RFID Data Management in Supply Chains: Challenges,

Approaches and Further Research Requirements

Adam Melski, Lars Thoroe and Matthias Schumann

University of Goettingen, Institute of Information Systems, Dep. 2, Goettingen, Germany

Abstract. The implementation of RFID leads to improved visibility in supply

chains. However, as a consequence of the increased data collection and

enhanced data granularity, supply chain participants have to deal with new data

management challenges. In this paper, we give an overview of the current

challenges and solution proposals in the area of data collection and

transformation, data organization and data security. We also identify further

research requirements.

1 Introduction

As a result of, in particular, efforts towards standardization and the falling costs of

technology, RFID (Radio Frequency Identification) systems are leaving their niche

and are being increasingly implemented in an effort to eliminate inefficiency and the

lack of visibility in global supply chains. Large retailers like Wal-Mart [1] and Metro

[2] function as the primary pioneers in the introduction of RFID, but smaller

businesses, for instance, the medium-sized textile company Lemmi Fashion [3], have

recently started to optimize their supply chains with the help of this new technology

as well. Above all, the implementation of RFID leads to improved visibility in

complex and, when using conventional technologies like the barcode, hardly

transparent, supply chains [4]. These advantages are being utilized in at the expense

of new challenges in the area of data management, which can be primarily attributed

to the rise in data volumes. The substantial data volumes are a result of the increased

amount of data capture points, more frequent capture sessions and enhanced data

granularity. Considering this background information, the following areas of

investigation can be identified:

• Data capture and transformation: RFID systems function first and foremost as

data generators. Because of the physical characteristics of the technology, the data

are often faulty (dirty data). Besides, the data possess a raw character (low-level

data) and must therefore be filtered from the middleware, compressed and properly

transformed before being relayed to their respective application systems (high-level

information).

• Data organization: The exchange of object related data has seen a significant

increase in RFID-supported supply chains. The provision and relay of the data

Melski A., Thoroe L. and Schumann M. (2007).

RFID Data Management in Supply Chains: Challenges, Approaches and Further Research Requirements.

In Proceedings of the 1st International Workshop on RFID Technology - Concepts, Applications, Challenges, pages 61-74

DOI: 10.5220/0002413200610074

Copyright

c

SciTePress

represent new challenges for the hitherto existing informational architecture in

business networks.

• Data security: The more data on their products businesses save and exchange, the

simpler it becomes for competitors to gain access to these data. These businesses

are therefore exposed to a greater danger of manipulation and unauthorized data

retrieval, particularly because of the fact that data are stored directly on the object.

This contribution provides an overview of the current challenges and solution

proposals in the above-mentioned areas of data management in RFID-based supply

chains. Besides the illustration of the present state of research, the demands of future

research will be identified. In section 2, general data management challenges will be

derived based on the characteristics of RFID systems. Thereupon, current data

management concepts will be presented in section 3 on the basis of the three

identified areas of data management. Furthermore, future research questions will be

identified in this section. Finally, section 4 concludes with a short summary.

2 RFID Data Management Challenges

RFID systems use radio waves to facilitate communication between transponders and

readers. This leads, on the one hand, to the capability to identify objects from a

reasonable distance without line of sight; on the other hand, the identification process

is subject to conventional physical influences and can lead to reading anomalies (e.g.

tags are not recognized). Besides, mistakes can occur at the operational process level.

For example, a product in the supermarket can make its way more than once from the

warehouse to the supermarket shelf and back again (e.g. because there's no shelf

room). Such cyclic object movements could be interpreted as anomalies and then

wrongly filtered by the system [5]. Besides, if sensors which, for instance, measure

the local temperature are implemented in addition to RFID tags, then they can cause

incorrect data to be delivered because of a technical defect [6]. For the reasons just

named, the demand for increased data filtering in RFID systems is collectively posited

in the relevant literature [7] [8] [9].

Data capture by means of RFID requires no manual actions, which causes a

decrease in the cost of the data capture process. This implies that the number of

capture sessions and points increases. For instance, with the implementation of so-

called smart shelves, data from the objects on the shelves can be read continuously.

This has multiple effects:

• Firstly, the data quantity increases significantly. These data must be compressed

before they are relayed. On this point, the implementation of so-called aggregation

methods is discussed in the literature [10]. These methods decrease data quantity

without loss of information. In addition, suitable archiving methods should be

implemented as a means of separating old, as well as obsolete, data from data

being presently used. This would guarantee a better system performance [11]. This

is because, in RFID systems, which, above all else, create a memory map of the

62

real world in its digital counterpart, current data (e.g. concerning ongoing good

movements) are of primary interest [12].

• Secondly, RFID data are quite dynamic, whereby the time component must be

adequately mapped. New data models are therefore necessary [13].

