CHITOSAN FOR MEMS

Demonstration of Micromechanical and Optical Biosensors

Stephan T. Koev, Peter H. Dykstra, Reza Ghodssi

MEMS Sensors and Actuators Lab, Institute for Systems Research, Departement of Electrical and Computer Engineering

University of Maryland, College Park, MD 20742, U.S.A.

Gary W. Rubloff

Institute for Systems Research, Department of Materials Science and Engineering

Univerisity of Maryland, College Park, MD 20742, U.S.A.

William E. Bentley

Fischell Department of Bioengineering, Univerisity of Maryland, College Park, MD 20742, U.S.A.

Gregory F. Payne

Center for Biosystems Research, University of Mayland Biotechnology Institute, College Park, MD 20742, U.S.A.

Keywords: Chitosan, MEMS, DNA hybridization, Microcantilever, Fluorescence.

Abstract: This paper presents the biological functionalization of MEMS sensors by using the polysaccharide chitosan.

Chitosan is a unique polymer due to its abundance of primary amine groups and its ability to be

electrodeposited with spatial and temporal control. Biomolecules such as DNA and proteins can be attached

to chitosan films by standard coupling chemistries. This biofunctionalization approach was demonstrated for

two different MEMS devices: a microcantilever and an optical sensor. The devices were coated with

chitosan and probe DNA and were used for detecting the hybridization with target DNA. Here, we describe

the design, fabrication procedure, and testing results for both of these biosensors.

1 INTRODUCTION

Functionalizing surfaces for the detection of specific

analytes is a common practice for many biosensor

devices. Electrochemical sensors, for example, often

employ hydrogels which selectively block the

diffusion of particular molecules or entrap enzymes

to enable specific detection (Geng et al., 2008). It is

a greater challenge to functionalize surfaces of

microelectromechanical systems (MEMS) sensors

due to their small size. MEMS sensors hold many

advantages over their macroscale counterparts,

including low cost due to batch fabrication

techniques, high-throughput screening ability, and

small required sample volumes. Several

functionalization schemes have been demonstrated

for MEMS devices (Mizutani, 2007), including the

self-assembly of thiol labeled molecules to gold

surfaces and of silane labeled molecules to silica

surfaces. These techniques require time consuming

laboratory procedures to ensure the integrity of the

biomolecules and offer limited control over their

patterning.

We report the use of an amine rich

polysaccharide, chitosan, to functionalize surfaces in

both mechanical and optical MEMS biosensors.

Chitosan can be selectively electrodeposited on

patterned conductive surfaces, and it has primary

amine groups at every repeating sugar unit of its

polymer structure (Yi et al., 2005). The amine

groups can be used for covalent attachment of

various biomolecules, making chitosan an excellent

interface between microfabricated devices and

biological components. Here, we present the

attachment of probe DNA to chitosan-coated sensors

used for the detection of target DNA.

109

Koev S., Dykstra P., Ghodssi R., Rubloff G., Bentley W. and Payne G. (2009).

CHITOSAN FOR MEMS - Demonstration of Micromechanical and Optical Biosensors.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 109-112

DOI: 10.5220/0001552801090112

Copyright

c

SciTePress

2 CHITOSAN PROPERTIES

Chitosan is derived from the partial deacetylation of

chitin, an abundant material found in nature. At low

pH below a pKa value of 6.3, chitosan is cationic

and soluble in water. However, as the pH rises,

chitosan becomes protonated and insoluble. We take

advantage of chitosan’s pH dependent solubility to

electrodeposit a chitosan film with spatial and

temporal control in the MEMS sensors. In an

electrochemical reaction, the pH at the cathode

surface will rise due to the reduction of the hydrogen

ions. This rise in pH will cause a film of chitosan to

form over the conductive surface with a rate

dependent on the applied bias (Yi et al., 2005).

