PLUG-AND-PRODUCE TECHNOLOGIES

On the Use of Statecharts for the Orchestration of Service Oriented Industrial

Robotic Cells

Germano Veiga and J. Norberto Pires

Mechanichal Engineering Department, University of Coimbra

Rua Luís Reis dos Santos, Coimbra, Portugal

Keywords: Service Oriented Architectures, SCXML, Industrial robotic cells.

Abstract: Programming industrial robotic workcells is a challenging task, namely because it means dealing with

several types of machines, mange the data flow between them and orchestrate their basic functionality into a

working program. In this work service oriented architectures are used for the task of programming robotic

workcells along with managing the communication between cell components, and a statechart model engine

is implemented to orchestrate the system logic. The objective of this paper is to focus in merging service

oriented architectures with StateCharts XML, and in evaluating that robotic workcell programming

approach using a simple laboratory test bed.

1 INTRODUCTION

The integration of different components in an

industrial robotic cell is a time consuming task.

Nowadays, industrial automation is using

technologies originally designed for wider range of

non-traditional industrial companies. The evolution

of vision systems, 3D scanners, intelligent sensors

PLC’s, with their special languages and

programming environments, etc., originated an

enormous collection of interesting and powerful

devices which are easier to program, although harder

to integrate in their full extent. Consequently,

porting plug-n-play concepts from PC’s to the

industrial automation environment is a promising

opportunity. Even though similar to plug-n-play, in

many aspects, the plug-n-produce concept (Veiga et

al. 2007) has to deal with some specifics from the

industrial automation world. One of these specifics

is related with the presence of many highly

programmable devices. Considering an industrial

robotic cell, connecting a sensor to a robot controller

can be compared to connecting a mouse to a PC, but

integrating a programmable vision system or a PLC

with an industrial robot requires some orchestration

logic. To materialize this plug-n-produce concept

regarding highly programmable devices, service

oriented architectures (SOA) have been pointed as a

promising approach (SMErobot

TM

2007-2009).

service oriented architectures are composed by

autonomous services and are extensively event

driven.

Finite-state automatons are very commonly used

in the task of modeling the behavior of industrial

automation systems. Due to their discrete event

nature, industrial systems are well described by

states and event driven transitions.

Harel StateCharts are a widely used extension to

the finite-state automata model, and SCXML

(Barnett et al. 2007) is a modern standardized way

of specifying them.

The purpose of the current paper is to evaluate a

SCXML-derived language to program service-

oriented industrial robotics cells. This paper also

presents a software application that materializes this

concept, and the results obtained using a simple

laboratory robotic test bed.

2 SOA - UPNP

With the advent of internet, service oriented

architectures (SOA) emerged to increase the degree

of decoupling between software elements. A SOA

relies on highly autonomous but interoperable

systems. The definition of a service is ruled by the

larger context; this means that all technological

details are hidden, but also that the concept which

271

Veiga G. and Norberto Pires J. (2008).

PLUG-AND-PRODUCE TECHNOLOGIES - On the Use of Statecharts for the Orchestration of Service Oriented Industrial Robotic Cells.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics, pages 271-277

DOI: 10.5220/0001505102710277

Copyright

c

SciTePress

supports the service is more business (or process)

oriented (instead of being technology oriented).

SOA enables software engineers to focus more on

the business logic and less on the interconnection

details. At the device level, service-oriented

architectures are emerging as the way to deal with

the increasing amount of embedded devices present

in our homes and offices.

In manufacturing, the inherent complexity

(necessarily hidden from the user) associated with

the presence of many types of devices and machines

makes the concept of service-oriented architectures

particularly attractive (SIRENA 2005, SODA 2006,

SOCRADES 2006). In fact, it leads to the idea that

each workcell programming block (that is, not only

physical devices) should be considered as a potential

device (SOA device style) that offers programming

services.

Considering a holonic workcell structure (Gou,

1998), with holons composed by automation

devices, like an industrial robot or a vision system,

one can classify as uncommon the need to have real-

time in the communication framework. The majority

of the component connections can instead be

described in terms of coarse-grained services, with

synchronous calls for setup and asynchronous events

for operation.

Considering an industrial robotic cell ecosystem,

past work (Veiga et al, 2007) revealed that service-

oriented architectures can provide a suitable

platform to a plug-n-produce environment.

