DETECTING ‘YELLOW STAIN’ IN WOOD USING SPECTRAL

METHODS

Gerald McGunnigle

CTR AG, Villach, Austria

Keywords: Wood inspection.

Abstract: This paper deals with the detection of ‘yellow stain’ in wood samples using colour. We describe an

investigation into the spectral properties of the stain and use the findings to design a detection system. We

found that infected regions invariably differed from healthy regions in the 400nm to 450nm region of the

spectrum. We developed a system based on an economical RGB camera and an optimised light source. The

source consists of two narrow bands: one in the blue channel of the camera where the discriminative

information is held, and one in the red channel that acts as a normalisation factor to remove the effect of the

natural patterning of the wood. A simple classifier was used with the red and blue channels of the camera

and produced results that agreed with our client’s subjective judgement.

1 INTRODUCTION

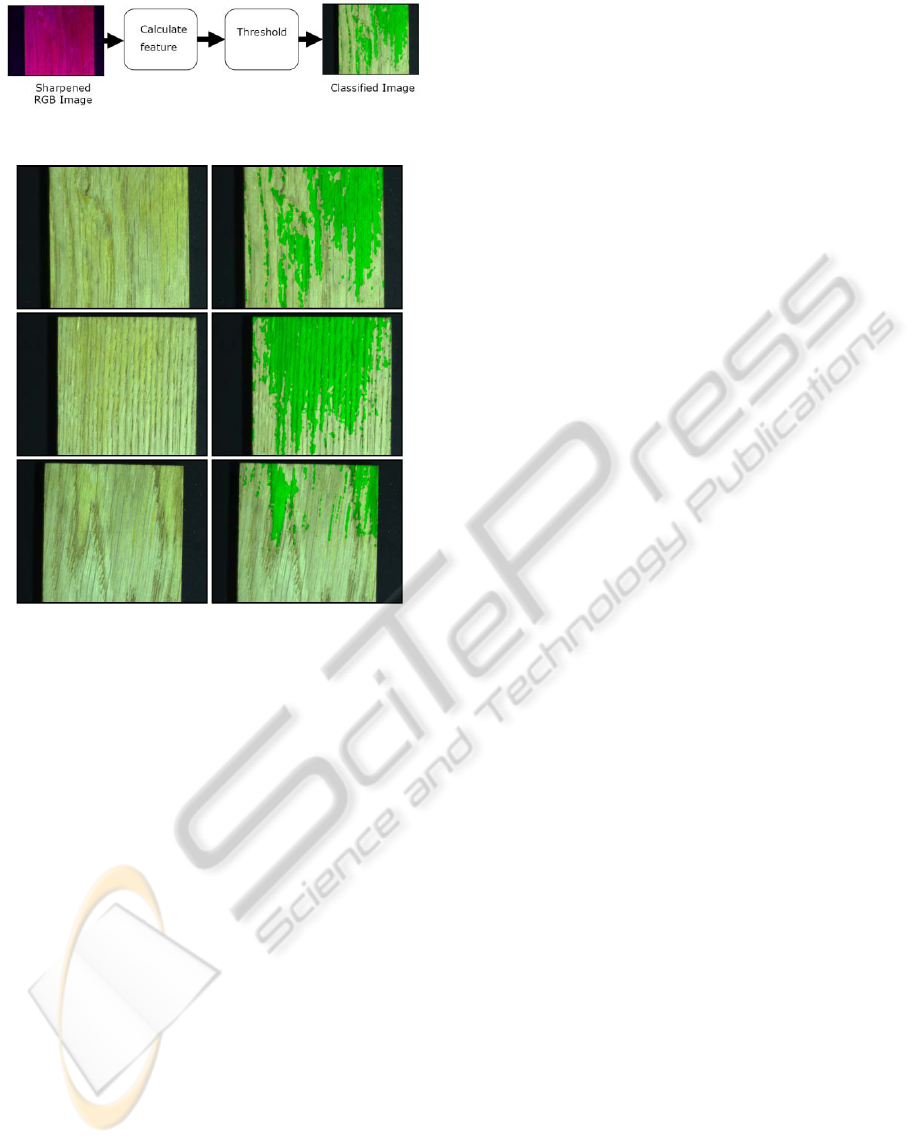

This paper deals with the detection of ‘yellow stain’

