REGISTRATION APPROACHES FOR AUGMENTED REALITY

A Crucial Aspect for Successful Industrial Application

Katharina Pentenrieder and Peter Meier

Metaio GmbH, Infanteriestrasse 19, Munich, Germany

Technical University Munich, Germany

Keywords:

Augmented Reality, Applications, Industrial Registration.

Abstract:

In the past years, a variety of Augmented Reality (AR)-based applications were created, aiming to support

industrial processes. Although these first demonstrator applications or prototypes cover all parts of the indus-

trial product process - design, planning and production, service and maintenance - only a few of them actually

turned into established and applied solutions. Reasons for this lack of acceptance are - amongst others - their

insufficient usability and accuracy.

One crucial step in the accuracy chain for an Augmented Reality system is the registration of real and virtual

world. This paper presents different approaches for industrial registration, which are being investigated in the

context of an Augmented Reality based factory planning application. The resulting toolbox promises to be

helpful and valuable for general application in industrial AR. To support the choice for an optimal registra-

tion method for a given scenario, the toolbox is currently being evaluated according to usability and accuracy

criteria. The current state of this evaluation as well as future planned studies are also outlined here.

1 INTRODUCTION

In the past years, a variety of AR-based applications

were created, aiming to support industrial processes.

These applications cover all parts of the industrial

product process: design, production and planning,

or service and maintenance. However, only a few

of them actually managed to develop from demon-

strator applications or prototypes into valuable and

established solutions. Regenbrecht et al. state, that

the maturity of contributing technologies (tracking,

displays, etc.) does not suit the demanding industrial

conditions yet regarding robustness, reliability,

quality and practical experience (Regenbrecht, 2006).

With respect to quality and practical experience, a

successful industrial AR application must be easy to

use and sufficiently accurate, offering a well thought

out interface which meets the concrete needs of the

industrial environment.

One important aspect for AR applications in general

and in specific for industrial AR scenarios is precise

alignment of virtual content with the user’s view of

the real world, hence good registration accuracy.

1.1 Motivation

The overall registration accuracy is depending on sev-

eral influence factors. In (Holloway, 1997), Holloway

lists tracking, calibration and modeling as main error

sources in AR systems. For industrial environments,

the tracking factor often needs to be extended by a

referencing offset pose (translation and rotation) con-

necting the tracking target (or tracking world) coordi-

nate system with the model coordinate system which

later holds the virtual content (see figure 1).

The tracking system in general provides as output

the transformation between the tracking world coordi-

nate system and the tracking target coordinate system.

However, sometimes an additional offset is needed to

move from the tracking target to the required model

coordinate system. Digital car bodies or car parts

for instance, usually have a specific model coordi-

nate system which lies in the middle of the front axle

(right-handed, y pointing to the back of the car, z go-

ing up). When tracking a real car body in an AR fac-

tory planning scenario, the tracking target cannot be

placed in accordance with the model coordinate sys-

tem, but needs to be attached to some surface part of

the car body. To overlay virtual information on the

real car body, it is thus necessary to determine the

426

Pentenrieder K. and Meier P. (2008).

REGISTRATION APPROACHES FOR AUGMENTED REALITY - A Crucial Aspect for Successful Industrial Application.

In Proceedings of the Third Inter national Conference on Computer Graphics Theory and Applications, pages 426-431

DOI: 10.5220/0001099704260431

Copyright

c

SciTePress

offset from the target coordinate system to the model

coordinate system.

Figure 1: Coordinate systems in an industrial AR environ-

ment.

1.2 Support for Industrial Registration

Motivated by these needs, this work presents differ-

ent tools for supporting industrial registration. The

following approaches for the determination of the ref-

erence offset are described:

• Referencing using an external coordinate mea-

surement machine (CMM): The most reliable ref-

erencing process requires a CMM at hand.

• Referencing using 3D-3D correspondences:

Given tracking data and CAD data, manu-

ally defined correspondences can be used for

referencing.

• Referencing using 2D-3D correspondences: In

this case, image data and CAD data are combined

to do the referencing process.

