POSITION/FORCE CONTROL OF A 1-DOF SET-UP POWERED

BY PNEUMATIC MUSCLES

Aron Pujana-Arrese, Kepa Bastegieta, Anjel Mendizabal, Ramon Prestamero and Joseba Landaluze

IKERLAN Research Centre, Arizmendiarrieta 2, E-20500 Arrasate (The Basque Country), Spain

Keywords: Pneumatic muscle, Robotic Arm, Position/Force Control, Hybrid Control, Impedance control.

Abstract: A one-degree-of-freedom set-up driven by pneumatic muscles was designed and built in order to research

the applicability of pneumatic artificial muscles in industrial applications, especially in wearable robots such

as exoskeletons. The experimental set-up is very non-linear and very difficult to control properly. This paper

describes the control of this mechatronic system’s interaction with its environment, controlling both its

position and the force exerted against it. The classic position/force control techniques - hybrid control and

impedance control - have been adapted to pneumatic muscles and applied to the experimental set-up

developed. An alternative solution is also proposed whereby force or torque control is based on the

calculation made by an estimator instead of on direct measurement by a sensor. The article presents a

detailed analysis of the force and torque estimator used to close the control loops in the two position/force

control schemes. Finally, the article concludes by presenting the experimental results obtained and the most

outstanding conclusions of the study as a whole.

1 INTRODUCTION

The group of researchers from the IKERLAN

technology centre working on the development of

mechatronic systems have been involved for the last

three years in the design and construction of an

upper limb IAD (Intelligent Assist Device)

(Martinez, 2007; Martinez, 2008). More specifically,

the device is an exoskeleton for helping the user

carry out routine tasks in the workplace (Figure 1).

One of the requirements established from the start

was to include non-conventional actuators as far as

possible. Among the alternatives studied, artificial

pneumatic muscles were considered to be the most

suitable forms of actuation. In order to study the

applicability of this type of actuators in

biomechatronic systems a 1-DoF experimental set-

up was built, driven by a pair of antagonistic

pneumatic muscles. Initially, a dynamic model of the

pneumatic muscle was created, and then used to

make the full model of the experimental set-up. This

model was experimentally validated (Pujana-Arrese,

2007).

Motivated by the high degree of non-linearity of

the experimental prototype, the authors developed

different solutions for robust control of the system’s

angular position: from a first initial attempt using

basic controllers, to more advanced techniques

achieved such as H

∞

or the non-linear sliding mode

technique (Pujana-Arrese, 2008; Arenas, 2008).

This paper takes a step further as regards control

of the mechatronic system’s interaction with its

environment, controlling not only the position but

also the force exerted against it. An alternative

Figure 1: Exoskeleton ÎKO (IKerlan’s Orthosis) worn by a

dummy.

228

Pujana-Arrese A., Bastegieta K., Mendizabal A., Prestamero R. and Landaluze J. (2009).

POSITION/FORCE CONTROL OF A 1-DOF SET-UP POWERED BY PNEUMATIC MUSCLES.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Robotics and Automation, pages 228-237

DOI: 10.5220/0002208902280237

Copyright

c

SciTePress

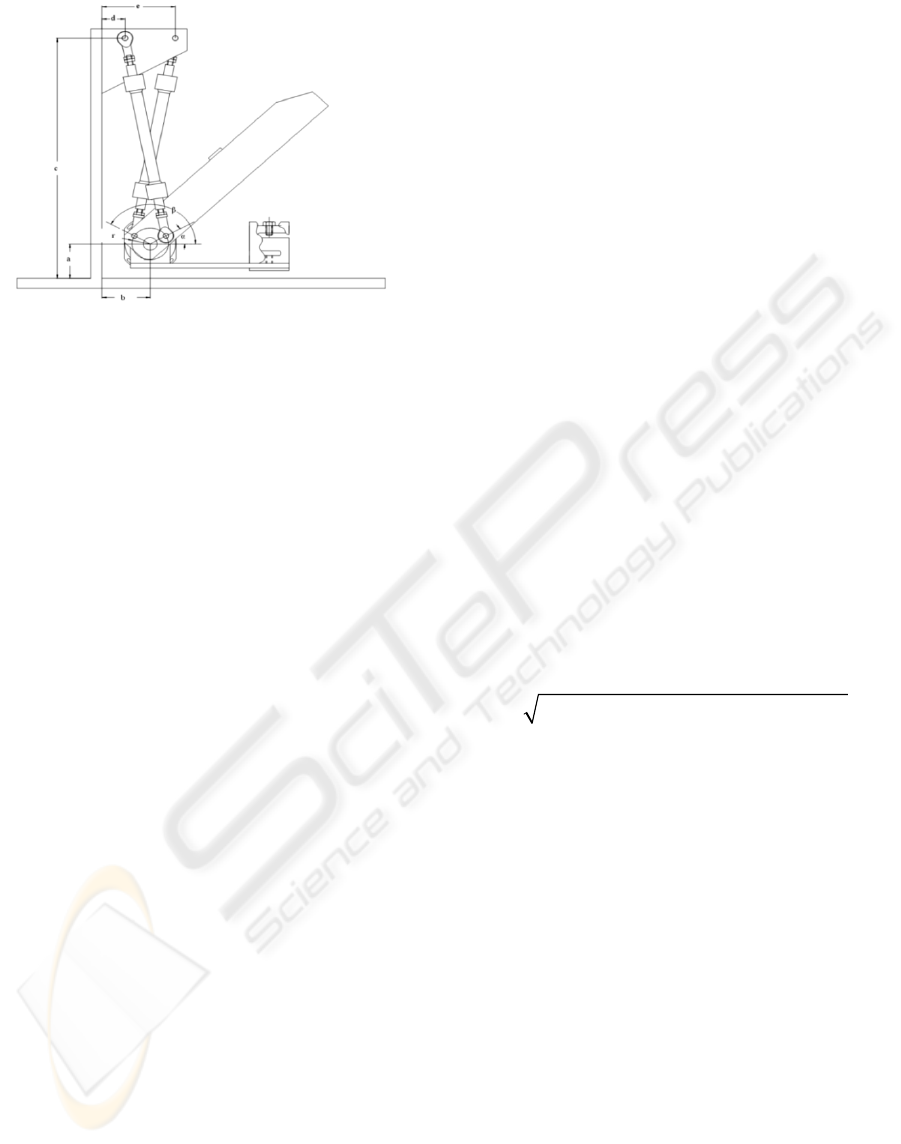

Figure 2: Geometric model of the 1-DoF robotic arm.

solution is also put forward whereby the force or

torque control is based on the calculation made by

an estimator instead of on direct measurement by a

sensor.

A classic, in the field of the position/force

control, is the Hybrid Controller strategy put

forward by Raibert and Craig (1981). The controller

carries out its action using selection matrixes which

establish some spatial directions where position

control must be carried out and some others where

force must be controlled. In this way the force and

position control actions are uncoupled by using the

appropriate treatment of the spatial geometry where

the manipulation task is being carried out. Another

classic strategy is Impedance Control (Hogan,

1985), which does not control the position or the

force but the dynamic relation between the two. This

type of control strategy is deemed to be very suitable

for IADs, although it needs to be adapted depending

on the specific application.