3 MICROMECHANICAL

SENSOR

3.1 Design

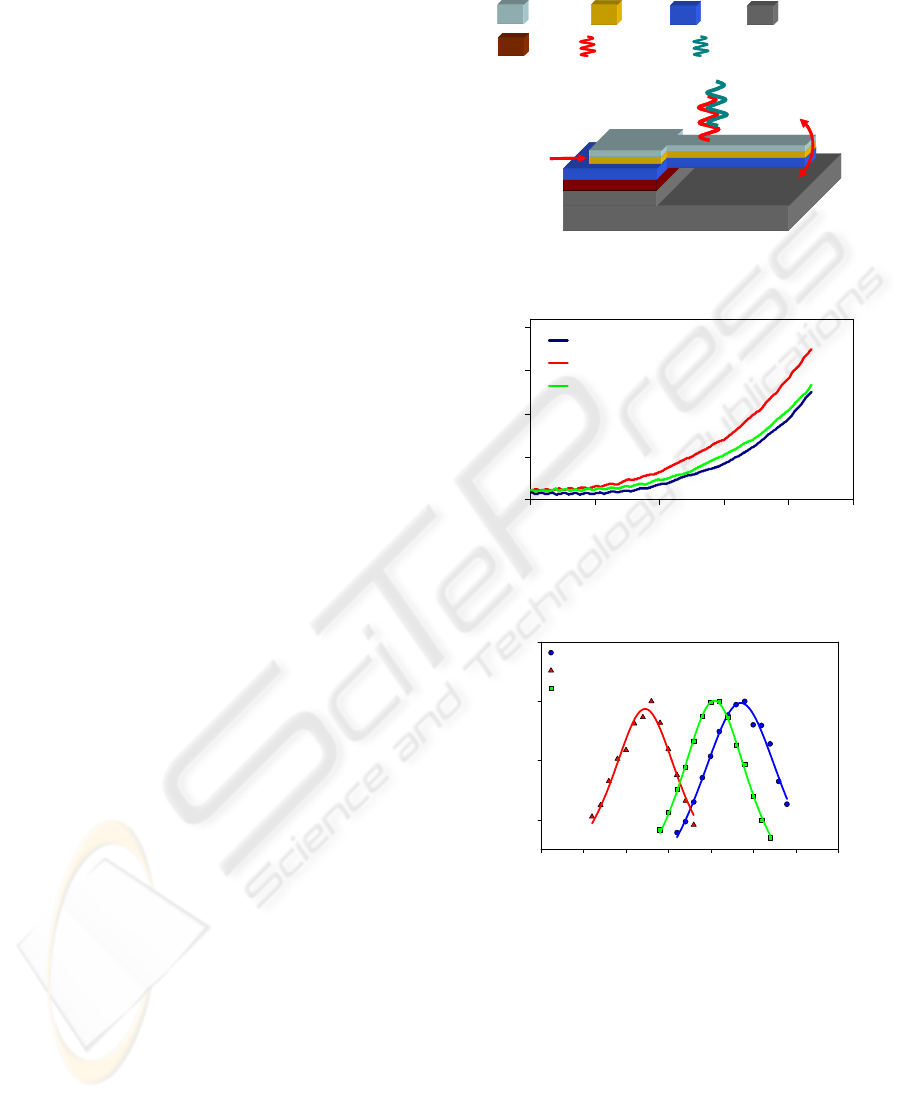

The cantilever sensor consists of layers of Si

3

N

4

(500nm thick), Au/Cr (100nm thick), and chitosan

with probe DNA (~100nm) on a silicon substrate as

shown in Fig. 1 (Koev et al., 2007). The cantilever

length and width are 100μm and 40μm respectively.

When exposed to target DNA with a complementary

sequence to the probe, the target binds to the probe

and causes two different effects that can be used for

detection. First, the mass of the cantilever is

increased, causing a drop in its resonant frequency

(dynamic mode detection). Second, the surface

stress is increased, causing the cantilever to deflect

(static mode detection). The cantilever displacement

and resonant frequency are measured with an optical

interferometer (Veeco NT1100). For resonant

frequency measurement, the device is

electrostatically actuated by applying a voltage

between the gold layer and the substrate.