in wood samples using colour, Figure 1. Yellow

stain is a discolouration of the wood surface caused

by a fungal infection. Although it does not affect the

structural integrity of the timber, it does affect

consumer perceptions of the material and its

economic value. An inspection system must match

the human visual system’s colour sensitivity to the

stain, yet be robust to the natural variation of healthy

wood.

Figure 1: Example of yellow stained wood (left) the

results of our classifier (right). For display we have lit the

sample with fluorescent light which makes the yellow

stain more apparent than under tungsten halogen light.

Timber is an important sector of the machine

vision sector. Commercial systems are available and

the topic is also the subject of academic research.

Colour is an important aesthetic characteristic of

timber but also a useful cue for identifying

abnormalities and much of the research has

concentrated on using colour, (Lampinen,

Smolander and Korhonen, 1995) (Kauppinen and

Silven, 1996) (Lebow, Brunner, Maristany and

Butler, 1996). Spectroscopy has been applied, (Jones

et al., 2005) and several authors have used

multispectral and hyperspectral techniques,

(Maristany et al., 1992) (Hagman, 1997) (Marszalec

and Pietikaeninen, 1993) (Butler, Brunner and

Funck, 2001). In this paper we will use

hyperspectral imaging to identify the features that

disclose yellow stain and use this information to

optimise the spectrum of the illumination so that

yellow stain can be detected using a conventional

RGB camera.

In this paper we identify spectral features for

detecting yellow stain and resolving it from the

background wood texture. We use hyperspectral

(HS) measurements, that is measurements that are

both spatially and spectrally resolved, to identify

spectral features that distinguish infected from

clearwood. We then ‘tune’ the light source so that

these features can be resolved by a conventional

RGB Camera.

This paper describes 2 tasks: first we use the HS

measurement system to measure spectra from both

infected and clear regions of the samples. The

spectra are analysed to identify wavelengths at

which the two region types differ. These

wavelengths are then used to design features that can

551

McGunnigle G. (2012).

DETECTING ’YELLOW STAIN’ IN WOOD USING SPECTRAL METHODS.

In Proceedings of the 1st International Conference on Pattern Recognition Applications and Methods, pages 551-554

DOI: 10.5220/0003756205510554

Copyright

c

SciTePress

be extracted from the measured data and used for

classification. Second, we use a conventional RGB

camera with spectrally optimised lighting to classify

a series of samples.

We applied this approach to a number of samples

supplied by our client. Afterwards the client was

asked to examine the samples by hand and compare

his judgement with our classification. In all cases the

client agreed with the classification and was satisfied

with the approach. This evaluation is, like that of the

consumer, subjective. However, the fact that this

approach gave satisfactory results suggests that the

optimised lighting approach is superior to an earlier

approach based on a high end colour linescan

camera.

2 BACKGROUND

Yellow stain is a discolouration of cut hardwood

affecting European oaks, chestnut and walnut

species. The discolouration is the result of tannic

acids being metabolised by the fungus Paecilomyces

variotii. The initial infection and its progression are

closely associated with the vascular structure of the

wood. Fungal spores enter the structure of the wood

in regions where the vascular structure has been

breached, e.g. the wood has been cut across the

grain. The infection then spreads most rapidly along

the tracheids, especially through the less dense

earlywood. Because the spread of the infection is

largely determined by the microstructure of the

wood, the visible results are correlated with the grain

of the wood. Therefore although the stained regions

may extend over long distances in the grain

direction, they are often spatially localised in the

perpendicular direction. Colour measurements must

therefore be both spectrally accurate and spatially

localised.