The object of this paper is to present the

algorithms implemented for controlling interaction

with the environment, stressing the fact that an

estimator requiring no direct measurement of either

the torque or the force exerted by the mechatronic

device has been developed for this purpose. The first

point contains a brief description of the experimental

set-up used for this study, and the paper then goes on

to present a theoretical review of the control

techniques most commonly used for these ends:

Hybrid Control and Impedance Control. There then

follows an in-depth analysis of the force and torque

estimator used to close the control loops in both

cases, and there is then a detailed description of the

control diagram used for both the Hybrid Control

and Impedance Control. Finally, the article

concludes by presenting the experimental results

obtained, and the most outstanding conclusions of

the study as a whole.

2 SET-UP DESCRIPTION

A human arm orthosis-type application has been

taken into consideration when designing the set-up.

To this end and albeit with a single degree of

freedom, it was considered that it should allow for

the greatest angular displacement possible, and that

it should be able to transport the greatest mass

possible at the tip (emulating a weight borne by the

hand). On the other hand, however, it needed to be

confined to the length of the pneumatic muscles. In

seeking a compromise between all the specifications,

a displacement of around 60º and a maximum mass

to be moved at the tip of 8 kg were set. By trying to

minimize the length of the muscle required, the

design focused on the mechanism that would enable

the arm and inertias to rotate with good dynamics by

means of the two muscles.

The pneumatic muscle that was chosen was the

DMSP-20-200N manufactured by Festo. Figure 2

and Figure 3 show the resultant mechanism and a

picture of the prototype. The parameter values that

define the mechanism are:

a=5 mm; b=85 mm; c=491 mm; d=40.6 mm

e=129.4 mm;

α

=0º-60º;

β

=120º-180º; r=32 mm

From these values the distance L (mm) between

the ends (joining points of the mechanism) of the

pneumatic muscles is:

175059 2841.6 cos 26624 sinL

αβ

=+⋅−⋅

When the muscles are without pressure, the

distance L is of 423 mm, with the length of the

muscle fibre being 200 mm. The centre of the arm

mass with regard to the centre of rotation is at a

height of 17.6 mm and at a horizontal distance of

205 mm, considering that the arm is in the horizontal

position. The arm mass is 0.987 kg. The centre of

the additional masses placed on the end of the arm

would be at a height of –24 mm and at a horizontal

length of 367 mm with regard to the centre of

rotation, always bearing in mind that the arm is in

the horizontal position. The set-up may be rotated so

that the arm moves in a horizontal plane and the

effects of gravity are therefore cancelled out. The

prototype (Figure 3) includes a FAGOR S-D90

encoder, which supplies 180,000 pulses per turn, and

a load cell on the lower stop of the model.

The schematic diagram of the set-up, which

includes the control hardware, sensors and

pneumatic circuit, is shown in Figure 4. As the

figure shows, two Festo MPYE-5-1/8HF pneumatic

servo-valve are used for actuation, each linked to

POSITION/FORCE CONTROL OF A 1-DOF SET-UP POWERED BY PNEUMATIC MUSCLES

229

Figure 3: Picture of the experimental set-up.

one pneumatic muscle and controlled independently

by the controller. The controller hardware is PIP8,

an industrial PC made by the company MPL, which

is very similar to The MathWorks’ xPCTargetBox.

A PC104 card (Sensoray model 526) was

incorporated into the PIP8 in order to read and write

all the system signals. Control algorithms were

implemented in Simulink and code was generated

and downloaded in the aforementioned hardware by

means of two of The MathWorks’ tools: RTW and

xPCTarget.

3 POSITION/FORCE CONTROL

ALGORITHMS OVERVIEW

Research into pneumatic muscles has been carried

out considering them as orthosis actuators. And an

orthosis, or exoskeleton, is a wearable robotic

device. In an initial approach, the basic control of an

orthosis-type device can be considered to be based

on position control, where the user creates the

movement set-point and closes the loop aided by the

human body’s own sensors. Detecting the user’s

intention and creating the movement set-point on the

basis of this is a key element. Another very

important factor to be taken into account is the

interaction with the environment, whether from the

perspective of controlling the force exerted so as not

to cause damage to persons within the robotic

device’s field of action, or because the device is

being used as a force augmentation system. From

this point of view, its functioning is similar to that of

a robotic manipulator. There are two classic

position/force schemes for robotic manipulators:

hybrid control and impedance (or admittance)

control. These schemes have been considered valid

for the case of an arm orthosis, although they have

some special characteristics that must be taken into

account when the actuators are pneumatic muscles.

Figure 4: Schematic diagram of the set-up and pneumatic

circuit.

3.1 Hybrid Position/Force Control

Hybrid control is a conceptually simple method for

controlling both the position and the contact force

generated at the tip of a manipulator during a task

involving restricted movement. The method does not

specify any feedback control law for regulating the

errors, but rather a control architecture in which any

position and force control techniques can be

considered. The principle of hybrid control is based

on the idea that each manipulation task can be

described by specifying a set of contact surfaces.

These surfaces serve to detail the restrictions

existing in the system, which may be either natural

or artificial.

The natural restrictions are connected with the

system’s particular mechanical and geometrical

characteristics. Artificial restrictions, on the other

hand, are connected with the control task objectives,

and are specified in terms of position or force

parameters.

Natural and artificial restrictions are defined

within the space of the task, not within the space of

the actuations. One natural and one artificial

restriction may be specified for each degree of

freedom of the task. In general, taking the task

geometry into account, it is not difficult to determine

the natural restrictions existing and decide on the

most suitable way of dividing the space of the task

on the basis of these.