Nevertheless, there are several approaches to

SOA, namely, if we consider only the four most

relevant platforms: Jini (Jini 2006), UPnP (UPnP,

2007), DPWS (Chan, 2006) and DSSP (Nielsen,

2007).

Jini is an architecture proposed by Sun

Microsystems based on Java. This fact makes it

platform independent but language dependent. It

also carries a large memory footprint, due to the

presence of a virtual machine and extensive

libraries, making it less appropriate for very small

devices.

UPnP and DPWS rely extensively on standard

network protocols such as TCP/IP, UDP, HTTP,

SOAP, XML, and the web technology. This makes

them platform and language independent, which is a

major advantage for their adoption. XML formats

are broadly used and accepted and provide modern

data interchange mechanisms and communications.

Their style is close to the one defined in the

enterprise world with the pair WSDL/SOAP.

Although similar in many aspects, the UPnP and

DPWS architectures use different languages for

device description and different protocols for

discovery and event notifications. There is an

enormous dynamics around DPWS. Nevertheless,

the new Microsoft operating system, Microsoft

Vista, supports both technologies under the name

plug-and-play extensions for Windows (PnP-X,

2006)

DSSP is a simple SOAP-based protocol that

defines a lightweight, REST-style service model

(Nielsen, 2007) that also relies extensively on web

technology. Paired with concurrency and

coordination runtime (CCR) it constitutes the major

parts of the Microsoft Robotics Studio (MSRS)

platform.

DSSP architecture style is radically different

from the WSDL/SOAP model. UPnP and DPWS are

very similar technologies which mean that concepts

and design styles can be easily ported between each

other.

In this work UPnP was selected due to

representativeness of the platform, the quantity and

quality of the tools available, and our experience

with the UPnP based services.

3 SCXML

StateChart XML (SCXML) can be described as an

attempt to render Harel StateCharts in XML. The

aim of this standard is to provide a basis for future

standards in the area of multimodal dialogue

systems. Even though this effort is being carried by

the W3C group for voice technologies, SCXML

provides a generic state-machine based execution

environment and a modern (XML) state machine

notation for control abstraction. In fact, SCXML is a

candidate for control language within multiple

markup languages coming out of the W3C.

Harel StateCharts are an extension to finite-state

automata. These extensions are needed in order to

make finite-state automata useful, and they include:

Hierarchy

– StateCharts may be hierarchical, i.e.,

a state may contain another statechart down to an

arbitrary depth.

Concurrency

– Two or more statecharts may be

run in parallel, which means that their parent state is

in two states at the same time.

History

– A state holds information that allow a

“pause and resume” behavior.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