• Thirdly, the data accumulate continuously (asynchronous) [14]. Whereas a barcode

is only read when needed, transponders continually transmit data to the reader.

These data must be processed in real-time and then relayed to the connected

systems.

• Fourthly, as objects pass multiple read points, data from different readers must be

compressed to complex events which represent the object flow. This generally

occurs through the definition of predefined rules [15].

RFID allows the data from multiple objects to be read simultaneously (bulk

reading). Possible collisions, by which more than one signal arrives simultaneously,

and therefore cannot be separated by the reader, must be avoided through the

implementation of anti-collision algorithms [16].

The efficient identification procedure of RFID is not the only reason why it is of

interest for business processes. Rather, it is the ability to store data directly on the

object that provides impetus for innovative implementation. The fact that the data are

bound to the object means that they can be read at all times by whoever is the

temporary possessor of the object. Although this, in most cases, is not problematic,

being even desired, there are certain 'sensitive' data which should not be accessible to

everyone. This is, as a result of public discussion, especially the case as it pertains to

consumer privacy (for instance, pertaining to shopping at the supermarket) [17]. But

companies also cannot afford to give away sensitive data (e.g. product features,

maintenance data). The data stored on the tag must therefore be adequately protected

against potential abuse or manipulation. Suitable data protection mechanisms (e.g.

encryption) must be implemented.

In open-loop supply chain applications, by which the tagged object runs through a

series of supply chain levels, data stored on the object and/or in central databases

should be accessible to all partners. Only in this way can the transparency in the

supply chain be enhanced. The construction of an information network which spans

all companies and makes access to these data possible is, consequently, necessary to

this end. Furthermore, questions of data allocation and distribution

(centralized/decentralized data storage) need to be considered.

3 RFID Data Management Concepts

3.1 Data Collection and Transformation

An important question in the area of RFID data collection in supply chains regards the

data capture points and the tagging level (pallet/case/item). The vision of complete

visibility through the use of RFID appears to be economically unreasonable in most

cases. The relevant literature attests retail in particular as the last element in the

supply chain high potential benefits through RFID data collection. Thus, the

63

distribution of costs and benefits of an RFID implementation within supply chains

continues to be an object of research [18] [19].

A further important area of research is the performance capability of the reading

infrastructure. Two main factors are relevant for the measurement of the performance

capability of a data capture system: accuracy and efficiency [20].

Acurracy: A 100% data capture is not necessary in all applications; however, in many

cases – for instance, when striving to monitor product movement in supply chains

exactly – a read rate of near to 100% is practically required. This rate, however, is

often not achieved and faulty readings occur. The most significant example of faulty

reading is the failure to identify tags which are located within the vicinity of a reader.

The most important sources of these failures can be assigned to collisions [21] [22].

In order to avoid disturbances through collisions, there exist various anti-collision

protocols; the development of effective and efficient algorithms remains, however, a

topic of research [23] [24] [25] [26]. Another source of failures is the tag detuning,

misalignment and shielding [21] [27].

A possible solution for this category of problems lies in the redundant

implementation of RFID infrastructure. On the one hand, the accuracy of the system

can be improved through the implementation of several readers with overlapping

reader fields. On the other hand, several tags (so-called mirror tags) can be used for

the identification of a single object [20].

Efficiency of data capture: An essential criterion in this case is the speed at which the

tags are read. The speed at which a single tag is read depends on the frequency being

used by the system as well as on the extent of the content to be read. The latter is

greatly determined by the chosen form of data organization. The demand for research

exists with respect to the question as to with which level of data organization the

required speed of data provision for controlling the application can be reached. The

quick bulk reading of several tags is equally a topic of current research [23].

For the afore-mentioned reasons, data input verification in RFID systems needs too be

more sophisticated. Faulty readings have to be identified and eliminated. Several

statistical techniques for the cleaning of RFID data are discussed in the relevant

literature [5] [28] [29]. For instance, Jeffrey, Garofalakis, Franklin present an adaptive

smoothing filter which aggregates and analyses the data from several read cycles

using different, self-tuning window sizes [29].

Following the collection phase, the large quantities of raw data must then be

transformed into usable information. The process of data transformation consists of

the following steps: reduction of the quantity of data, selection of relevant data and

generation of information which serves as a basis for decision-making.

The first two steps are generally taken over by the readers (intra-reader reasoning)

[10]. The generation of information relevant to the decision-making process is,

however, carried out by the connected middleware. This results from the fact that data

from the local reader are no longer sufficient for this process, the generation of

complex events requires an analysis of the data from multiple readers (inter-reader

reasoning) [14].

64

Reduction of data quantity. In general, readers should only relay data to the

middleware when additional information can be generated through the use of these

data. For instance, if transponders are located within the reader field of a particular

reader for a longer period of time, then the same data are read over and over again.