For the case of an orthosis, normally mixed

exercises are performed, which consist of both

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

230

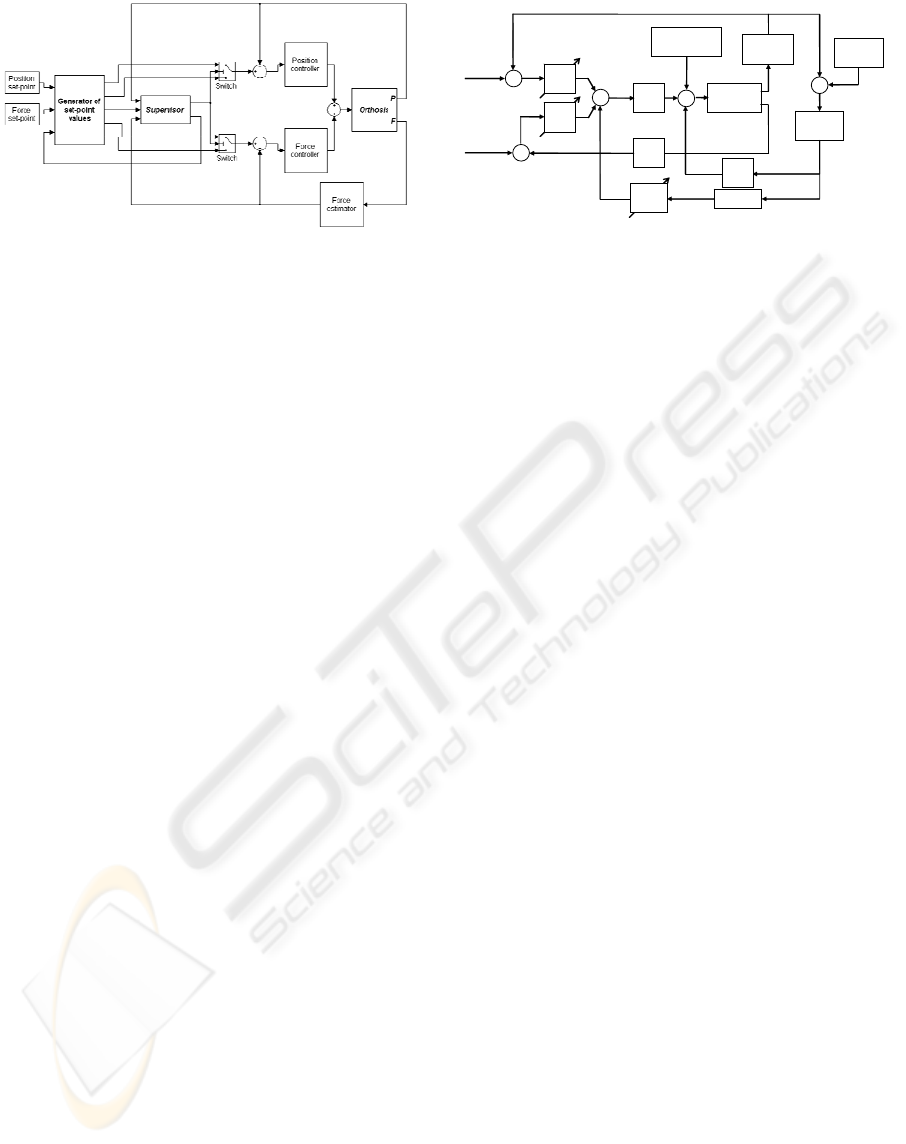

Figure 5: Structure of the hybrid position/force controller.

stages of free movement and stages of restricted

movement. The restricted movement part can be of

much less importance than in the case of a robotic

manipulator, any may simply consist of a force

control loop, which does not necessarily have to act

at the same time as the position control in other

directions. In any case, a supervisor, able to switch

between the different configurations of the

manipulator and the corresponding control laws, is a

key element. A supervisor of this type must pay

special attention to the impact between the

manipulator and the environment, and to its

separation.

Figure 5 shows a diagram of position/force

hybrid control valid for both an orthosis and the 1-

DOF set-up used to analyse the specific case of the

pneumatic muscles. It basically consists of two

independent controls, one for position and the other

for force, and a supervisor that switches between one

control type and another depending on the contact

with the environment. The supervision is based on

the information on the force exerted, which may be

provided by a force sensor or an estimator. The

supervisor, at the same time as the set-point

generator, makes the transition between the

controllers in a soft manner, to prevent rebounds and

to assure the system’s stability.

As already mentioned, the hybrid control scheme

does not impose the control techniques that are used

for the position controller and for the force

controller.

3.2 Impedance Control

Impedance control is another classic force control

scheme, and it is of great interest in the case of

orthoses. It does not require a supervisor and it is

able to take on the control of a composite task, with

free and restricted movement stages, maintaining the

system’s stability without changing the control

algorithm. It is based on the idea of controlling the

dynamic relationship between the force and position

ORTHOSIS

Kinematic

transformation

J

t

Senso

r

K

f

τ

θ

θ

X

F

int

X

e

·

+

_

+

_

Inertial, gravitational

and friction effects

J

-1

K

p

K

v

δ

X

X

D

+

_

+

_

V

D

+

+

J

δ

V

_

+

Environment

position

Stiffness

Figure 6: Structure of the impedance controller.

variables of the physical systems. It is presumed that

in any manipulation task the environment contains

inertias and kinematical restrictions, i.e. systems

accepting forces as input and responding by means

of displacements (admittances). The manipulator in

contact with the environment must accordingly

behave as an impedance and respond with a

determined force to the displacement of the

environment. The general strategy may be

established in terms of controlling a movement

variable and at the same time providing the

manipulator with a disturbance response in the form

of impedance. Thus, the interaction between the

manipulator and its environment can be modulated

and controlled by acting on the impedance values.

In impedance control, the functional form of the

torque of a manipulator’s actuators is well-known:

where each line of the second member represents a

contribution of a different nature to the total torque.

The first line corresponds to terms dependent on the

position, the second to terms of speed, the third to

terms of force, and the fourth to terms of inertial

coupling. Within the field of the actuations, this

equation expresses the behaviour that the controller

should be able to induce in the manipulator, in the

form of a non-linear impedance. The input variables

are the desired Cartesian positions and speeds, and

the terms – linear or not – that specify the required

dynamic behaviour, characterised by the magnitudes

M, B, and K. Figure 6 shows the typical impedance

control structure for a robotic manipulator or for an

orthosis, in which the feedback gains of the position,

speed and force loops, K

p

, K

v

and K

f

respectively,

depend on the reference inertia and mass tensors and

on the values designed for stiffness, K, and damping,

B, and they are deduced from the control law (1).

[]

11

act 0

11 1

0

11 t

int int

1

() () () ()

()J () () ()

() () ()

() () (, ) (, )

IJ MKXL S

IMBVJ V

IJ MF J F

IJ G C

τθθ θθ

θθ θω ω

θθ θ

θθθω θω

−−

−− −

−−

−

=−

⎡⎤

+−

⎣⎦

+−

++

+

+

(1)

POSITION/FORCE CONTROL OF A 1-DOF SET-UP POWERED BY PNEUMATIC MUSCLES

231

The force feedback F

int

, based on a measured

force or estimated force, has the effect of changing

the apparent inertia of the manipulator. However, the

impedance control scheme can also be applied

without a sensor or force estimator. In this case the

force is not explicitly controlled, but, depending on

the impedance values used in the controller design,

the force the system exerts on the environment is

limited.

4 TORQUE/FORCE ESTIMATOR

As already mentioned in the introduction, on most

occasions different sensors are used to directly

measure the force or torque exerted by the actuators

in order to control the interaction between the

mechatronic system and its environment

(Tsagarakis, 2007; Jia-Fan, 2008).

This paper puts forward the idea of carrying out

the control of the interaction between a mechatronic

system driven by pneumatic muscles and its

environment without any direct measurement at all

of either the torque exerted by the pneumatic

actuators or the force exerted by the arm. The torque

and force are calculated on an estimated basis from

the angular position of the arm and the pressures on

the pair of muscles, as set out in the ensuing

paragraphs.

The force exerted by each muscle can be

modelled on the basis of its contraction and interior

pressure according to equation (2) (Pujana-Arrese,

2007).

/

·

/

·

/

/

/

(2)

w here

··

·

·

(3)

q is the contraction of each muscle (up and down), P

is the pressure exerted on each muscle, and the

parameters D

1

, D

2

, D

3

, a, b, c, d and e are constants

obtained from empirical tests for characterising the

behaviour of the muscles (Pujana-Arrese, 2007).

To calculate muscle contraction, trigonometric

formulas are used to relate this contraction with the

angle formed between the arm and the vertical

(Figure 2). The torque exerted by the combination of

the two pneumatic muscles

can thus be

deduced as:

··sin

2

2

·

·sin

2

2

(4)

where F

up

is the force exerted by one pneumatic

muscle, F

down

is the force exerted by the other

pneumatic muscle, and r is the distance between the

rotation point and the lower joining points of the

pneumatic muscles. The angle of the arm with

respect to the vertical is designated as θ, while θ

top

and θ

down

are the angles corresponding to the

physical limit stops of the prototype. α

up

is the angle

formed with respect to the horizontal by the muscle

designated as up, while α

down

is the angle formed by

the other muscle with respect to the horizontal.