272

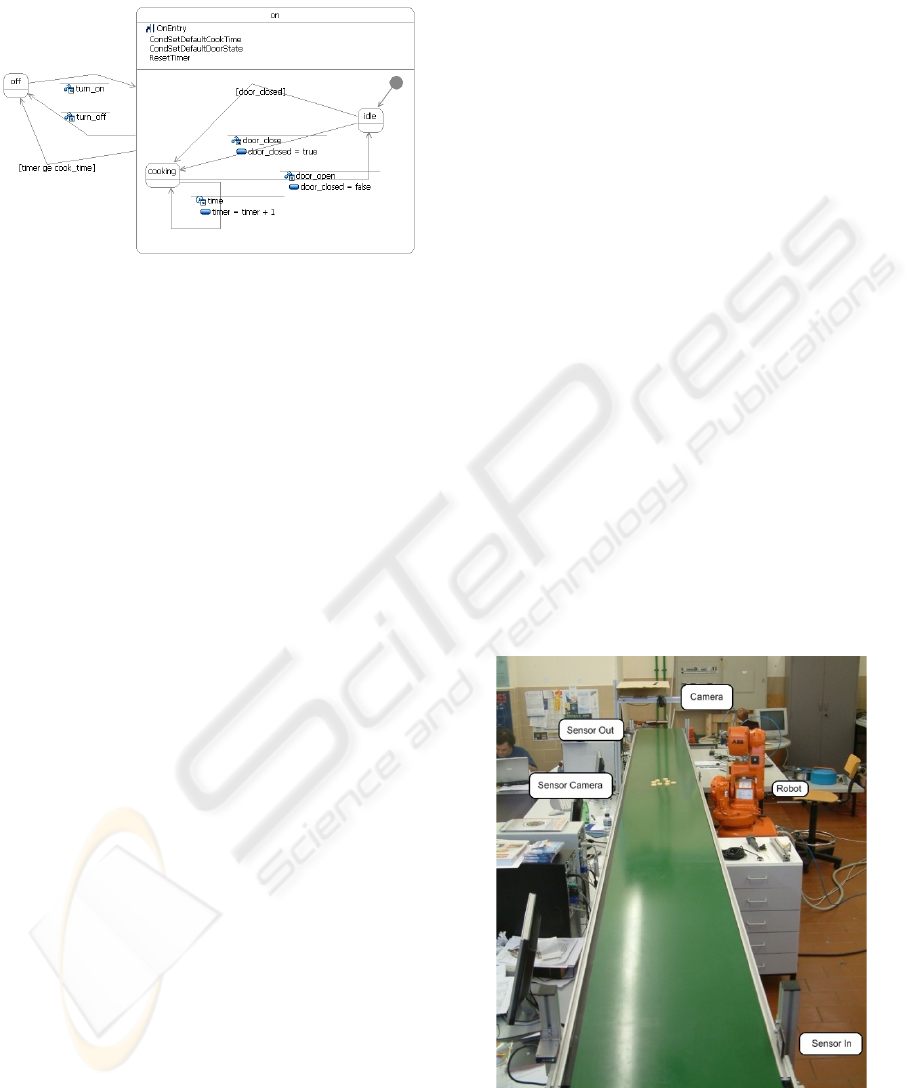

Consider for example the microwave oven model

presented in Figure 1.

Figure 1: Microwave oven (Adapted from Barnett et al

2007).

The equivalent SCXML specification is:

<?xml version="1.0"?>

<scxml xmlns=

"http://www.w3.org/2005/07/scxml"

version="1.0"

initialstate="off">

<state id="off">

<!-- off state -->

<transition event="turn_on">

<target next="on"/>

</transition>

</state>

<state id="on">

<initial>

<transition>

<target next="idle"/>

</transition>

</initial>

<onentry>

…

</onentry>

<transition event="turn_off">

<target next="off"/>

</transition>

<transition cond="${timer ge

cook_time}">

<target next="off"/>

</transition>

<state id="idle">

<transition

cond="${door_closed}">

<target next="cooking"/>

</transition>

<transition event="door_close">

<assign name="door_closed"

expr="${true}"/>

<target next="cooking"/>

</transition>

</state>

<state id="cooking">

…

</state>

</state>

</scxml>

Has it can be seen in this example, an SCXML

statechart can be divided in two major parts: the first

composed by the machine states and correspondent

transitions, and the other composed by the

executable content.

The SCXML executable content consists of

actions that are performed as part of taking

transitions and entering and leaving states. The

executable content is responsible for the

modification of the data model, for raising events

and invoking functionality on the underlying

platform. It’s worth noting that executable content

cannot cause a state change, or fire a transition,

except indirectly, by raising events that are then

caught by transitions. This separation in the

specification leaves room for platforms to add

additional executable content corresponding to

special features.