For any particular user, however, the most important data are, first and foremost,

those data pertaining to when the object entered the reading field of the reader and

when the object moved outside the range of that reader. All readings that occur

between these two events are redundant, because they deliver no new information on

the status of the object. This implies that readings should only be relayed when the

status of the object changes. In this way, the quantity of data is reduced without loss

of information [8].

Selection of relevant data. In the next step, the pre-filtered data are subjected to a

selection process. The following scheme, for example, can be used [8] [10] [30]:

• Combination: If a pallet, together with the objects that it contains, is identified,

then these data can be combined into a cluster and relayed together.

• Passing process: If objects pass a gate (for instance, upon entering the warehouse),

then, instead of the events 'object appeared' and 'object disappeared', only a 'pass

event' should be relayed to the applications.

• Simplification of movement paths: For specific data analysis purposes, less

important object movements (like the movement of an object from one warehouse

shelf to another) can be simplified, without the loss of significant information.

Generation of information relevant to the decision-making process. In the final step of

the transformation, information relevant to the decision-making process is generated

from the already-filtered data. During this process, single events are aggregated to

complex events [31], and RFID data are combined with additional context data, as

well as being evaluated according to predefined rules [8]. If, for instance, a product

was identified at specific read points, e.g. 'shelf' and then 'exit', without having first

been identified at the read point 'cashier', then it could be a matter of theft.

Wang and Liu propose a new data model called DRERM (Dynamic Relationship

ER Model) to adequately map RFID data in information systems [11]. Due to the

addition of dynamic relations, the suggested model supports complex queries in the

category of object monitoring and object traceability. Gonzales et al. introduce so-

called RFID-cuboids, which represent RFID data on different abstraction levels (e.g.

data is clustered and presented in an abstract way for decision-makers) [30].

3.2 Data Organization

There are two basic possibilities for data storage in RFID systems: Object-related data

can be deposited in databases and referenced by means of a unique ID (data-on-

network), or data can be stored on the transponder and therefore directly on the object

(data-on-tag) [32].

65

Data-on-Network. In a data-on-network system, a unique ID is stored on the

transponder while all other object related data remain in central databases, which can

be either managed by an information intermediary or can maintain with the supply

chain partners. This is mainly due to the fact that RFID was still too expensive at the

end of the '90s for wide-scale implementation. RFID found itself in a vicious circle, in

which high costs entailed a minimal adoption of the technology and a minimal

adoption of the technology resulted in high costs. For this reason, low-cost

transponders, simple data exchange protocols and elementary data structures were

expected to lead to a breakthrough [33].

If an object is located within the reader field of an RFID reader, then a data

quadruplet is transmitted, consisting of the reader ID, the antenna ID, the object ID

and the time stamp of the reading [8]. With this information, it can be unequivocally

determined where an object is/was located at what time. Further data can be retrieved,

when needed, by the middleware over various networks (e.g. over the internet). In this

case, the data source must be known, that is, the middleware must have access to

information as to which database must be queried in order to retrieve the pertinent

object data.

There are two conceivable possibilities for data storage in this case. On the one

hand, object-related data can be stored centrally and administered by an intermediary;

on the other hand, these data can be stored in each partners’ local databases.

Case study: Forestry. In order to reduce the shrinkage rate of wood on its way from

the forest to the saw mill, the leading German forestry company Cambium has been

using RFID technology since 2005 [34]. The traditional process of putting a small

plastic flag on the logs and then recording the relevant data on paper lead to 15 %

shrinkage in quantity and quality. Therefore, the logs are now furnished with a nail-

shaped RFID tag. The only information on each transponder is a simple unique ID.

Further data (type of tree, length, quality etc.) are sent to a central database using a

handheld device. The data are accessible to all participants in the supply chain

(primarily the forest proprietor, forest workers, haulers, shippers and saw mills). In

order to determine possible discrepancies in quantity, the tags are queried before each

step in the transportation process and the relevant IDs are then transmitted to the

central database. According to the company's initial calculations, it is assumed that

the implementation of RFID will result in a 70 % reduction in shrinkage.

The case-in-point example of data organization using RFID technology

distinguishes itself through the following advantages:

• From the perspective of the participants in the supply chain, it is a matter of a

relatively simple organizational architecture, by which the data management is

outsourced to an informational intermediary.

• Low-cost transponders, on which only an object ID is stored, can be utilised.

However, the following disadvantages can also be identified:

• Central systems distinguish themselves through poor scalability and the problem of

a single point of failure: If there is a system failure at the central point of

operations, then the entire supply chain is affected.

• In the case of central data management, questions of data ownership must be

answered.

66

• A connection to the network is necessary.