Despite the good results obtained on simulation,

the experimental tests showed lack of accuracy of

the estimated value with regard to the torque

actually exerted by the muscles. The main reason for

this is that equation (2) does not contemplate

hysteresis, which is a feature of the pneumatic

muscles. The error assumed on ignoring the effects

of hysteresis means the estimator is not applicable in

cases where the arm moves freely. However, when

the arm is blocked by collision, the pressures, and

consequently the torque, increase in such a way that

the measurement error is not critical.

In order to obtain an estimator that behaves

correctly for free movement, with the system

moving at low torque values, a development based

on Newton’s laws of motion is proposed. This new

estimator calculates the torque by means of equation

(5), which is in fact the development of Newton’s

sec nd lao w of motion.

··

·

sin

.

··

·sin

·

(5)

where m is the mass of the arm, L the distance

between the rotation point and the arm’s centre of

gravity, θ the angle between the arm and the vertical,

β the angle between the rotation point and the centre

of gravity, and I

o

its inertia on the rotation point. N is

the number of extra masses placed on the tip, and m

p

is the weight of each mass (N⋅m

p

thus represents the

mass placed at the tip of the arm).

This torque estimator functions correctly but has

two negative aspects. The first is that if the structure

has two or more degrees of freedom instead of one,

calculating the equation becomes rather

complicated. The other aspect is that if any kind of

interaction is produced with the environment, e.g. a

collision, when the arm movement is blocked

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

232

equation (5) is no longer of use for estimating the

torque exerted by the actuators.

Knowing that the torque estimator based on

Newton’s law of motion calculates the torque

correctly in the case of free movement, and that the

moment evaluated by the torque estimator based on

the muscle pressures can be acceptable when an

interaction occurs with the environment, it was

decided to create a hybrid torque estimator. This

hybrid estimator requires some kind of observer to

indicate whether an interaction with the environment

has occurred, so that the desired estimator can be

selected at each time. In short, when free movements

are made the estimator used will be the one based on

Newton’s laws (

), and in the case of limited

movements or interactions with the environment the

estimator used will be the one based on the pressures

of each muscle (

), switching between them

where necessary.

The switch between the torque estimator and the

force estimator is practically instantaneous: all that

is needed is to apply ation (6): next equ

Where

is equal to

in the case of no

interaction with the environment, or equal to

if

there is a collision. l is the distance between the

rotation point and the tip of the arm on which the

force is to be calculated.

(6)

5 HYBRID POSITION/FORCE

CONTROL OF THE SET-UP

Figure 5 shows a diagram of the Hybrid Control

implemented. It basically consists of a supervisor

block that switches between position control and

force control according to the status of the

interaction between the arm and its environment (in

this case, the lower limit stop). The position control

is thus carried out separately from the force control,

i.e. the system is controlled by the position

algorithm until the supervisor block detects that a

collision has occurred. When this happens, it

switches between the controls as soft as possible,

activating the force control.

5.1 Position Control Algorithm

The hybrid control structure enables different,

independent algorithms to be implemented for

position and force control. In the last few years the

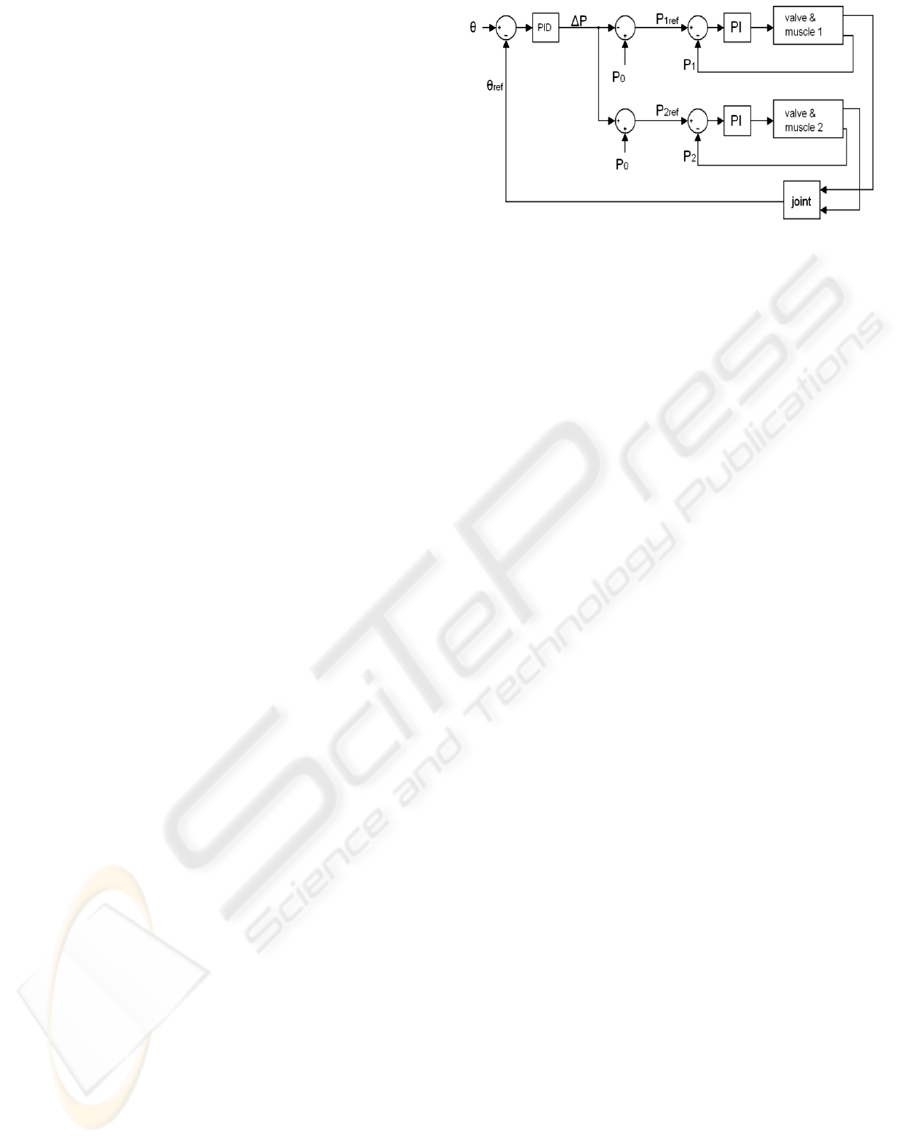

Figure 7: Diagram of the internal pressure loops based

position control algorithm.

authors have conducted research into the position

control of this same experimental device.

Owing to the fact that the results obtained with a

classical PI controller were not good, due to its high

non-linearity, other advanced control techniques

were applied in order to correctly control the angular

position. Firstly, a PID-based controller was

enhanced with linear and non-linear internal loops.

However, good performance requires the use of

robust or non-linear control techniques (Thanh,

2006; Balasubramanian, 2007) and in this context,

the application of different control techniques is

found in the literature. Therefore, a robust linear

control technique H

∞

(Pujana-Arrese, 2008), and a

robust non-linear technique, sliding-mode (Arenas,

2008), were applied.