• Referencing using digital data manipulation

(CAD-based): Finally, the referencing process

can be bypassed by bringing model and tracking

target coordinate system into accordance.

The different approaches shall be evaluated

according to their usability and accuracy. This

evaluation process is currently undertaken and its

results will support the choice of referencing tools for

concrete application scenarios. Usability is measured

in terms of needed input data, needed knowledge for

performing the registration and time consumption of

the task. For accuracy evaluation, an estimate for the

resulting pose accuracy shall be determined based on

the underlying calculations.

2 RELATED WORK

Registration and registration error analysis have been

subject to many publications in the area of Aug-

mented Reality. A comprehensive overview on reg-

istration error analysis is given in (Holloway, 1997).

Here, Holloway states tracking, calibration and mod-

eling as main sources of registration error. Based

on these sources of error, research has been done

to improve or analyze registration accuracy in terms

of tracking systems (Hoff and Tyrone, 2000), (Davis

et al., 2003), calibration methods (Gibson et al.,

2002), (Vigueras Gomez et al., 2005) or complete AR

systems (Kato and Billinghurst, 1999).

This work covers another aspect of registration,

needed besides good tracking and calibration, when

the tracking target cannot be placed at the desired lo-

cation: the determination of a referencing offset, as

described above (see figure 1).

In their work on the integration of Augmented Reality

in the assembly domain, Reinhart et al. mention the

importance of referencing, that is the determination of

the relative position of displayed objects to known ref-

erence marks (Reinhart and Patron, 2003). Another

example of referencing problems is given in (Appel,

2003). The author states the great effort which is

needed to reference markers (of a marker based opti-

cal tracking system) in the spacious environment and

to place them at the needed positions.

In the following sections, this problem shall be

met by presenting several approaches for industrial

referencing.

3 APPROACHES FOR

REGISTRATION

In the context of an AR application for factory

planning, several approaches for registration were

developed. The application itself is described in

detail in (Pentenrieder et al., 2007). 3D digital

planning data is augmented onto high-resolution

2D images of the real factory to offer possibilities

for AR-based factory planning in terms of distance

measurements, collision detections or variance

comparisons. Tracking is realized through an optical

marker-based tracking.

Depending on the type of application and the

available resources, it is necessary to calculate an

additional referencing offset as described above. The

following possibilities for referencing are available:

REGISTRATION APPROACHES FOR AUGMENTED REALITY - A Crucial Aspect for Successful Industrial

Application

427

3.1 Referencing using an External

Coordinate Measurement Machine

With an external coordinate measurement machine

(CMM), the referencing process can be achieved by

using the referencing functionalities of the CMM.

CMMs provide high-precision measurements based

on a measuring probe. They are equipped with a mea-

suring software, that allows to transform the internal

origin coordinate system to an arbitrary location us-

ing point correspondences.

Using CMM referencing in the context of AR-based

factory planning, requires a CMM which is already

referenced to the model coordinate system (e.g. the

car body coordinate system). This can be achieved

using the CMM measuring software. Then, 3D point

correspondences between tracking target coordinate

system and model coordinate system are used to de-

termine the needed offset. Figure 2 shows an excerpt

of the tool for CMM referencing. The user needs

to specify the four marker corner points of a paper

marker (tracking target) in the CMM coordinate sys-

tem (model coordinate system). Based on these four

points the transformation between the marker coordi-

nate system and the model coordinate system is cal-

culated, by setting up the transformation matrix using

the point coordinate vectors.

u

x

v

x

w

x

c

x

u

y

v

y

w

y

c

y

u

z

v

z

w

z

c

z

0 0 0 1

−1

with u =

−−−→

P1P4,

v =

−−−→

P1P2

and w = u × v

For our marker tracking, the origin lies in the cen-

ter of the marker (c = (P1 + P2 + P3 + P4)/4). The

coordinate axes are indicated in figure 2, z pointing to

the observer.

In addition, an accuracy value for the corner point

accuracy can be specified which is then used to esti-

mate the accuracy of the resulting transformation (po-

sitional and rotational accuracy), see section 4.