Hyperspectral imaging allows measurement of

the colour spectrum at each pixel in an image. The

result of a hyperspectral measurement is a three

dimensional data set (or spectral cube) with two

spatial dimensions (as with a normal image) and a

third dimension corresponding to the colour

spectrum. In fact the particular camera, sensor and

lighting combination used in this report extends the

colour spectrum into the NIR and has a working

range from 380nm to 950nm. Our system is based

on an imaging spectrograph which diffracts light

along one of the axes of the sensor plane. Each

frame from the camera has one spatial and one

spectral axis. The spectrograph performs push-

broom scanning, i.e. it is used as a line scan camera,

with the spectral cube being built up slice by slice as

each frame is captured. Hyperspectral imaging has

been used for online inspection, however in this

paper we will use it as an analytical tool to optimise

a conventional inspection system.

3 HYPERSPECTRAL

MEASUREMENT SETUP

3.1 Lighting

The spectral range of the imaging system is defined

by the design of the imaging spectrograph, the

response of the camera, and the spectrum of the

incident illumination. In general we use tungsten

halogen lamps because they are broadband,

economical and are capable of supplying the large

amount of light required by a hyperspectral system.

They approximate a black body radiator and

therefore suffer from a significant disadvantage for

colour measurement: they are relatively weak at the

blue end of the spectrum.