3.2 Fabrication

The cantilever is fabricated on a 4 inch Si wafer with

two contact lithography steps. First, a layer of Si

3

N

4

is deposited by chemical vapor deposition (CVD),

and layers of Cr and Au are deposited by sputtering.

The metal is patterned by wet chemical etching, and

the Si

3

N

4

is patterned by reactive ion etching. The

cantilever is released by etching the Si substrate with

KOH. Chitosan is deposited on the fabricated device

by immersing it in an acidic chitosan solution and

applying a negative voltage. Amine-labeled probe

DNA is attached to the chitosan with glutaraldehyde

as a crosslinker.

Si

3

N

4

Si

Au/Cr

Chitosan

SiO

2

Electrode for

chitosan

deposition and

electrostatic

actuation

Displacement

measured by

interferometry

Target DNA

Probe DNA

Si

3

N

4

Si

Au/Cr

Chitosan

SiO

2

Electrode for

chitosan

deposition and

electrostatic

actuation

Displacement

measured by

interferometry

Target DNA

Probe DNA

Figure 1: Cross sectional schematic of microcantilever

sensor.

-0.2

0.8

1.8

2.8

3.8

0 20406080100

Position along cantilever (

μ

m)

Height (

μ

m) .

Before hybridization

After hybridization

After denaturation

Figure 2: Static response of cantilever to complementary

DNA hybridization and denaturation.

Frequency (kHz)

57 58 59 60 61 62 63 64

Amplitude (A. U.)

0.6

0.8

1.0

1.2

Before hybridization

After hybridization

After denaturation

Figure 3: Dynamic response of cantilever to DNA

hybridization and denaturation.

3.3 Testing and Results

The device is immersed in a complementary target

DNA solution for hybridization and in a urea

solution for denaturation (Koev et al., 2007). After

each step, the device is rinsed with deionized water

and dried. Then, the resonant frequency and the

bending profile of the dried cantilever are measured

by interferometry as described previously. Fig. 2

shows the static response to DNA hybridization, and

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

110

Fig. 3 shows the dynamic response. Both responses

demonstrate that biological recognition occurred and

was transduced to a mechanical signal.