Figure 2: CMM referencing.

Figure 3: Referencing using 2D-3D point correspondences.

3.2 Referencing using 2D-3D

Correspondences

The next option for referencing is based on 2D-3D

point correspondences which are provided by the user

through clicks. The tool requires image data and cor-

responding 3D digital data. Figure 3 presents the tool

in usage. 2D points are selected in the image of the

scene and 3D points are chosen in a viewer show-

ing the corresponding digital model. The point cor-

respondences are sent to a camera pose estimation al-

gorithm, that calculates the transformation from the

camera coordinate system (in our case this is the

tracking world coordinate system) to the model co-

ordinate system.

3.3 Referencing using 3D-3D

Correspondences

When information on specific points in the 3D model

is available, 3D-3D correspondences can be used for

referencing. In this case, selected locations are used

which are known in the 3D digital model and can

be tracked easily in the real environment. An ex-

ample from industry are specific drill-holes which

are calibrated precisely when the object is manufac-

tured. These holes are known exactly in the digital

data. Their real counterparts can be tracked by us-

ing adapters, that fix the tracking target to the calibra-

tion point (e.g. drill hole). Figure 4 depicts a marker

equipped with an adapter to fit the drill holes of an

align fixture. The 3D-3D referencing tool uses shots

of a scene featuring adapter markers for selected cali-

bration points and a list of corresponding digital 3D

coordinates to estimate the transformation between

camera (tracking world) coordinate system and model

coordinate system. Given this transformation, the off-

sets from each marker (tracking target) to the model

coordinate system can be calculated, referencing thus

each single marker to the model coordinate system.

For optimization purposes, the tool first optimizes the

GRAPP 2008 - International Conference on Computer Graphics Theory and Applications

428

Figure 4: Adapter for 3D-3D referencing.

offsets between all available markers over all given

images and then performs the referencing step to the

model coordinate system. That way, the resulting

transformation is optimized with respect to the given

images and offers thus optimal conditions for later

planning and analysing tasks based on the same im-

age data.

3.4 Referencing using a CAD-based

Approach

The last approach requires some knowledge in the

CAD environment. Here, the digital model itself is

manipulated to fit better the requirements for its usage

in the AR scenario. A favorable location in the real

environment is chosen which can be easily retrieved

in the digital representation, for instance a drill-hole.

The tracking target is placed at the chosen location in

the real world. Then, a CAD tool is needed to move

the coordinate system of the digital model from its

current position to the location chosen for the tracking

target in the real environment. That way, the transfor-

mation from the tracking target coordinate system to

the model coordinate system does no longer require

a translation, as their origins are identical. To com-

pensate for the rotational discrepancy, the model is

loaded in the factory planning environment and rota-

tion changes around the different axes are performed

with sub-degree precision, until optimal visual con-

sistency is achieved.

4 EVALUATION APPROACH

The referencing toolbox shall be evaluated with re-

spect to accuracy and usability criteria. As this work

is in progress, this section presents the current state of

our analysis.

4.1 Accuracy Evaluation

For the evaluation of accuracy, some assumptions on

the input accuracy are needed which can then be used

to calculate an accuracy statement for the resulting

translation and rotation. The next paragraphs de-

scribes the basic work which has already been done in

order to prepare for a comprehensive accuracy study.

CMM Referencing. When a CMM is used for ref-

erencing, the input accuracy is provided by the posi-

tional accuracy of the CMM which is usually stated

in the machine specification. Given this value, the

resulting transformation accuracy can be calculated

using backward error propagation (see for instance

(Hartley and Zisserman, 2003)).

The base formula for backward propagation is given

by

[R|t] ·q

k

= p

k

⇒ [R|t]· q

k

− p

k

= 0

where [R|t] denotes a 4 × 4 transformation matrix

based on rotations around the three axes r

x

,r

y

,r

z

and

a three-dimensional translation (t

x

,t

y

,t

z

), p

k

are the

measured points in the CMM coordinate system and

q

k

are the corresponding points in the marker (target)

coordinate system.

