein C., 1975. Continuous cultures of

fused cells secreting antibody of predefined

specificity, In Nature, 256, 495.

Sukhorukov V. L., Reuss R., Endter J. M., Fehrmann S.,

Katsen-Globa A., Gessner P., Steinbach A., Müller K.

J., Karpas A., Zimmermann U. and Zimmermann H.,

2006. A biophysical approach to the optimisation of

dendritic-tumour cell electrofusion. In Biochemical

and Biophysical Research Communication, 346, 829.

Tada M., Takahama Y., Abe K., Nakatsuji N. and Tada T.,

2001. Nuclear reprogramming of somatic cells by in

vitro hybridization with ES cells. In Current Biology,

11, 1553.

Okada Y., 1958. The fusion of Ehrlich's tumor cells

caused by HVJ virus in vitro. In Biken Journal, 1, 103.

Pontecorvo G., 1975. Production of mammalian somatic

cell hybrids by means of polyethylene glycol

treatment. In Somatic Cell and Molecular Genetics, 1,

397.

Skelley A. M., Kirak O., Suh H., Jaenisch R. and Voldman

J., 2009. Microfluidic control of cell pairing and

fusion. In Nature Methods, 6, 147.

Zimmermann D., Terpitz

U., Zhou A., Reuss R., Müller

K., Sukhorukov V. L.,Gebner P., Nagel G.,

Zimmermann U. and Bamberg E., 2006. Biophysical

characterisation of electrofused giant HEK293-cells as

a novel electrophysiological expression system. In

Biochemical and Biophysical Research

Communications, 348 (2), 673.

Masuda S., Washizu M. and Nanba T., 1989. Novel

method of cell fusion in field constriction area in fluid

integrated circuit. In IEEE Trans. Ind. Appl, 25, 732,

1989

Techaumnat B., Tsuda K., Kurosawa O., Murat G., Oana

H. and Washizu M., 2008. High-yield electrofusion of

biological cells based on field tailoring by

microfabricated structures. In IET Nanobiotechnology,

2 (4), 93.

Kirschbaum M., Guernth-Marschner C. R., Cherré S., Pna

A., Jaeger M. S., Kroczek R. A., Schnelle T., Mueller

T. and Dusch C., 2012. Highly controlled

electrofusion of individually selected cells in

dielectrophoretic field cages. In Lab Chip, 12, 443

Dalmay C., Villemejane J., Joubert V, Francais O., Mir L.

M., Le Pioufle B., 2011. Design and realization of a

microfluidic device devoted to the application of ultra-

short pulses of electrical field to living cells. In

Sensors and Actuators B : Chemical, 160 (1),

1573Fricke H., 1924. J. of Applied Physics, 24, 575

Krupke R., Hennrich F., Kappes M. M. and Löhneysen

H., 2004. Surface Conductance Induced

Dielectrophoresis of Semiconducting Single-Walled

Carbon Nanotubes. In Nano Letters, 4 (8), 1395.

Salmanzadeh A., Kittu H., SSano M. B., Roberts P. C.,

Schmelz E. M., 2012. Dielectrophoretic differentiation

of mouse ovarian surface epithelial cells,

macrophages, and fibroblasts using contactless

dielectrophoresis. In Biomicrofluidics, 6, 024104.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

72