4 OPTICAL BIOSENSOR

4.1 Design

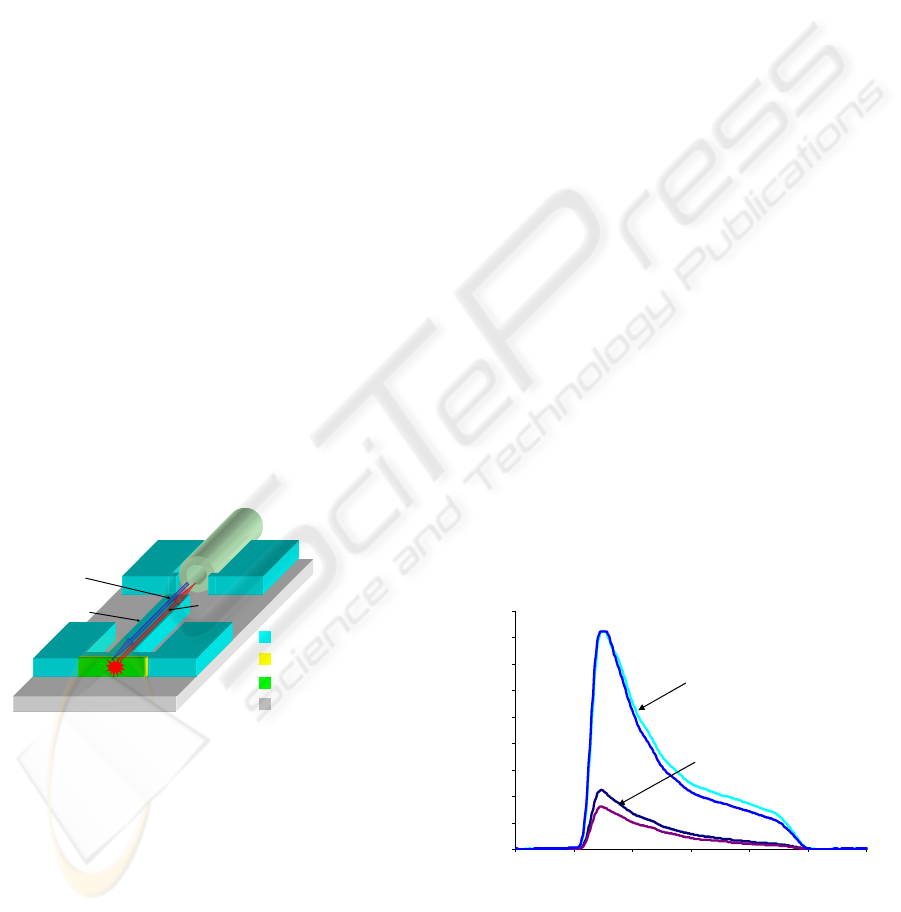

Our design for the biophotonics platform is shown in

Fig. 4 (Powers et al., 2005). A thick photosensitive

polymer, SU-8, is used to define both the fluidic

channel and the optical waveguide on a pyrex

substrate. SU-8 is ideal for this application due to its

chemical inertness, ability to be spun very thick, and

high optical transmission for visible wavelengths.

Pyrex is chosen due to its smaller index of refraction

compared to the SU-8 (1.47 to 1.59). As shown in

the schematic, excitation light is applied through the

same optical fiber which collects the fluorescence

emission through the use of an off-chip bi-

directional coupler. In order to maximize the

collection efficiency at the waveguide facet, the

chitosan is deposited onto the sidewall of the SU-8

channel. A film of indium tin oxide (ITO) is chosen

to facilitate this deposition. Indium tin oxide is

conductive and mostly transparent to visible

wavelengths. The height of the SU-8 is chosen to be

110 μm in order to adequately couple the emitted

fluorescence into a multimode fiber with a core

diameter of 62.5 μm.

Optical

Path

Electrode (ITO)

Chitosan

Pyrex

Emission

Fluid Channel

Optical Fiber

Fiber Holder

Polymer (SU-8)

Waveguide

Excitation

Waveguide

Figure 4: Schematic of the optical biosensor.

4.2 Fabrication

Gold electrodes are initially patterned on a 4 inch

pyrex wafer using standard lithography techniques.

Prior to the addition of the SU-8, an adhesion

promoter AP300 (Silicon Resources, USA) is spun

on the wafer and baked on a hotplate in order to

improve the adhesion between the SU-8 and the

pyrex. SU-8 is spun to a thickness of 110 μm and

patterned to create the waveguides and fluidic

channel. Indium tin oxide is deposited using

magnetron RF sputtering to achieve a final thickness

of 200 nm. The sidewall of ITO is created by

patterning AZ9245 photoresist over the features on

the wafer and etching away the exposed ITO in a 1:1

HCl:DI water solution. In order to functionalize the

ITO surface, the wafer is submerged in a chitosan

solution at a pH of 5.07 (Sigma-Aldrich, USA)

while a voltage bias of 2 VDC is applied to the

electrodes. After 15 minutes, a film of chitosan on

the order of a few microns thick is deposited onto

the ITO electrode. The wafer is rinsed with DI water

to remove any excess residues. An optical fiber is

aligned to the output waveguide by a patterned fiber

clamp structure and is glued in place using UV-

curable epoxy. The index-matching epoxy fills the

gap between the fiber and the waveguide to

eliminate losses due to reflections.

