MULTIAGENTS IN MANUFACTURING PRODUCTION LINES

Designing Fault Tolerant Adaptive Production Lines

Eugen Volk

High Performance Computing Center Stuttgart (HLRS), Nobelstraße 19

70569 Stuttgart, Germany

Keywords: Multiagents, fault tolerant, agent based manufacturing.

Abstract: The usage of multiagents for autonomous, fault tolerant and flexible adaptation of production lines is not

widespread in industrial applications. This paper presents usage of multiagents in industrial applications by

showing a realization within a fictive example of a car body manufacturing production line. The mechanism

presented here for coordination of agents in multiagent based production line factory is based on contract

net protocol and uses ontological matching of individual task ontologies, to find an appropriate contractor.

1 INTRODUCTION

Multiagent systems are mostly used for monitoring

or planning purposes in industrial applications

whereas the usage of multiagents for autonomous,

fault tolerant and flexible adaptation of production

lines is not widespread in these environments. This

paper aims to introduce the usage of multiagents in

industrial applications by showing a realization

within a fictive example of a car body

manufacturing production line.

2 SCENARIO DESCRIPTION

According to Wikpedia, a production line is defined

as a set of sequential operations established in a

factory whereby materials are put through a refining

process to produce an end-product. A production

line for automobile has a car as its end-product. The

assembly of a car consists of several steps, including

forming, welding, grounding, painting etc.. Each

step is done by specialized machines. The transport

of semi-manufactured products between different

machines is done by transport system. Typically a

factory produces several car types, in different

production lines.

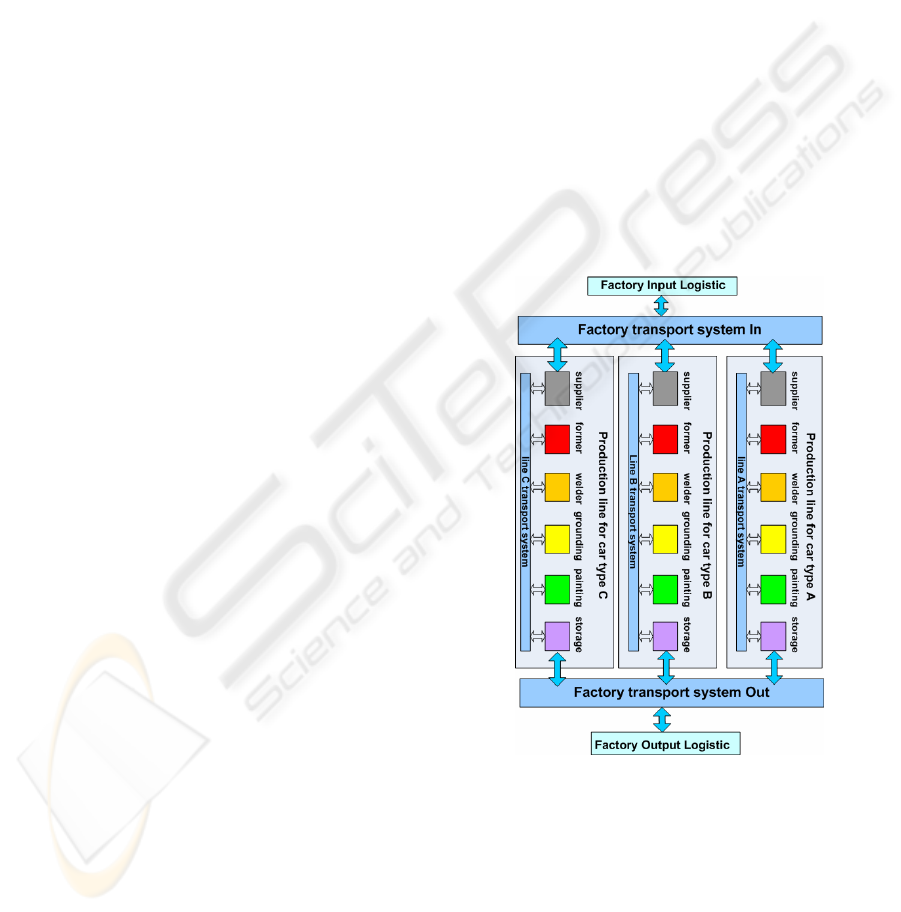

Figure 1 shows such a factory,

consisting of three production lines: for car types A,

B and C.

Figure 1: car-body manufacturing with 3 lines.