Subsequently, based on an idea applied by

Tsagarakis and Caldwell (2007), a new position

controller was developed based on an internal

pressure loop for each muscle. This new position

algorithm requires the use of one servo-valve for

each pneumatic muscle instead of one single valve

for each DoF, as used with the position algorithms

that were designed and implemented previously.

Although this new solution initially doubles the

variables that have to be controlled for each degree

of freedom, it can be considered as a single-variable

approach for each joint. Based on the symmetrical

co-contraction of the opposing muscles, an

asymmetrical variation is set in the pressure of each

muscle. Thus, based on an initial pressure (P

0

) the

setting is increased in one of the muscles and

redu ed b nt ( ther. c y the same amou ΔP) in the o

∆;

∆

(7)

Accordingly, from the control point of view, the

position control problem is still SISO with the

angular position of the joint (θ) as the output and the

pressure variation (ΔP) as the input.

Figure 7 shows the position control schematic

based on the internal loops that control the pressure

POSITION/FORCE CONTROL OF A 1-DOF SET-UP POWERED BY PNEUMATIC MUSCLES

233

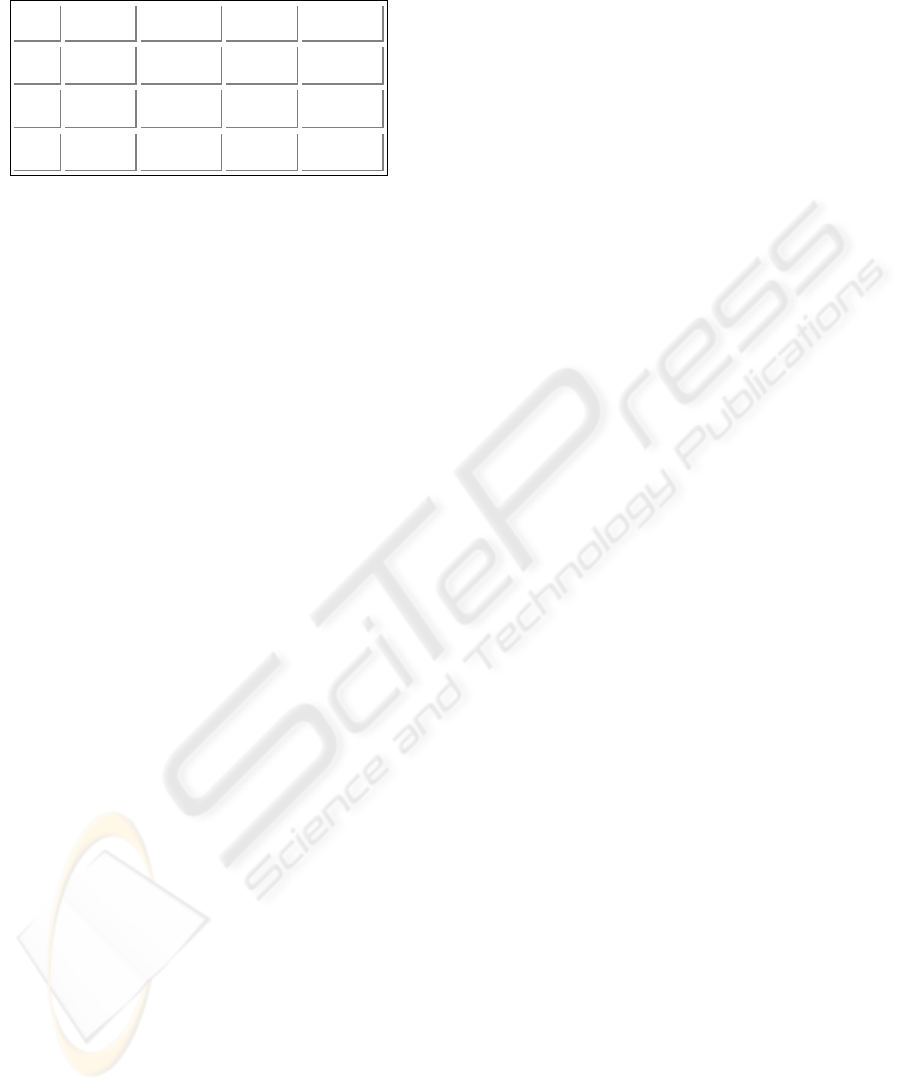

Table 1: Force PID parameters for the different impact

points.

64.8º 48.2º 37.5 27.2º

K

p

0.045 0.025 0.03 0.025

K

i

0.05 0.05 0.03 0.04

K

d

0.002 0.0002 0.001 0.0005

in each muscle, implemented by means of PI

algorithms. As it has been already mentioned, the

pressure set-point for each controller is set on the

basis of an initial value (P

0

), adding and subtracting

the same quantity (ΔP). The value of this

increase/reduction is the output of the most external

loop of the controller (the position loop). This loop

has also been implemented by means of a PID

algorithm. The gains of both pressure loops were

adjusted to the values K

p

=4, K

i

=4, and the gains of

the position loop to K

p

=0.21, K

i

=1.2, K

d

=0.04, being

P

0

=3 bar.

The experimental results for the hybrid

position/force control shown later in this paper were

obtained with the position algorithm based on the

internal pressure loops tuned for a nominal load of 3

Kg placed at the tip.

5.2 Force Control Algorithm

Whereas direct measurement with the encoder

located on the axis is the procedure used for position

control, the value calculated by the force estimator is

used to close the force control loop. The reaction of

the device to any impact can thus be controlled

without requiring the use of a sensor at the exact

point of collision.

Unlike the case with position control, simulation-

based tests confirm that to control the force correctly

it is not necessary to design such complex

algorithms. Also, the specifications of orthosis-type

devices are much more restrictive for position

control than they are for force control, in which it is

normally sufficient for the force to be limited in the

case of an inopportune collision.

The algorithm implemented is simply a PID

tuned for a nominal load of 3 Kg. In any case, due to

the non-linearity of the system, the response varies

depending on the angular position in which

switching between position control and force control

occurs. With the aim of obtaining a more uniform

response, four points distributed over the whole

range of movement of the metal arm were selected.

These five points divide the movement of the system

into five different zones. By means of impacts

applied to these points, four different PID algorithms

were tuned. Finally, a gain scheduling type strategy

was implemented, which linearly combines the

outputs of the two PIDs delimiting the zone in which

the collision occurs.

Table 1 shows the PID algorithm parameter

values for each of the points expressed according to

their angular situation with respect to the vertical

plane.

6 IMPEDANCE CONTROL OF

THE SET-UP

The classic impedance control formulation is based

on the hypothesis that the actuation system is able to

supply the torque required by the control algorithm,

i.e. the impedance control output is the torque set-

point for the actuator. This hypothesis is not so

evident in the case of one degree of freedom

actuated by means of an antagonistic pair of

pneumatic muscles. Tsagarakis (2007) puts forward

the same algorithm based on the independent

pressure loops used for controlling the angular

position, which, as can be observed in Figure 7, is

the one that has been implemented. As explained

above, the scheme has two separate PI controllers

for controlling the internal pressure of each muscle

and an external loop governed by a PID, which in

this case serves to close the torque loop. Logically,

the tuning of the pressure loops is the same as in the

case of the position control, i.e. K

p

=4, K

i

=4, while

the optimum values for the torque loop gains are

K

p

=0.12, K

i

=0.6, K

d

=0.0024.