4.3 Testing and Results

The optical biosensor was tested in response to

attachment of probe DNA and to hybridization with

target DNA (Badilita et al., 2007). Amine labeled

fluorescent probe DNA is attached to the chitosan by

glutaraldehyde crosslinking. The optical output was

measured by using an optical spectrum analyzer.

Fig. 5 shows the spectrum of the output signal

collected through the waveguide from probe DNA

labeled with Alexa Fluor 633. The emission signal is

filtered by a band pass filter with cutoff at 660nm.

The signal was measured before and after DNA

attachment. There is a clear increase in the measured

intensity due to the fluorescence signal from the

attached probe DNA.

Spectral Response to DNA Functionalization

0

500

1000

1500

2000

2500

3000

3500

4000

4500

640 660 680 700 720 740 760

Wavelength (nm)

Intensity (A. U.)

1) DNA Signals

2) Background Signals

Figure 5: Spectra of optical emission signals received both

1) after introduction of fluorescent DNA and 2) when no

fluorophores are present.

CHITOSAN FOR MEMS - Demonstration of Micromechanical and Optical Biosensors

111

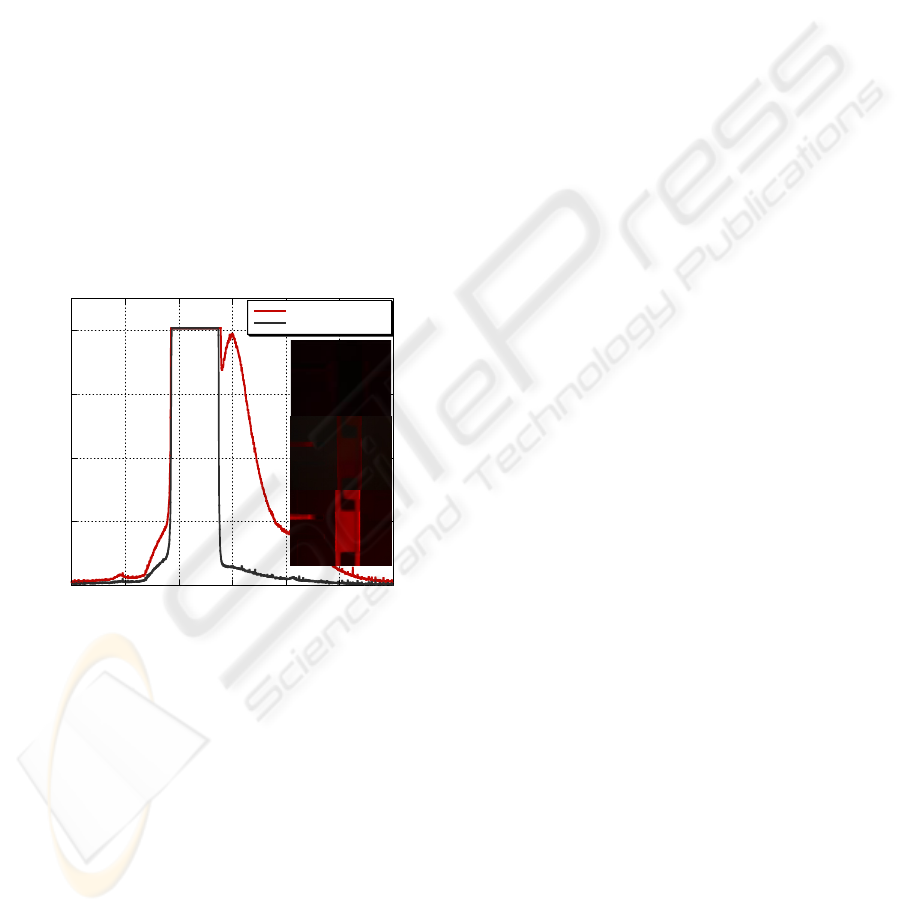

For the DNA hybridization experiments, the

chitosan surface functionalized with probe DNA was

exposed to matching or mismatching DNA solutions

for 30 min at room temperature. In order to

emphasize the selectivity, the mismatching DNA

was twice as concentrated (8 μM) as the matching

DNA (4 μM). Both DNA sequences were labeled at

the 5’ end with AlexaFluor 633 fluorophore. The

response was analyzed with a fluorescence

microscope and a spectrum analyzer.