Example: EPCglobal. A concrete example of the implementation of a decentralized

data-on-network system is the EPC network [35]. The focus of the EPCglobal concept

is the EPC (Electronic Product Code) number, with the help of which each

transponder is allocated a unique identification number. The EPC constitutes the only

information stored on the transponder. Other data pertaining to the object are

deposited in external databases and referenced by means of unique identification

numbers. The relay of the data to the relevant data source occurs by means of the

Object Naming Service (ONS). The data sources are then offered by the EPC

Information Systems (EPC IS). In order to facilitate the exchange of components

between the EPCglobal network and external processes, the XML-based markup

language PML (Physical Markup Language) was created [36]. The data retrieved

from the readers is filtered and transformed by the middleware.

The data organization in distributed databases possesses the following advantages:

• The decentralized system is easily scalable.

• Compared with centralized data organization, data ownership is clearly regulated.

• Low-cost transponders can be utilized.

In addition to these advantages, however, the following disadvantages must be taken

into account:

• Decentralized data organization represents a complex organizational architecture,

above all requiring extended controls on identity and access.

• A connection to the network is necessary.

Data-on-Tag. The data-on-tag concept is based on the assumption that data that are

needed for the creation of the abstract model in the information system are not

necessarily gathered 'online'. On the contrary, they are captured at the point of action,

which does not necessarily have to be within range of any network. Additionally, it is

not always possible to make control data, which represent real world changes,

available to the real world online. In such cases, the needed data must be physically

present at the point of action [32]. Therefore, it lends itself to store the data on the tag,

the data thereby accompanying the object. Thus, in the data-on-tag concept, the

separation of physical objects from the data pertaining to them, as in conventional

technologies and informational systems, is abolished.

Case study: Lemmi Fashion. The textile manufacturer Lemmi Fashion is equipping all

of its clothing with RFID transponders, which, in addition to their unique IDs, contain

data concerning size, color and other specific information, since the middle of 2005.

The company is implementing RFID technology at the product level in its entire

worldwide supply chain and, for this reason, belongs to the pioneers in the textile

industry [3]. Passive transponders (with a frequency of 13.56 megahertz) are already

being used at four different points in the clothes production and distribution process

(the manufacturing facilities being located mostly in Asia): (1) as the products leave

the manufacturing facility, (2) upon entering the distribution center, (3) in the transfer

from quality control to the warehouse and (4) upon exiting the distribution center. In

addition, several of Lemmi Fashion's customers have already announced their

67

intention to implement an RFID infrastructure (5), whereby all supply chain

participants would profit from the technology. This requires standardization of the

memory’s structure [37].

The data-on-tag concept is distinguished by the following advantages:

• No complex infrastructure or network connection is required.

• The organizational concept scales well by means of decentralized data

management on the object itself (each object representing a small database).

The following disadvantages must be reckoned with:

• In the case that data on the tag is not stored redundantly, access to the data on a

particular object is only possible when that object is physically present.

• The higher storage capacity of the transponders used in data-on-tag systems has the

result that they are more expensive than those used in data-on-network systems.

• The data stored on the tag must be protected from unauthorized access.