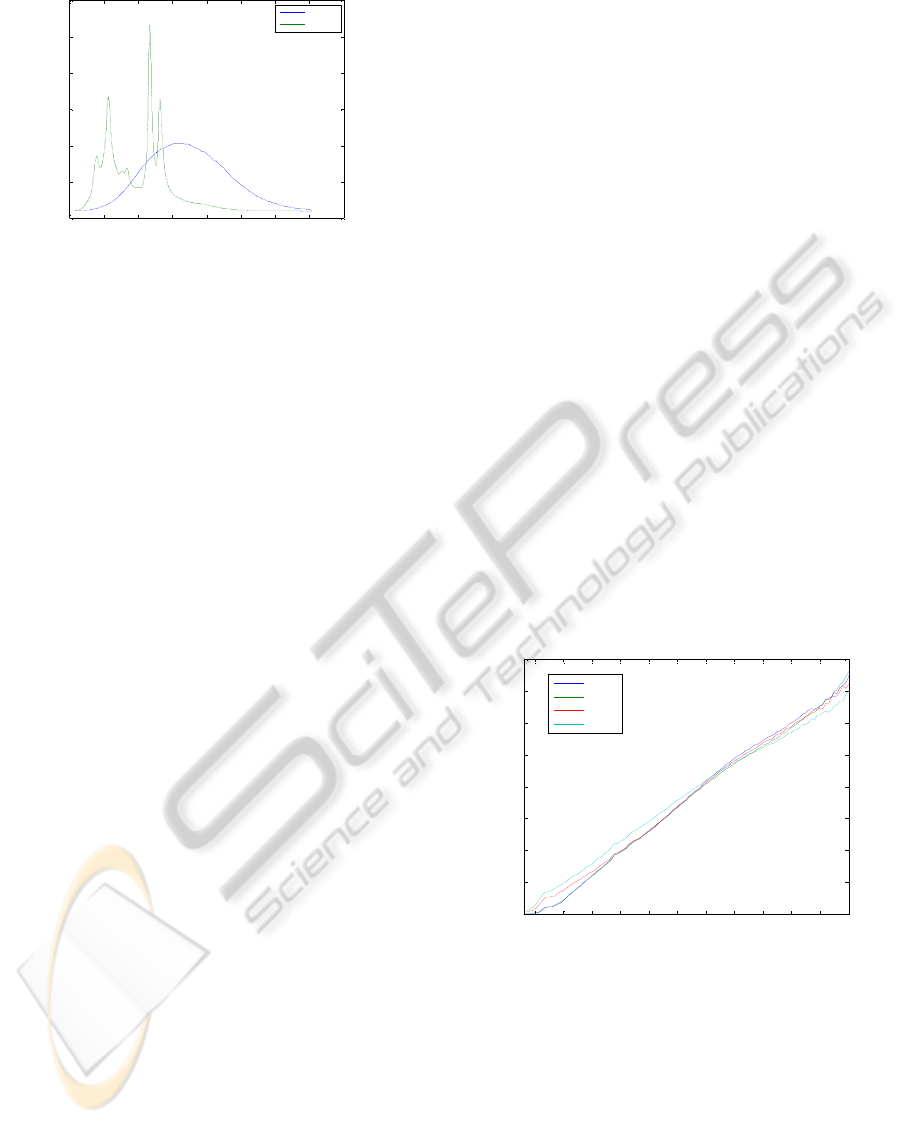

It is critical that our hyperspectral measurement

system has sufficient signal in the blue. The X-Cite

source (Lumen Dynamics, Canada.) is largely

composed of a number of narrowband spectral peaks

and would normally not be considered for spectral

measurements Figure 2. However, by combining it

with the tungsten halogen source and reducing it to

12% of its maximum value, we can extend the

spectral range of the system further into the short

wavelengths without reducing the system’s dynamic

range.

3.2 HS Measurement Setup

The measurement uses a Jai CV M4 CL

monochrome camera, 10 bits, 1380 x 1030 pixels,

with a V10 (150µm slit) Imspector (Specim,

Finland) and a 25mm lens (Electrophysics, USA).

The sample is lit with two 500W tungsten halogen

lamps run from a dc power supply, and a metal

halide light source (Lumen Dynamics, Canada.). The

samples were scanned using a linear stage (National

Instruments, USA) with a longitudinal resolution of

300µm and a lateral resolution of 75µm. Between

300 and 500 frames were captured for each sample

giving raw data sets of between 1 and 2Gb. To

validate the system we imaged a series of colour

standards (Labsphere, USA). Our measurements

conform closely with the published reflectance

curves.

ICPRAM 2012 - International Conference on Pattern Recognition Applications and Methods

552

Figure 2: System response to white standard for tungsten

halogen and xCite light sources.

4 SPECTRAL MEASUREMENTS

4.1 Method

We measure the spectra of small regions

corresponding to both stained and clear wood. The

raw data is corrected for dark noise, as well as the

spatial and spectral inhomogenities of the light

source using the white and dark standards. The

spectrum is heavily oversampled (to a nominal

resolution of 1nm), we downsample this to the

resolution of the CIE standards (5nm). This

significantly reduces the memory requirements of

subsequent calculations. Next the RGB image is

calculated from the HS cube and displayed—the

user then crops the ROI from the image. The

corresponding spatial region is then cropped from

the HS cube and the cube is then normalised at each

pixel by the sum of the spectral intensities at that

pixel. An RGB image is then recalculated and

displayed with the blue channel accentuated. The

user then marks 4 small regions (5pix x 5pix) on the

image. The average spectrum of each region is then

plotted.

4.2 Results

Spectra for selected points on the test sample are

shown below. All the spectra have an almost exactly

linear relationship with wavelength, Figure 3. Most

of the yellow stain spectra are distinguished by

having lower energy in the 400-450nm range than

the clearwood spectra.

Aside from this feature, the spectra are devoid of

distinctive characteristics. This suggests that

techniques such as differentiating the spectra are not

worthwhile and features based on the intensity of the

spectrum at defined wavelengths may be the most

effective approach. This means that a multispectral

rather than hyperspectral system is appropriate for

this data set.

5 SHARPENED RGB

In the previous section it was shown that the 400nm-

450nm region of the spectrum is critical for

detecting yellow stain. We based our first feature on

light reflected from the wood surface after it has

been lit with a metal halide lamp filtered with a blue

glass filter. This feature is measured by the blue

channel of the RGB camera.

Wood is an inhomogeneous material and its

reflectivity varies from latewood to earlywood. An

inspection system must be able to detect yellow

stain, but ignore the intensity variations caused by

the normal structure of the wood. Our second feature

is used to normalise the response of the first feature.