For the calculation, three point correspondences are

needed which form the matrix

F =

[R|t] · q

1

− p

1

[R|t] · q

2

− p

2

[R|t] · q

3

− p

3

= 0

The Jacobian matrix which represent the uncertainty

is then given by

J

F

=

δF(q

k

, p

k

)

δ(t

x

,t

y

,t

z

,r

x

,r

y

,r

z

)

This calculation process is integrated in the tool de-

picted in figure 2. Concrete accuracy values can be

calculated by entering a positional accuracy for the

used coordinate measurement machine together with

the determined 3D points.

2D-3D Referencing. For 2D-3D referencing the in-

put accuracy is the accuracy with which the user can

click a specific point in an image and on a 3D digi-

tal model. To determine this click accuracy tests were

performed using our marker tracking as basis. The

participants were asked to click on three example im-

ages of a paper marker (1: camera image 640x480

pixel, 2: camera image 3008x2000 pixel, 3: simu-

lated image 3008x2000) of different quality and se-

lect a specific corner point within the environment of

the 2D-3D referencing tool. For image 1 and 2 the

results were compared with the respective corners de-

tection results of our marker tracking algorithm, for

image 3 the real values were known due to simulation.

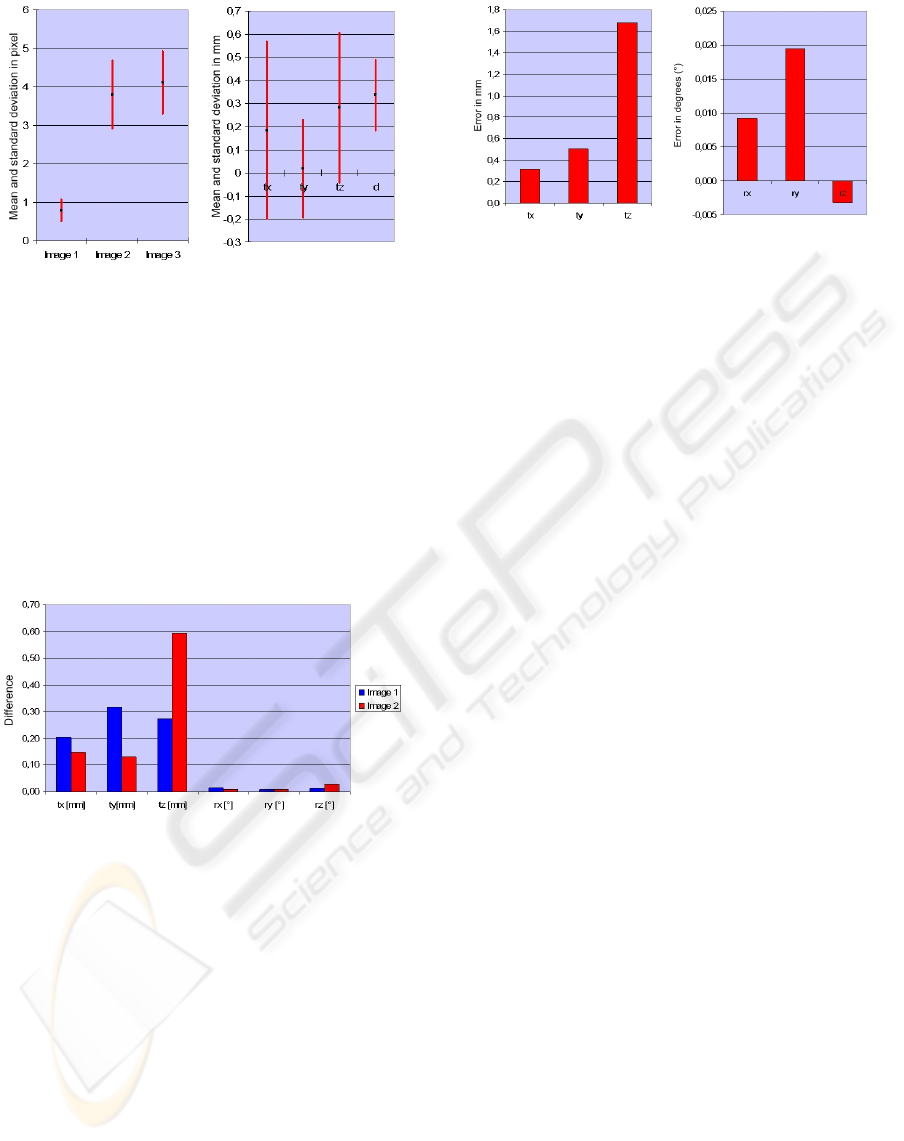

The results of this study (average euclidean distance

and standard deviation in pixel) are shown in figure

REGISTRATION APPROACHES FOR AUGMENTED REALITY - A Crucial Aspect for Successful Industrial

Application

429

Figure 5: Results of the click tests: (a) 2D case (b) 3D case.

5 (a). A similar test was performed for the 3D case,

whose results are visualized in figure 5 (b) (mean er-

ror and standard deviation in 3D and for the euclidean

distance). In a second step, the detected errors and

standard deviations were used to add Gaussian noise

to the correct marker corners and compare the noisy

pose results with the correct ones. Figure 6 presents

those results for the low (image 1) and the high reso-

lution case (image 2). User clicks can thus compete

very well with image based corner detection.

Figure 6: Differences in translation and rotation for the im-

ages.

3D-3D Referencing. For the 3D-3D referencing

case we consider the 3D model data to be perfect.

Thus, the optimization depends on the quality of

the adapter and on the marker tracking determining

the location of the marker. Figure 7 shows a pose

error calculation for a representative 3D-3D refer-

encing scene based on the accuracy information de-

termined for our marker tracking (see (Pentenrieder