4 EXPERIMENTS

4.1 Experimental Setup

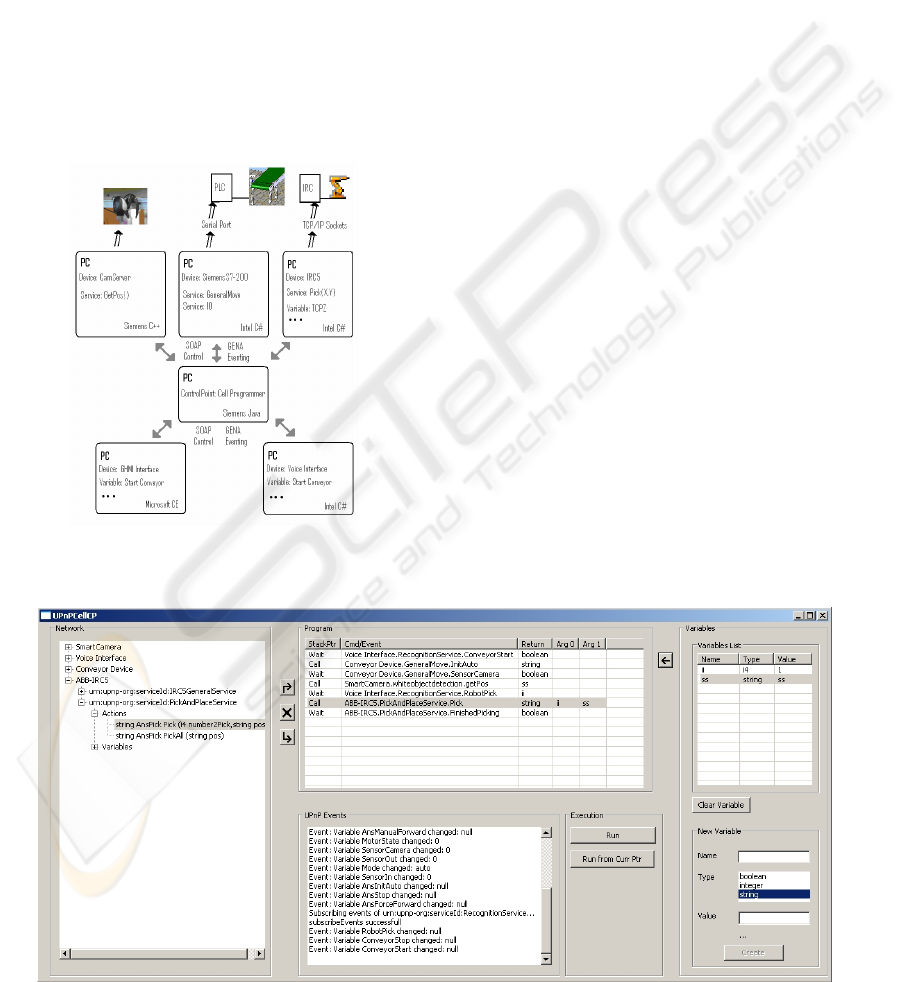

The robotic cell used in this demonstration is

composed of an industrial robot (ABB IRB 140),

equipped with the modern IRC5 controller, a

conveyor controlled by a PLC (Siemens S7-200) and

a USB web camera (Figure 2).

Figure 2: Equipment for experimental setup.

Basically, the conveyor transports sample pieces

over the machine vision system which calculates the

PLUG-AND-PRODUCE TECHNOLOGIES - On the Use of Statecharts for the Orchestration of Service Oriented Industrial

Robotic Cells

273

number and position of the pieces. The results are

sent to the robot controller to command the robot to

pick them from the conveyor and place them into a

box.

Two different applications were developed to

operate the cell: a speech interface and a PDA

interface.