Since we already use the blue channel of the camera,

we must use either the red or green channels for this

second feature. We opted for red to reduce crosstalk

with the blue channel. To obtain this feature the

sample is lit simultaneously by two sources: a

tungsten halogen source, filtered with a red

interference filter and a metal halide source filtered

by a blue filter.

Figure 3: Sample spectra.

A conventional RGB camera is used to image the

scene at a resolution of 640x480 pixels. The

classification algorithm is remarkably simple: a

feature is calculated from the red and green camera

channels and then thresholded to give a classified

image, Figure 4. The results are shown below in

Figure 5. We believe that these results are promising

— especially considering the simplicity of the

classifier.

300 400 500 600 700 800 900 1000 1100

0

2

4

6

8

10

12

x 10

5

Wavelength (nm)

Intensity

Halogen

xCite

400 450 500 550 600 650 700 750 800 850 900 950

0

0.002

0.004

0.006

0.008

0.01

0.012

0.014

0.016

Wavelength (nm)

Intensity

YS 1

YS 2

Clear 1

Clear 2

DETECTING 'YELLOW STAIN' IN WOOD USING SPECTRAL METHODS

553

Figure 4: Sharpened RGB classifier.

Figure 5: Test samples (left) and classification results

(right).

6 CONCLUSIONS

This paper has shown that a colour based

classification of yellow-stain must be based on the

spectral band ranging from 400 to 450nm. We have

developed a lighting system that gives intense

illumination at these wavelengths — these

wavelengths corresponds to the blue channel of the

RGB camera. Wood is not a homogenous material,

and the reflectivity varies from early wood to

latewood. By using narrowband illumination

corresponding the camera’s red channel, we can

normalise the blue channel and obtain a stable

feature for detecting yellowstain. Using a simple

threshold classifier this approach was shown the

detect yellowstain effectively.

ACKNOWLEDGEMENTS

This project was supported within the COMET

Programme by BMVIT, BMWFJ and the federal

provinces of Carinthia and Styria.

REFERENCES

Lampinen, J., Smolander, S. and Korhonen, M., (1995),

Wood Surface Inspection System Based on Generic

Visual Features, Industrial Applications of Neural

Networks, pages 3542. World Scientic Pub. Co.

Kauppinen, H., Silven, O. (1996) The effect of

illumination variations on color-based wood defect

classification, Proceedings of the 13th International

Conference on Pattern Recognition, 25-29 Aug.

pp.828 - 832 vol.3. Vienna, Austria

Lebow, P., Brunner, C., Maristany, A., Butler, D. (1996),

Classification of Wood Surface Features by Spectral

Reflectance, Journal of Wood and Fiber Science,

Volume 28, Number 1 / January, pp.74-90

Jones, P., Schimleck, L., Peter, G., Daniels R., and Clark,

A. (2005) Non-destructive estimation of Pinus taeda L

tracheid morphological characteristics for samples

from a wide range of sites in Georgia, Wood Science

and Technology, Volume 39, Number 7, 529-545,

Maristany, A., Lebow, P., Brunner, C., Butler, D., and

Funck, J. (1992) Classifying wood-surface features

using dichromatic reflection, Proc. SPIE 1836, 56

(1993); Optics in Agriculture and Forestry, 16

November 1992, Boston, MA, USA

Hagman, O., Multivariate prediction of wood surface

features using an imaging spectrograph, (1997)

European Journal of Wood and Wood Products,

Volume 55, Number 6, 377-382,

Marszalec, E. and Pietikaeinen, M., Color analysis of

defects for automated visual inspection of pine wood,

(1993) Machine Vision Applications in Industrial

Inspection, San Jose, CA, USA

Butler, D., Brunner C. and Funck, J., Wood-Surface

Feature Classification Using Extended-Color

Information, (2001), European Journal of Wood and

Wood Products, Volume 59, Number 6, 475-482,

ICPRAM 2012 - International Conference on Pattern Recognition Applications and Methods

554