The process starts with the “Factory Input Logistic”,

which supplies the production lines of the factory

with material being required for the production of

car bodies of different types. The “Factory Input

Logistic” uses “Factory transport system In” to

transport the right material to supplier of the

addressed production line. The supplier of the

production line uses “line transport system” to

deliver the material to the former. The former

processes material to metal pieces/sheets and hands

567

Volk E. (2008).

MULTIAGENTS IN MANUFACTURING PRODUCTION LINES - Designing Fault Tolerant Adaptive Production Lines.

In Proceedings of the Tenth International Conference on Enterpr ise Information Systems - AIDSS, pages 567-570

DOI: 10.5220/0001712605670570

Copyright

c

SciTePress

these over to the welder, via the line transport

system. The welder creates a car-body, by welding

the metal pieces, which were formed by the former.

The welder uses line transport system to transport

the car-body to the grounding, whereupon the

grounding hands the grounded car body over to the

paining. After the car body has been painted, it will

be transported via line transport system to line

storage and then via “factory transport system out”

to “Factory Output Logistic”, where it will be

delivered to other manufacturing factories, in order

to be finally wired, equipped and assembled to cars.

3 REQUIREMENTS ON

PRODUCTION LINE

FACTORIES

A production line factory must be fault tolerant. This

means it must be able to detect failure, recover from

system failure and minimize impact on the whole

production.

The classical approach would be to create a

centralized system for the whole factory or at least

for a single production line. This system is able to

monitor the execution of every production step of

the involved machines. In case of failure detection,

such a centralized system would identify the

machine which caused failure and would be able to

compensate occurred failure, doing predefined

workaround i.e. finding a machine or a resource with

the same capabilities as the failed machine and with

available capacity, while ensuring transport to and

from this founded machine. However, such a central

system would require the knowledge about the

whole production process, including transportation,

and also the information about the status of the

machines on every production step. In case of a

production line extension, such a centralized system

would require updated information about the

production process and also the monitoring status of

new machines.

In contrast to centralized system, a fully

distributed system, realized as Multiagent System,

would be able to adopt on occurred failure

dynamically in a flexible manner, without the need

of keeping ready knowledge on the whole

production process. In case of production line

extension, the changes would be handled locally,

updating only mutual dependency of affected

machines being represented by agents.

4 USING MULTIAGENTS

An agent is defined (Wooldridge 1999) as a

computer system that is situated in some

environment and that is capable of autonomous

actions in this environment in order to meet its

design objectives. A cooperative Multiagent System

consists of several interacting agents, which

coordinate their actions in order to achieve a

common goal. The design of cooperative Multiagent

Systems consists of the design of agents themselves

and the coordination mechanisms that enable a

group of agents with different capabilities through

interactions to combine their capabilities to

accomplish as a group in order to reach a common

goal, which could not be reached by one of the

involved individuals alone. One of the common

goals in car-body production line scenario is to keep

the production line running, despite the failures or

fall out of machines, which are represented in this

scenario as autonomous agents with individual

capabilities.