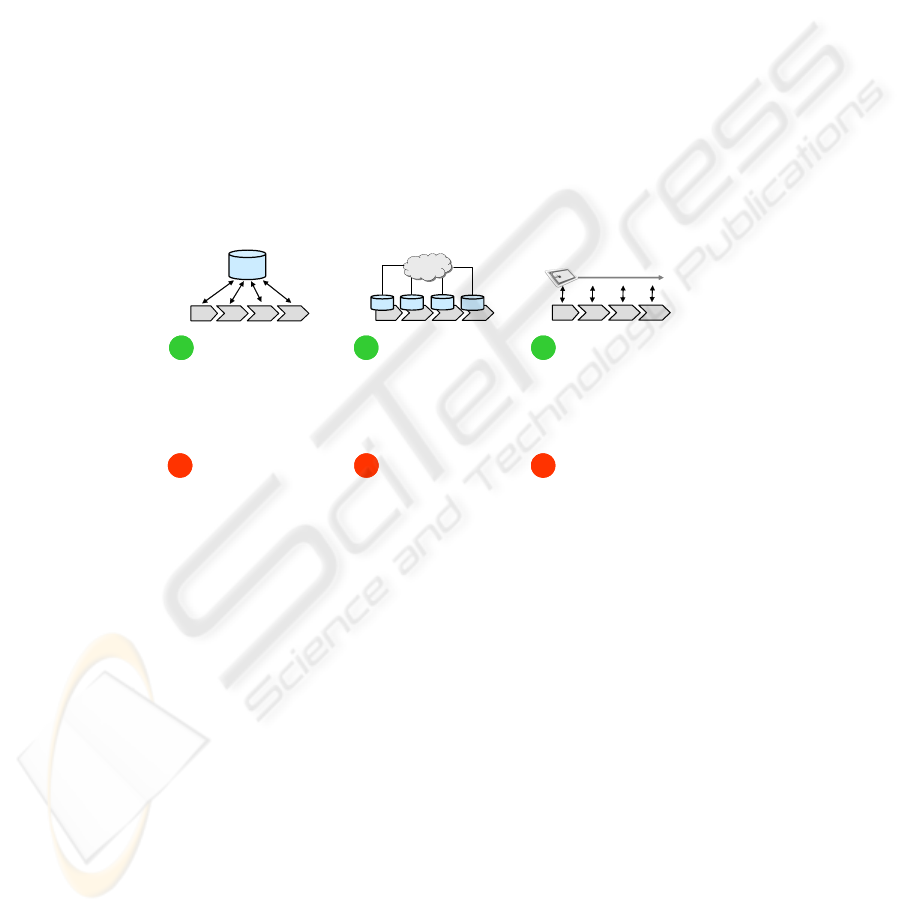

The following figure summarizes and illustrates the advantages and disadvantages

of the proposed concepts of data organization.

Data in central DB

DB

Data in distributed DB

DB

Data on transponder

DB

DB

DB

Internet

++

++ ++

__ __ __

• simple architecture

• simple data management

• low priced tags

• scalability

• no problems concerning

ownership of data

• low priced tags

• complex architecture

• enhanced identity and

access control

• network connection

• single point of failure

• scalability

• ownership of data

• network connection

• data access only when

object present

• cost of tags and storage

capacity

• encryption

• simple architecture

• scalability

• data capture „offline“

Data-on-Network

Data-on-Tag

Fig. 1. Comparison of the concepts of data organization.

3.3 Data Security

The problem of data privacy and security plays a central role in the research on RFID,

although the literature is primarily focused on the protection of personal consumer

data (personal privacy) (e.g. [38] [39] [40]), corporate data security typically being

neglected: “Industrial privacy, i.e., data secrecy, is important too, but less frequently

considered” [41]. Indeed, the two areas of research are based on different

considerations: While consumers are afraid of omnipresent surveillance (loss of

privacy, objects being associated with people), companies are primarily interested in

protecting company-internal data from unauthorized access and potential

manipulation. However, the problems are not completely independent of one another,

68

considering the fact that data security represents a required prerequisite in order to

guarantee data privacy.

Especially in supply chains, the guarantee of data security is of primary

importance, due to the fact that, in these complex systems, a great deal of (mostly

insecure) cross company data exchange occurs. From the perspective of a participant

in the supply chain, four primary threats to data security can be identified [42]:

Corporate espionage threat. Supply chain data can be spied out by competitors by

querying transponders at designated places along the supply chain. Alternatively,

communication can be bugged on the air interface. Both cases can lead to the

evaluation of information from traffic patterns between transponders and readers (e.g.

concerning the transmitted data quantity or the number of read sessions). Using

information on goods movement, competitors can better formulate their own stocking

strategies: 'Individually tagged objects could also make it easier for competitors to

learn about stock turnover rates; corporate spies could walk through shops

surreptitiously scanning items' [41]. A further threat is represented by so-called

'spoofing', in which transponders are imitated by the competitor in order to gain

access to the transponder data, as well as so-called 'cloning' – the (unauthorised)

capture of data and replication of transponders in order to, for instance, counterfeit

high-value products [43].

Competitive marketing threat. By using objects outfitted with transponders, the

unauthorized access by competitors of information on consumer preferences, which

they can then use for their own personal marketing strategies, is made easier.

Infrastructure threat. The RFID infrastructure can, for example, be subjected to

precise denial-of-service attacks, by which the sensitive flow of data can be disturbed.

Physical attacks can, for example, consist of interrupting the flow of power to the

reader(s) or excessive demands on the components. So-called 'shielding' represents

another threat, in which the radio interface can be blocked by metal objects, or

reduced by purposefully transmitting disruptive signals.

Trust perimeter threat. In supply-chain-wide RFID systems, large data volumes are

being exchanged increasingly more often, which opens up more possibilities for

competitors to intercept this information.

In order to guarantee the security of the data on tag, cryptographic protection

measures, in particular, are being propagated [44]. This approach, however, has grave

disadvantages:

• The implementation of cryptographic protection measures is associated with

considerable costs. This represents a great challenge, particularly as it concerns

identification at the product level, where the tag price plays an important role.

• Low-cost passive transponders do not have enough storage capacity for

cryptography. And, although, according to Moore's Law, the storage and

processing capacity of transponders will continue to grow, it is more likely that the

69

prices will fall in similar capacity classes than that new functionality will be

offered at the same price [43].

• The implementation of cryptographic functions for the identification and

authentication of data has the consequence that only transponders and readers

which belong to a certain system are capable of communicating with one another.