The impedance control strictly speaking was

implemented by adapting the general control law (1)

to the experimental prototype presented in this

study. The first step was to obtain a dynamic model

of the system. In the field of robotics there are

several methodologies for system modelling

(including those of Newton-Euler and Lagrange-

Euler), but in this case, given the mechanical

simplicity of the prototype, the model was obtained

by means of the physical equations.

First of all, the forces acting on the system

needed to be identified. The intervening forces are

the force of gravity and the two forces exerted by the

pneumatic muscles. One of the muscles pulls

upwards while the other pulls downwards. The

resulting torque is the difference between them:

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

234

·

(8)

where is the inertia of the body. When the existing

forces had been established, the dynamic model was

obtained by applying Newton’s second law for the

rotationa ovements: l m

·

···sin

(9)

where m is the mass of the arm, θ the angle between

the vertical and the arm, and L the distance between

the centre of gravity and the rotation point. Finally,

x

g

and y

g

are the coordinates of the centre of gravity

with respect to the rotation point.

To fully complete the dynamic model of the

system, all that remains is to calculate the inertia .

The inertia of the arm with respect to its centre of

gravity should be calculated (10), and transformed

with respect to e rotation point by means of

Steiner’s the r

th

o em (11).

12

·

·

(10)

(11)

where l is the length and a the width of the arm, d is

the distance between the rotation point and the

centre of gravity, and m the mass of the arm.

It has not been taken into account up to now that

plates with extra weight can be placed on one end of

the arm. To do this, the terms corresponding to the

extra masses should be inserted in the dynamic

model.

·

···sin

·

··

·sin

·sin

(12)

where N is the number of extra masses, m

p

the

weight of each extra mass, L

p

the distance between

the centre of gravity of the extra weights and the

rotation point of the arm, and x

p

and y

p

are the

coordinates of the centre of gravity of the extra

weights with respect to the rotation point.

The next step is to establish the reference

impedance (13). In this case, the parameters K, B

and M are not matrixes but merely parameters

simp thelifying tuning process.

(13)

Figure 8: Experimental results in the intermediate

displacement zone.

The impedance control law (14) to be applied,

which is a simplified form of the general law (1), is

obtained by equalling the term of the angular

acceleration i (1n 3).

·

·

·

(14)

If the control law is analysed, apart from the

parameters to be tuned (K, B and M), it can be

observed that there is a term,

, which is the

torque measured when the arm interacts with the

environment. This torque can be the estimated

torque, as described for the hybrid control, but it is

not essential in the control law. This term was not

used in the law implemented, as the results were

analogous.

represents the static part of the

idynam c equation (12).

···sin

·

·

·

·sin

(15)

As can be observed, it is dependent on the mass

at the tip, and it is therefore not robust to mass

change. However, this mass can be estimated during

the free movement phase. The design parameters K,

B and M were experimentally adjusted and the

following values were obtained: K=3.1, B=0 and

M=0.5.

To close the torque loop, the most common

procedure is to use the direct reading by means of a

torque sensor placed on the actual rotation axis, as

done by Tsasarakis (2007) and Jia-Fan (2008).

However, as described in section 4 of this paper, an

estimator was used to calculate the torque exerted by

the antagonistic pair of muscles from the reading of

their position and their internal pressures.

0 1 2 3 4 5 6 7 8 9 10 11 12

36

38

40

42

44

46

Time[s]

Angl e[º]

Set-point

Hybrid Control

Impedance Control

POSITION/FORCE CONTROL OF A 1-DOF SET-UP POWERED BY PNEUMATIC MUSCLES

235

1 2 3 4 5 6 7 8 9 10

55

56

57

58

59

60

61

62

Time[s]

Angle[º]

Position set-point

Hybrid Control

Impedance Control

1 2 3 4 5 6 7 8 9 10

0

10

20

30

40

50

Time[s]

F[N]

Force set-point

Hybrid Control

Impedance Control

Figure 9: Position responses during a collision. Figure 10: Estimated force responses during a collision.

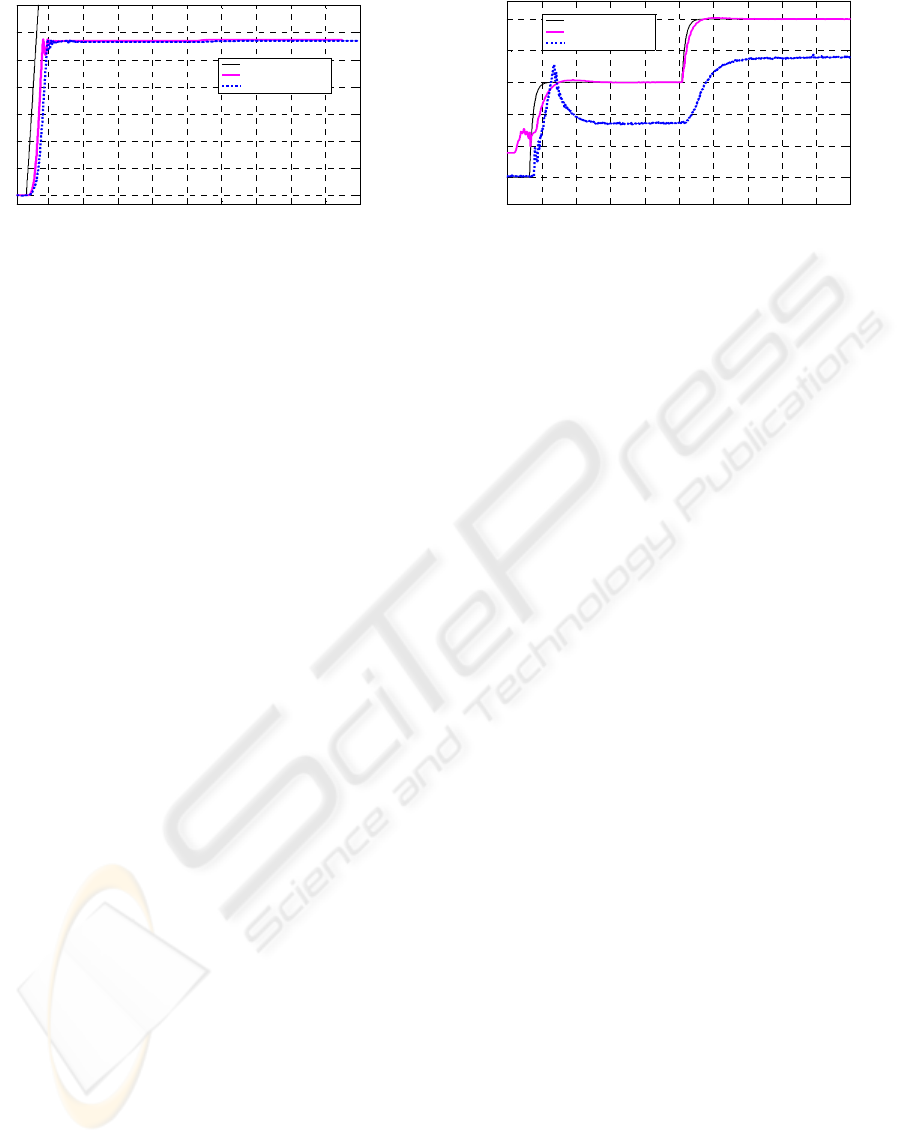

force executed by the pneumatic muscles against the

lower limit stop when the collision happens. In fact,

during the collision, controllers are not comparable

to each other. Hybrid control carries out the tracking

of a force set-point whereas the reaction force of the

impedance control is proportional to the error

between the position set-point and the collision

point. Force set-point for the hybrid control is 30 N

for the first 5 s and then increases up to 50 N. After

some initial disturbances due to the impact and the

commutation between the controllers, the estimated

force increases smoothly until it reaches the set-

point. This response could be faster, but the

parameters were tuned to achieve an acceptable

force control with a weight placed in the tip within

the range of 0 to 6 Kg. In the impedance control the

influence of the collision is lower, and after an initial

peak the estimated forced is limited. After the first 5

s position set-point increases, and the control reacts

to this rise increasing the torque as it is shown in the

graph of the force.