Fig. 6 displays the intensity response to both

matching and mismatching DNA sequences. A

strong emission signal with a peak at about 650 nm

is demonstrated only for the matching DNA

sequence. The images on the right of the figure

display the fluorescence microscope images of the

sensor area after subjection to both the matching and

mismatching DNA. These results were also

demonstrated to be repeatable using the same device

by washing away the target DNA with a 4 M urea

solution at 95

o

C for 30 min and reintroducing the

DNA samples.

0

1000

2000

3000

4000

500 550 600 650 700 750 800

1-Matching DNA

1-Mis-Matching DNA

INTENSITY [a.u.]

WAVELENGTH [nm]

(a)

(b)

(c)

Figure 6: Collected output spectra demonstrating

successful DNA hybridization. Inset: fluorescence

microscope images of device: (a) after probe DNA

attachment (b) after mismatching target DNA (c) after

exposure to matching target DNA.

5 CONCLUSIONS

Chitosan enables a wide range of applications due to

its unique structure and relative abundance in nature.

We have reported the successful design, fabrication

and testing of two distinct MEMS biosensors which

utilize chitosan as a functionalization layer. Our

microcantilever has a deposited film of chitosan on

its surface to facilitate attachment of probe DNA. Its

structure allows for highly sensitive detection due to

mass loading. Our biophotonics sensor utilizes a

novel sidewall pattern of chitosan to improve

fluorescence emission capture into a planar

waveguide. DNA hybridization experiments have

been successfully performed with both devices. By

bridging the world of MEMS with the world of

biology through mechanical or optical detection,

chitosan forms the missing link allowing for more

robust and selective biological sensors.

ACKNOWLEDGEMENTS

This work was funded by the Laboratory for

Physical Sciences, the National Science Foundation,

and the R. W. Deutsch Foundation.

REFERENCES

Badilita, V., Shamim, I., Yi, H., Koev, S. T.,

Gerasopoulos, K. & Ghodssi, R. (2007) Chitosan-

Mediated Biomems Platform For Optical Sensing. The

14th International Conference On Solid-State Sensors,

Actuators, And Microsystems (Transducers '07). Lyon,

France.

Geng, R., Zhao, G., Liu, M. & Li, M. (2008) A Sandwich

Structured Sio2/Cytochrome C/Sio2 On A Boron-

Doped Diamond Film Electrode As An

Electrochemical Nitrite Biosensor. Biomaterials, 29,

2794.

Koev, S. T., Powers, M. A., Yi, H., Wu, L.-Q., Bentley,

W. E., Rubloff, G. W., Payne, G. F. & Ghodssi, R.

(2007) Mechano-Transduction Of Dna Hybridization

And Dopamine Oxidation Through Electrodeposited

Chitosan Network. Lab On A Chip, 7, 103-111.

Mizutani, F. (2007) Biosensors Utilizing Monolayers On

Electrode Surfaces. Sensors And Actuators B, 130, 14-

20.

Powers, M. A., Koev, S. T., Schleunitz, A., Yi, H.,

Hodzic, V., Bentley, W. E., Payne, G. F., Rubloff, G.

W. & Ghodssi, R. (2005) A Fabrication Platform For

Electrically Mediated Optically Active

Biofunctionalized Sites In Biomems. Lab On A Chip,

5, 583-586.

Yi, H., Wu, L.-Q., Bentley, W. E., Ghodssi, R., Rubloff,

G. W., Culver, J. N. & Payne, G. F. (2005)

Biofabrication With Chitosan. Biomacromolecules, 6,

2881-2894.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

112