Because it is the goal of EPCglobal and ISO that the data stored on transponders be

universally readable, traditional encryption methods are not suitable to protect the

data from abuse.

In an effort to counter the problems just illustrated, a series of security measures

are proposed in the literature. In order to secure low-cost transponders against

counterfeit, a so-called 'relational check code' is proposed, with the help of which it

can be ascertained whether data on the transponder were manipulated [45]. However,

no determination can be made as to which part of the data was changed or to what

degree the change occurred. The problem of counterfeit protection is also treated in

[46]. The authors propose that the block of data comprising the unique object ID be

used to deposit secret information (generated using three hash functions out of the

data blocks Header, Object Class and Object ID) in this memory. Using this approach,

it is possible to determine which data were manipulated. The proposed method has the

advantage that no additional memory is required and, furthermore, no calculations are

performed on the transponder.

Using the two security measures just illustrated, it is not possible to prevent

counterfeit, only to discover it after the fact. In order to achieve an effective level of

data security, active measures are necessary: Floerkemeier et al. describe the

prototypical implementation of a 'watchdog tag', which monitors and records all

reader activity in the proximity [47]. Rieback et al. propose the implementation of a

device with the name 'RFID Guardian', which, similar to a computer firewall,

intercepts reader queries and evaluates them before relaying them to the transponders

[48].

In order to solve the problem of the 'competitive marketing threat', Juels proposes

so-called 'pseudonym throttling' [43]. This is also a simple security mechanism which

can be utilized in low-cost tags. The tag contains a short list of random IDs or

pseudonyms. During each consecutive reading, the tag transmits the next available

pseudonym from its list. In order to eliminate the danger that the list of pseudonyms is

intercepted by multiple read queries performed within a short period of time, the tags

are programmed so that they transmit their data with a predetermined delay.

3.4 Summary of Future Research Requirements

The following table summarizes the topics illustrated up to this point and gives an

overview of suitable research questions relating to data management in the context of

RFID-based supply chains.

70

Table 1. Overview of research questions.

Data collection and transformation

What consequences do demands on efficiency and accuracy have when choosing a type of data

organization?

Extent of the data collection: What degree of visibility is economically reasonable?

How can the performance of the RFID data collection be adequately measured?

Into what form must the data be transformed for various information consumers along the supply chain?

To what extent should the data transformation process be decentralized? What problems result when

extensive data transformation is already being conducted before relay to the applications?

Which traditional data warehouse concepts can be used in RFID systems? How can the data effectively

be mined? What (potential) modifications must be made?

Data organization

What degree of decentralization is advantageous with respect to the proposed concepts?

Will new information intermediaries arise to manage the huge data volumes?

Which data should be stored on the object and which data should remain in databases?

Based on which rules should stored data be synchronized in a redundant data management system (data-

on-network, as well as data-on-tag)?

Which supply chain steps are well-suited for 'object-accompanying' data storage?

How should the access concepts be regulated in a decentralized data management system?

Data security

What value do the data stored on the object represent for the company and what could competitors

possibly do with the data?

How can data security be guaranteed while still maintaining the use of low-cost tags?

What alternative security measures could be employed instead of encryption (mainly because of costs

and storage capacity)?

How can the RFID infrastructure be protected from denial-of-service attacks?

To what extent do additional security measures restrict the propagandized 'open' RFID systems?

4 Conclusion

Although RFID has entered supply chain management practice, the technology still

poses several challenges that need to be addressed by research. In this contribution we

discuss the particular challenges and possible solutions that practice faces in the field

of RFID data management. The massive amount of potentially unreliable data is the

main challenge in the field of data collection and transformation. Whereas progress

has been made in the development of algorithms for the fast and reliable bulk reading,

the improvement of these methods still constitutes a topic for future research in order

to provide the accuracy and efficiency that practice requires. Other research

opportunities remain in the field of data transformation, which deals with the question

71

how raw and dirty data can be converted into information. Data organization persists

to be of interest for research and practice. The recent inclusion of user memory in the

standards of EPCglobal indicates a gain in importance of the data-on-tag concept. The

extent of implementation of this decentralized approach as well as questions

concerning the access of distributed data will be future objects of research. Data

security faces severe challenges as research finds itself caught between the need for

security measures and the necessity for simple and low priced tag architectures. This

predicament intensifies when one considers possible effects of item-level tagging on

consumer privacy. In response to early experiences from retailers who faced massive

opposition when piloting item-level tagging, research needs to continue with the

development of feasible security measures. In summary it can be ascertained that

although RFID data management has been the object of intense research for the last

few years, a variety of topics for future research remain.