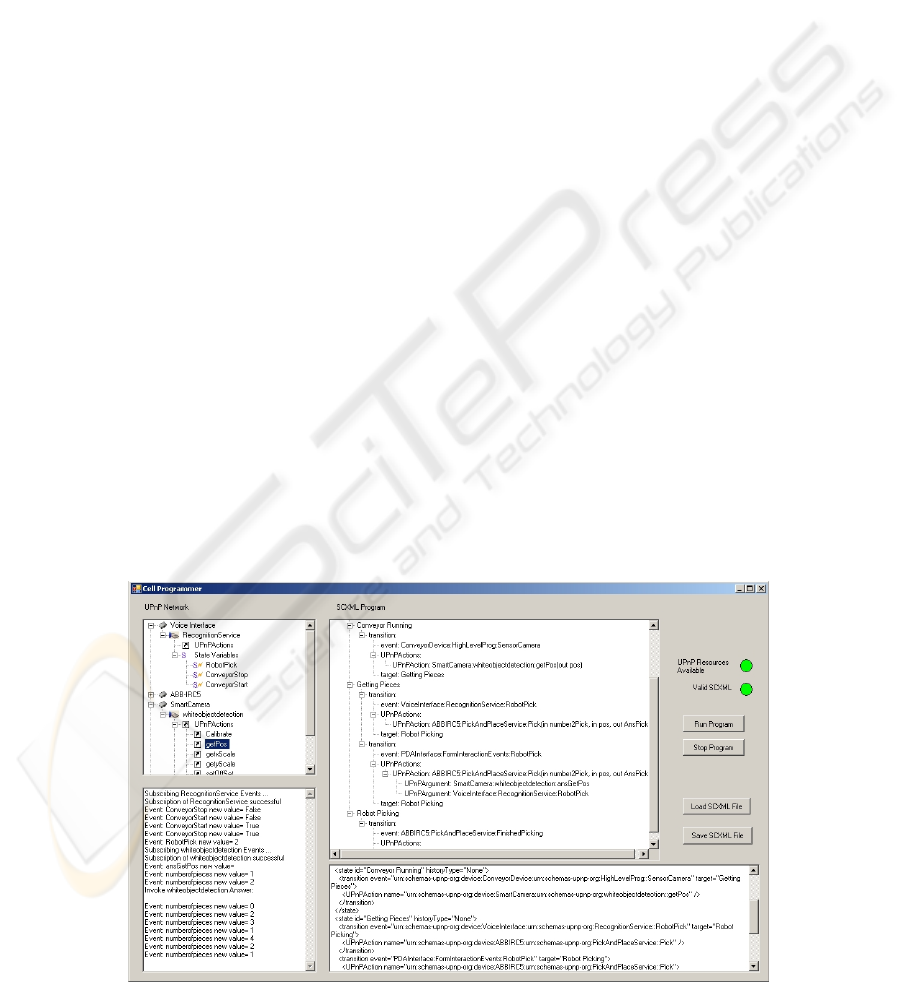

4.2 Previous Work

In previous work (Veiga et al, 2007) this Industrial

Robotic cell test-bed was used in order to validate

SOA in a plug-n-produce environment. The cell

components were represented in the network by

UPnP devices that provided services as way to

expose their functionality (Figure 3).

Figure 3: UPnP Network of the industrial test-bed.

Five UPnP devices representing five workcell

components were developed. In some of these

devices an extra layer was needed because native

UPnP support could not be implemented. Detailed

description can be found in (Veiga et al, 2007).

The Cell Programmer Interface (Figure 4) is a

software application developed to control the flow of

high level tasks in a manufacturing cell. Basically,

it’s an UPnP control point, with some tools suitable

to build a generic stack. This stack represents the

control flow of process related tasks. In the left side

of this interface a tree shows all UPnP devices

founded on the network.

Clicking over them it is possible to get additional

information (access the presentation page, for

example). Using the “arrow” button, actions or

events are added to the stack. Furthermore, when

running the resulting program and the program

counter is pointing to an event, it means that the

program is “waiting” for that event to occur.

Inversely, if the program counter is pointing to an

action, it means that it is calling that action and

waiting for the return. There is also the possibility of

defining auxiliary variables to store values that can

be used as arguments in later stack steps.

4.3 Analysis

The simple stack approach revealed to be very

limited to handle more complex systems. These

systems often have concurrent tasks, multiple

transition events and many other orchestration

requirements which are impossible to model with a

simple stack system.

Figure 4: Simple orchestration system (Veiga et al, 2007).

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

274

To address this problem, this paper proposes a

more powerful orchestration model that relies on

standard technologies (SCXML) and solves many of

the described problems.

Another issue with the previous approach was

related with the use of the auxiliary variables and the

need to check the presence of remote functionality

on distributed systems. A robot cell program is only

valid if all the services needed are available, but also

if the used variables have the desired value. If this

value is obtained by previous steps it’s not possible

to check if that value is still valid (corresponding to

a live device, for example). To address this issue the

solution proposed only relies on UPnP state

variables to manage data, discarding the use of

auxiliary variables

4.4 Implementation

The software developed can be divided in two

distinct parts: the implementation of the statechart

engine; and the user interface itself.

4.4.1 StateChart Engine

Actually there are too few SCXML implementations

available, and the most notable effort is

CommonsSCXML (CommonsSCXML 2007). Since

CommonsSCXML is still in a 0.x version, and there

was the need to extend the standard functionality, it

was decided here to develop an SCXML engine

from scratch.

The application presented in this paper was

developed in C# following the guidelines of (Samek,

M. 2002) including the basic part of the SCXML

language. Considering the W3C standard (Barnett et

al. 2007), our implementation doesn’t include the

Extensions to the basic State Machine Model and the

Executable Content.

This approach was taken not only for simplicity

but also with the objective of keeping the cell

program as simple as possible. This objective of

simple orchestration programs is sustained by the

holonic cell structure referenced earlier, where

devices expose high-level functionality services and

the cell orchestration programs are reduced in terms

of flow control, managing data etc. As such, all

executable content within the cell orchestration

program is always related with processing UPnP

events or UPnP actions.