et al., 2006) ).

CAD Referencing. For the CAD approach it is dif-

ficult to create an accuracy statement. The output

again depends on the quality of the target adapter

and the tracking. The position is then fixed manu-

ally through coordinate system movement. Due to

Figure 7: Pose error for 3D-3D referencing.

CAD scaling and the selection of favorable points the

re-positioning of the coordinate system can be done

with model accuracy, meaning with the accuracy of

the model tessellation (polygonal representation of

the real object). The rotation is adapted manually. In

case a 0.1

◦

step size is taken, the maximum accuracy

achievable is in this range.

4.2 Usability Evaluation

For the usability evaluation the following criteria are

regarded: input requirements, needed knowledge to

perform the referencing process and output informa-

tion.

CMM Referencing. CMM referencing requires

knowledge about the usage of the CMM and its mea-

suring software. Thus a skilled person needs to do the

task, providing CMM point coordinates as input for

the referencing tool. The output consists of a trans-

formation from the marker coordinate system to the

CMM coordinate system and a corresponding accu-

racy value for the calculation.

2D-3D Referencing. 2D-3D referencing is proba-

bly the easiest way of creating a reference offset.

Corresponding image and model data needs to be

available. By simple clicks, the user identifies cor-

respondences between 2D and 3D world. The result

is given as a transformation from the camera to the

model coordinate system. Different from the other

approaches, here no intermediate marker coordinate

system is needed.

Still, it is important to have image data available

where correspondences can be identified easily.

3D-3D Referencing. 3D-3D referencing requires a

set of images which show markers attached to se-

lected locations of an object, that are also known in

GRAPP 2008 - International Conference on Computer Graphics Theory and Applications

430

the digital world. The tool then calculates the ref-

erencing offsets based on this input data. However,

the crucial aspect is the acquisition of this data, hence

the positioning of the markers using adapters and the

identification of the corresponding CAD point infor-

mation. For special locations (e.g. drill holes) this

digital data might already be given and adapters for

such holes need to be manufactured once and can then

be reused.

As the referencing offset is optimized over all mark-

ers and over all images, the outcome is favorable for

analysis with the given image set.