References

1. Seidman, T.: The Race for RFID. The Journal of Commerce 4, 48 (2003) 16-18

2. Collins, J.: Metro Group reaps gains from RFID. RFID Journal (2005)

3. Speer, J. K.: Making (13.56) Waves. Apparel 2 (2006) 22-24

4. Michael, K., McCathie, L.: The Pros and Cons of RFID in Supply Chain Management.

Proceedings of the International Conference on Mobile Business (2005) 623-629

5. Rao, J., Doraiswamy, S., Thakkar, H., Colby, L. S.: A deferred Cleansing Method for RFID

Data Analytics. Proceedings of the 32nd VLDB Conference, Seoul (2006) 175-186

6. Jeffery, S. R., Alonso, G., Franklin, M. J., Hong, W., Widom, J.: Declarative Support for

Sensor Data Cleaning. Pervasive Computing (2006) 83-100

7. Janz, B. D., Pitz, M. G., Otondo, R. F.: Information Systems and Health Care II: Back to

the Future with RFID: Lessons Learned - Some Old, Some New. Communications of the

Association for Information Systems 15, 7 (2005) 1-32

8. Cheong, T., Kim, Y.: RFID Data Management and RFID Information Value Chain Support

with RFID Middleware Platform Implementation. Lecture notes in computer science, Vol.

3760, Springer-Verlag, Berlin Heidelberg New York (2005) 557-575

9. Zhang, X., Hu, T., Janz, B. D., Gillenson, M. L.: Radio Frequency Identification: The

Initiator of a Domino Effect. Proceedings of the 2006 Southern Association for Information

Systems Conference (2006) 191-196

10. Floerkemeier, C., Lampe, M.: RFID Middleware Design - Addressing Application

Requirements and RFID Constraints. Proceedings of the 2005 joint conference on Smart

objects and ambient intelligence, Grenoble (2005) 219-224

11. Wang, F., Liu, P.: Temporal Management of RFID Data. Proceedings of the 31st VLDB

Conference, Trondheim (2005) 1128-1139

12. Babcock, B., Babu, S., Datar, M., Motwani, R., Widom, J.: Models and Issues in Data

Stream Systems. Proceedings of 21st ACM Symposium on Principles of Database Systems

(PODS 2002), June 3-5, 2002, Madison, Wisconsin (2002)

13. Hu, Y., Sundara, S., Chorma, T., Srinivasan, J.: Supporting RFID-based Item Tracking

Applications in Oracle DBMS Using a Bitmap Datatype. Proceedings of the 31st VLDB

Conference, Trondheim (2005) 1140-1151

14. Sarma, S.: Integrating RFID. QUEUE 10 (2004) 50-57

15. Hanebeck, C.: Managing Data from RFID & Sensor-based Networks. Retrieved from:

www.globeranger.com/pdfs/futureoftheedge/GlobeRangerRFIDData.pdf (2004)

72

16. Shih, D., Sun, P.-L., Yen, D.C.: Taxonomy and Survey of RFID Anti-Collision Protocols.

Computer and Communications 29, 11 (2006) 2150-2166

17. Spiekermann, S., Berthold, O.: Maintaining privacy in RFID enabled environments -

Proposal for a disable-model. In: Robinson, P., Vogt, H., Wagealla, W. (eds.): Privacy,

Security and Trust within the Context of Pervasive Computing. Springer-Verlag, Berlin

Heidelberg New York (2005) 137-146

18. Hardgrave, B. C., Armstrong, D. J., Riemenschneider, C. K.: RFID Assimilation Hierarchy.

40th Annual Hawaii International Conference on System Sciences (2007)

19. Asif, Z., Mandiviwalla, M.: Integrating the Supply Chain with RFID: A Technical and

Business Analysis. Communications of the AIS 15 (2005) 393-427

20. Vaidya, N., Das, S. R.: RFID-Based Networks – Exploiting Diversity and Redundancy.

Technical Report (2006)

21. Finkenzeller, K.: RFID Handbook: Fundamentals and Applications in Contactless Smart

Cards and Identification. John Wiley & Sons, New York (2003)

22. Jain, S., Das, S. R.: Collision Avoidance in a Dense RFID Network. Proceedings of the 1st

international workshop on Wireless network testbeds, experimental evaluation &

characterization. ACM Press, New York (2006) 49-56

23. Kodialam, M., Nandagopal, T.: Fast and Reliable Estimation Schemes in RFID Systems.

Proceedings of the 12th annual international conference on Mobile computing and

networking. ACM Press, New York (2006) 322-333

24. Huang, X.: An Improved ALOHA Algorithm for Improved RFID Identification. Lecture

Notes in Computer Science, Vol. 4253. Springer-Verlag, Berlin Heidelberg New York