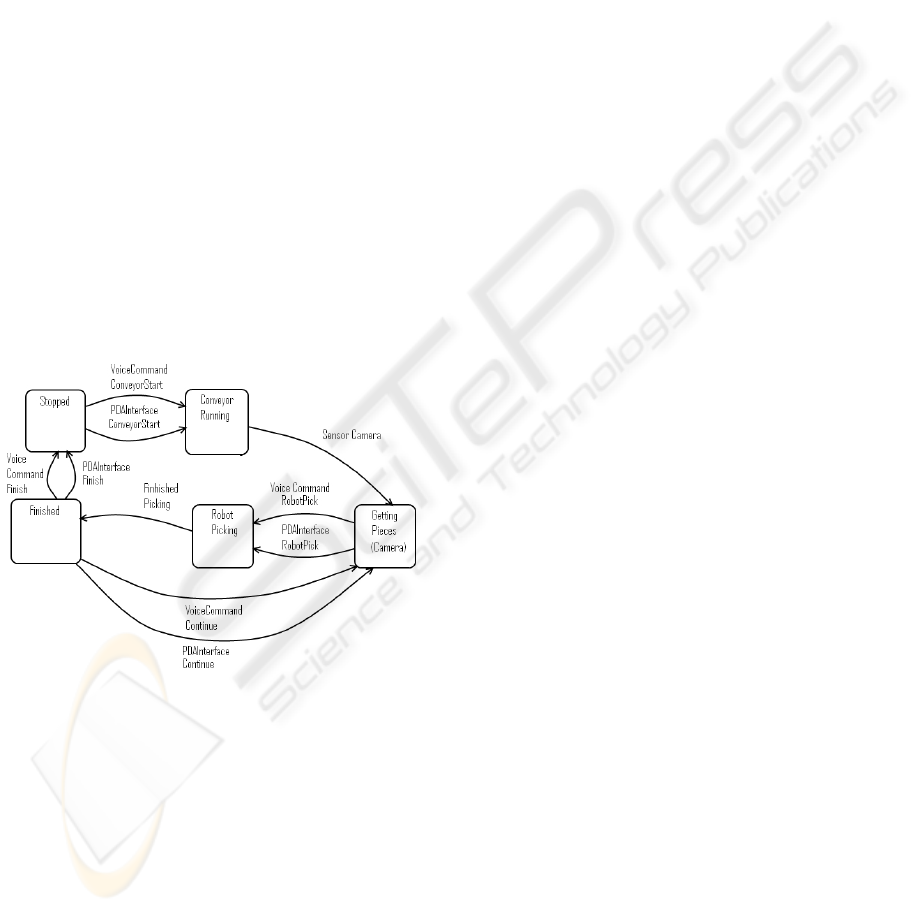

4.4.2 User interface

The UPnPSCXMLCellProgrammer is a graphical

user interface that allows the composition of

workcell orchestration programs relying on UPnP

devices and the SCXML derived model (Figure 5).

To behave like this the StateChart engine has the

added capability to recognise whether an event or

executable content are UPnP or not.

When the engine gets an UPnP event it converts

it into an SCXML event. When the statechart engine

finds an UPnP action inside an executable content

block it just calls that action with the parameters

(UPnP arguments) enclosed.

Figure 5: UPnPSCXMLCellProgrammer Interface.

PLUG-AND-PRODUCE TECHNOLOGIES - On the Use of Statecharts for the Orchestration of Service Oriented Industrial

Robotic Cells

275

In this application the user can drag and drop

UPnP actions and UPnP events from the UPnP

network and place them into the SCXML program.

It’s worth noting that the events in this program are

always network events, and that only UPnP actions

can be assigned to the OnEntry and OnExit handlers

and to the executable content of the transitions,

which are executed between the OnExit handler of

the source state and the OnEntry handler of the

current state.

UPnP events and UPnP actions are defined by

their complete Unified Resource Name (URN) that

includes the name of the action or service, plus the

URN of the owning service, plus the URN of the

device.

5 EXPERIMENTS AND RESULTS

The test bed used to experiment this new approach

that merges UPnP with SCXML is the same used

previously (Figure 2). The program logic is a little

bit more complex with the objective to show some

of the new possibilities (Figure 6).

Figure 6: Program statechart.

In fact, the new program logic allows the user

to give alternatively speech commands or PDA

commands, and re-picking leftovers before asking

the conveyor to run again.