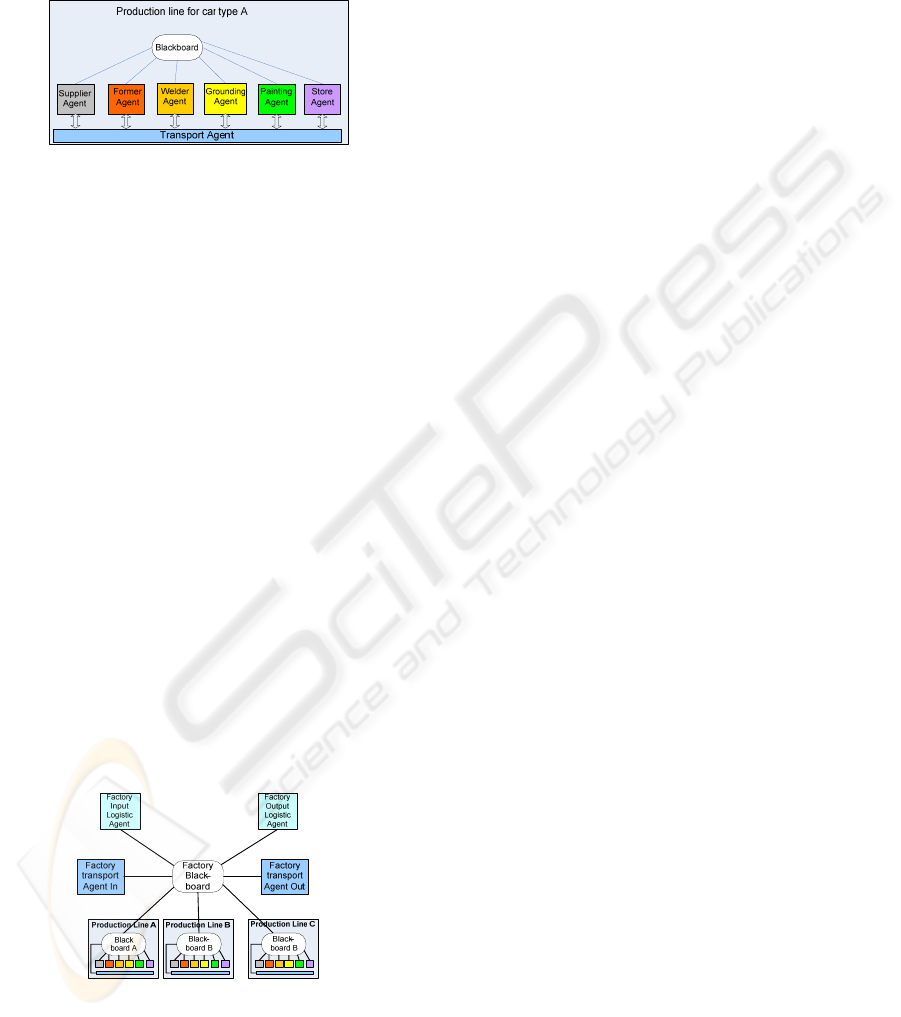

4.1 Production Line Agents

The architecture of a single production line of car

body manufacturing using multiagents is depicted in

Figure 2. A production line consists of several agents

with specific capabilities and a Blackboard, which

enables agents to interact with each other by writing

messages on it, which then can be read by all agents

of a production line.

Each production line agent (supplier agent,

former agent, welder agent, grounding agent,

painting agent) has beside the characteristic

capabilities of its machine (transport, welding,

grounding etc) also further capabilities:

a. check of performance of its machine

b. check of available free/used production

capacity resources

c. fallout detection of its machine

d. access to local production line Blackboard,

which is used to exchange information

between line agents.

Besides capabilities, each production line agent

has following knowledge:

a. task specific knowledge about its capability

b. identification of other agent(s) from which

the agent gets its materials.

c. identification of other agent(s) in

production line which consumes produced

part-products.

Whereas first knowledge must be presented, the last

two (identification of other agents) knowledge can

be gained by writing announcements on the

ICEIS 2008 - International Conference on Enterprise Information Systems

568

(production line) Blackboard for agents which

deliver material, and announcements for agents who

consume produced part-products. In case of a fall-

out of a machine, an agent has the responsibility to

find another agent who is able to complete its task.

Figure 2: Agents in production line.

4.2 Structure of Factory

As already noted in the scenario description, a

factory consists of several production lines. The

architecture of a fictive factory, consisting of three

production lines (A, B and C) is depicted in

Figure 3

It consists of “Factory Transport Agent In”, “Factory

Transport Agent Out”, “Factory Input Logistic

Agent”, “Factory Output Logistic Agent”, the three

production lines (with production line agents) and a

factory Blackboard, which enables exchange of

information between Blackboards of production

lines and factory agents. A factory Blackboard is

connected to production lines Blackboards (A, B,

C). The announcements on a single production line

Blackboard, made by production line agents, will not

be published automatically on the factory

Blackboard, unless the announcing agent triggers the

line Blackboard to submit its announcement on the

next higher level Blackboard – the factory

Blackboard. The announcements on Factory

Blackboards are submitted automatically on all

production line blackboards (A, B, C). If an agent

replies to an announcement, then its reply will be

routed by Blackboards hierarchically to former of

the announcement.

Figure 3: Hierarchy of agents in factory.

4.3 Coordination Protocol

As already mentioned, in the case of a fall-out of a

machine an agent has the responsibility to find an

agent with similar capabilities, which is able to

execute the task of the failed machine. In order to do

that it uses a Contract Net Protocol (Huhns &

Stephens 1999), a mechanism for negotiation and

distribution of tasks. An agent wanting to solve a

task is called a manager; agents that might be able to

solve the task are called potential contractors.

The adapted contract net protocol consists of the

following steps:

From manager perspective:

1. Announce a task that needs to be performed by

writing Task (e.g. welding) on local production

line Blackboard, with task ontology describing

the composition of a car body (e.g. in form of a

CAD drawing with size of used materials and

area/places where these shall be welded)

2. Receive and evaluate bids from potential

contractors:

• In case of the answer is positive, the

manager gets an estimated time for

completion of the corresponding task

(welding).

• In case of the answer is negative, go in

hierarchy level up and announce task again

on Factory Blackboard (Step 1).