(2006) 1157-1162

25. Floerkemeier, C., Wille, M.: Comparison of Transmission Schemes for Framed ALOHA

based RFID Protocols. International Symposium on Applications and the Internet

Workshops (2006) 92-97

26. Myung, J., Lee, W.: Adaptive splitting protocols for RFID tag collision arbitration.

Proceedings of the seventh ACM international symposium on Mobile ad hoc networking

and computing. ACM Press, New York (2006) 202-213

27. Floerkemeier, C., Lampe, M.: Issues with RFID Usage in Ubiquitous Computing

Applications. Lecture Notes in Computer Science, Vol. 3001. Springer-Verlag, Berlin

Heidelberg New York (2004) 188-193

28. Jeffery, S. R., Alonso, G., Franklin, M. J., Hong, W., Widom, J.: A Pipelined Framework

for Online Cleaning of Sensor Data Streams. Proceedings of the 22nd International

Conference on Data Engineering (2006) 140

29. Jeffery, S. R., Garofalakis, M., Franklin, M. J.: Adaptive Cleaning for RFID Data Streams.

Proceedings of the 32nd International Conference on Very Large Data Bases, Seoul (2006)

163-174

30. Gonzales, H., Han, J., Li, X., Klabjan, D.: Warehousing and Analyzing Massive RFID Data

Sets. Proceedings of the International Conference on Data Engineering (2006)

31. Bornhövd, C., Lin, T., Haller, S., Schaper, J.: Integrating Automatic Data Acquisition with

Business Processes Experiences with SAP's Auto-ID Infrastructure. Proceedings of the 30th

VLDB Conference, Toronto (2004) 1182-1188

32. Diekmann, T., Melski, A., Schumann, M.: Data-on-Network vs. Data-on-Tag: Managing

Data in Complex RFID Environments. 40th Annual Hawaii International Conference on

System Sciences (2007)

33. Sarma, S.: A History of the EPC. In: Garfinkel, S., Rosenberg, B. (eds.): RFID –

Applications, Security and Privacy. Addison-Wesley, Upper Saddle River, NJ (2006) 37-56

34. Trigg, J. B.: Progress for RFID: An Architectural Overview and Use Case Review. (2005)

35. Schuster, E. W., Allen, S. J., Brock, D. L.: Global RFID: the value of the EPCglobal

network for supply chain management. Springer-Verlag, Berlin Heidelberg New York

(2007)

73

36. Thiesse, F., Michahelles, F.: An overview of EPC technology. Sensor Review 26, 2 (2006)

101-105

37. Harmon, C. K.: The necessity for a uniform organisation of user memory in RFID. Int. J.

RFID Technology and Applications 1, 1 (2006) 41-51

38. Garfinkel, S., Juels, A., Pappu, R.: RFID privacy: An overview of problems and proposed

solutions. IEEE Security and Privacy 3, 3 (2005) 34-43

39. Henrici, D., Mueller, P.: Tackling security and privacy issues in radio frequency

identification. In: Ferscha, A., Mattern, F. (eds.): Pervasive Computing. Lecture Notes in

Computer Science, Vol. 3001, Springer-Verlag, Berlin Heidelberg New York (2004), 219-

224

40. Spiekermann, S., Ziekow, H.: RFID: A 7-point plan to ensure privacy. European

Conference on Information Systems (ECIS ’05), Regensburg, Germany (2005)

41. Juels, A.: RFID Security and Privacy: A research Survey. (2005)

42. Garfinkel, S., Juels, A., Pappu, R.: RFID Privacy: An Overview of Problems and Proposed

Solutions. IEEE Security and Privacy 3, 3 (2005) 34-43

43. Juels, A.: Authentication and Identification - Minimalist Cryptography for Low-Cost RFID

Tags. Lecture notes in computer science 3352, (2005) 149-164

44. Avoine, G.: Cryptography in Radio Frequency Identification and Fair Exchange Protocols.

PhD thesis, EPFL, Lausanne (2005)

45. AVANTE International Technology: Supply Chain Security and Loss Prevention through

Effective Counterfeit Prevention and Detection RFID Data Structure. (2005)

46. Potdar, V., Wu, C., Chang, E.: Intrusion Detection - Tamper Detection for Ubiquitous

RFID-Enabled Supply Chain. (2005)

47. Floerkemeier, C., Schneider, R., Langheinrich, M.: Sensors and Tags - Scanning with a

Purpose - Supporting the Fair Information Principles in RFID Protocols. Lecture notes in

computer science, Vol. 3598, Springer-Verlag, Berlin Heidelberg New York (2005) 214-

231

48. Rieback, M. R., Crispo, B., Tanenbaum, A. S.: Mobile Security - RFID Guardian: A

Battery-Powered Mobile Device for RFID Privacy Management. Lecture notes in computer

science, Vol. 3574, Springer-Verlag, Berlin Heidelberg New York (2005) 184-194

74