7 EXPERIMENTAL RESULTS

Initially, controllers were tuned by simulation, using

the non-linear model previously developed (Arrese-

Pujana, 2007). Continuous-time controllers were

discretized with sample time of 2 ms and then

embedded into the control hardware.

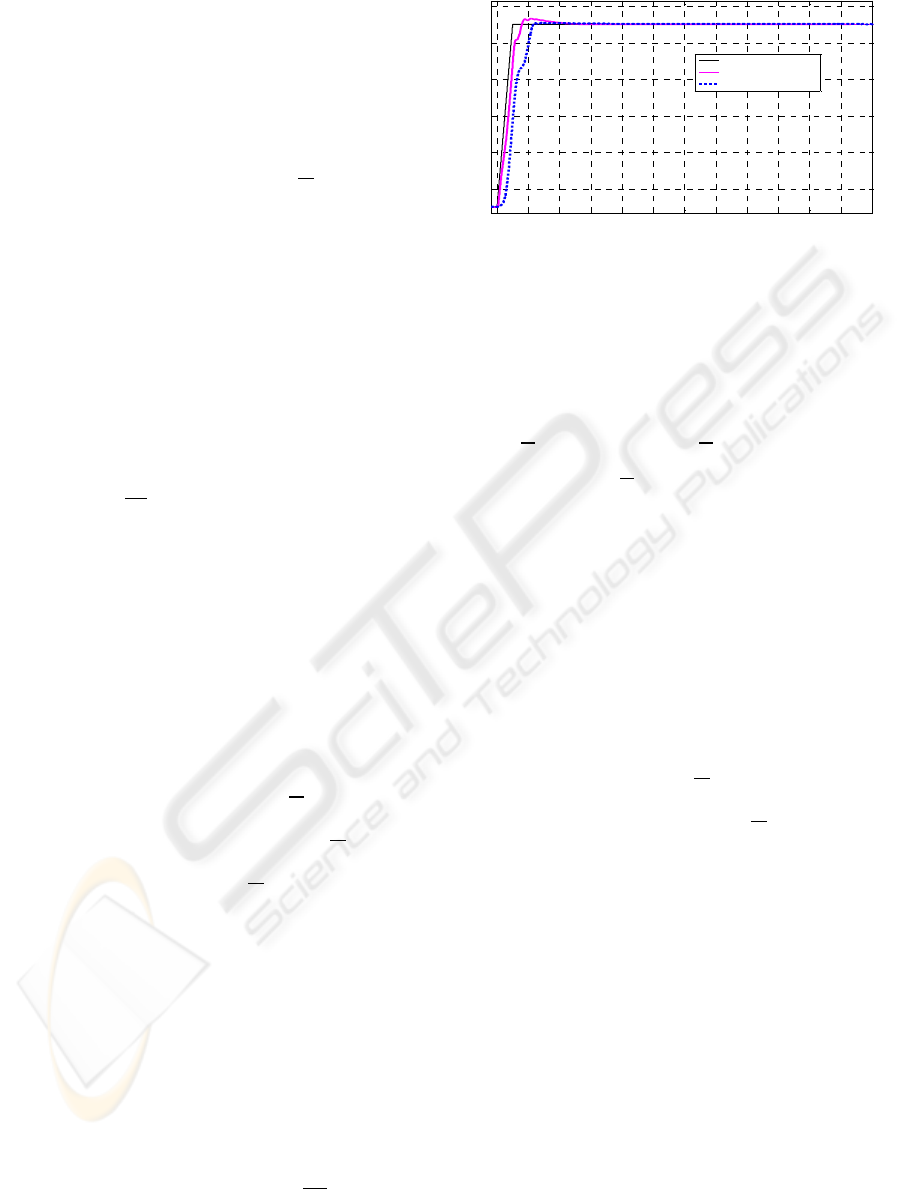

With the objective of comparing the behaviour of

both control techniques, Figure 8 shows the

experimental response to a position step of 10º with

a slope of 20º/s. This input signal has been applied

to the intermediate zone within the motion range.

Moreover, the arm has been loaded by attaching in

its tip a weight of 3 Kg. This trial has been carried

out in free movement without any collision with the

environment.

The decoupling between the position and the

force permits to adjust the hybrid control, thus it is

possible to obtain a very fast position response

which is almost identical in all the zones with a very

little overshoot. Impedance control is not used to

control explicitly the position, so, its response is

more conservative because the same control law and

the same tuning are used to control both the free

movements and the collisions with the environment.

Regarding the steady state error, both algorithms are

able to eliminate it.