3. Check transport possibilities to/from possible

contractors by writing transport announcement

on local Blackboard.

• If there are transport possibilities then

compare transport and execution time of all

bids and award a contract to a suitable

contractor.

• Else go in hierarchy level up and announce

on factory board for transport possibility.

4. If appropriate contractor found:

• Delegate transport of material to contractor.

• After completion of task delegate the

transport from the contractor to the agent

which is next in the production chain

(consumes part-products).

From a contractor perspective:

1. Receive task announcements by looking

periodically on production line Blackboard.

2. Evaluate own capability with the required

capabilities of Task.

• Check available capacity resources.

• Compare task ontology of announced task

with own task ontology by looking for

similarities.

• Check received CAD-data for task

execution

MULTIAGENTS IN MANUFACTURING PRODUCTION LINES - Designing Fault Tolerant Adaptive Production Lines

569

• Calculate time for task execution

3. Respond (decline, bid)

• A bid consists of the calculated time for the

execution of the task (welding)

• In case of available capability to execute the

task, reserve for the duration of negotiation

(defined by time-out of protocol) required

available capacity resources.

4. If the bid is accepted, then perform the task

(welding)

5. The welded car-body will be transported via

from the manager pre-reserved transport agent

to the destination agent (painting agent).

The critical step in the proposed protocol is step 2 of

contractor perspective: comparison of two

ontologies in order to determine whether they are

similar and whether the task can be executed from

the possible contractor. Several approaches for the

automated comparison of ontologies are summarized

by Gal, Modica & Jal 2003. One of the approaches

that can be used in the selected scenario is the

composition matching algorithm, which uses

linguistic matching. Another approach could be

comparison of schema and data format used in CAD

files.

5 PROPERTY OF PROPOSED

DESIGN AND CONCLUSIONS

The proposed design of production line factory with

multiagents enables treatment of failure by starting

on lowest hierarchy level – on production line agent

where the failure occurs. The agent, who detects

failure on its machine(s), initiates the process of

finding appropriate alternative agent with similar

capabilities and available resources. The

announcements are propagated step by step

hierarchically upwards, ensuring the “treat failure

local first” strategy, which ensures shortest transport

paths. This strategy is also selective and reduces

overflow of all Blackboards with announcements.

The hierarchy of production line to a factory can be

extended to composition of several factories to a

concern with different locations or even further to

consortium consisting of several concerns. The

information spread can be reduced further, if a

blackboard system on each level is aware of all

agents reading or writing on it. This can be done by

announcements made by each blackboard “who is

here with which abstract capability”, starting with

the lower level and proceeding with higher level and

so building routing tables. This enables to distribute

announcements more selectively (even to agents),

based on abstract capabilities (as topic), but requires

routing capability of blackboards. The task ontology

based evaluation of agent capabilities presumes no

common ontology and so only those agents which

are able to understand required task ontology (done

by checking similarity between ontologies) and able

to execute required task, answer with time

calculation for task execution. The calculation of

task execution in the bid on task announcement,

together with time for transport execution form

performance criteria for optimisation of the overall

performance and enables so distributed resource

scheduling. The usage of multiagent systems in

industrial manufacturing enables the factory to adapt

autonomous and fast to unknown problem, while

keeping production process running.

The proposed approach, based on ontological

matching and contract net protocol, could be used in

SLA-negotiation of BREIN project, if ontological

matching becomes a challenging issue in project.

The BREIN project aims at realizing an intelligent,

on multiagents, web-semantic and web-services

based infrastructure, capable to setup and manage

goal-driven dynamic virtual organization of service

provider/consumer, while optimizing usage of

resources.

ACKNOWLEDGEMENTS

This work has been supported by the BREIN project

(http://www.gridsforbusiness.eu) and has been partly

funded by the European Commission’s IST activity

of the 6th Framework Programme under contract

number 034556. This paper expresses the opinions

of the author and not necessarily those of the

European Commission. The European Commission

is not liable for any use that may be made of the

information contained in this paper.

REFERENCES

Weiss, G., 1999 Multiagent Systems, a modern approach

to distributed artificial intelligentce. The MIT press.

Huhns, M., N., Stephens, L., M., 1999. Multiagent

Systems and Societies of Agents.

Gal, A., Modica, G., Jamil, H., 2003. Improving Web

Search with Automatic Ontology Matching.

Wooldridge, M., 1999. Intelligent Agents, in Multiagent

Systems.

The BREIN Project, Website http://www.eu-brein.com/

The Wikipedia Website www.wikipedia.com

ICEIS 2008 - International Conference on Enterprise Information Systems

570