In comparison with the previous situation much

more complex orchestration schemes can be

obtained. Statecharts provide a very nice way to

model systems logic but are very limited when

dealing with data processing. With this combined

approach pairing statecharts with SOA all data

processing is made within SOA, leaving statecharts

for modeling systems states and logic. Considering

the experiments made so far we can point statecharts

as a suitable model to orchestrate holonic

automation workcells, due to their capabilities in

dealing with events and states in opposition of

dealing with data processing.

6 CONCLUSIONS

This paper reports results from an ongoing research

work. Experiments done so far revealed that the

added features enable the cell programmer to define

powerful and more complex orchestrations that can

handle complex systems.

Consequently, merging service oriented

architectures with statecharts proved to be an

interesting approach to model the workcell

orchestration logic. Future work will focus on the

evaluation of this approach with more complex

systems and in providing a more user friendly

graphical interface.

ACKNOWLEDGEMENTS

This work has been mainly funded by the European

Commission’s Sixth Framework Program under

grant no. 011838 as part of the Integrated Project

SMErobot

TM

.

REFERENCES

Abb, 2005 ABB IRC5 Documentation, ABB Flexible

Automation, Merrit, 2005

Ahn S. C., Kim J.H., Lim K., Ko H.,Kwon Y and Kim H.,

2005 UPnP Approach for Robot Middleware P

Proceedings of the 2005 IEEE International

Conference on Robotics and Automation Barcelona,

Spain, April 2005.

Barnett, J. et al, 2007. State Chart XML (SCXML): State

Machine Notation for Control Abstraction.

http://www.w3.org/TR/2007/WD-scxml-20070221/

Chan, S., Conti, D., Kaler, C., Kuehnel, T., Regnier, A,

Roe, B., Sather, D., Schlimmer, J., Sekine, H., Thelin,

J., Walter, D., Weast, J., Whitehead, D., Wright, D.,

and Yarmosh, Y. (2006). "Devices Profile for Web

Services."

http://schemas.xmlsoap.org/ws/2006/02/devprof/

CommonsSCXML, 2007, available from:

http://jakarta.apache.org/commons/scxml

James, F. and H. Smit ,2005 Service Oriented Paradigms

for Industrial Automation. In: IEEE Transactions on

Industrial Informatics, Vol. 1, no. 1 February 2005.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

276

Gou L., P. Luh, and Y. Kyoyax (1998). Holonic

Manufacturing Scheduling: Architecture, Cooperation

Mechanism, and Implementation. '97., IEEE/ASME

International Conference on Advanced Intelligent

Mechatronics Vol 37, 213-231,

Harel D. 1987. StateCharts: A Visual Formalismfor

Complex Systems. Science of Computer Programming

8, North Holland.

Nielsen, H. and G. Chrysanthakopoulos. (2007)

Decentralized Software Services protocol – DSSP/1.0

PnP-X (2006): Plug and Play Extensions for Windows

Specification. Available:

www.microsoft.com/whdc/Rally/pnpx-spec.mspx.

Samek, M. (2002). Pratical StateCharts in C/C++,

CMPBooks

Schlimmer J., S. Chan, C. Kaler., T. Kuehnel, R. Regnier,

B. Roe, D. Sather, H. Sekine, D. Walter, J. Weast, D.

Whitehead, and D. Wright (2004) Devices Profile for

Web Services: A Proposal for UPnP 2.0 Device

Architecture.Available:

http://xml.coverpages.org/ni2004-05-04-a.html.

SIRENA Project (2005), Service Infrastructure for Real-

time Networked applications, Eureka Initiative ITEA.

Available: www.sirena-itea.org.

SOCRADES. (2006). "Service-Oriented

Cross-layer infRAstructure for Distributed smart

Embedded devices." http://www.socrades.eu/

SODA. (2006). "Service Oriented Device and Delivery

Architecture." http://www.soda-itea.org/

UPnP forum (2004).Available: http://www.upnp.org

Veiga G., Pires JN, Nilsson K.. On the use of SOA

platforms for industrial robotic cells: Intelligent

Manufacturing Systems Proceedings IMS2007, Spain,

2007

SMErobot

TM

(2007-2009), The European Robot Initiative

for Strengthening the Competitiveness of SMEs in

Manufacturing, www.smerobot.org

PLUG-AND-PRODUCE TECHNOLOGIES - On the Use of Statecharts for the Orchestration of Service Oriented Industrial

Robotic Cells

277