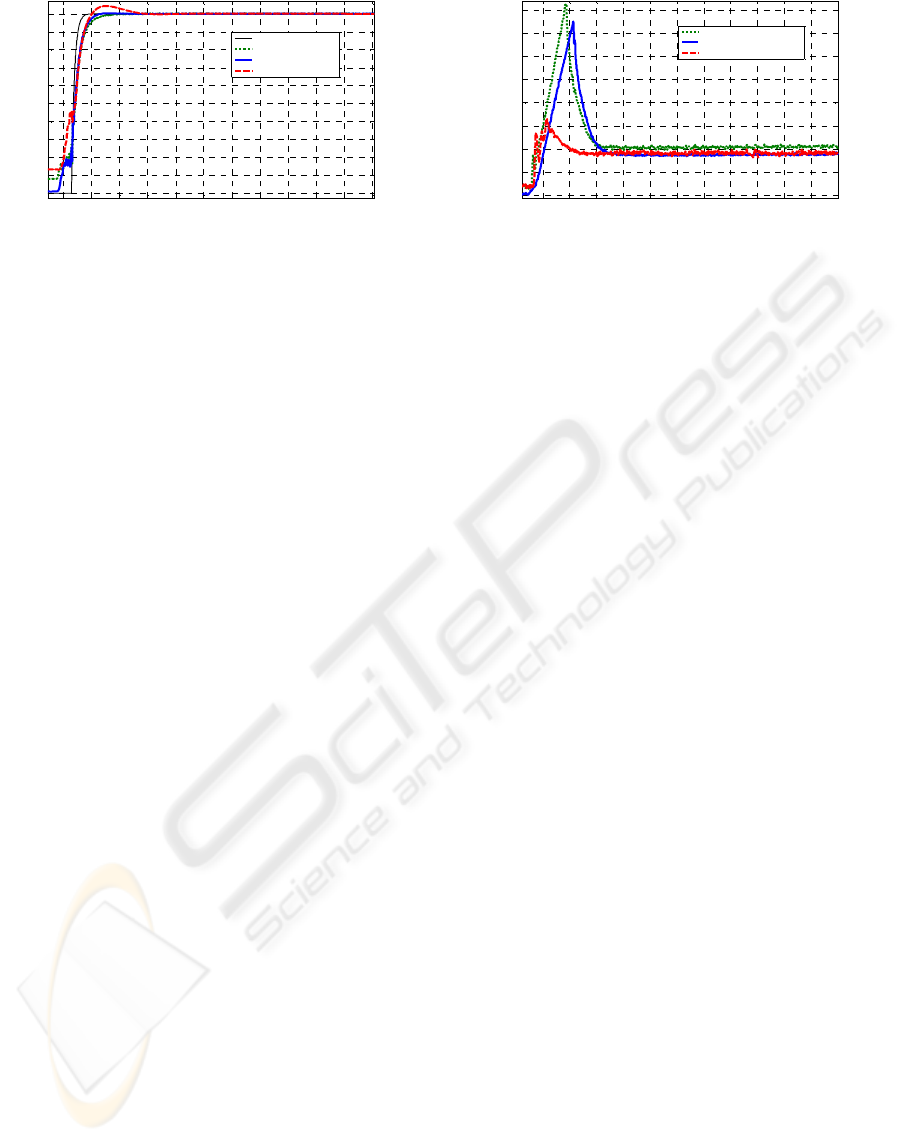

The robustness of the controllers can be tested by

changes in the weight placed at the extreme of the

arm. In Figure 11 it can be observed that the tuning

performed for the hybrid controller is suitable to

manage collisions with different loads within the

range 0 to 6 Kg, although in the upper limit of the

range (with 6 Kg) a minor overshoot happens.

Hybrid control offers a robust behaviour in free

movements as well.

The trial showed in Figures 9 and 10 was

performed in order to study the behaviour of both

controllers with collisions. In this case, the arm is

initially 55º away from the vertical plane and it is

generated an ascendant position set-point with a

slope of 20º/s. The lower limit stop was located at

61.5º, so when the arm tries to track the set-point

and reaches this position a collision happens.

Analyzing the dynamic of the position response

(showed in Figure 9) it can be observed that the

rebound happened after the collision has bigger

amplitude with the hybrid control, due to the

commutation between the position control and the

force control. Figur 10 shows the estimate of the

Impedance control does not offer a robust

behaviour with changes in the load. In fact, the

algorithm (14) needs to specify the weight of the

mass placed at the extreme of the arm. To solve this

problem, it was developed an initialization function

which it is used to carry out a set of free movements

are useful to estimate the extra weight. Thus, the

control systems can work autonomously. Once the

extra weight is estimated the results showed in

Figure 12 are obtained for different tip masses

during a collision and maintaining the same control

parameters.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

236

Figure 11: Estimated force response with different tip

masses for hybrid control.

Figure 12: Estimated force response with different tip

masses for impedance control.

8 CONCLUSIONS

This article is a study about the control issue of the

interaction with the environment of a 1-DOF

experimental set-up powered by pneumatic muscles.

Due to the non linear behaviour of this kind of

actuators the control of the mechatronic device is

very complex both in free movements and when it

comes into contact with an obstacle, having a

different response depends on the movement zone or

the position where the impact occurs. Moreover, the

possibility of loading the extreme of the arm with

extra weight requires using robust algorithms. The

main contribution of this paper is the design and

implementation of a torque/force estimator which is

used to close the control loops. In spite of having a

structural error derived from the equation used to

model the force of the muscles, this inaccuracy only

appears when the arm impacts with an obstacle and

this is not critical because the dynamic is not

affected.

ACKNOWLEDGEMENTS

The material used in this paper was partly supported

by the Spanish Ministry of Education and Science

and European FEDER Fund (research project

DPI2006-14928-C02-01).

REFERENCES

Thanh, T-D.C., Ahn, K.K.,2006. Nonlinear PID control to

improve the control performance of 2 axes pneumatic

artificial muscle manipulator using neural network. In

Mechatronics, no. 16, pp. 577-587.

Balasubramanian, K., Rattan, K.S., 2005. Trajectory

tracking control of a pneumatic muscle system using

fuzzy logic. In NAFIP’2005, Annual Meeting of the

North American Fuzzy Information Precessing Society.

Pujana-Arrese, A., Riaño, S., Arenas, J., Martinez-

Esnaola, A., Landaluze, J., 2008. H

∞

position Control of

a 1-DoF Arm Powered by Pneumatic Muscles. In the 8

th

Portuguese Conference on Automatic Control

CONTROLO’2008, 21-23 July 2008, Vila Real, Portugal.

Arenas, J., Pujana-Arrese, A., Riaño, S., Martinez-

Esnaola, A., Landaluze, J., 2008. Sliding-mode

Position Control of a 1-DoF Set-up based on

Pneumatic Muscles. In UKACC Control Conference

CONTROL2008, 2-4 Setember 2008, Manchester.

Tsagarakis, N.G., Caldwell, D.G., 2007. A compliant

exoskeleton for multi-planar upper limb physiotherapy

and trining. In ICAR'07, The International

Conference on Advanced Robotics, 21-24 August

2007, Jeju Island, Korea.

Martinez, F., Retolaza, I., Lecue, E., Basurko, J.,

Landaluze, J., 2007. Preliminary design of an upper

limb IAD (Intelligent Assist Device). In the 9th

European Conference for the Advancement of Assistive

Technology, AAATE 2007, October 3rd-5

th

, Donostia.

Martinez, F., Retolaza, I., Pujana-Arrese, A., Cenitagoya,

A., Basurko, J., Landaluze, J., 2008. Design of a Five

Actuated DoF Upper Limb Exoskeleton Oriented to

Workplace Help. 2008. In IEEE International

Conference on Biomedical Robotics and

Biomechatronics, IEEE BioRob 2008, 19-22 October

2008, Scottsdale, Arizona, U.S.A..

Pujana-Arrese, A., Arenas, J., Retolaza, I., Martinez-

Esnaola, A., Landaluze, J., 2007. Modelling in

Modelica of a pneumatic muscle: Application to

model an experimental set-up. In the 21st European

Conference on Modelling and Simulation ECMS2007,

4-6 June 2007, Prague.

Raibert, M.H., Craig J.J., 1981. Hybrid Position/Force

Control of Manipulators. In Trans. of the ASME, vol. 102.

Hogan, N., 1985. Impedance Control: An Approach to

Manipulation : Part I - Theory. Part II - Implementation.

Part III – Applications. In Journal of Dynamic Systems,

Measurement, and Control, 107, 1-24.

1 2 3 4 5 6 7 8 9 10 11 12

0

5

10

15

20

25

30

35

40

45

50

Time[s]

F[N]

Set-point

Hybrid Control 0Kg

Hybrid Control 3Kg

Hybrid Control 6Kg

1 2 3 4 5 6 7 8 9 10 11 12

0

5

10

15

20

25

30

35

40

Time [s]

F [N]

Impedance Control 0 Kg

Impedance Control 3 Kg

Impedance Control 6 Kg

Jia-Fan, Z., Can-Jun, Y., Ying, C., Yu, Z., Yi-Ming, D.,

2008. Modeling and control of a curved pneumatic

muscle actuatorfor wearable elbow exoskeleton. In

Mechatronics, no. 18, pp. 448-457, 2008.

POSITION/FORCE CONTROL OF A 1-DOF SET-UP POWERED BY PNEUMATIC MUSCLES

237