CAD Referencing. Similar to the CMM referenc-

ing, the CAD-based approach requires a skilled per-

son who is able to manipulate the given digital model

data, such as moving the model coordinate system to

a specific location. Furthermore, the marker needs to

be placed at the corresponding location of the real ob-

ject, similar to the 3D-3D case. Then, the manipu-

lated model needs to be superimposed onto an image

of the real scene with the marker in place to optimize

the orientation of the model using manual adjustment.

Next to CAD knowledge, this approach therefore also

requires experience in manual adjustment.

5 CONCLUSIONS AND

OUTLOOK

Accurate registration of real and virtual data is

crucial for many Augmented Reality application. In

industrial environments, specific data, knowledge

and systems are available which can support the

registration process. Still, available resources differ

from application to application. It is therefore

necessary to provide the users with a comprehensive

toolbox of different referencing methods, offering the

flexibility to choose the referencing approach suiting

best the given application.

We created a toolbox of various referencing

methods and are currently evaluating the different ap-

proaches with respect to accuracy and usability. Our

first studies show, that each tool has its advantages

and disadvantages. Based on these first results, we

will further evaluate the different approaches using

industrial scenarios in factory planning. The concrete

application of all approaches to the same scenario

will allow an absolute comparison and actual user

feedback will help us to verify the current implemen-

tations and gain experience for improvements and

extensions.

ACKNOWLEDGEMENTS

Part of this work was funded by the EU Project DiFac

(FP6-2005-IST-5No.035079).

We thank Volkswagen Group Research for their

continuous collaboration and valuable support in the

field of AR-based factory planning.

REFERENCES

Appel, M. (2003). Augmented reality f

¨

ur innovative

service- und engineering l

¨

osungen im kraftwerksbere-

ich. In 3. ARVIKA-Forum.

Davis, L., Clarkson, E., and Rolland, J. (2003). Predicting

accuracy in pose estimation for marker-based track-

ing. In Second IEEE and ACM International Sympo-

sium on Mixed and Augmented Reality ISMAR.

Gibson, S., Cook, J., Howard, T., Hubbold, R., and Oram,

D. (2002). Accurate camera calibration for off-line,

video-based augmented reality. In International Sym-

posium on Mixed and Augmented Reality (ISMAR),

pages 37–46.

Hartley, R. and Zisserman, A. (2003). Multiple View Geom-

etry. Cambridge University Press.

Hoff, W. and Tyrone, V. (2000). Analysis of head pose ac-

curacy in augmented reality. In IEEE Transactions on

Visualization and Computer Graphics, volume 6.

Holloway, R. (1997). Registration error analysis for aug-

mented reality. In Presense: Teleoperators and Virtual

Environments, pages 413–432.

Kato, H. and Billinghurst, M. (1999). Marker tracking and

hmd calibration for a video-based augmentedreality

conferencing system. In Second IEEE and ACM In-

ternational Workshop on Augmented Reality (IWAR),

pages 85–94.

Pentenrieder, K., Bade, C., Doil, F., and Meier, P. (2007).

Augmented reality - based factory planning - an appli-

cation tailored to industrial needs. In Sixth IEEE and

ACM International Symposium on Mixed and Aug-

mented Reality (ISMAR).

Pentenrieder, K., Meier, P., and Klinker, G. (2006). Anal-

ysis of tracking accuracy for single-camera square-

marker-based tracking. In Dritter Workshop Virtuelle

und Erweiterte Realitaet der GI-Fachgruppe VR/AR.

Regenbrecht, H. (2006). Emerging Technologies of Aug-

mented Reality: Interfaces & Design, chapter In-

dustrial Augmented Reality Applications, pages 283–

304. Idea Group Publishers.

Reinhart, G. and Patron, C. (2003). Integrating augmented

reality in the assembly domain - fundamentals, bene-

fits and applications. ANNALS-CIRP, 52(1):5–8.

Vigueras Gomez, J.-F., Simon, G., and Berger, M.-O.

(2005). Calibration errors in augmented reality: a

practical study. In Fourth International Symposium on

Mixed and Augmented Reality (ISMAR), pages 154–

163.

REGISTRATION APPROACHES FOR AUGMENTED REALITY - A Crucial Aspect for Successful Industrial

Application

431